A scalable and variable multi-shape ring scissor mechanism

A scissor-type mechanism and a ring-shaped technology, applied in the parts of instruments, parts of lighting devices, instruments, etc., can solve the problems of unstable operation of the working platform of the elevator, asynchronous work, and low load capacity, etc. The effect of driving special-shaped parts to work and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

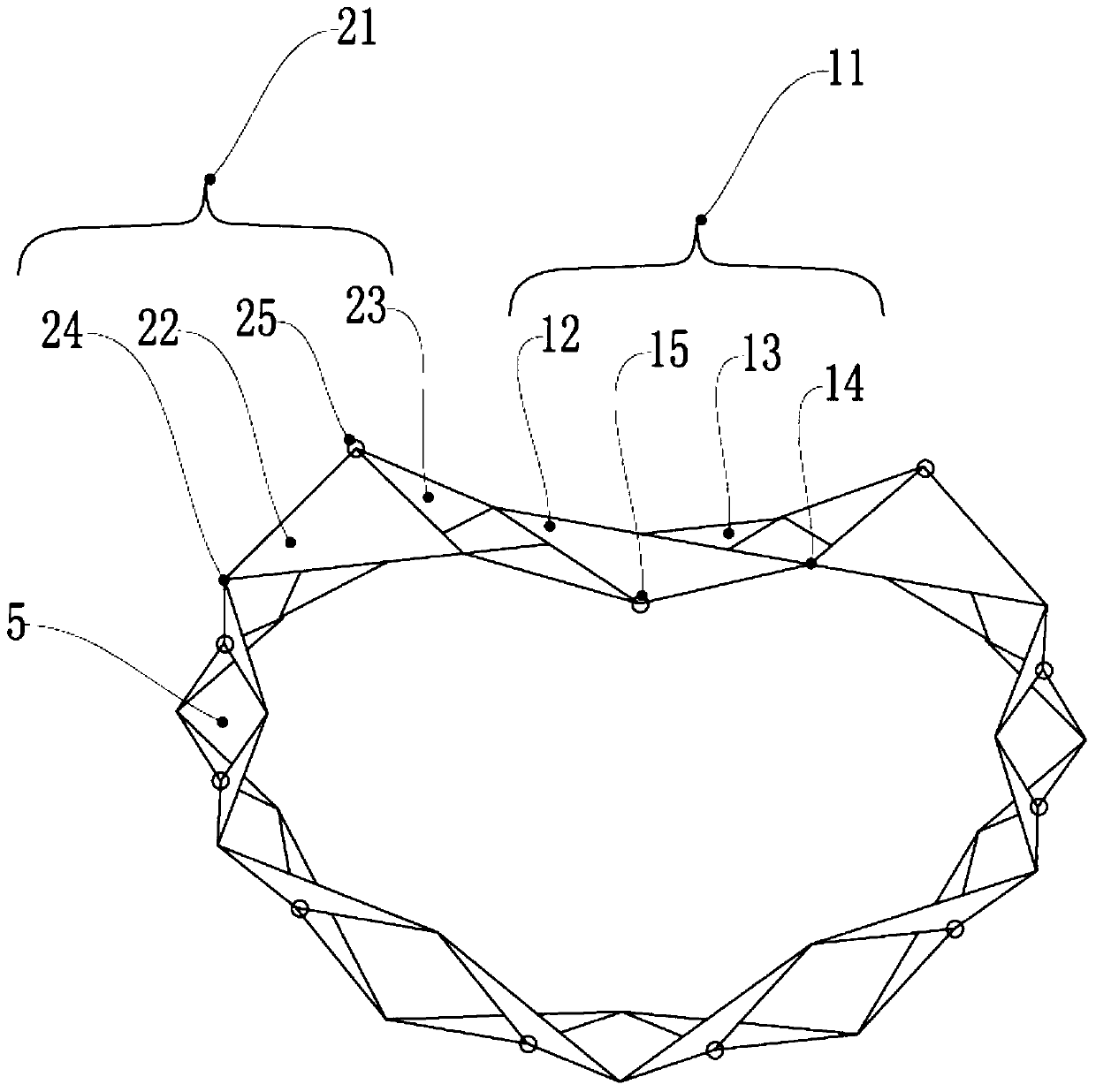

