Patents

Literature

37results about How to "Guaranteed installation progress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

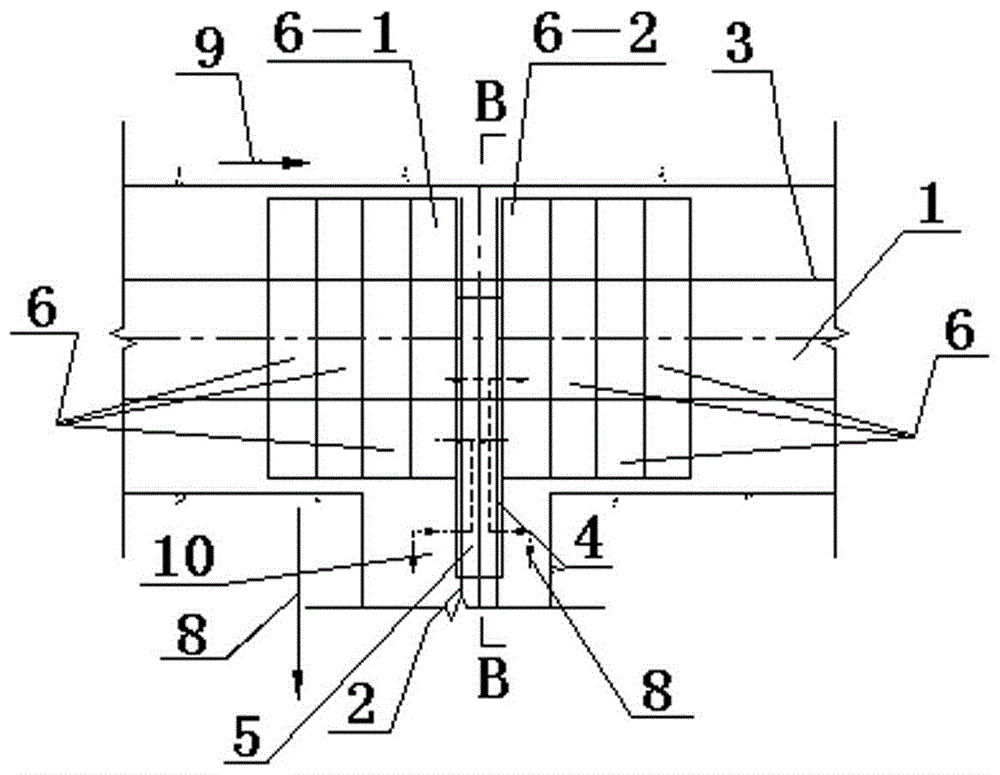

Assembly ship building unit element, modularization designing method

InactiveCN1948081AImprove build qualityGuaranteed Build QualityVessel partsModular designComputer module

A modular design method for building all units and assembling them together includes such steps as 3D modeling of ship body, 3D arrangement modeling for assembling, dividing it into functional or regional units or modules, providing the interfaces between units or modules, designing and drawing them, and integrating them together in frame mode while preserving the interfaces between them.

