Reforming furnace with central burner nozzle

A reformer and catalytic conversion technology, which is applied in the direction of furnace, furnace cooling, furnace components, etc., can solve the problem that the burner is easy to be burned, and achieve the effects of ensuring emergency cooling, preventing abnormal burning, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

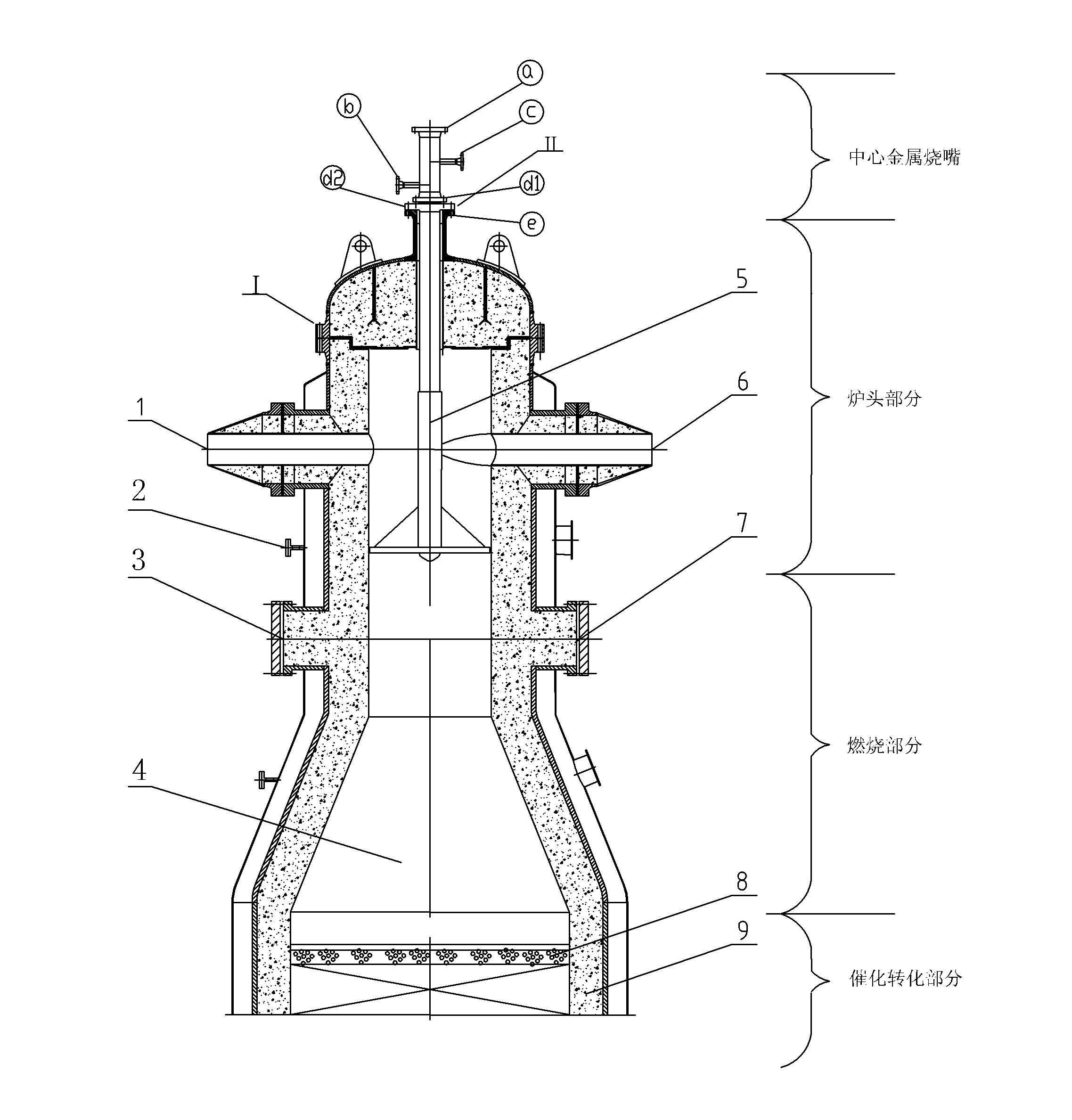

[0013] The central metal burner reformer of the present invention includes a central burner, a furnace head part, a combustion part, a catalytic conversion part and a converter outlet part, and the furnace head part includes a coke oven gas+steam inlet arranged on the furnace wall; the central burner The part includes the metal burner installation flanges d1 and d2 arranged at the center line of the furnace head e, and the central metal burner extending from the center hole of the metal burner installation flange to the furnace head; the central metal burner includes oxygen +steam inlet pipe a, cooling water inlet channel b and cooling water outlet channel c arranged on the wall of the oxygen+steam inlet pipe a.

