Telescoping mechanism

A telescopic mechanism and telescopic direction technology, applied in mechanical equipment, membrane boxes, etc., can solve the problems of high cost, complicated processing, inconvenient use, etc., and achieve the effect of free shrinkage and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

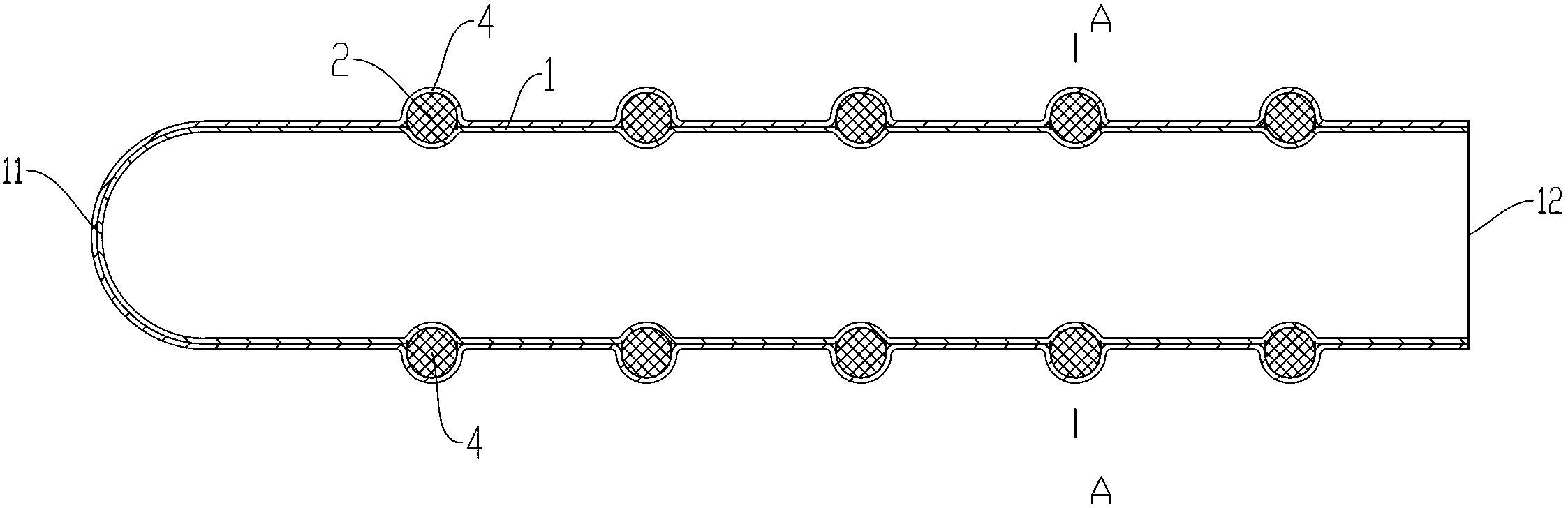

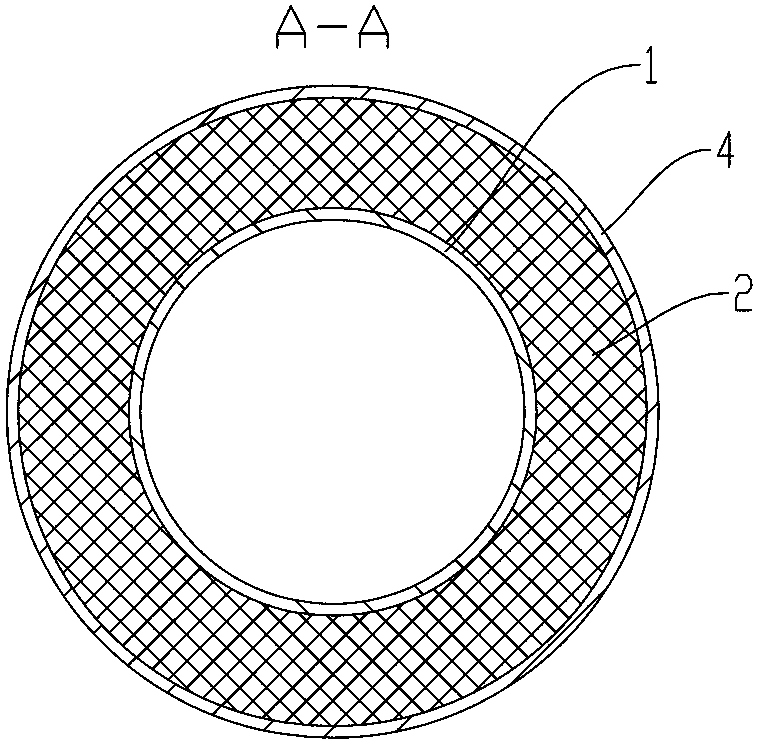

[0031] Embodiment one: if figure 1 , 2 As shown, the telescopic mechanism includes an airbag 1; one end of the airbag 1 in a set telescopic direction is set as a closed end 11, and the other end is set as an air intake end 12; A support member 2, the support member 2 supports the airbag 1 in a plane perpendicular to the telescopic direction; a space 3 for expansion and contraction is provided between every adjacent two support members 2 in the telescopic direction. The interval 3 refers to the gap between two supporting parts, that is, the space, and does not refer to any part.