Owner:DALIAN SHIPBUILDING IND

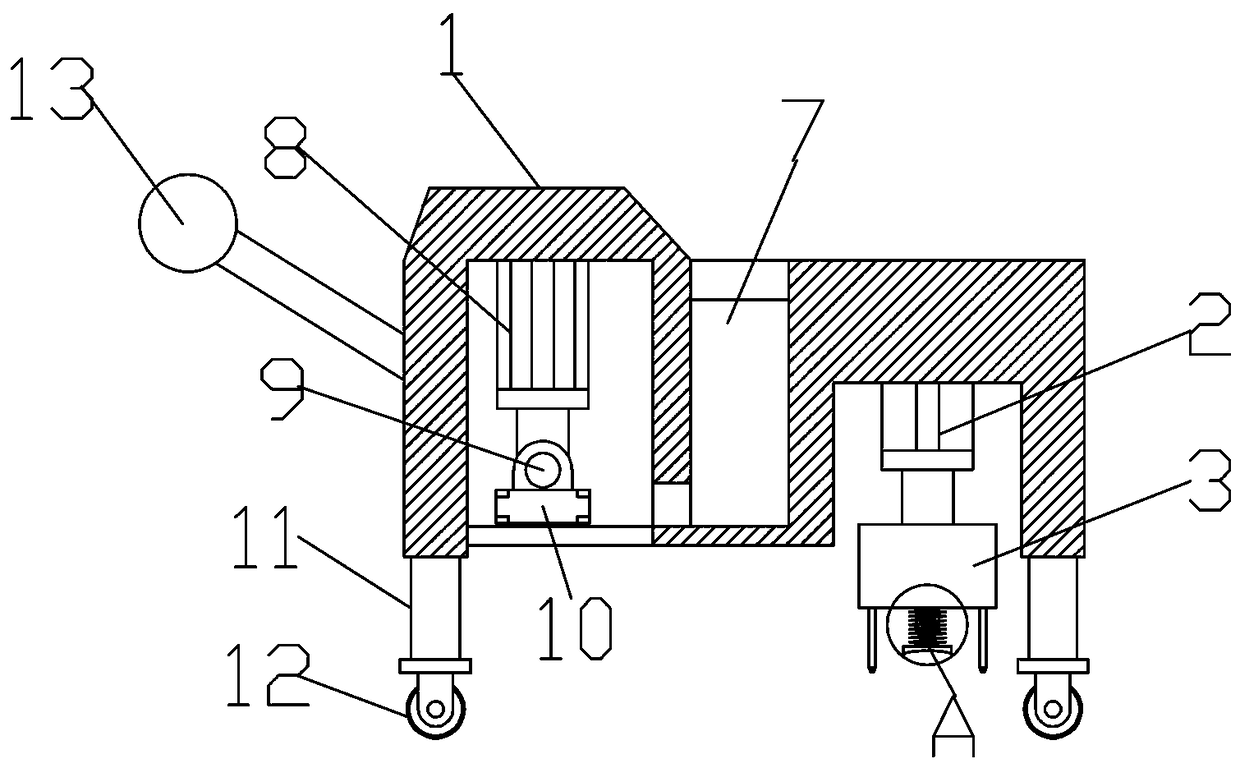

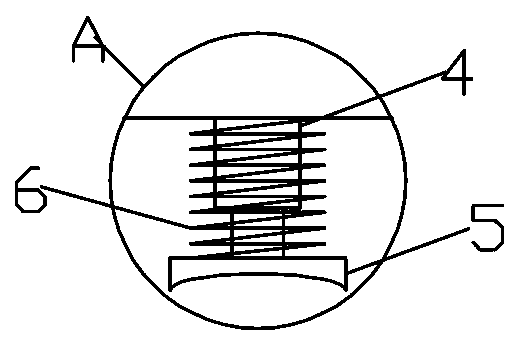

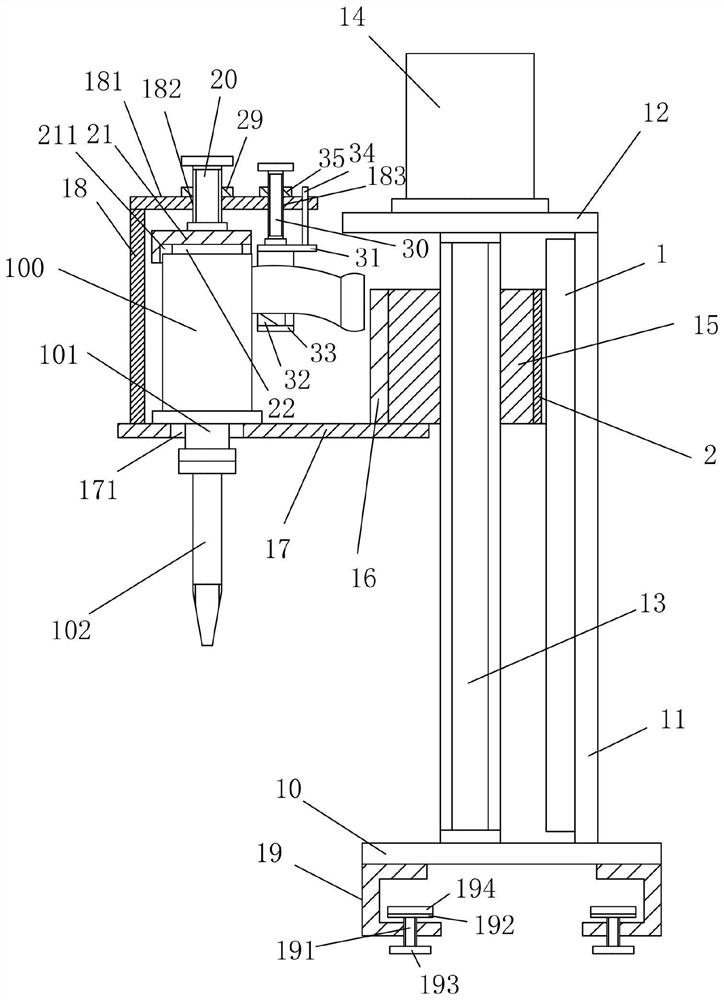

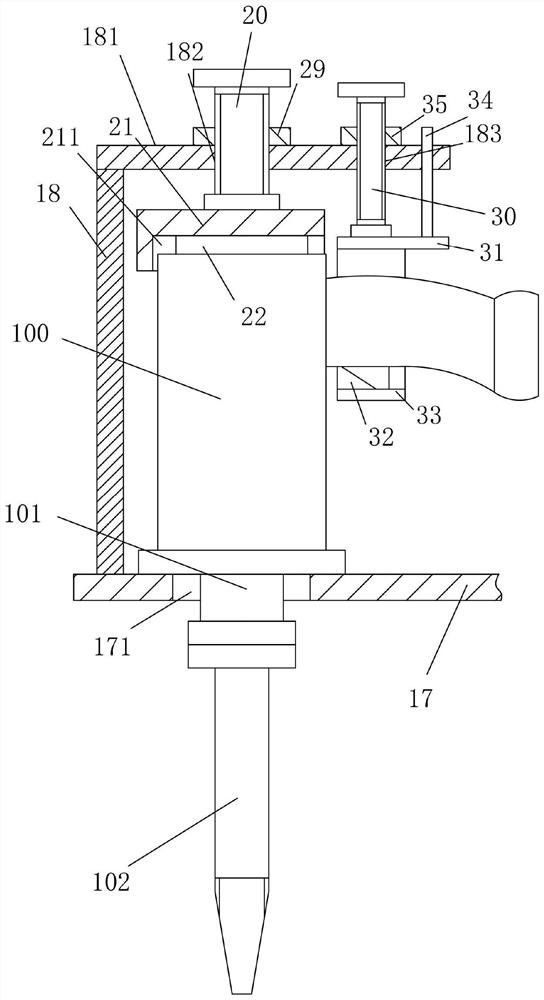

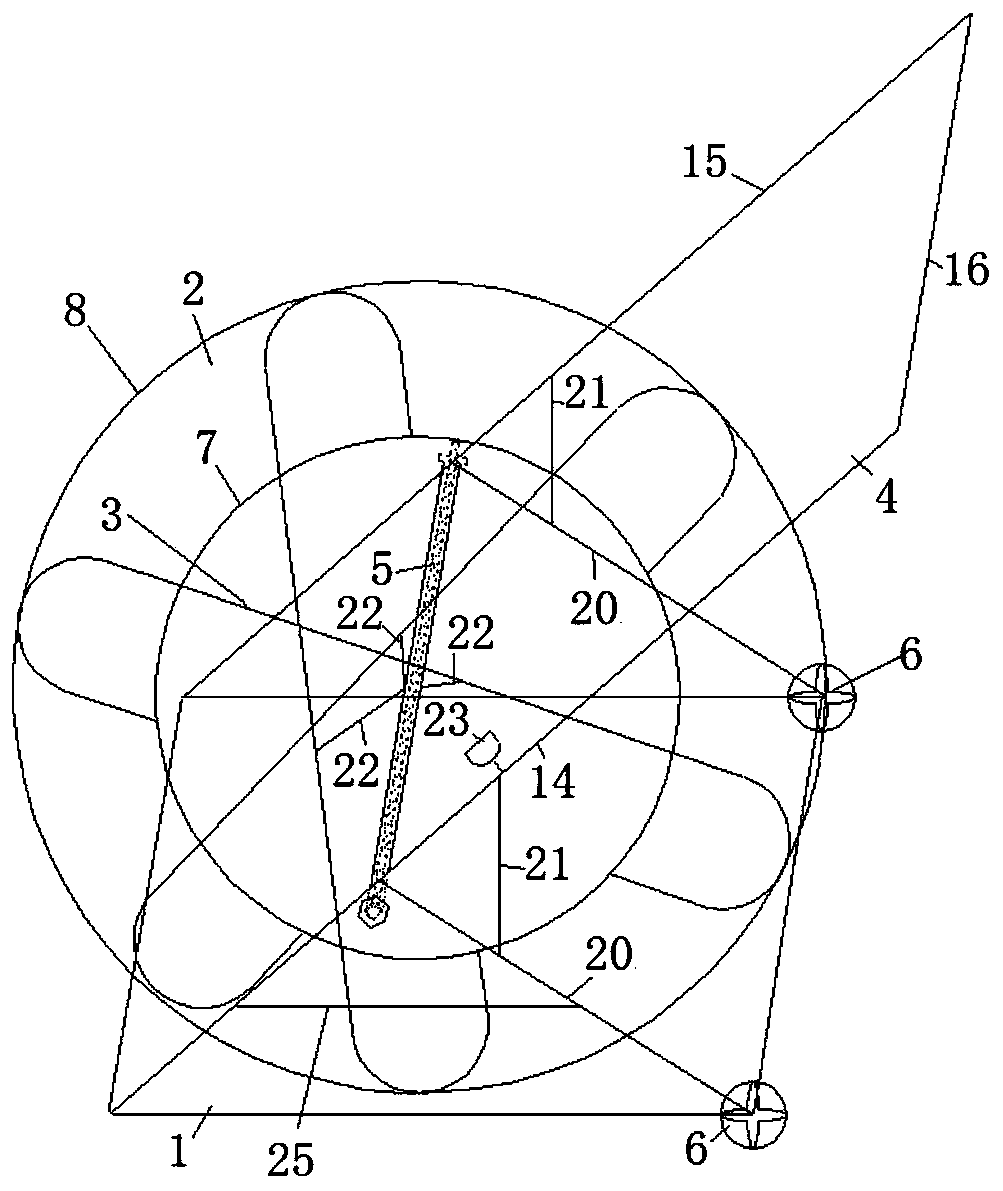

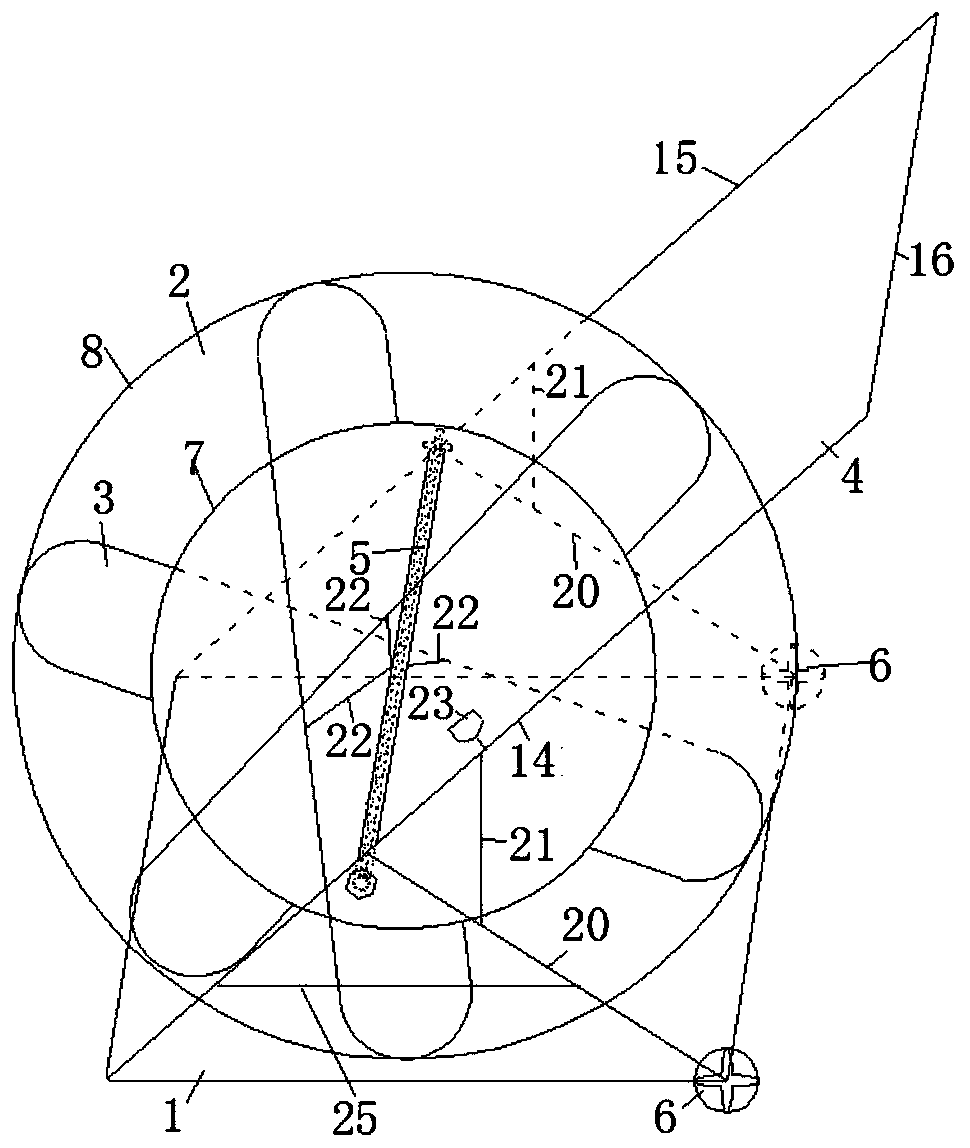

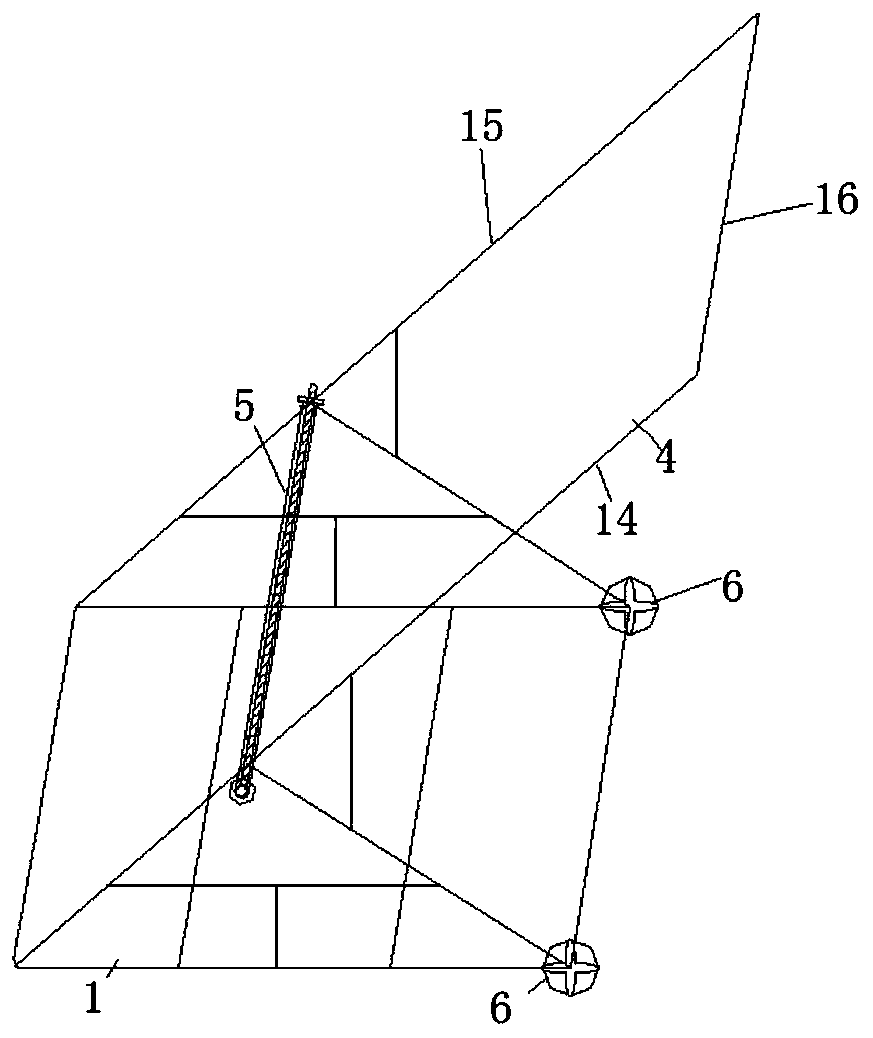

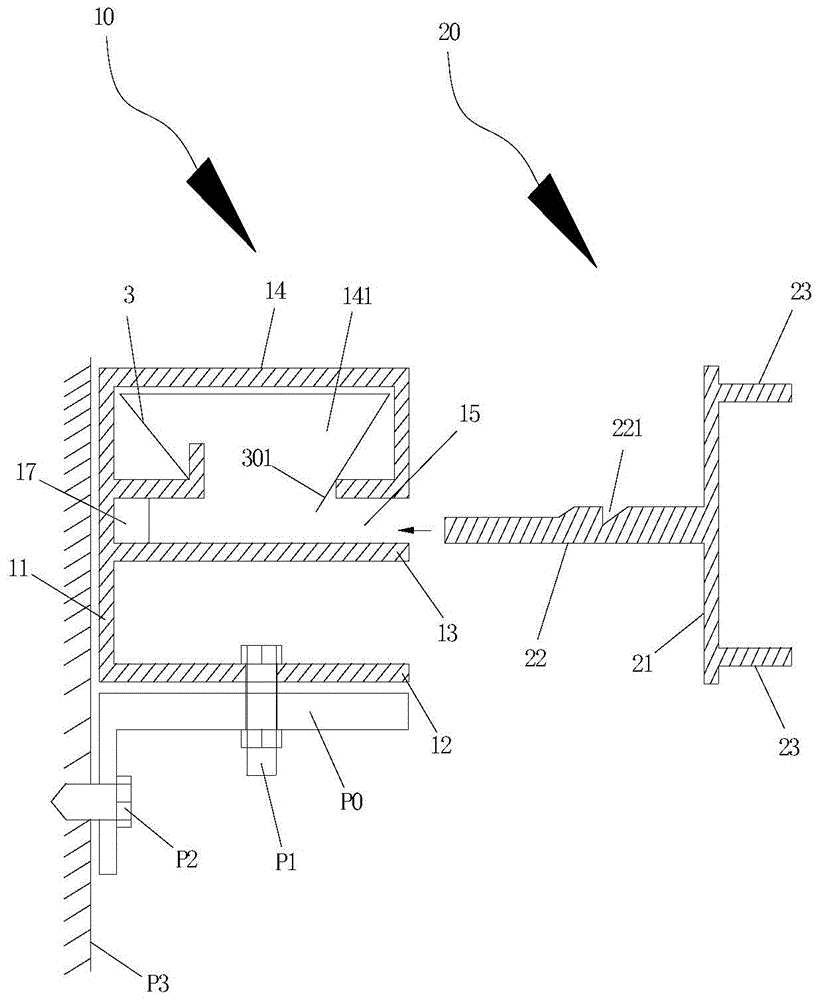

Speed bump mounting device

InactiveCN108755479AEasy to protect your healthSimple structureTraffic signalsRoad signsHydraulic cylinderSpeed bump

The invention discloses a speed bump mounting device. The problems that the mounting efficiency is low, the labor intensity is large, an existing speed bump is not beneficial for health of workers, and the mounting progress is delayed during mounting the existing speed bump are effectively solved. The speed bump mounting device comprises a mounting frame; a pressurized cylinder is fixed at the middle part of one side of the mounting frame; a perforating assembly is fixed at the bottom end of the pressurized cylinder; a partition plate is fixed on the internal side of the bottom of the perforating assembly; a motor is mounted at the part, running through the middle part of the partition plate, of the internal side of the perforating assembly; a first gear is fixed at the bottom end of the motor; second gears are connected to both the two ends of the first gear; electric drill bits are fixed at parts, running through the bottom end of the perforating assembly, of the middle parts of thebottom ends of the second gears; a telescopic rod is fixed at the middle part of the bottom end of the perforating assembly; an arc plate is mounted at the bottom end of the telescopic rod; a spring sleeves the part, between the perforating assembly and the arc plate, of the external side of the telescopic rod; a bolt box is mounted at the middle part of the mounting frame; a hydraulic cylinder isfixed at the upper part of the other side of the mounting frame; and an electric turntable is mounted at the bottom end of the hydraulic cylinder.

Owner:段欣彤

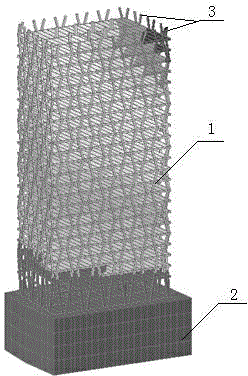

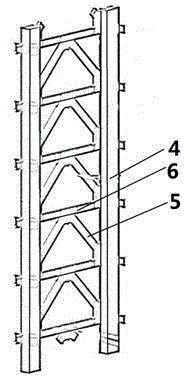

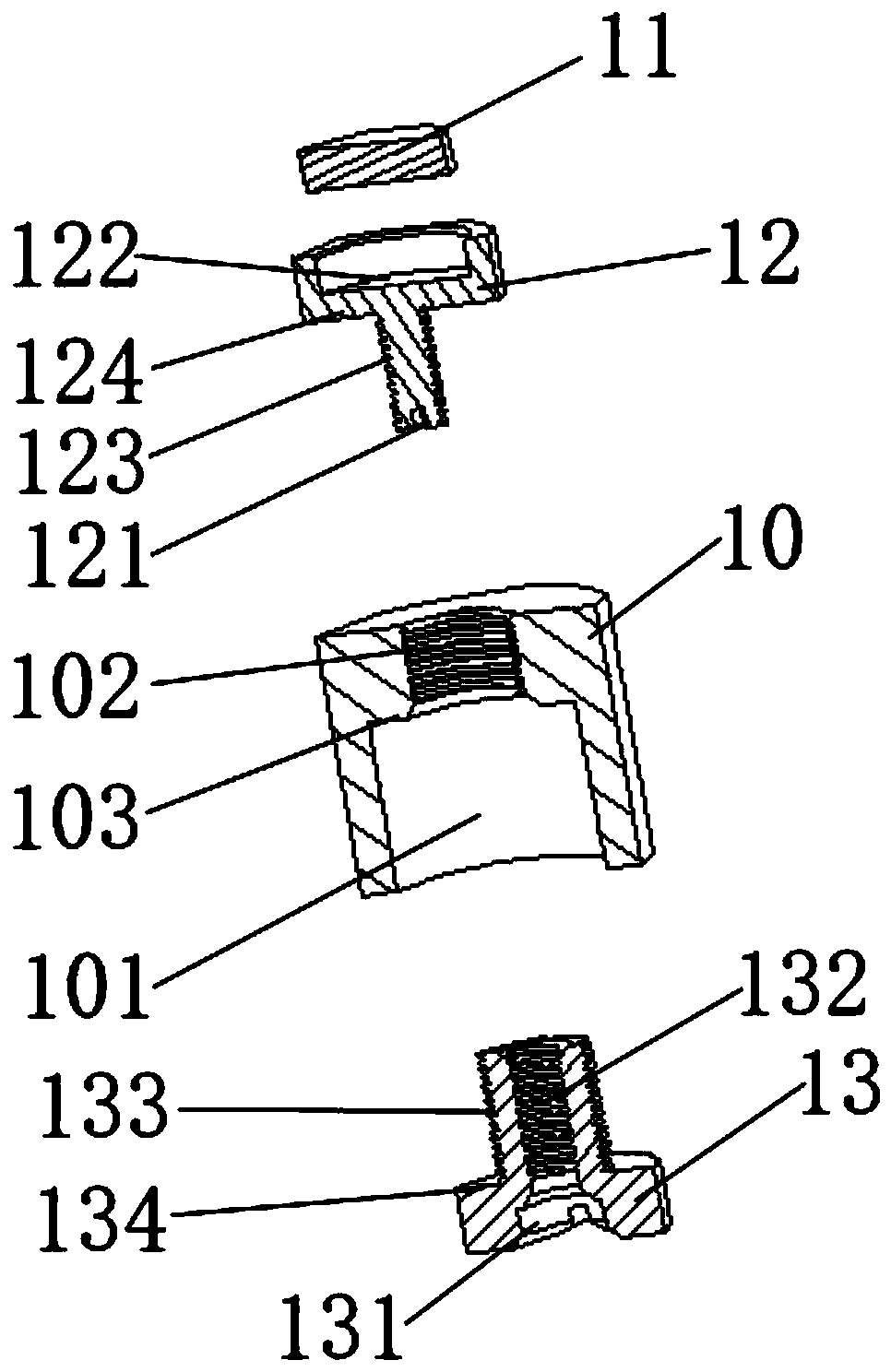

All-steel structure building and construction method thereof

InactiveCN105863042AGuaranteed installation accuracyGuaranteed installation progressArtificial islandsUnderwater structuresSteel columnsMesh grid

The invention discloses an all-steel structure building, formed by an underground all-steel structure and an overground all-steel structure. The material of steel structural members is low alloy high strength steel Q345B. Also disclosed is a construction method for the all-steel structure building. A reverse building method is used in construction, hoisting of steel columns is completed on a foundation pit, and basement steel beams are constructed and installed in stages. Steel beams of underground first floor and first floor are directly installed on the foundation pit by using a tower crane. Steel beams of underground second floor and third floor are installed layer by layer with a basement earthwork downward underground excavation process. Factory pre-assembly on honeycombed outer frame grid pillar-beam positions in relatively complex structure and core tube steel column supports is performed to ensure on-site installation precision, so as to ensure installation progress. The all-steel structure building is installed in an all-steel structure, and is high in structural strength. A main building lateral load resisting structure system can resist earthquake and wind load.

