Processing technique of hand-knitted inlaid technical woolen yarn

A kind of processing technology and technology, which is applied in the field of hand-knitting intarsia wool processing technology, can solve the problems of unsatisfied consumers' purchase needs, singleness, etc., and achieve the effects of rich profit returns, broad market prospects, and fashionable vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] Specific process path and parameters:

[0050] 1. Dyeing process

[0051] Technological process: pine balls, dyeing, rewashing, mixed carding.

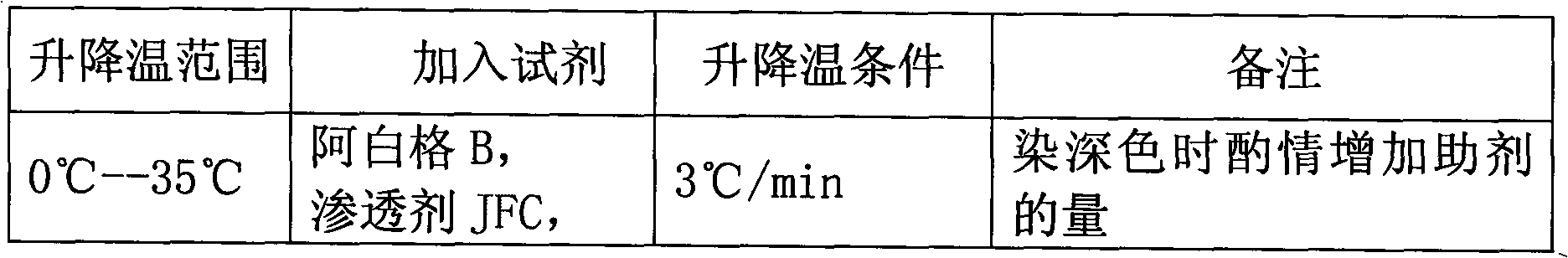

[0052] (1), wool dyeing process

[0053] Imported active and environmentally friendly dyes are used, and HE-600 vertical dyeing pots are used for equipment, and the dyeing bath ratio is 1:30.

[0054]

