Punching technology for inner sidewalls of parts of automobile covering component

A technology for automobile cover parts and parts, which is applied in the field of automobile parts production, can solve the problems of long production cycle, increased processing difficulty, increased cost, etc., and achieves the effects of simple, novel and compact structure, improved processing accuracy, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

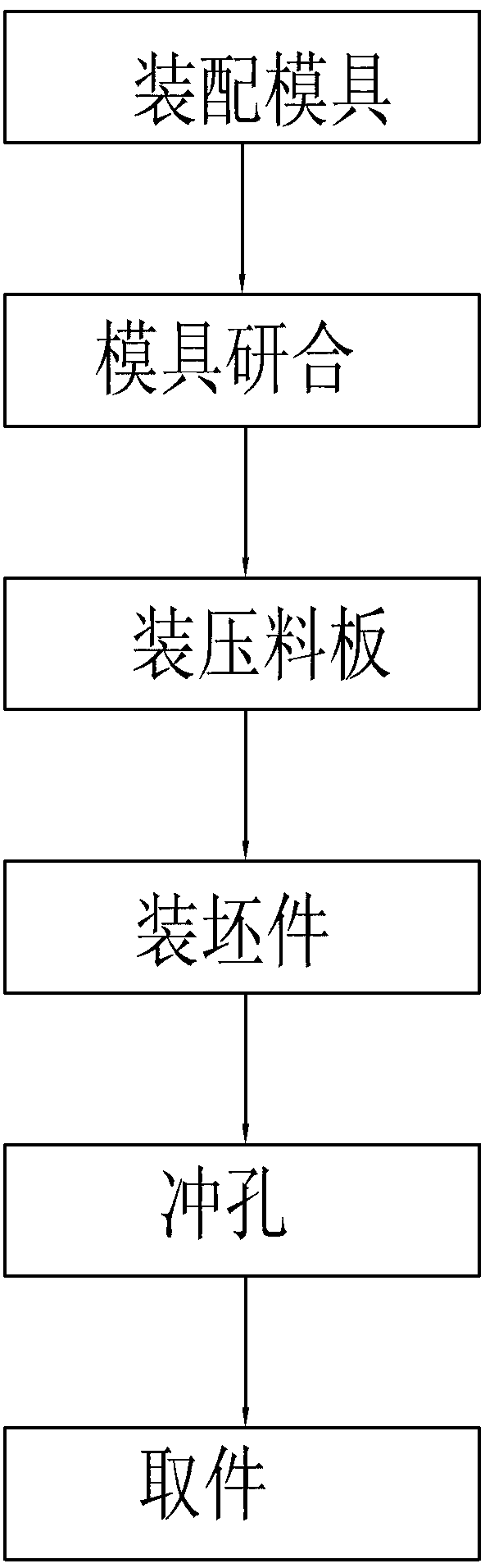

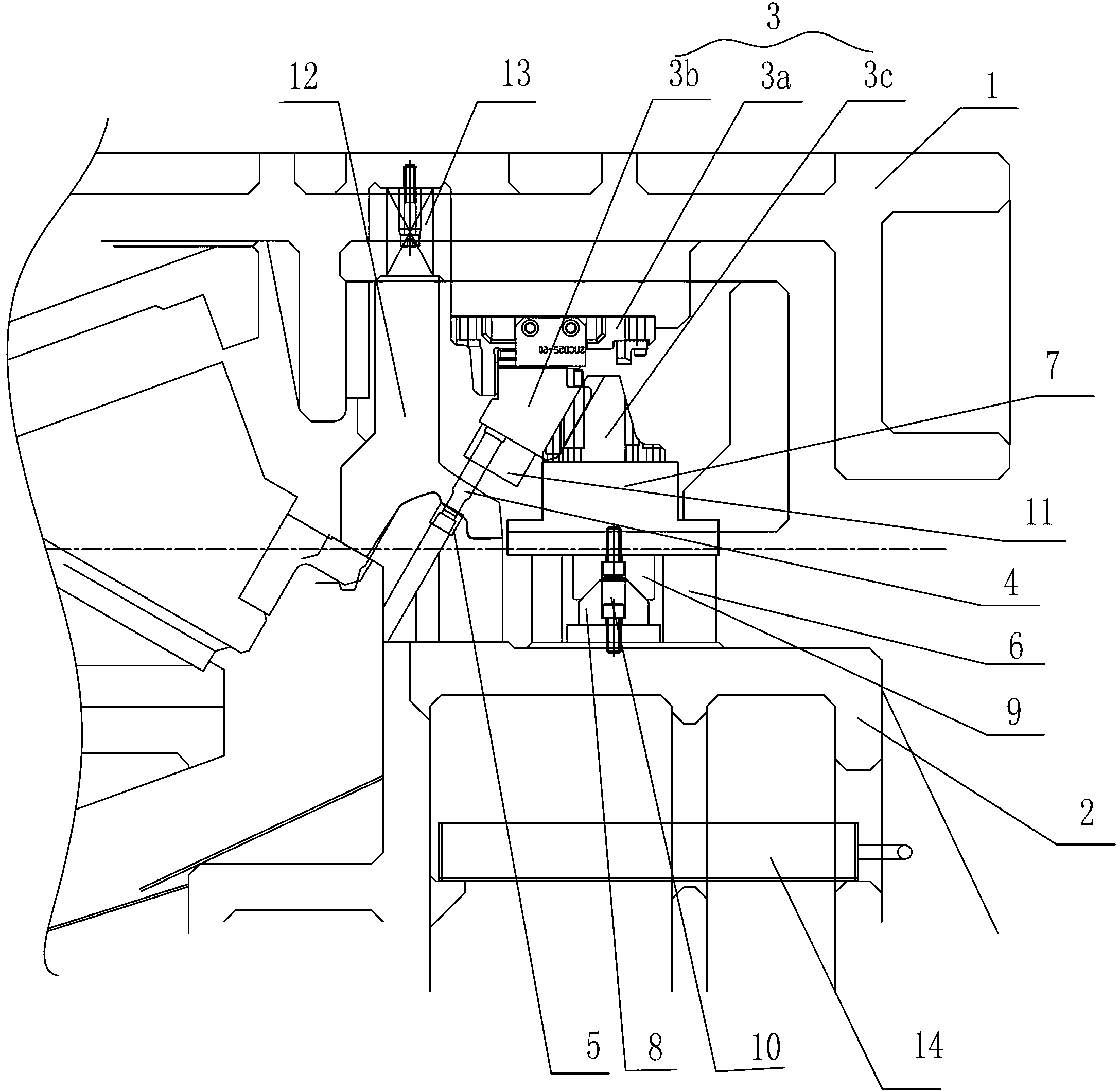

[0021] Such as figure 1 and figure 2 Shown a kind of punching process of the inner side wall of the automobile cover part, it is characterized in that comprising the following steps:

[0022] a. Assembling the mould: Install a wedge mechanism 3 between the upper mold 1 and the lower mold 2, the wedge mechanism 3 includes a slider seat 3a, a slider 3b and a driving block 3c, wherein the slider seat 3a is fixed to the upper mold 1 , the driving block 3c is connected to the lower mold 2 through the wedge pad 7 and the mold clamping pad 6, wherein the mold clamping pad 6 is two pieces, and the two mold clamping pads 6 are fixed on the lower mold 2 , the wedge pad 7 is supported on the mold clamping pad 6, the driving block 3c is fixed on the wedge pad 7, the punch 4 is fixed at the lower end of the slider 3b, and the Said lower die 2 is equipped with a die 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com