Owner:JIANGSU HUNING STEEL MECHANISM

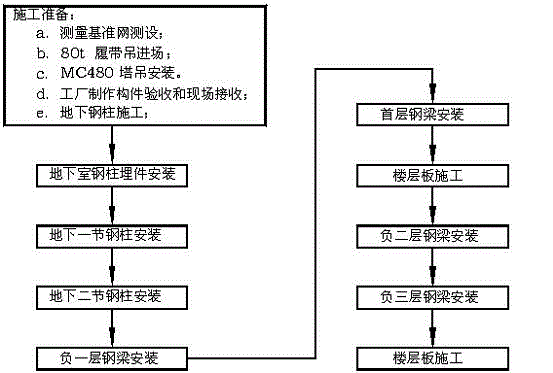

Whole-series oil-free SF6 gas recovering and filling device

The invention discloses a whole-series oil-free SF6 gas recovering and filling device. The whole-series oil-free SF6 gas recovering and filling device comprises a first vacuum pump, a second vacuum pump, a first ball valve, a second ball valve, a first check valve, a second check valve, a negative-pressure recycling machine, a compressor, an electromagnetic valve, a safety exhaust valve and pipelines, wherein an inlet of the first ball valve is connected with an inlet of the second ball valve, an outlet of the first ball valve is connected with the suction end of the first vacuum pump, an exhaust end of the first vacuum pump is connected with the suction end of the second vacuum pump, the inlet end of the safety exhaust valve is connected to the pipeline between the first vacuum pump and the second vacuum pump, the exhaust end of the second vacuum pump is open, an outlet of the second ball valve is connected to an inlet of the electromagnetic valve, an outlet of the electromagnetic valve is connected with the negative-pressure recycling machine through the pipeline, the negative-pressure recycling machine is connected with an inlet of the compressor through the second check valve and the pipeline, the inlet end of the first check valve is connected with the inlet pipeline of the electromagnetic valve, and the exhaust end of the first check valve is connected to the inlet pipeline of the compressor. The whole-series oil-free SF6 gas recovering and filling device has the advantages that SF6 gas is prevented from being in contact with oil, and the influence of the oil on the quality of the SF6 gas is avoided in theory.