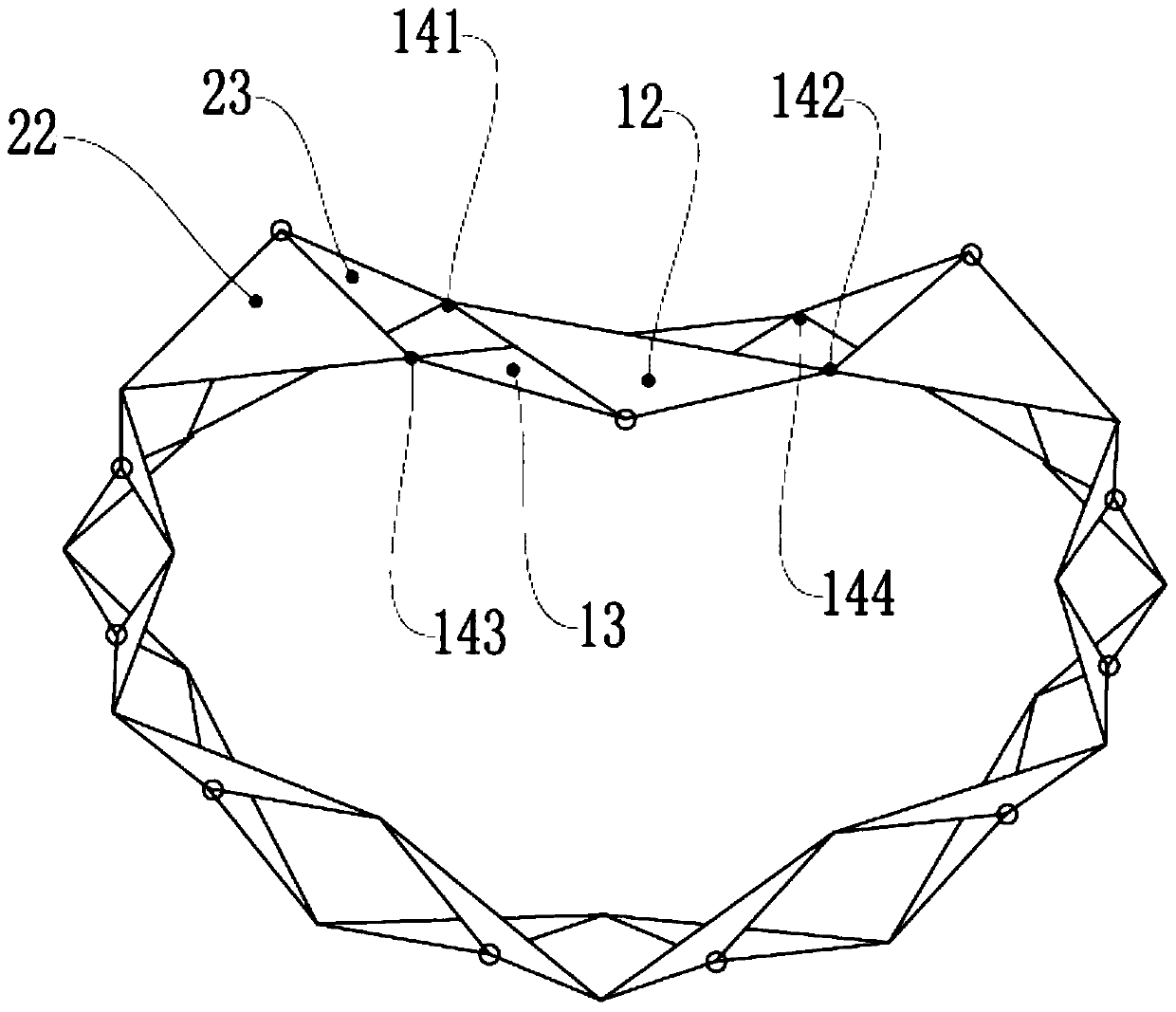

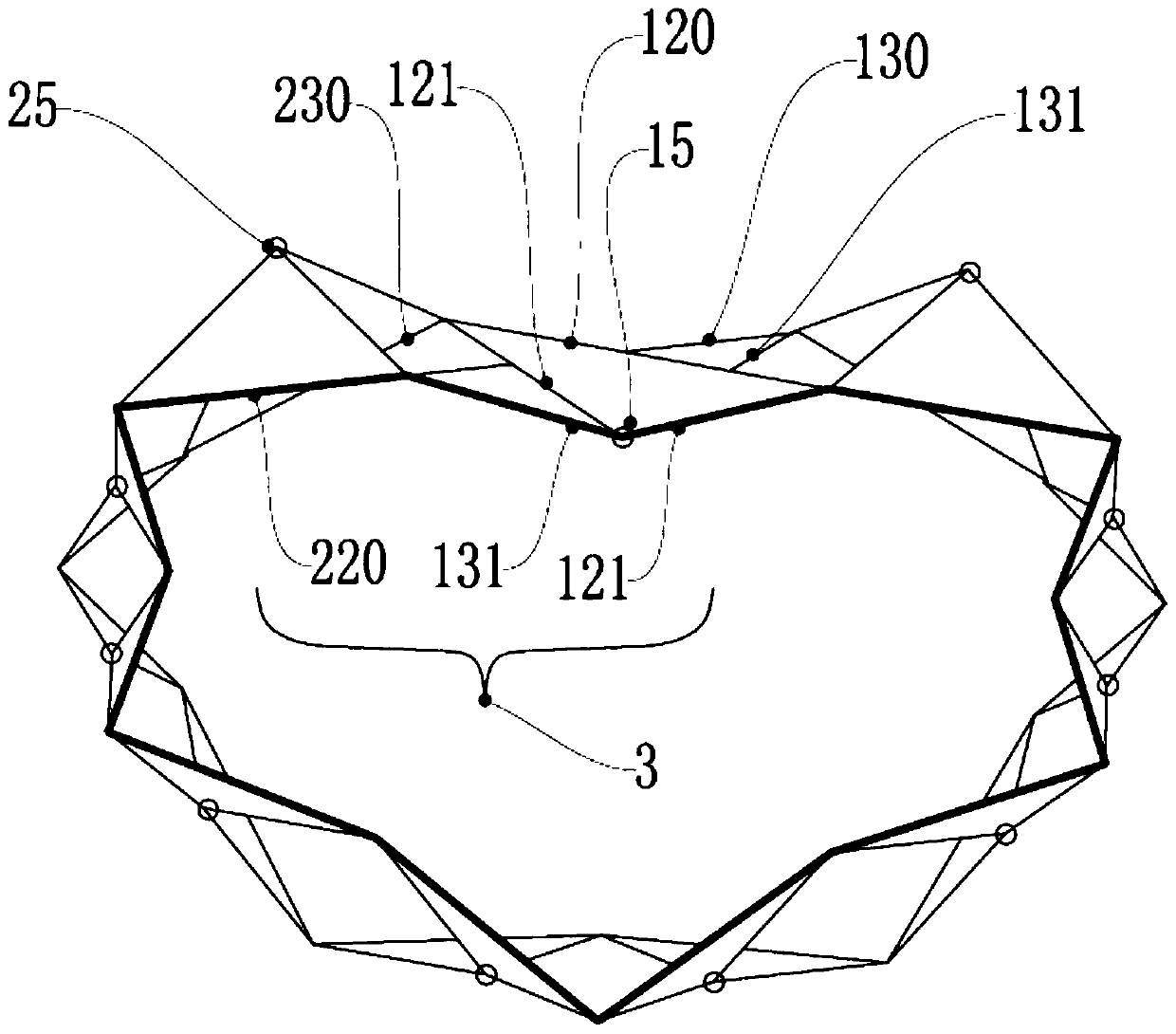

[0030] Such as Figure 1 to Figure 4 As shown, a multi-shaped annular scissor mechanism that can be stretched and changed, including an inner convex part and an outer convex part;

[0031] The inner convex part includes at least one inner convex scissor unit 11, and the inner convex scissor unit 11 includes an inner hinge shaft 15, an inner convex upper layer plate 12 and an inner convex lower layer plate 13;

[0032] The inner convex upper layer 12 and the inner convex lower layer 13 are stacked on each other, and the inner hinge shaft 15 passes through the inner convex upper layer 12 and the inner convex lower layer 13 in turn; the inner convex upper layer 12 and the inner convex lower layer Two inner convex hinge points 14 are respectively arranged on the plate 13;

[0033] In the inner convex ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com