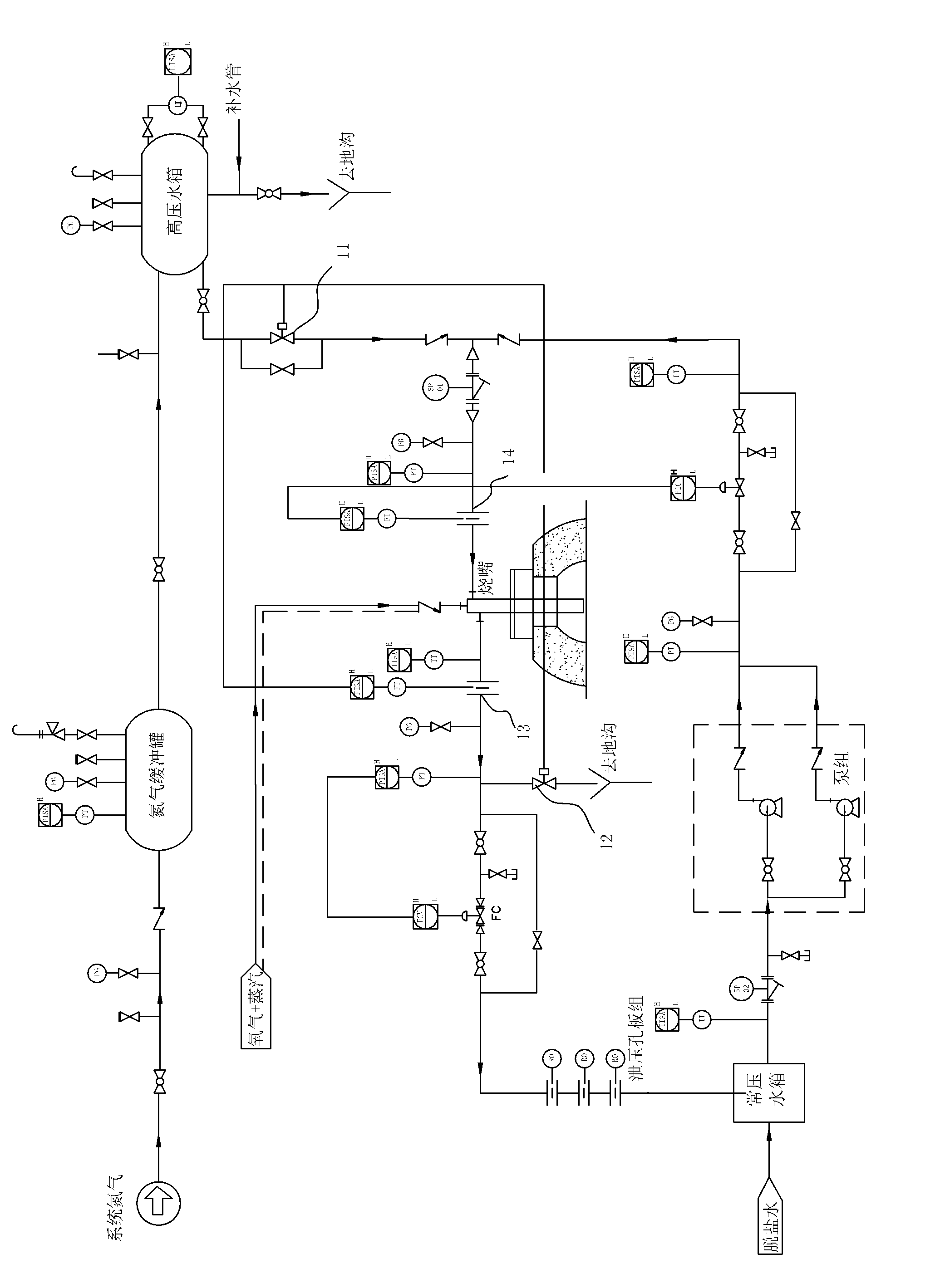

[0014] The metal burner cooling water system of the present invention includes an emergency water system in an accident state and a circulating water system in a normal state. The circulating water system includes an atmospheric water tank, a pump group, an inlet ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com