Owner:SHAANXI GUANDI GENERAL ELECTRIC

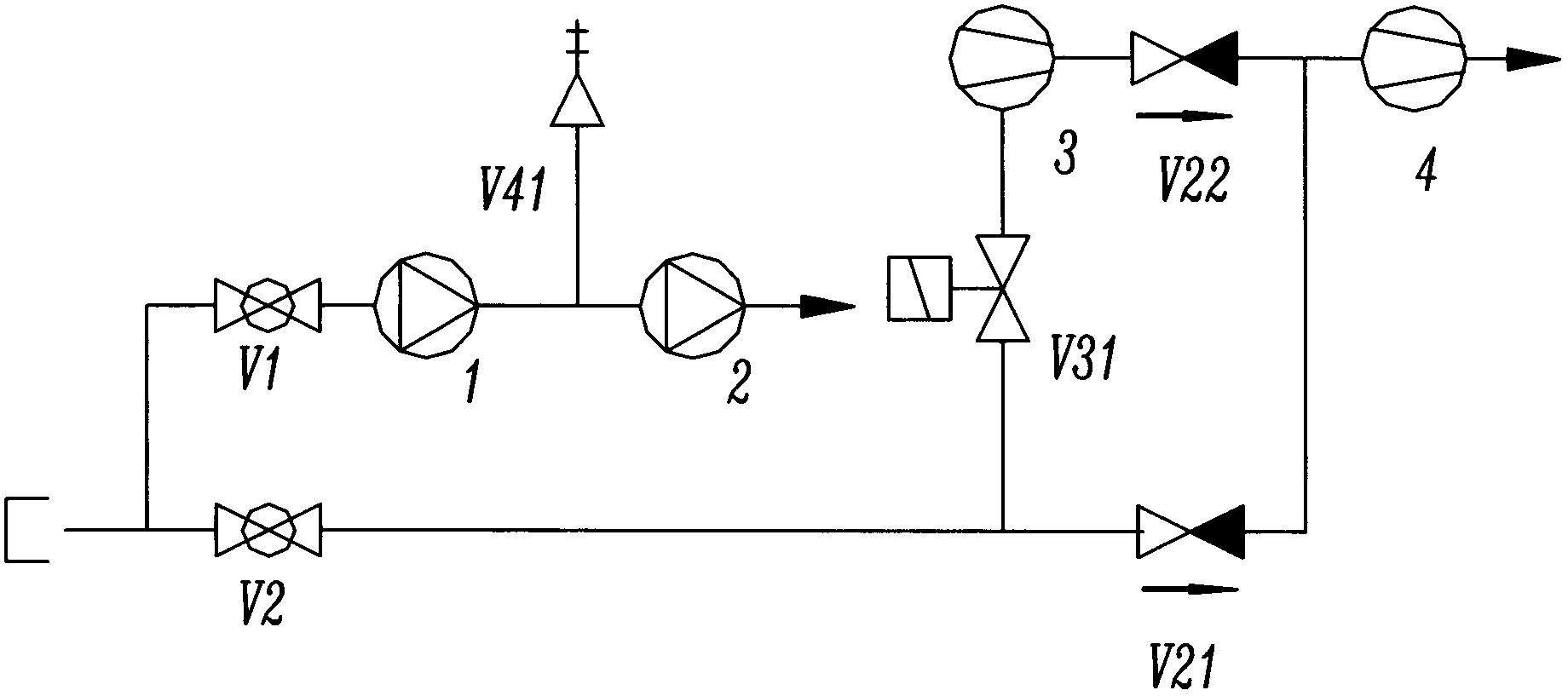

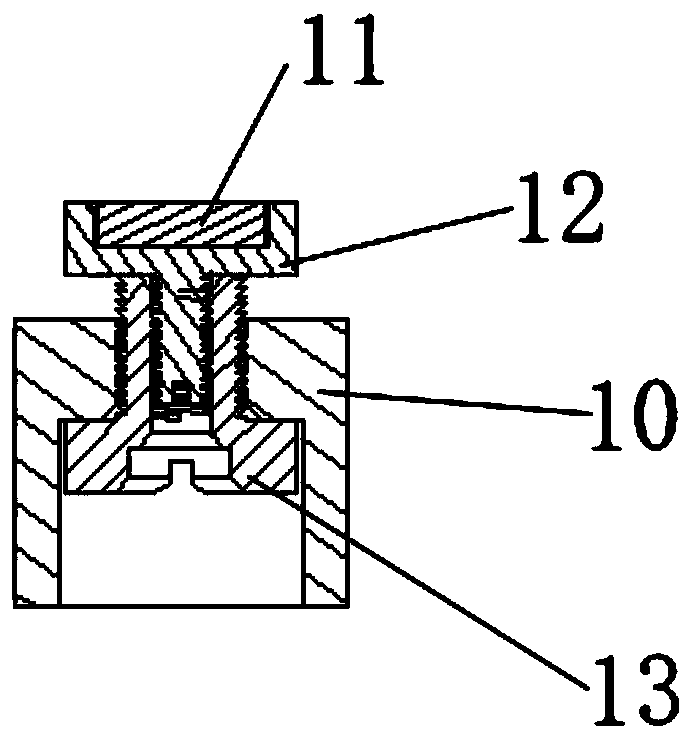

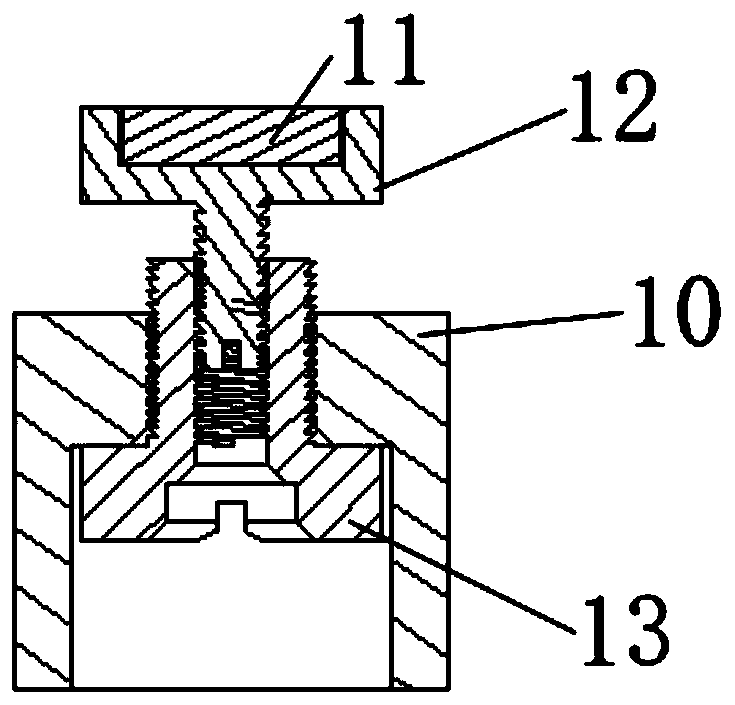

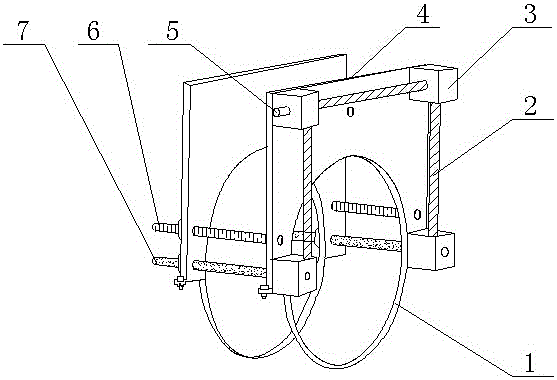

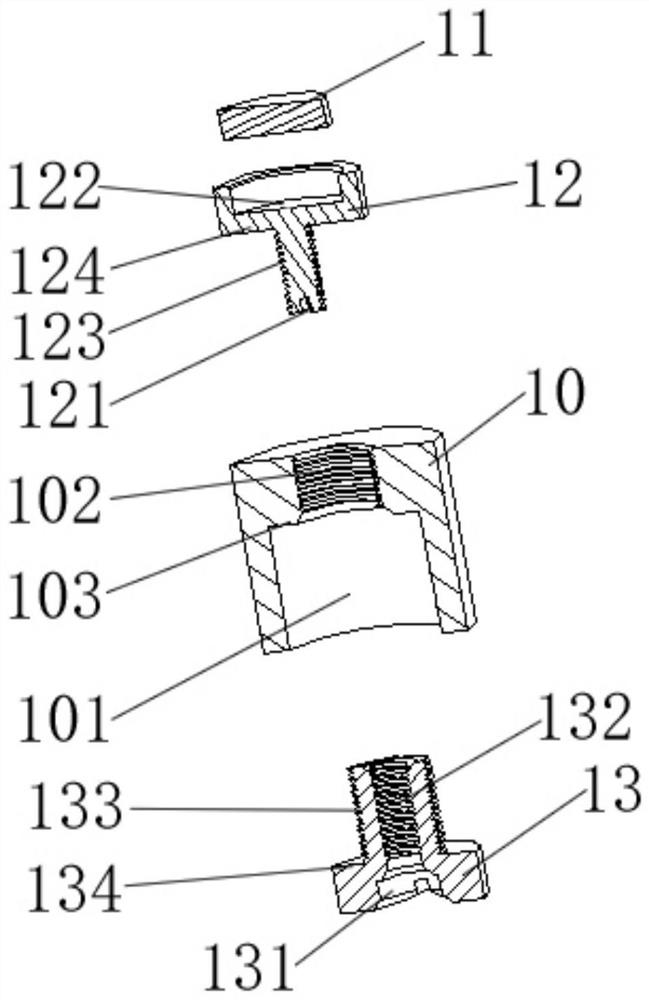

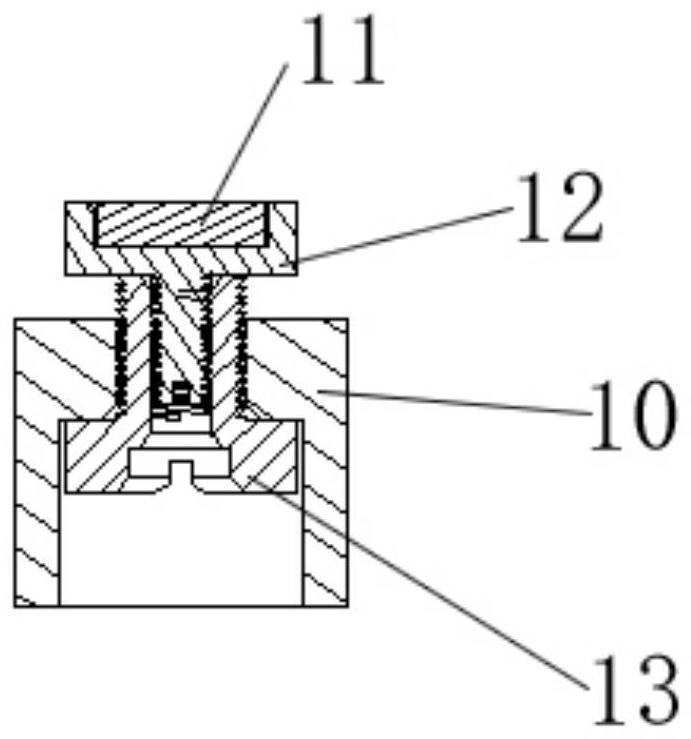

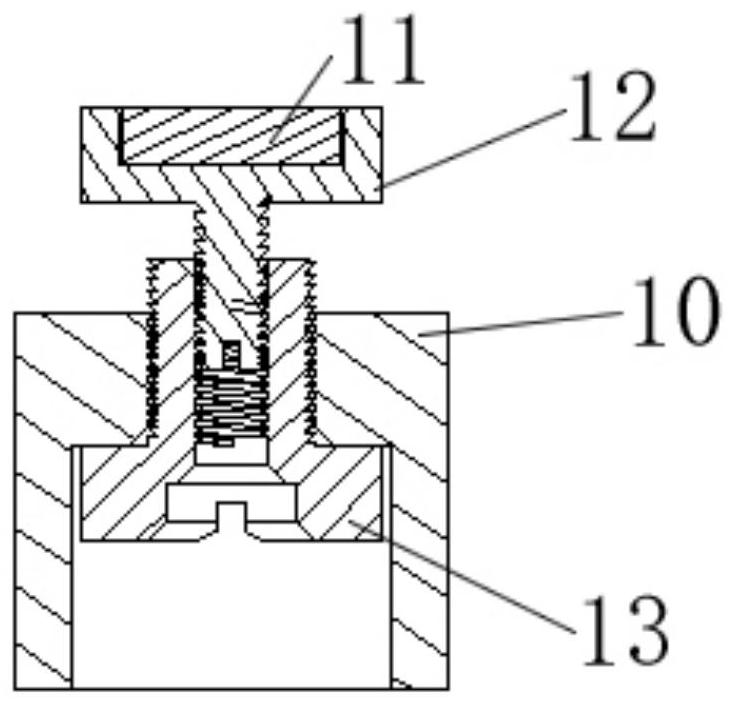

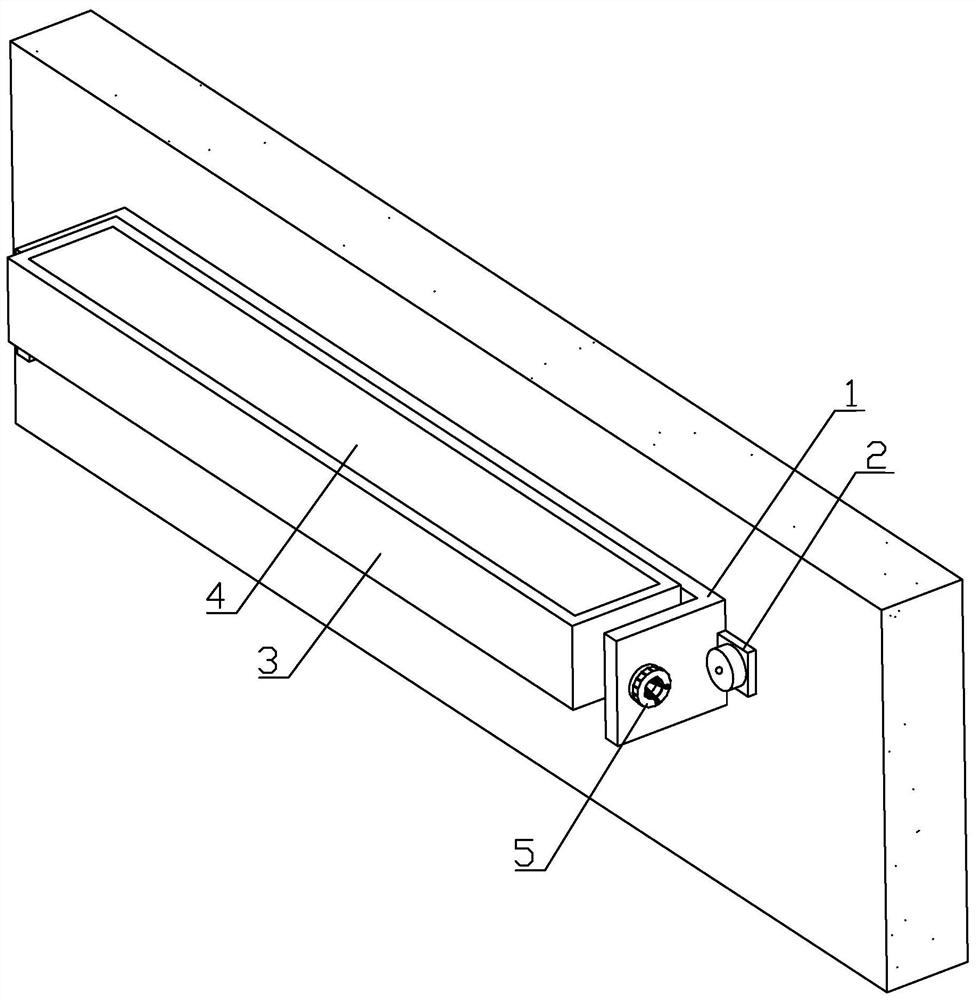

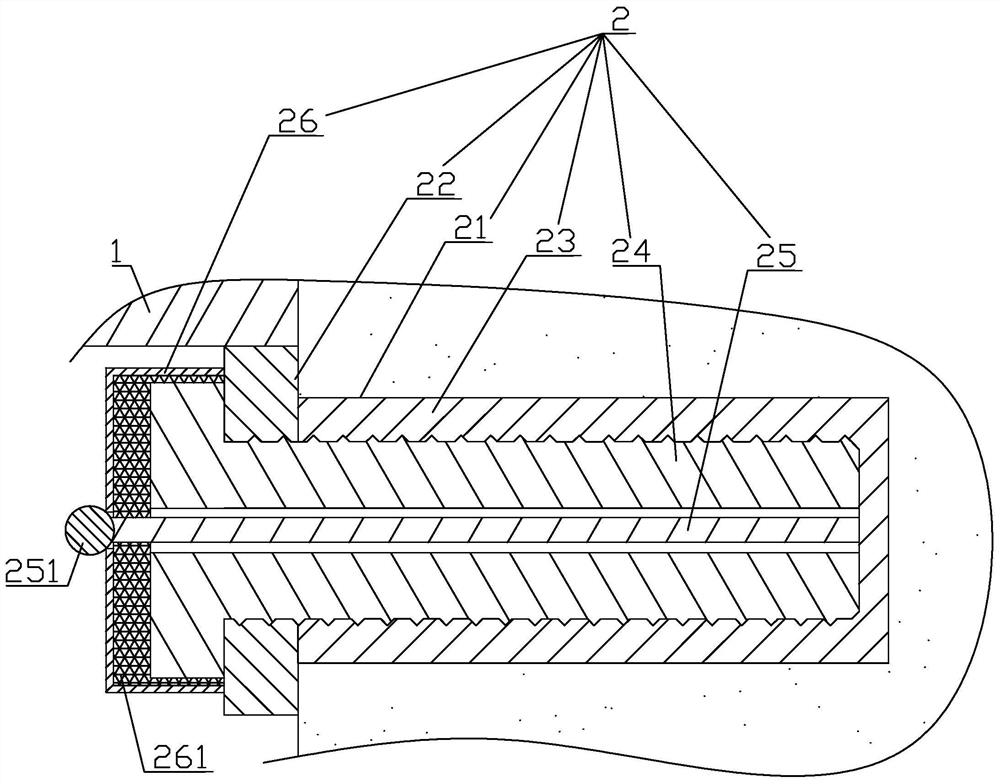

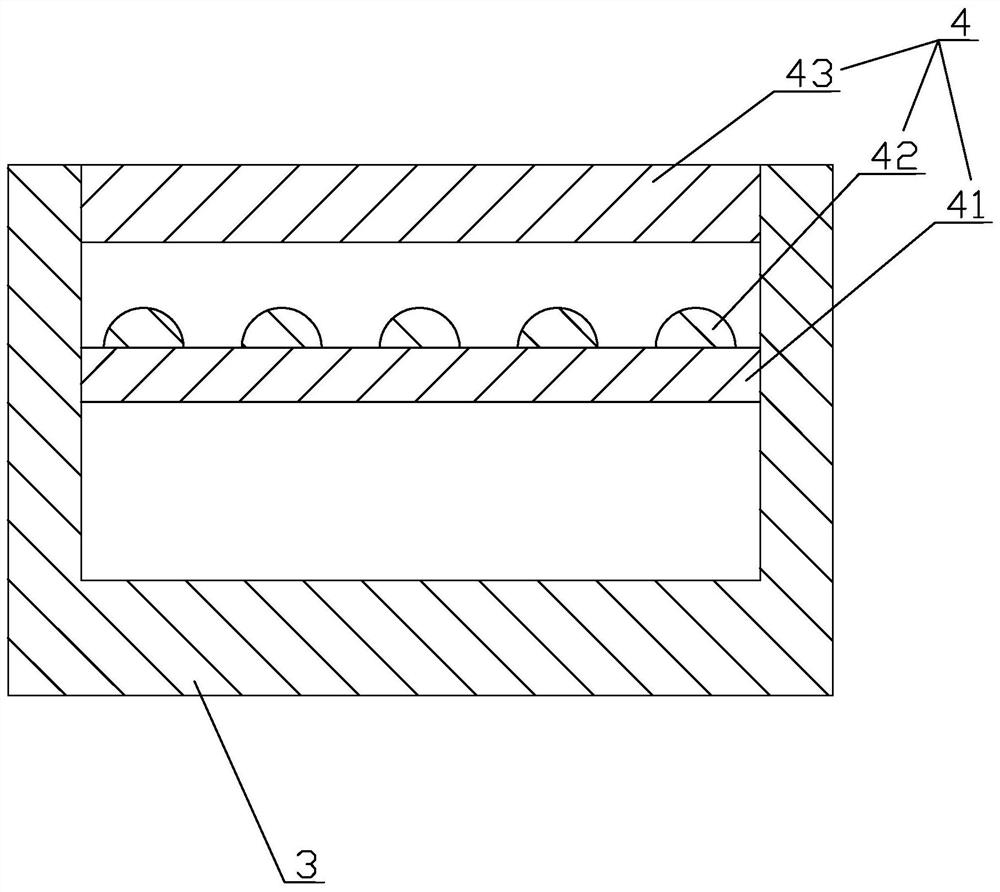

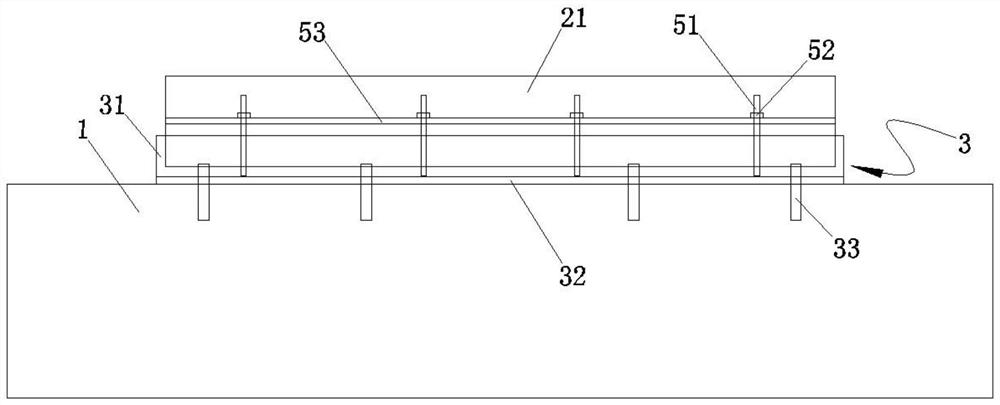

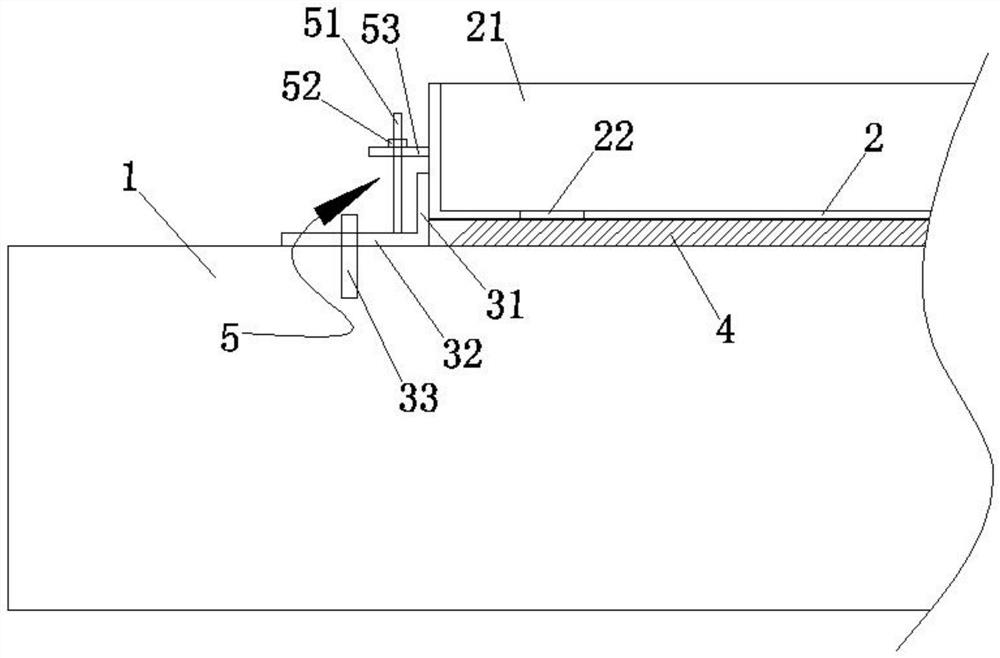

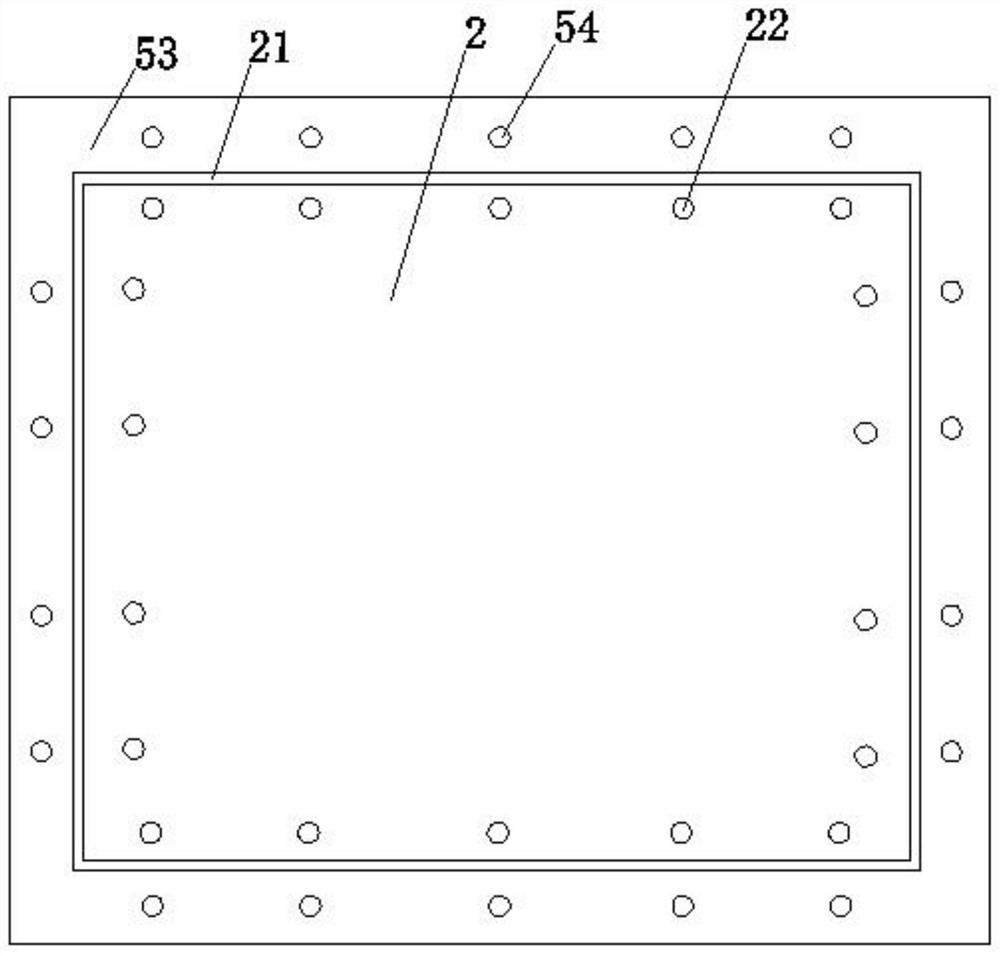

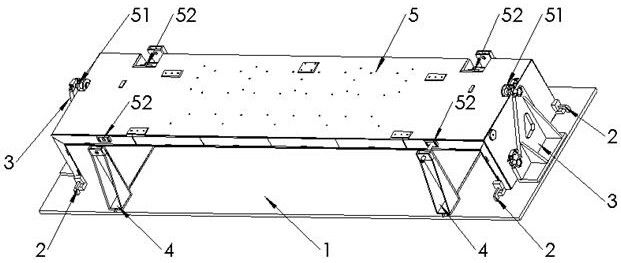

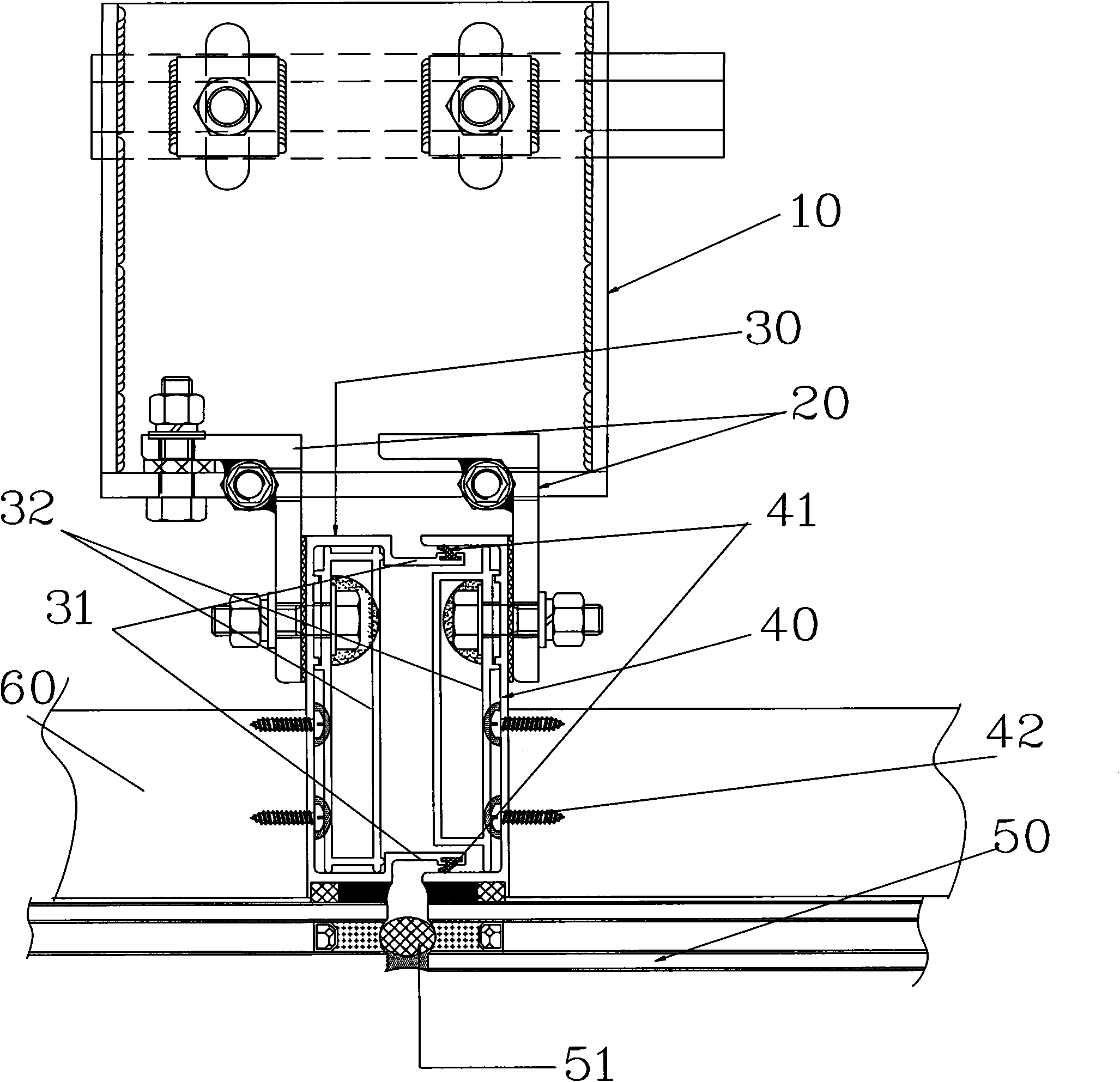

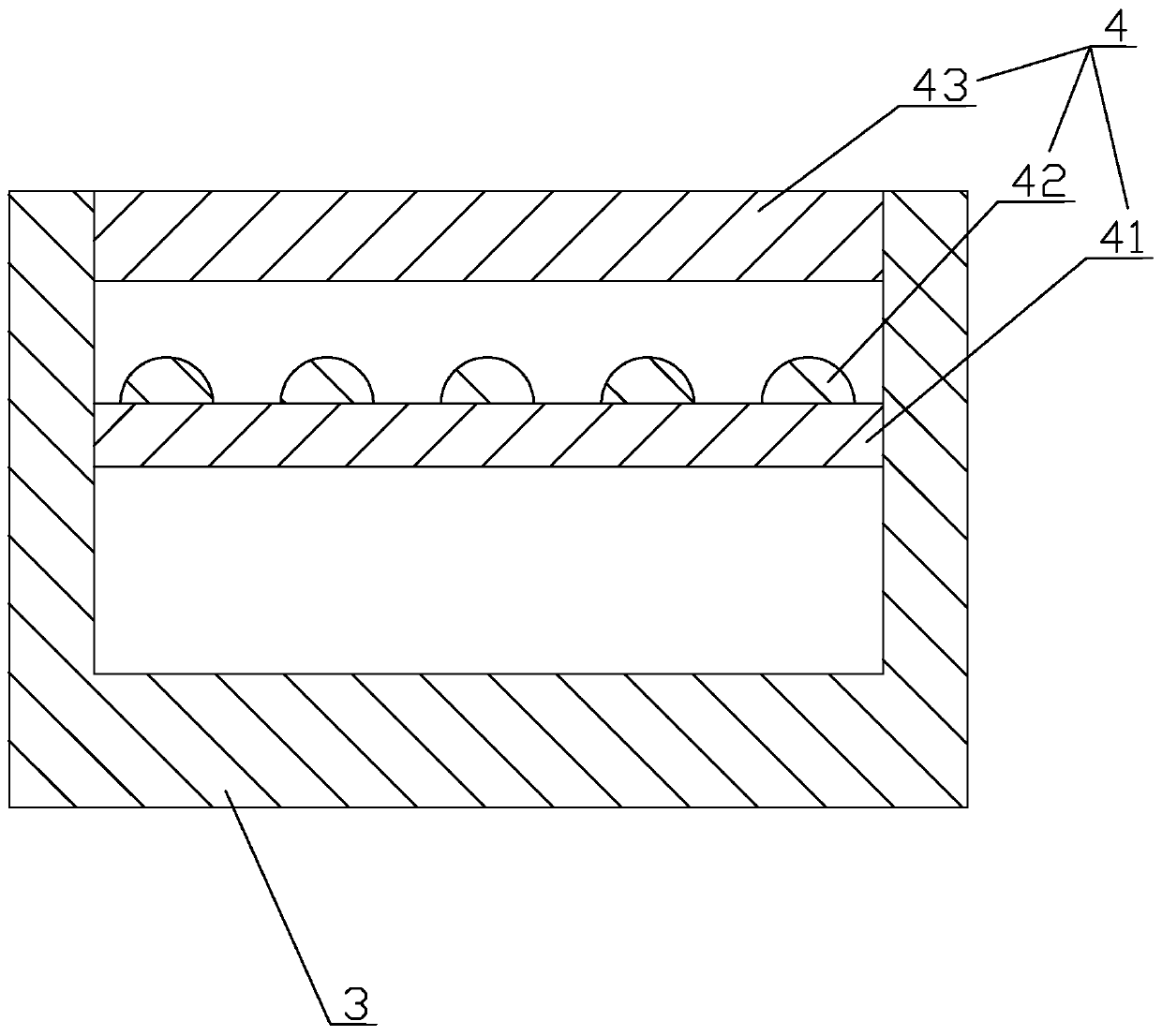

Flatness adjusting device for LED display module

ActiveCN110992848AThe overall structure is simple and reliableEasy to useIdentification meansLED displayEngineering

The invention relates to the field of LED display, in particular to a flatness adjusting device for a LED display module. The device comprises a fixing piece, an adsorption piece, a first adjusting piece and a second adjusting piece, the fixing piece is fixedly connected with a LED box body, the second adjusting piece is in threaded connection with the fixing piece, the first adjusting piece is inthreaded connection with the second adjusting piece, the adsorption piece is arranged in the first adjusting piece, and the adsorption piece is in magnetic connection with the display module. The novel flatness adjusting device for a LED display module is simple and reliable in structure and convenient to use. Through cooperative use of the fixing piece, the first adjusting piece and the second adjusting piece, standard quantification of initial installation is achieved, meanwhile, the installation positions of the display modules can be easily adjusted up and down, all the display modules can be adjusted up and down independently, adjustment is flexible and convenient, efficiency is high, and the installation progress and the display effect are well guaranteed.

