System and method for simultaneously producing alcohol-free wine and strong wine

A technology for alcoholic wine and high-quality wine, which is applied in the preparation of wine, chemical instruments and methods, biochemical equipment and methods, etc., can solve the problems of complex process and degraded wine quality, and achieves simple operation, high dealcoholization efficiency, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

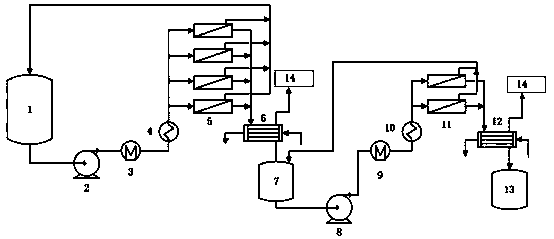

Method used

Image

Examples

Embodiment 1

[0075] Using the above system, the material of the base membrane that preferentially permeates organic matter pervaporation membranes is sulfonated polyetherketone (SPEK), the pore diameter of the base membrane is 80nm, the material of the separation layer is polydimethylsiloxane with terminal amino groups, and the The ammonia value of the amino polydimethylsiloxane is 0.2, and the mass ratio of the hydrophobic nano-titanium dioxide to the amino-terminated polydimethylsiloxane is 0.5:100. Inject 50kg of wine raw materials (alcohol content 12.5v / v%) into the raw material tank, heat it to 45°C and send it to the primary membrane separation system through the raw material pump. The raw material side is circulated, the permeate side is vacuumed, and the vacuum pressure is 5000Pa. The vapor on the permeate side is liquefied and collected in the first cooling device, the condensation temperature is maintained at -10°C, the alcohol content of the permeate is 36°, and the permeate flu...

Embodiment 2

[0077] Using the above system, the material of the base membrane that preferentially permeates the organic pervaporation membrane is sulfonated polyether ketone ether ketone ketone (SPEKEKK), the pore size of the base membrane is 20nm, and the material of the separation layer is amino-terminated polydimethyl Siloxane, the ammonia value of the amino-terminated polydimethylsiloxane is 0.4, and the mass ratio of the hydrophobic nano-titanium dioxide to the amino-terminated polydimethylsiloxane is 1:100. Inject 50kg of wine raw materials (alcohol content 12.5v / v%) into the raw material tank, heat it to 35°C and send it to the primary membrane separation system through the raw material pump. The raw material side is circulated, the permeate side is vacuumed, and the vacuum pressure is 10000Pa. The vapor on the permeate side is liquefied and collected in the first cooling device, the condensation temperature is maintained at -10°C, the alcohol content of the permeate is 30°, and the...

Embodiment 3

[0079] Using the above system, the material of the base membrane that preferentially permeates the organic matter pervaporation membrane is sulfonated polyether ketone ether ketone ketone (SPEKEKK), the pore diameter of the base membrane is 8nm, and the material of the separation layer is amino-terminated polydimethyl The siloxane, the ammonia value of the amino-terminated polydimethylsiloxane is 0.6, and the mass ratio of the hydrophobic nano-titanium dioxide to the amino-terminated polydimethylsiloxane is 1.5:100. Inject 50kg of wine raw materials (alcohol content 12.5v / v%) into the raw material tank, heat it to 35°C and send it to the primary membrane separation system through the raw material pump. The raw material side is circulated, the permeate side is vacuumed, and the vacuum pressure is 10000Pa. The vapor on the permeate side is liquefied and collected in the first cooling device, the condensation temperature is maintained at -5°C, the alcohol content of the permeate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com