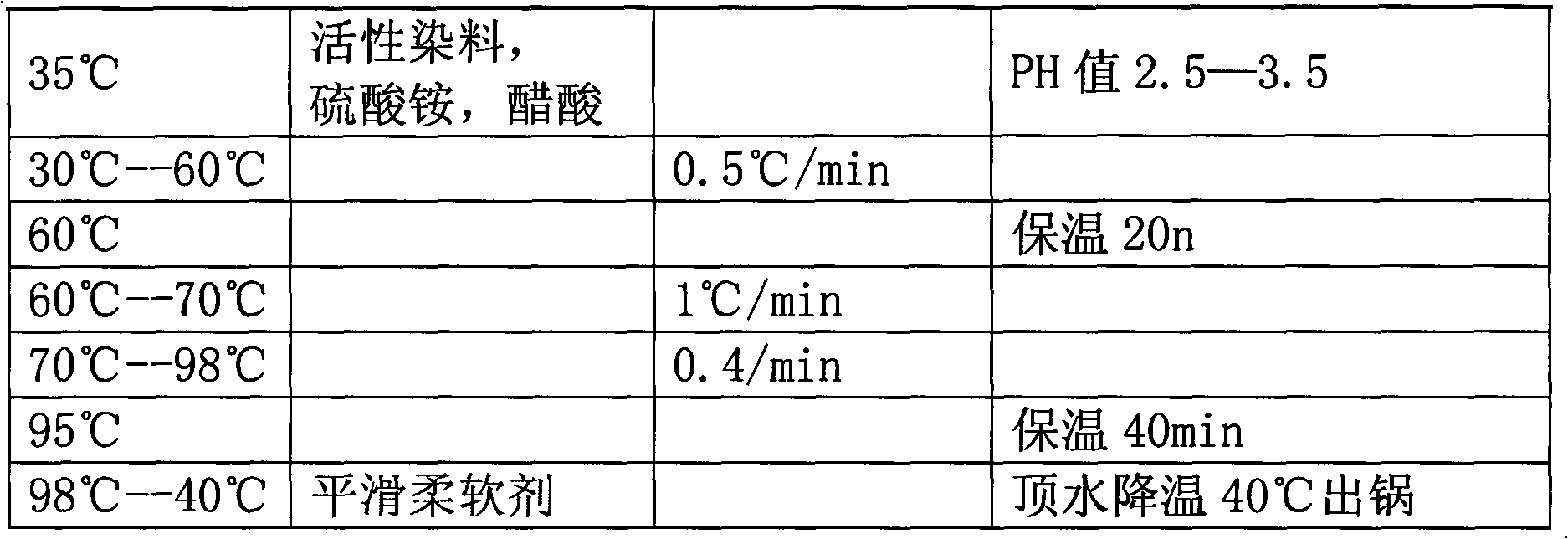

[0055] (2), polyester dyeing process

[0056] HE-600 vertical dyeing pot is used, and the dyeing bath ratio is 1:25.

[0057]

[0058] Note: Add brightening agent to polyester to make its shade consistent with other fibers.

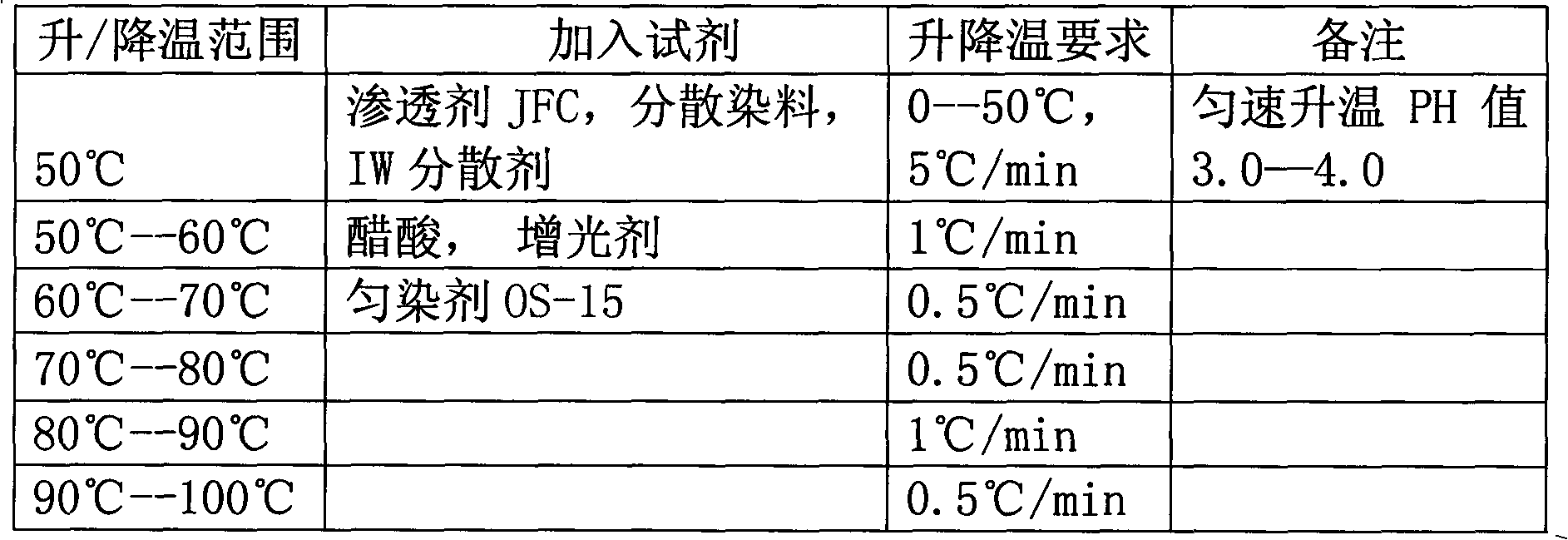

[0059] (3), Albaka dyeing process

[0060] HE-600 vertical dyeing pot is used, and the dyeing bath ratio is 1:35.

[0061]

[0062]

[0063] (4), acrylic dyeing process

[0064] HE-600 vertical dyeing pot is used, and the dyeing bath ratio is 1:25.

[0065]

[0066] Note: If you want to dye dark colors, you can add more sulfuric acid and acetic acid to lower the pH value and enhance t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Twist | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com