Owner:GUANGDONG VTRON TECH CO LTD

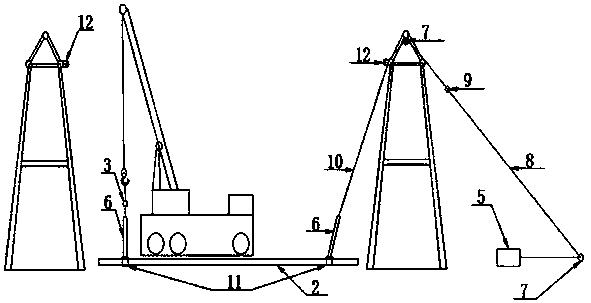

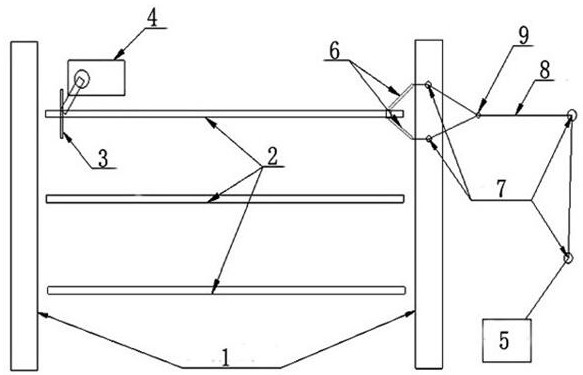

Inclined pulling hanging type tubular busbar hoisting method

ActiveCN110386543AGuaranteed installation progressEnsure a successTotally enclosed bus-bar installationsLoad-engaging elementsTransformerBusbar

The invention discloses an inclined pulling hanging type tubular busbar hoisting method. According to the hoisting operation steps, a special hanging beam is manufactured, and the special hanging beamis manufactured according to the distance of hanging holes in a civil engineering n-shaped framework and the total length and the weight of a tubular busbar; the left end of the tubular busbar is hoisted in a combined manner, and a crane is used for hanging the special hanging beam to sequentially connect an insulator chain and a hanging hardware fitting for hoisting; the right end of the tubularbusbar is hoisted in a combined manner, a winch mill is used for dragging a traction steel wire rope to sequentially connect a steel wire rope, the insulator chain and the hanging hardware fitting for hoisting; hanging holes in the crane side are hoisted and connected; hanging holes in the winch mill side are hoisted and connected, and the tubular busbar hoisting process is finished; levelness adjustment is conducted; and sling dismounting is conducted. According to the inclined pulling hanging type tubular busbar hoisting method, through manufacturing and using of the special hanging beam, ahoisting machine is reasonably arranged on the construction site, the hoisting work of a 500 KV transformer substation tubular busbar is safely and rapidly finished, the inclined pulling hanging typetubular busbar hoisting method can be used for installing of similar transformer substation tubular busbars, and a basic guarantee is provided for later tubular busbar hoisting.