[0032] In this embodiment, the support member 2 is fixed outside the airbag 1 . Each support member 2 is provided with a through hole 21 which can be nested and fixed on the airbag 1 .

[0033] When gas is inflated into the airbag 1 from the air intake end 12, the airbag 1 is gradually stretched out as the amount of gas charged increases, and the multiple support members 2 are gradually separated t...

Embodiment 2

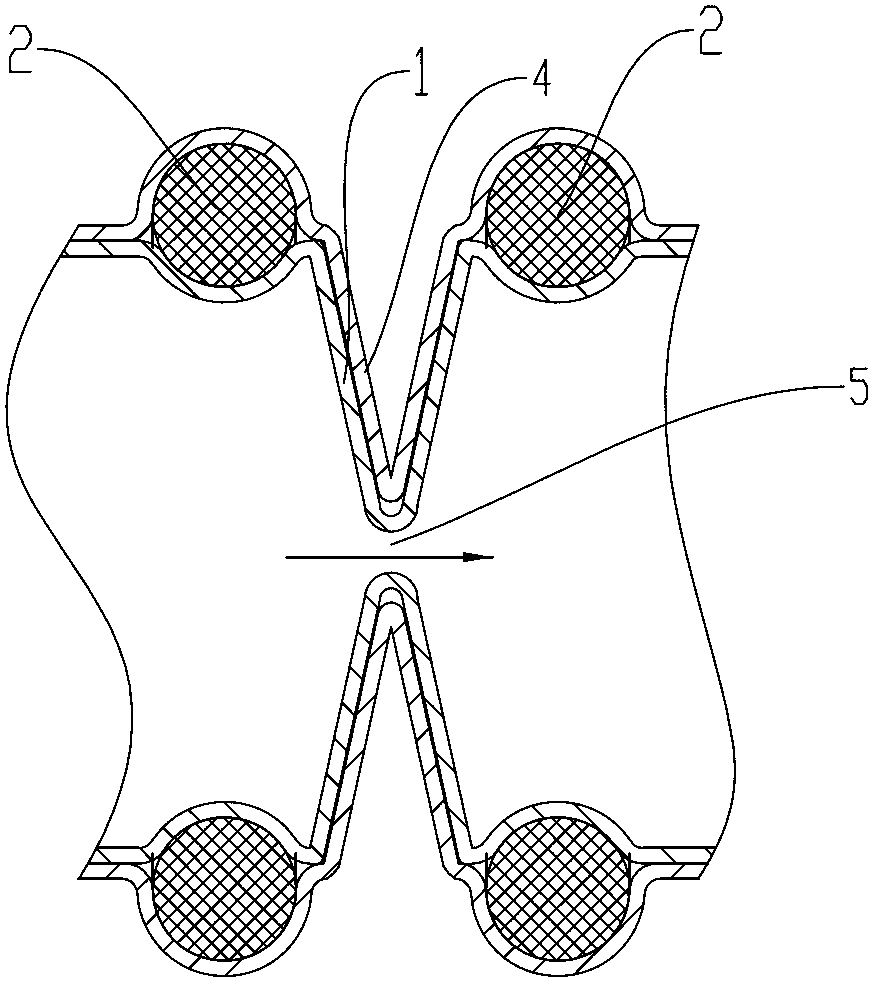

[0041] Embodiment two: if Figure 7 , 8 As shown, the difference between this embodiment and the first embodiment is that: the support member 2 is fixed inside the airbag 1; each support member 2 is provided with a through hole 21 along the stretching direction of the airbag.

[0042] The spacing distance between adjacent two supporting parts 2 is less than the diameter of the through holes on the two supporting parts at the two ends of the space, such as Figure 9 As shown, it can not only ensure the coherence and reliability of the contraction, but also ensure that the ventilated airway 5 is retained after the contraction, so as to prevent the airway 5 from being closed, resulting in incomplete contraction.

[0043] Preferably: the supporting member 2 is a supporting ring 7, such as an expanding ring. The supporting ring is correspondingly fitted with a snap ring 6 , and the wall of the airbag 1 is clamped between the supporting ring and the snap ring 6 . This kind of fix...

Embodiment approach

[0048] Other implementations: such as Figure 13As shown, the shapes of the supporting parts 2 are different. The shapes of the supporting parts 2 and the airbag 1 of this embodiment are all crescent-shaped, and the rest of the techniques are the same as in the first embodiment. The support component of this shape is very suitable for the needs of the field of prosthetics, and can complete the profiling of the human body such as the hand. The telescoping mechanism acts as a muscle in the prosthesis. The rest of the techniques can be the same as those in Embodiment 1 or 2, and will not be repeated here.

[0049] In addition, the shape of the support member and the airbag can be designed arbitrarily as required.

[0050] In addition: if Figure 14 As shown, each support member 2 in this embodiment is provided with a card slot 22, and the airbag 1 is fixed in the card slot 22 of the support member; and all support members 2 are located on the same side of the thin-walled long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com