Safety device of flexible tramcar

A safety device and mine car technology, applied in the field of mining machinery, can solve the problems of danger, high impact force, spark generation, etc., and achieve the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

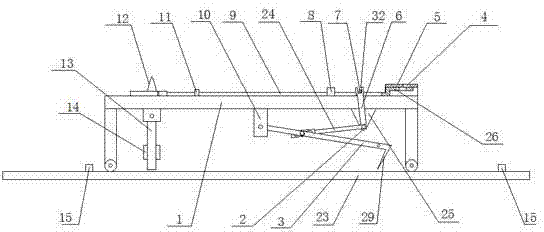

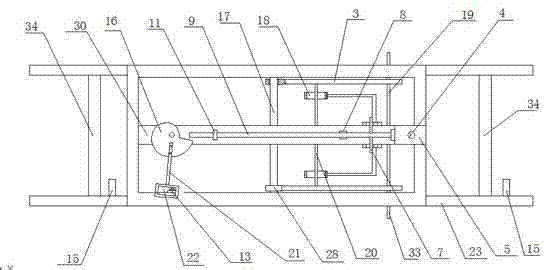

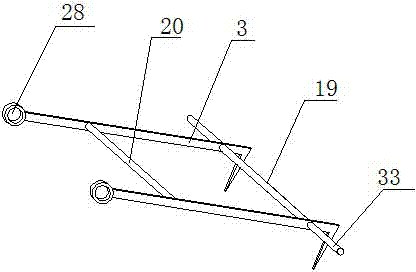

[0019] Such as Figure 1 to Figure 6 As shown, a flexible mine car safety device includes a mine car and a track 23, a frame 1 is arranged at the bottom of the mine car, a tow hook frame and a lever device are installed below the frame 1, and the middle part of the frame 1 is symmetrically provided with downward The support 10, a cross bar 17 is installed between the two symmetrical supports 10. Frame 1 rear portion is provided with downward support 25, is provided with transverse axis hole 2 in support 25; Frame 1 is provided with longitudinal guide plate 30, and guide plate 30 is provided with rotatable cam top block 16 and The latch seat 5, the front guide support 11 and the rear guide support 8 are provided between the cam top block 16 and the latch seat 5, the front guide support 11 has a guide hole, and the rear guide support 8 has a guide groove. A slide bar 9 is placed between the cam top block 16 and the latch seat 5, and the slide bar 9 is installed in the guide hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com