Owner:POWER CHINA HENAN ENG CO LTD

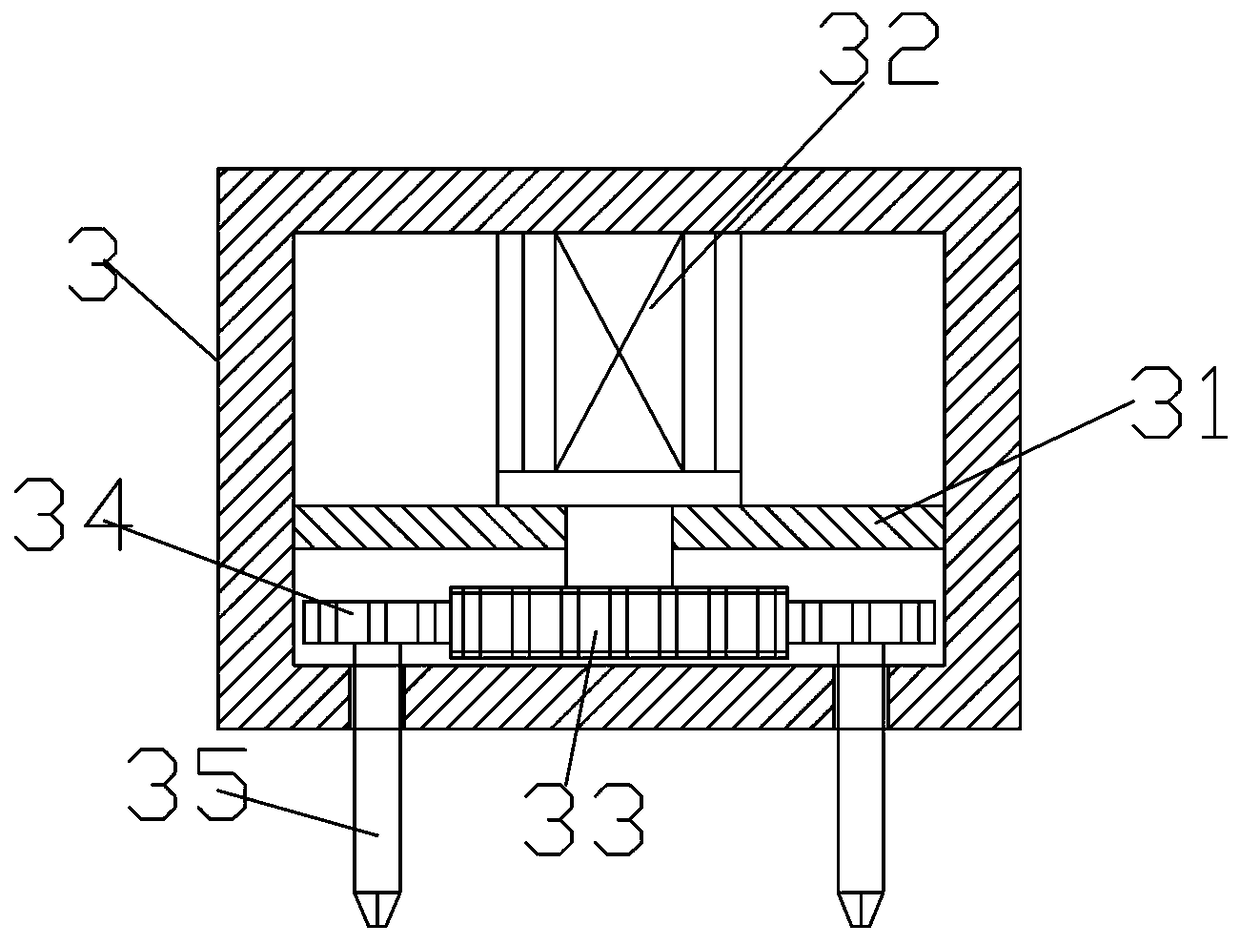

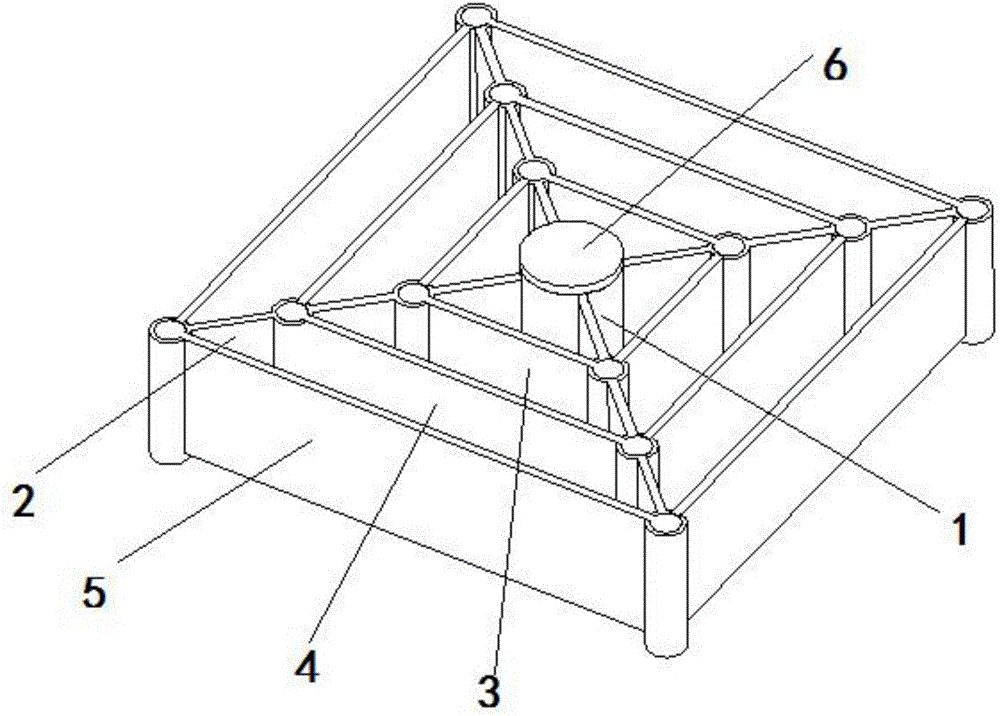

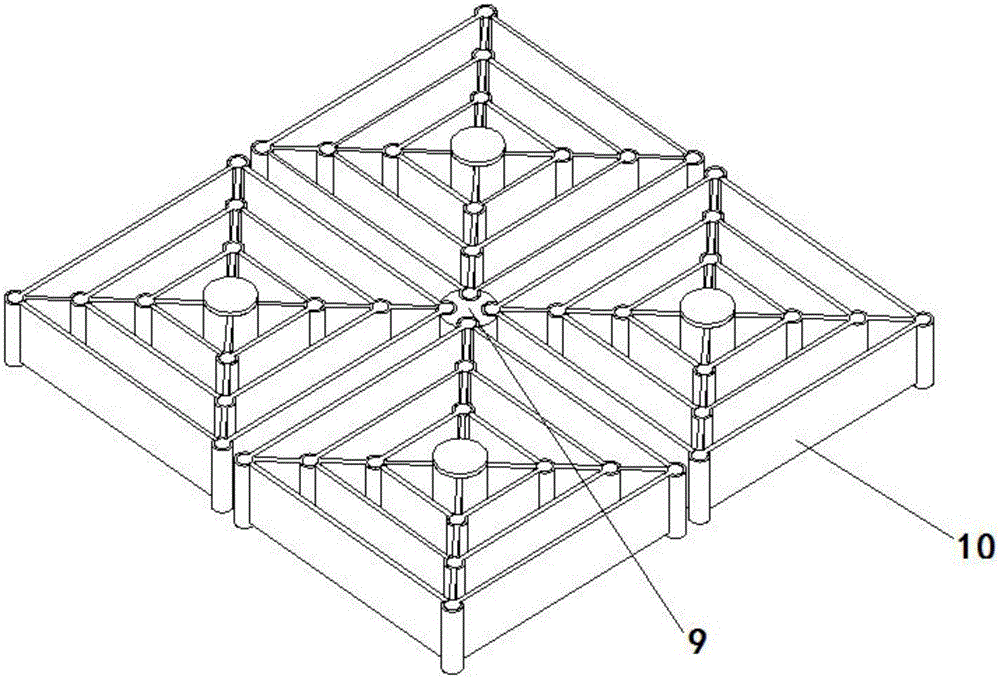

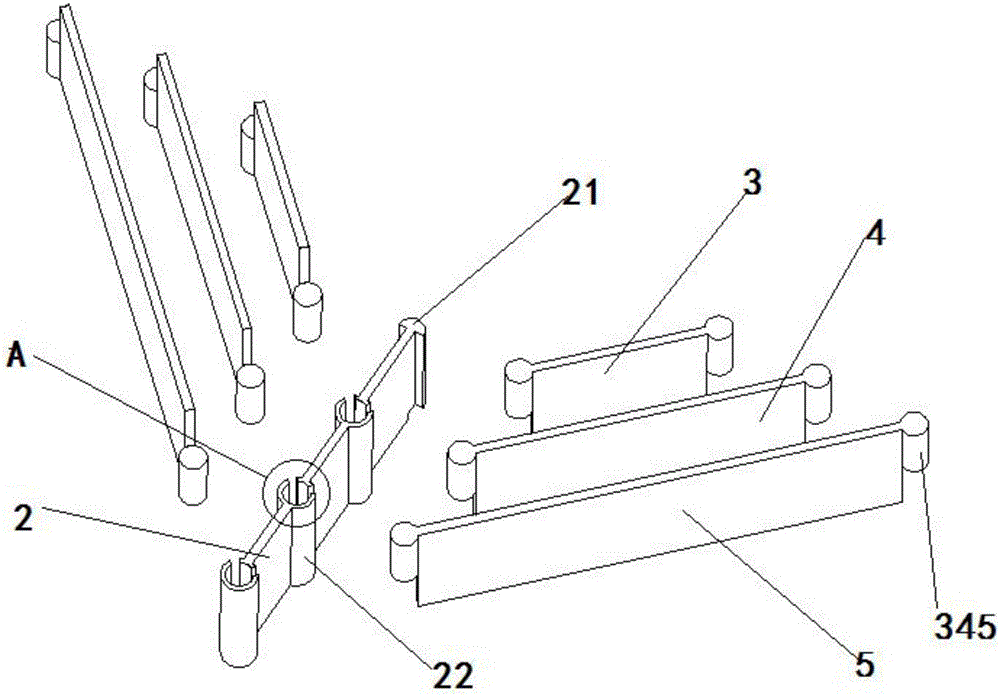

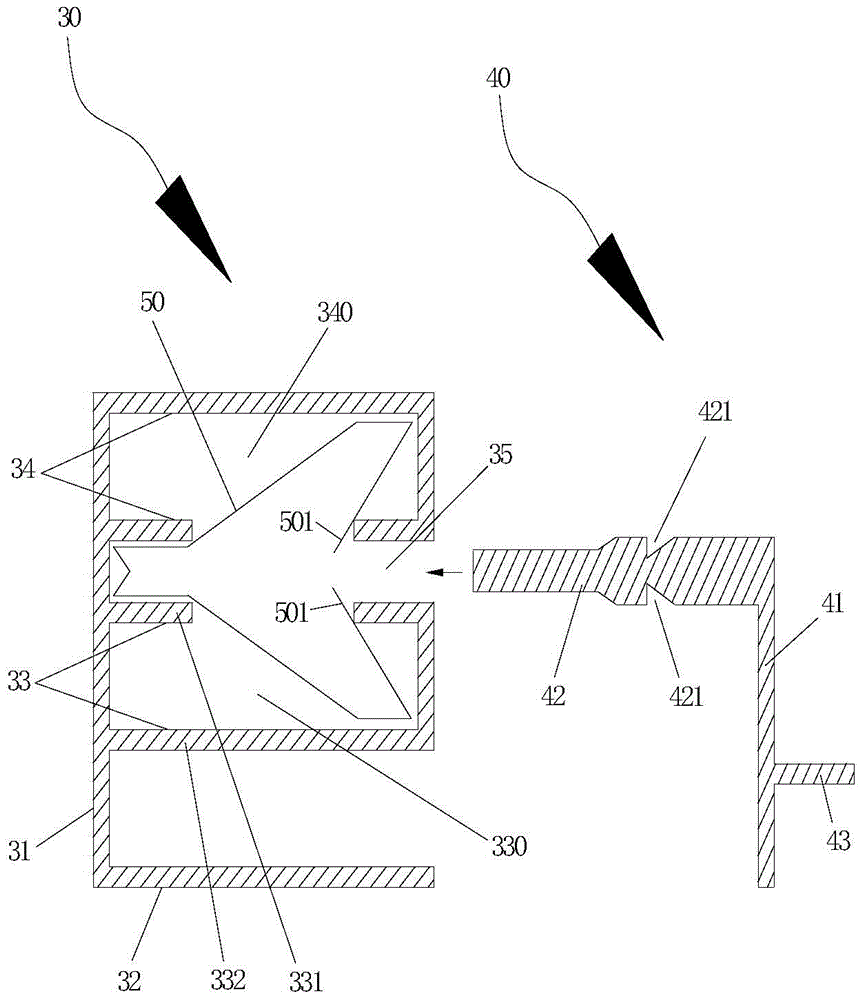

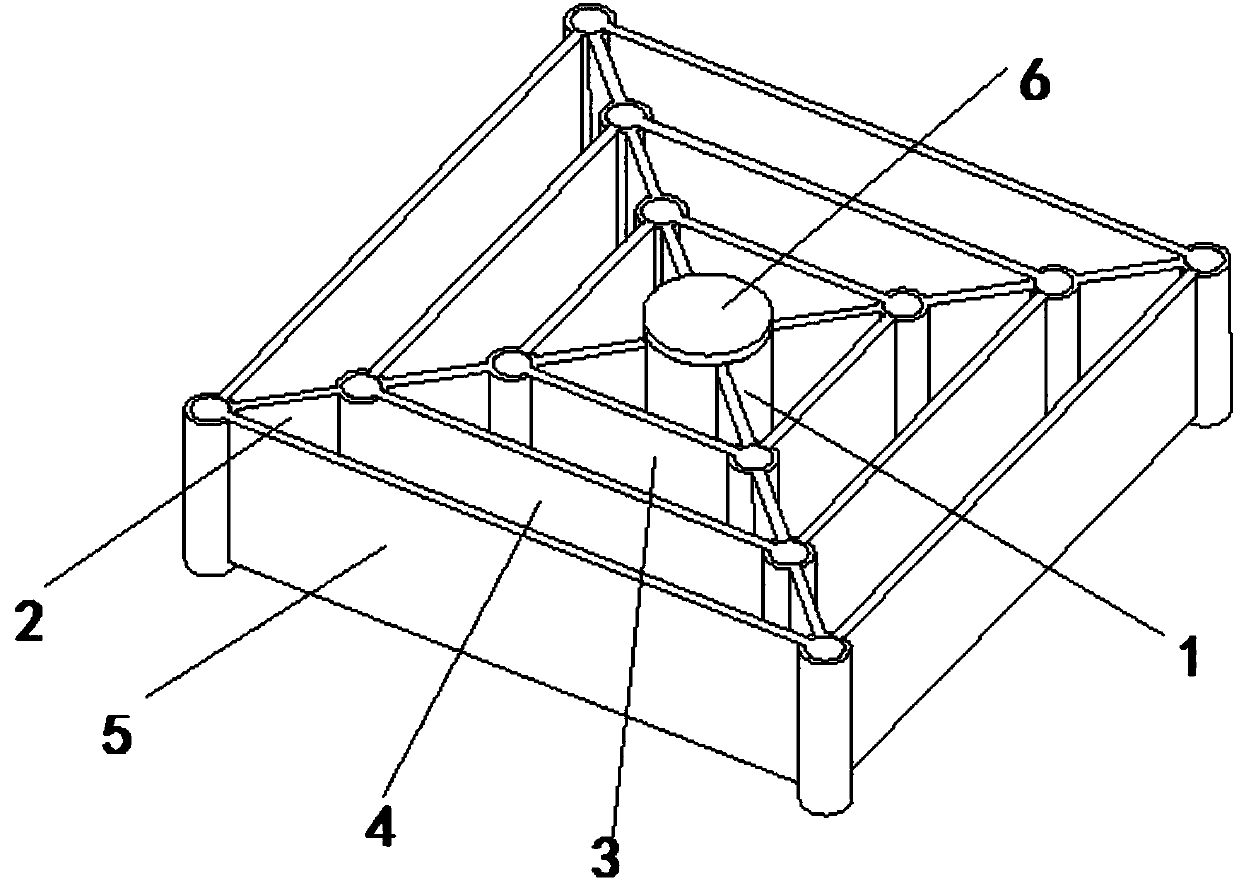

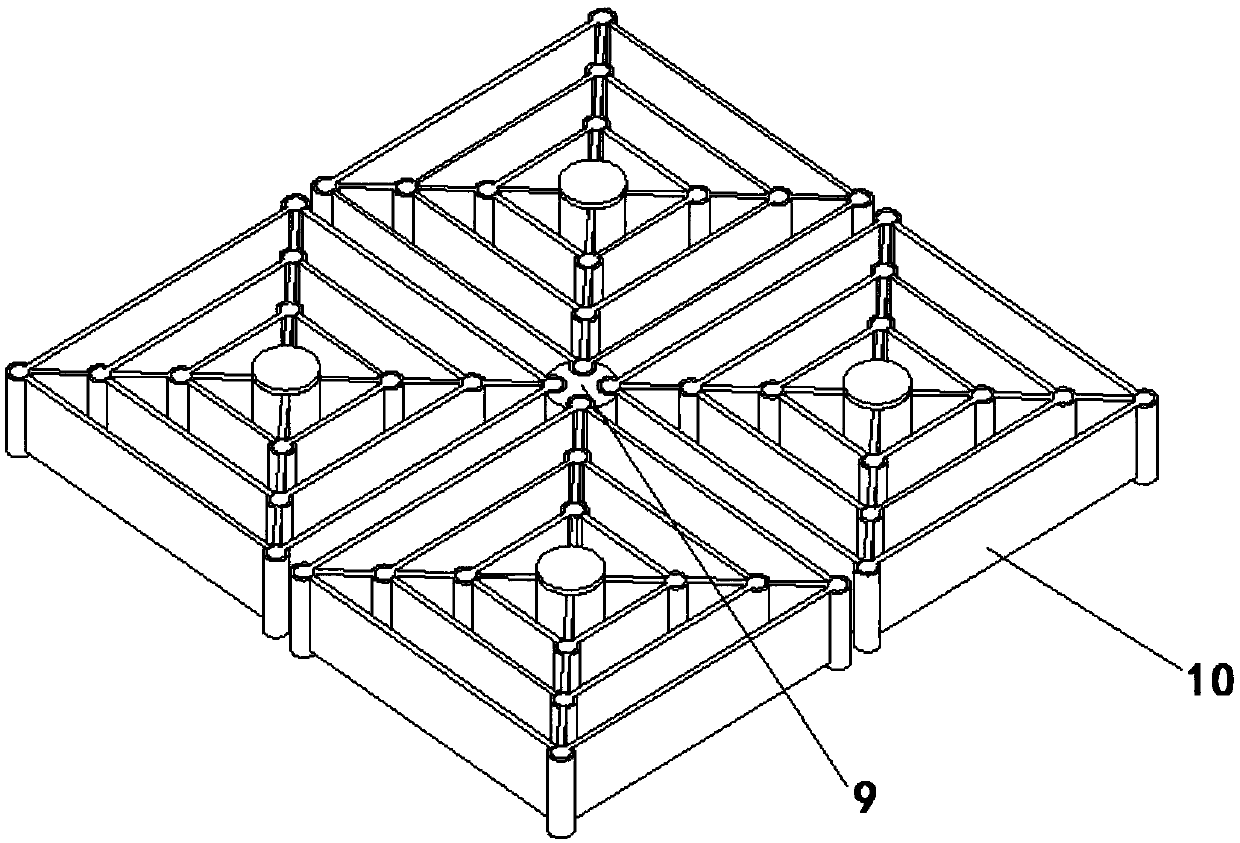

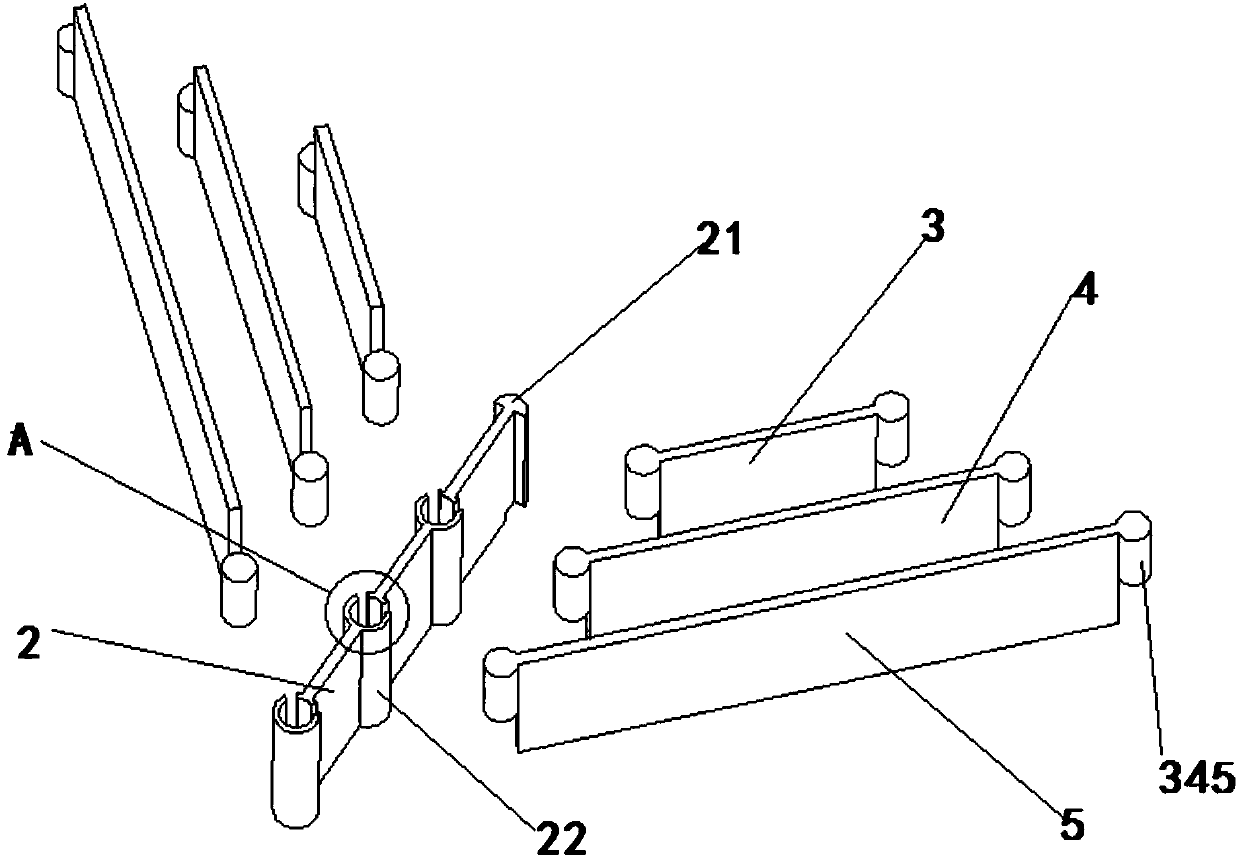

Detachable geocell

ActiveCN106013035AGuaranteed installation progressUniform pressureRoadwaysSoil preservationGeocellsEngineering

The invention discloses a detachable geocell. The detachable geocell comprises a connecting base and a basal cell. The basal cell comprises a fixing base. Clamping grooves are evenly distributed in the peripheral sides of the fixing base. A mounting groove is formed in the surface of the other end of the fixing base. The peripheral side of the mounting groove is connected with the clamping grooves in a cut-through mode. Connecting plates are mounted in the clamping grooves. Clamping heads are arranged at one ends of the connecting plates, mounted in the clamping grooves and placed between a pressure pad and a bottom cap. Three mounting columns are arranged on each connecting plate in the direction from the clamping head to the other end of the connecting plate at equal intervals. A columnar groove is formed in the surface of one end of each mounting column, and two connecting grooves are symmetrically formed in the peripheral side of each mounting column. Four connecting grooves are evenly distributed in the peripheral side of the connecting base. The connecting base is fixedly connected with the basal cell through the connecting grooves. Through the array type composite structure, the geocell is divided into a plurality of blocks with the same compartment area, so that pressure of fillers in grids to the inner walls of the geocell is uniform, the mounting service life of the geocell is greatly prolonged, and the mounting process of a whole project is ensured.

