Holder for glass run channel of automobile door and automobile door structure

A glass guide groove and holder technology, which is applied to windshields, vehicle parts, doors, etc., can solve the problems of poor installation operability, smooth lifting and lowering obstacles of the lifting glass 1, etc. The effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. The following embodiments are essentially preferable examples, and are not intended to limit the present invention, the application objects of the present invention, or the scope of use of the present invention.

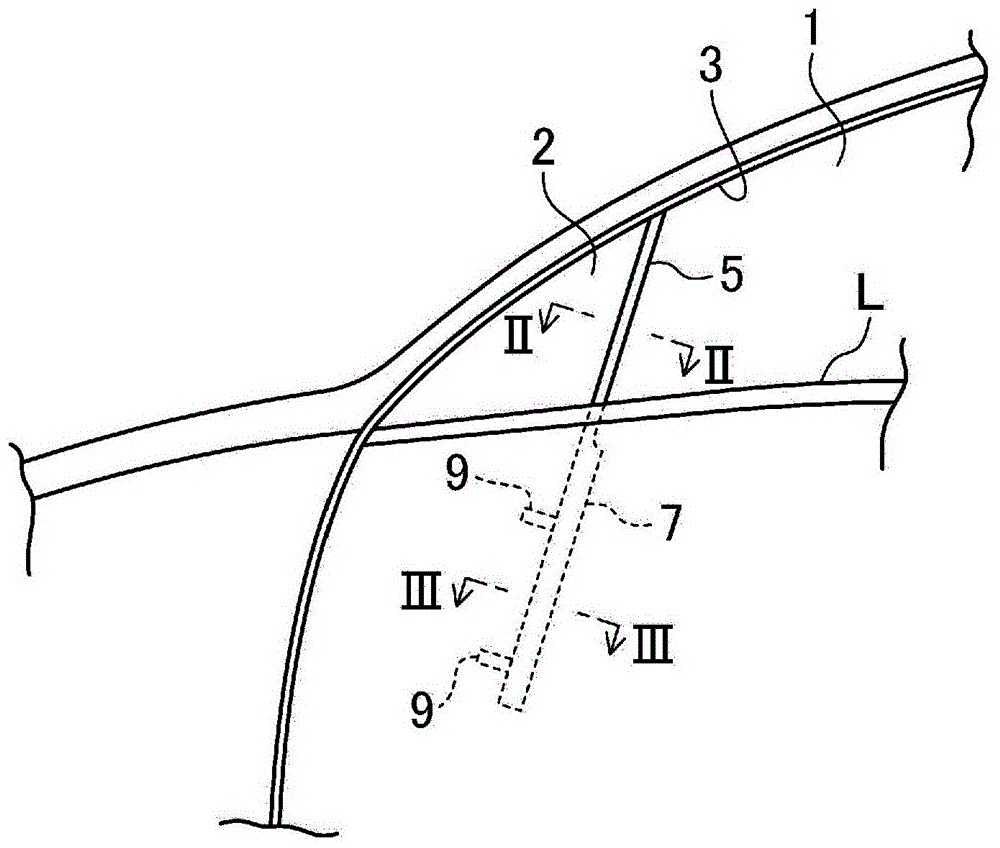

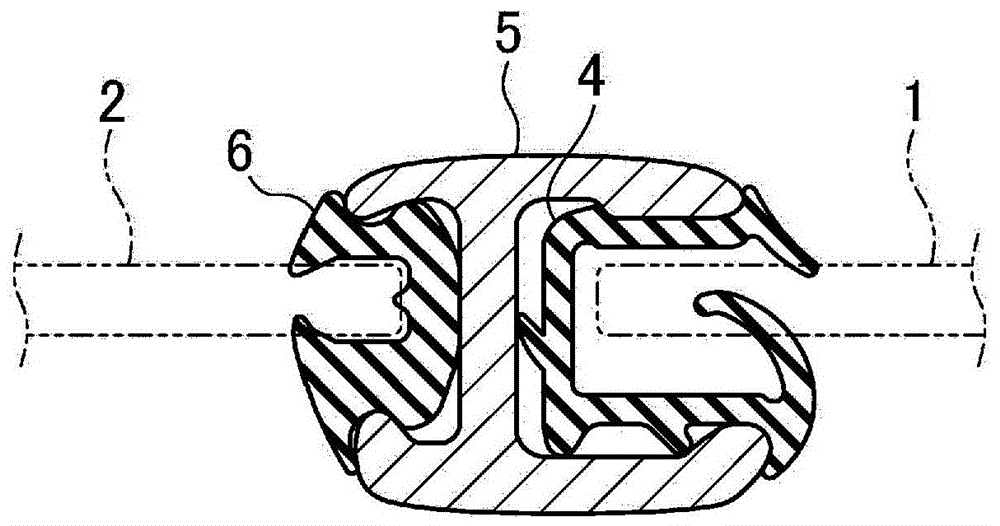

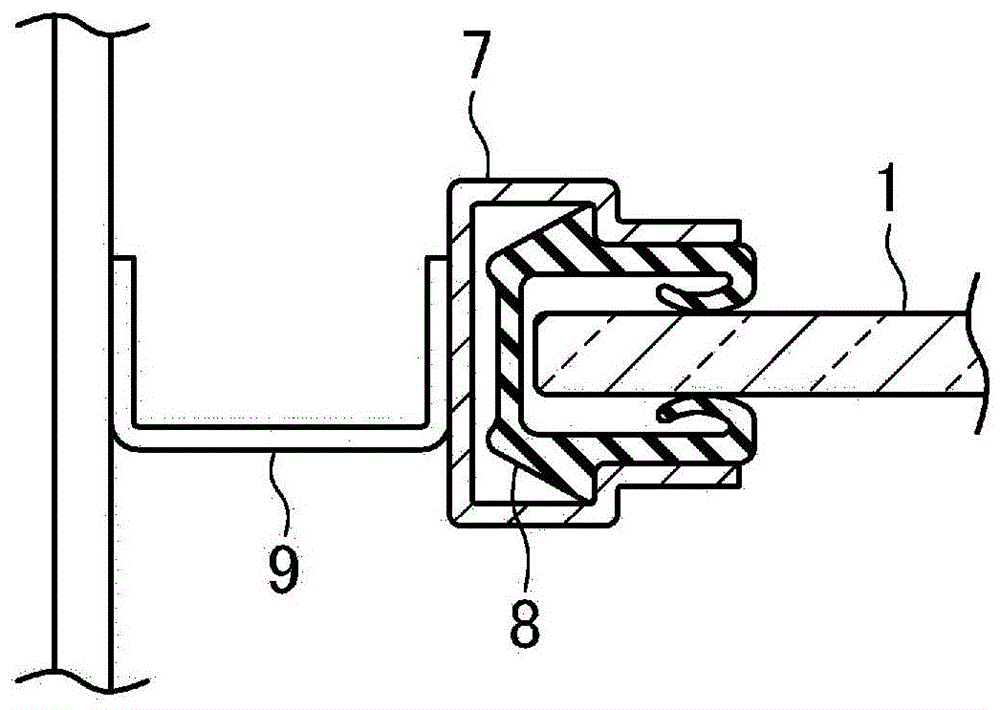

[0037] Figure 4 The structure of the front door of the automobile which concerns on embodiment is shown. exist Figure 4 Among them, 11 is a lifting glass; 12 is an adjacent side panel, and the adjacent side panel is set: adjacent to the lifting glass 11, located on the front side of the lifting glass 11, and fixed on the door and window; 13 is the inner panel of the car door. In order to raise and lower the lift glass 11 , a glass run channel 14 and a holder 15 for supporting the glass run channel 14 are provided on the front side (adjacent to the side plate 12 ) of the lift glass 11 . Figure 4 It is a figure which looked at the front part of a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com