Inhaul cable structure capable of being filled with dry air and realizing method thereof

A realization method and dry air technology, applied in the field of stay cables, can solve the problems of failure of stay cables, damage of polyethylene sheath, corrosion of steel wires, etc., and achieve the effect of improving safety and ensuring the stability of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

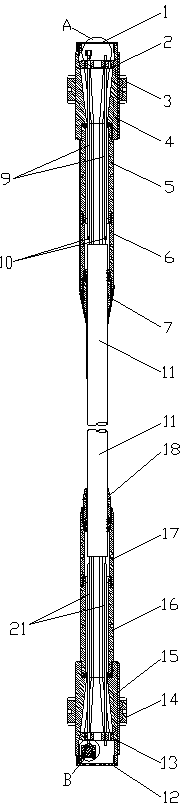

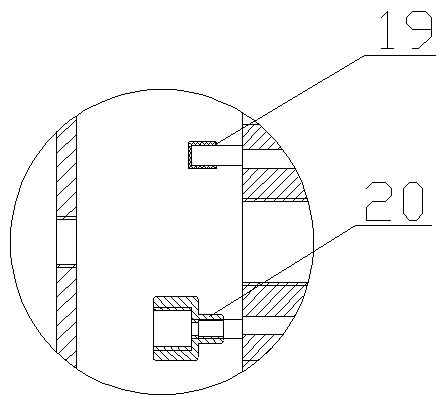

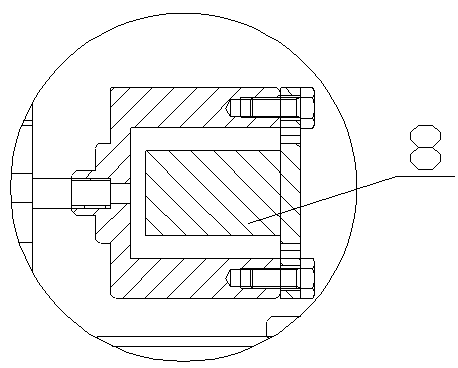

[0041] see Figure 1-3 , the present invention relates to a cable structure that can be filled with dry air and its implementation method, it includes a cable body 11, the two ends of the cable body 11 are respectively connected with an upper anchorage and a lower anchorage, and the upper anchorage Including the upper cover plate 1, the upper anchor plate 2 and the upper anchor cup 4, the upper anchor plate 2 is set in the upper anchor cup 4, the upper anchor cup 4 is provided with an upper nut 3, and the upper nut 3 makes the upper anchor compress the cable body 11. The lower anchor includes a lower cover plate 12, a lower anchor plate 13 and a lower anchor cup 15, the lower anchor plate 13 is set in the lower anchor cup 15, and the lower anchor cup 15 is provided with a lower nut 14, the lower nut 14 makes the lower anchor cup 15 The anchorage compresses the cable body 11, and the two ends of the cable body 11 are respectively fixed on the upper anchor plate 2 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com