Owner:ANHUI HUIFENG NEW SYNTHETIC MATERIALS CO LTD

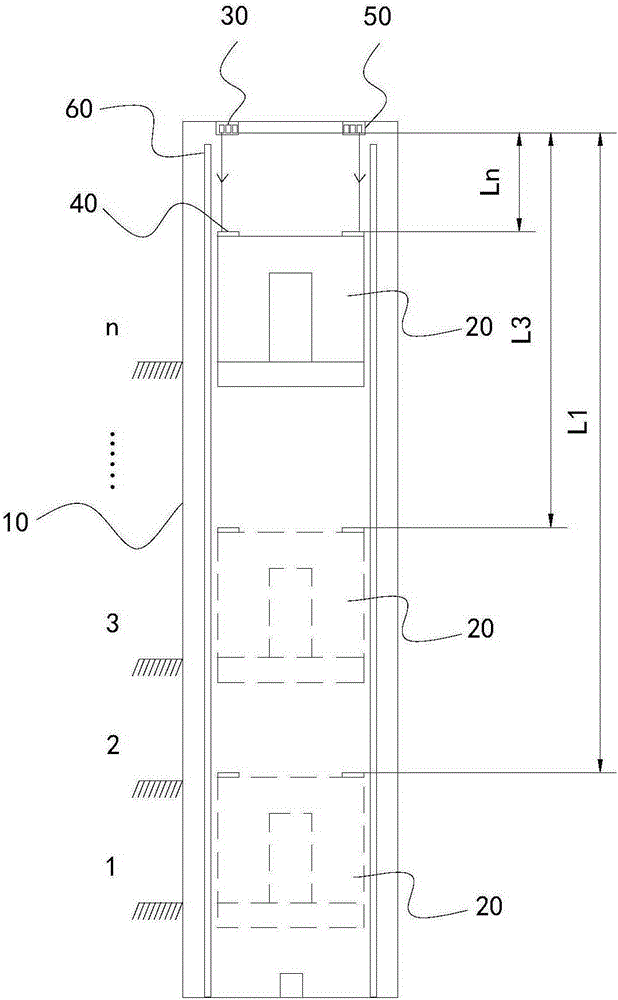

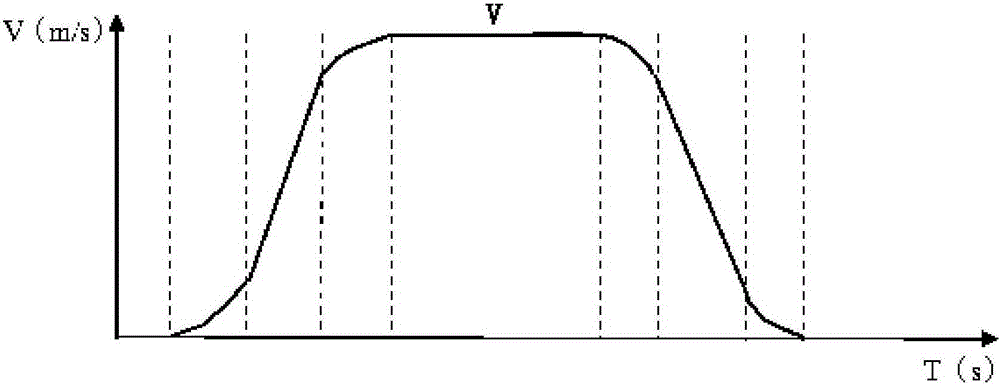

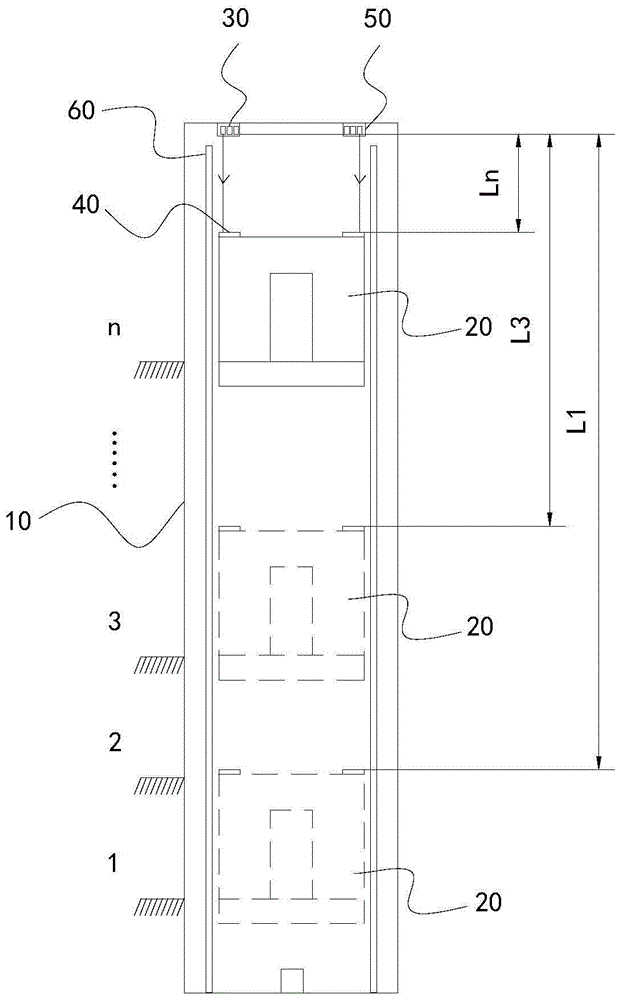

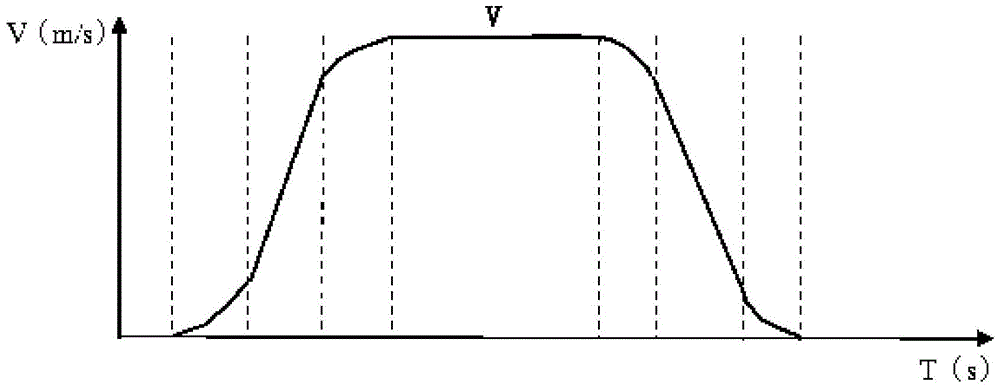

Control device and method of elevator flat floor position

ActiveCN105173935AGuaranteed uptimeSolve the problem of larger leveling errorsElevatorsControl systemSimulation

The invention relates to a control device and method of the elevator flat floor position. An elevator comprises a shaft, an elevator car, and a drive device driving the elevator car to move, and the elevator car and the drive device are arranged in the shaft. The control device of the elevator flat floor position comprises at least one ranging sensor arranged on the top or bottom of the shaft, baffles opposite to the ranging sensors, and a control system electrically connected with the ranging sensors. The baffles are fixed to the elevator car. The control system is electrically connected with the drive device. The ranging sensors are fixed to the shaft and matched with the baffles fixed to the elevator car. Thus, installing and adjusting are convenient, the installing convenience is improved, the production efficiency is high, and the installing progress of the elevator project is guaranteed. The real-time and accurate measurement is carried out on the position distance of the elevator car through the ranging sensors, the running of the elevator car is controlled through the control system, and the problem that the longer running time of the elevator is, the larger the generated flat floor error becomes is solved. The running of the elevator is safer, and the accuracy of the elevator flat floor position is guaranteed.

