Cooling water system for reforming furnace metal burner

A technology of cooling water system and reformer, applied in hydrogen production, etc., can solve problems such as metal burner burnout, and achieve the effect of ensuring emergency cooling and preventing abnormal burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

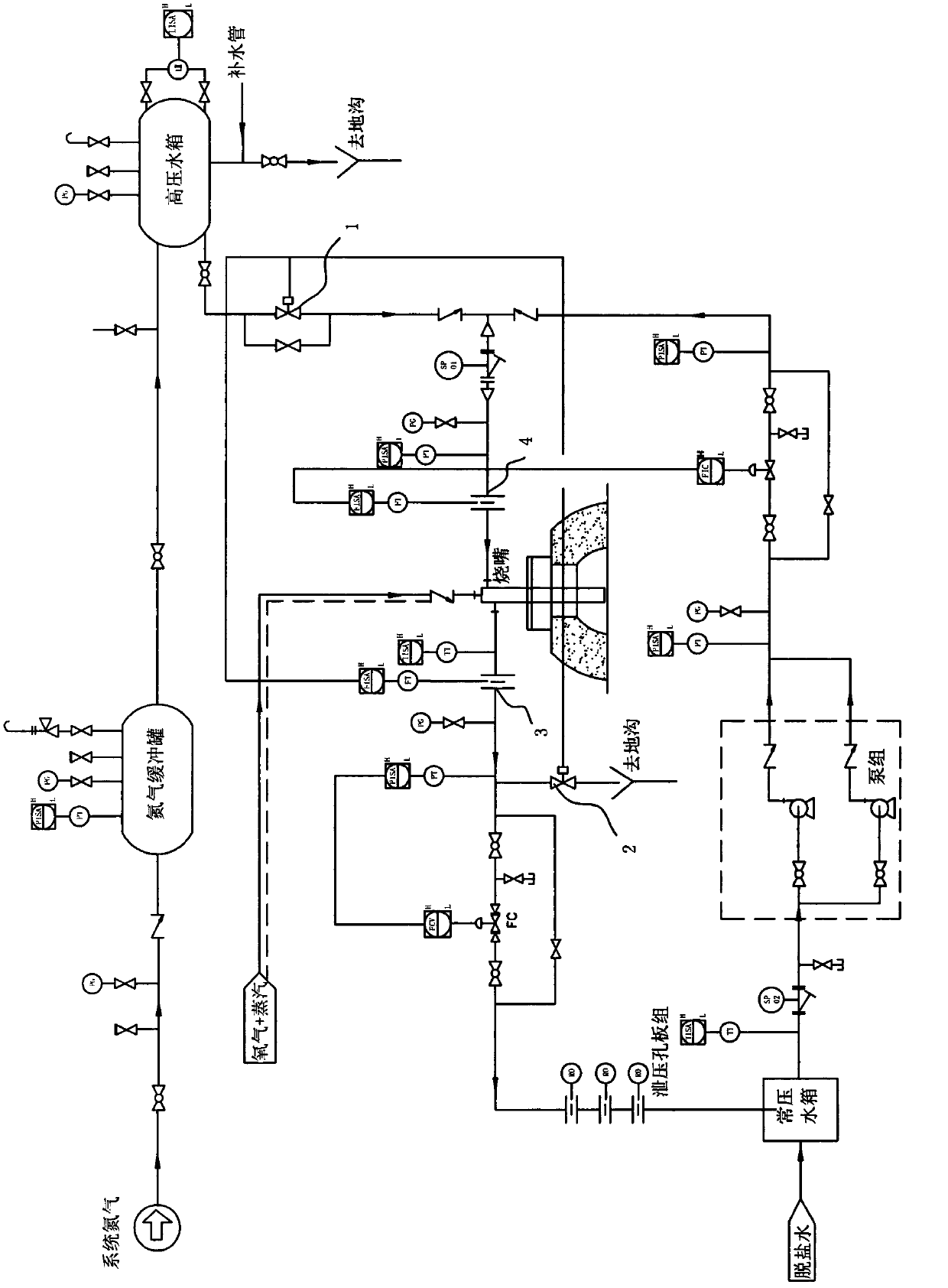

[0013] The metal burner cooling water system of the present invention includes an emergency water system in an accident state and a circulating water system in a normal state. The circulating water system includes an atmospheric water tank, a pump group, an inlet orifice plate, a burner water inlet pipe, a burner outlet pipe, an outlet orifice plate, and a pressure relief orifice group that are connected in sequence to form a water circuit. The pressure relief orifice group includes multiple a pressure relief orifice; the emergency water system includes a high-pressure nitrogen storage tank, a nitrogen buffer tank, a high-pressure water tank, a high-pressure water inlet solenoid valve, and a high-pressure drain solenoid valve; the nitrogen buffer tank communicates with the high-pressure water tank, and the high-pressure water tank passes through the high-pressure water inlet solenoid valve It is connected with the burner inlet pipe, the burner outlet pipe is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com