Owner:HITACHI ELEVATOR CHINA

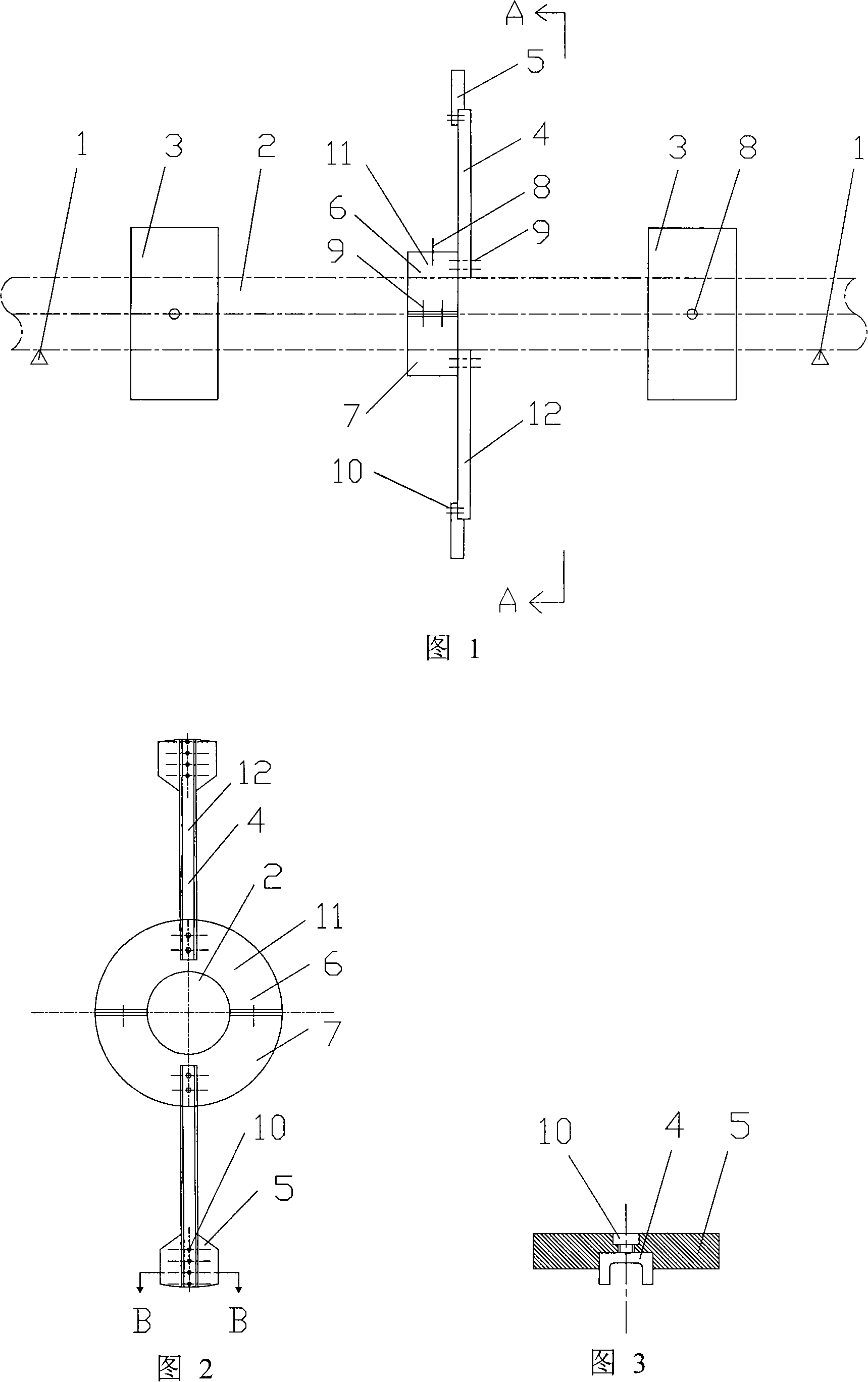

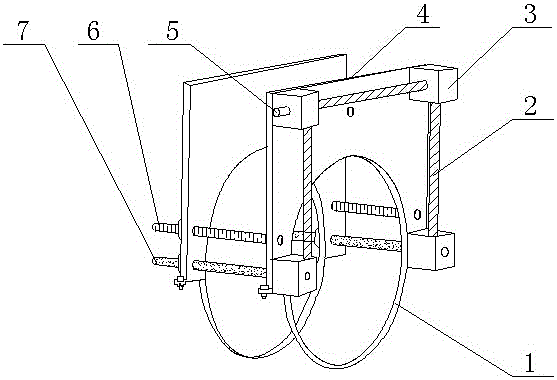

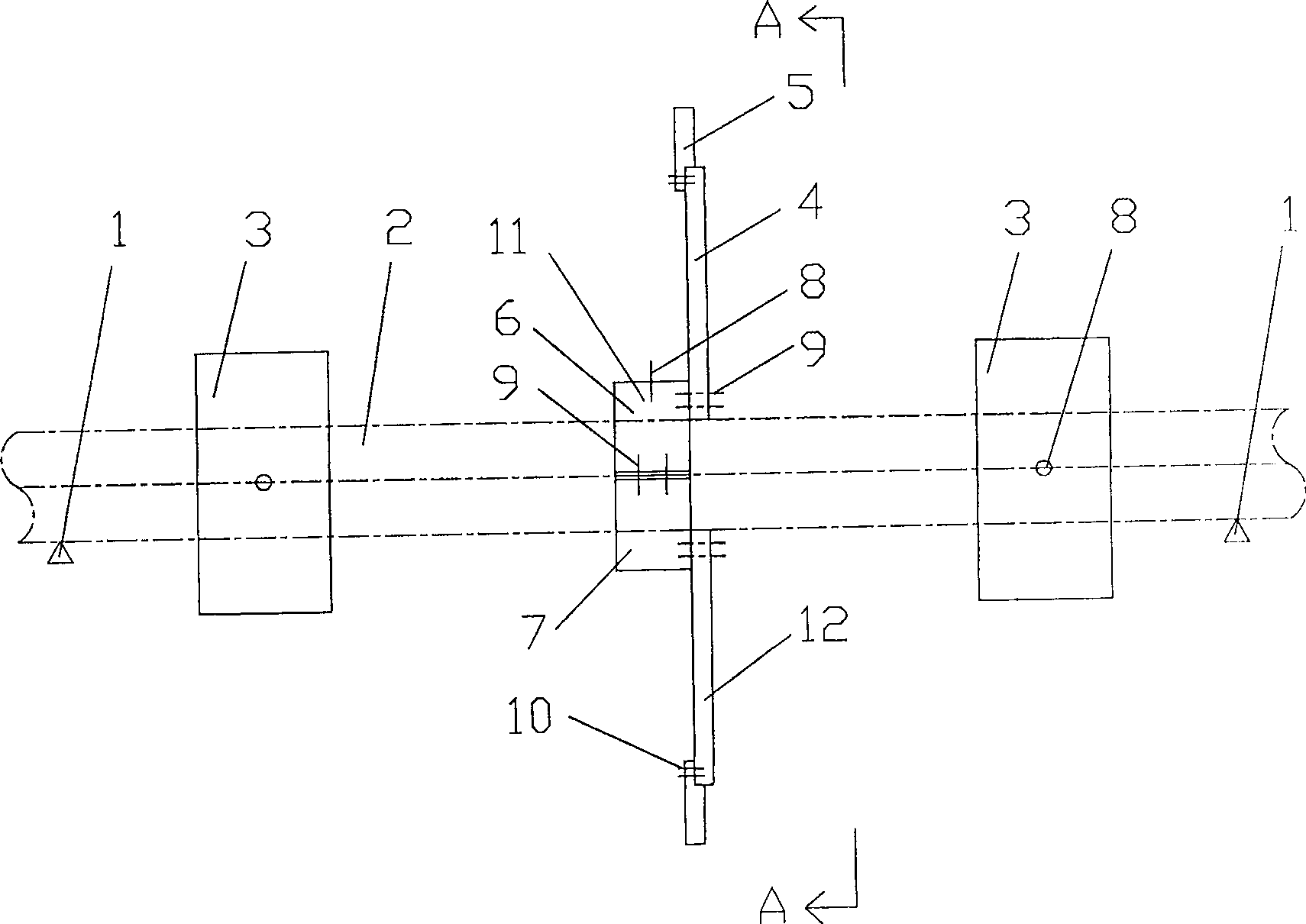

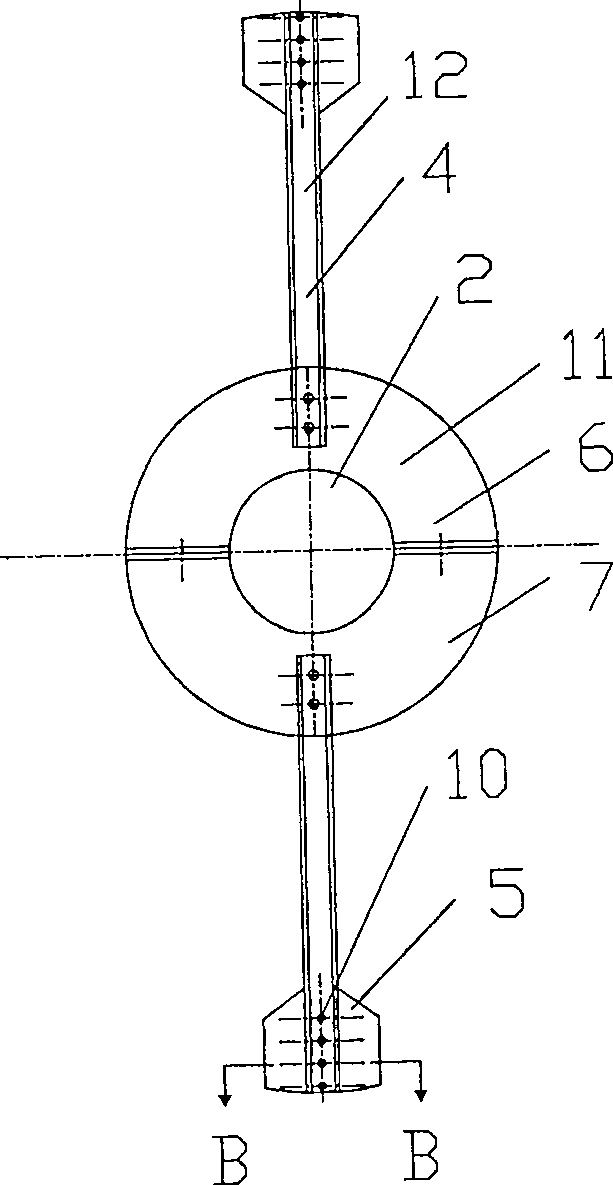

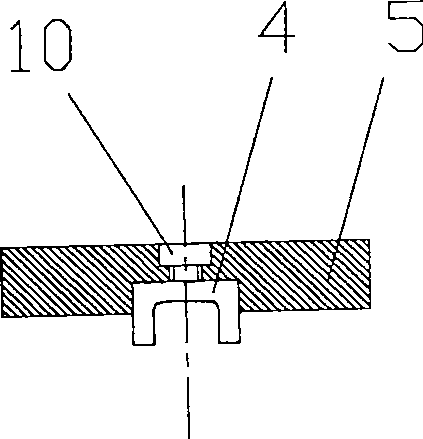

Steam turbine low-pressure end outer vapor lock axial direction positioning device

ActiveCN101126328ASimple structureVersatileLeakage preventionMachines/enginesRadial positionVapor lock

The invention relates to a steam turbine vapor lock axial location device, in particular to the axial location device for the vapor lock outside the low-pressure side of a steam turbine and the vapor lock of a rotor. The vapor lock axial location device used outside of the low-pressure side of the steam turbine comprises a dummy bearing, a dummy shaft, a shaft sleeve, an anchor ear and a positioning arm; the dummy bearing comprises a left bearing and a right bearing which are arranged on a cylinder, the two ends of the dummy shaft are transversely placed on the dummy bearings, a left shaft sleeve and a right shaft sleeve and the anchor are sleeved on the dummy shaft, the left shaft sleeve and the right shaft sleeve are arranged at both sides of the anchor ear respectively, the anchor and the shaft sleeve can make axial movement along the dummy shaft; the positioning arm comprises a positioning arm and a locating plate, one end of the positioning arm is connected with the end face of the anchor ear, the other end is provided with a movable locating plate, the positioning arm is vertical to the axis lead of the dummy shaft. The invention can adjust the axial direction and the radial position to simulate the low-pressure rotors of different sets, precisely locate the axial position of the vapor lock outside the low-pressure end and the rotor vapor lock; also, the invention has simple structure and strong versatility.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

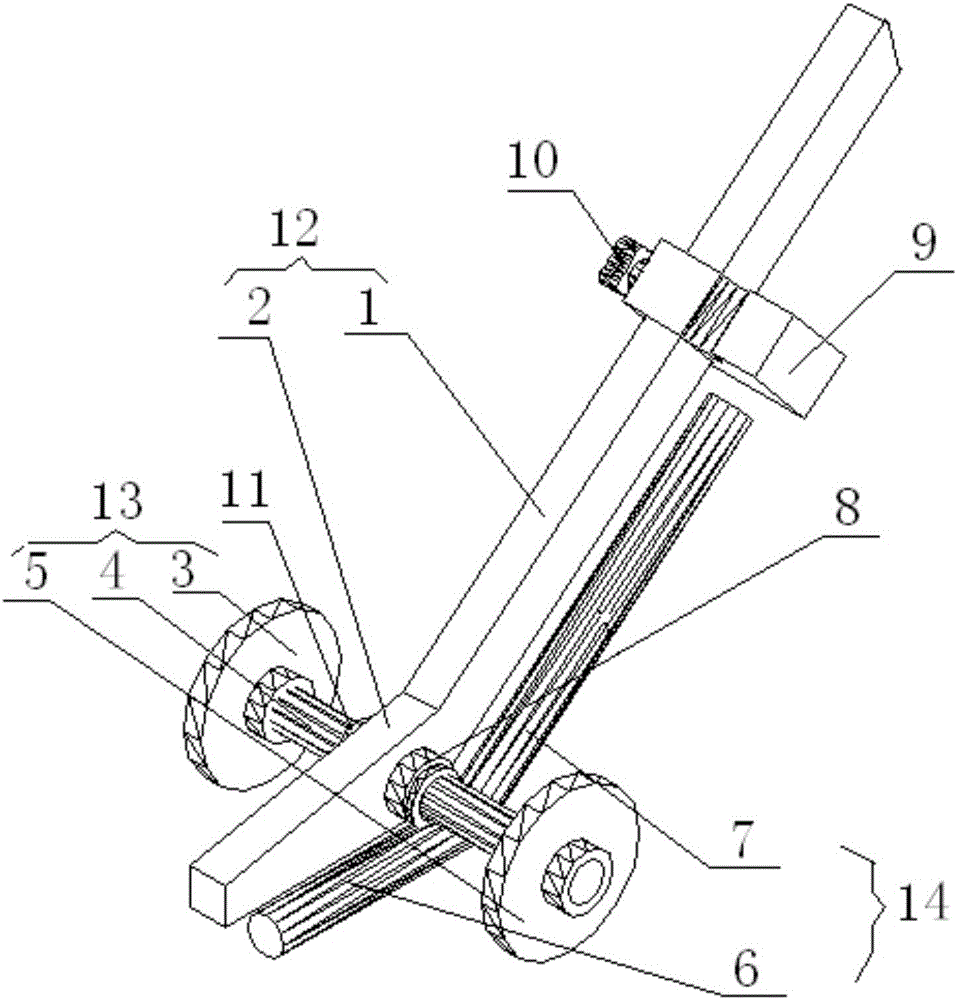

Auxiliary frame for electric drill machining

InactiveCN112453496AGuaranteed to move vertically downwardRealize automatic liftingWork benchesPortable drilling machinesElectric machineryStructural engineering

The invention discloses an auxiliary frame for electric drill machining. The auxiliary frame comprises a fixed bottom plate, a vertical supporting plate is fixed to the top face of the fixed bottom plate, an upper horizontal plate is fixed to the top face of the vertical supporting plate, the top end of a vertical lifting screw rod is hinged to the upper horizontal plate through a bearing, and thebottom end of the vertical lifting screw rod is hinged to the fixed bottom plate through a bearing; a lifting motor is fixed to the top face of the upper horizontal plate and drives the vertical lifting screw rod to rotate, a lifting adjusting block is connected to the vertical lifting screw rod in a threaded mode, a connecting fixing plate is fixed to the outer side wall of the lifting adjustingblock, a horizontal fixing plate is fixed to the bottom face of the connecting fixing plate, and a mounting through hole is formed in the middle of the outer side of the horizontal fixing plate. An electric drill can be fixed and automatically lifted, the condition that an electric drill bit of the electric drill vertically moves downwards is ensured, vibration and shaking are reduced, the machining precision is guaranteed, the electric drill can directly conduct machining at an existing mounting position, and the mounting progress is guaranteed.

Owner:义乌融鹄电子科技有限公司

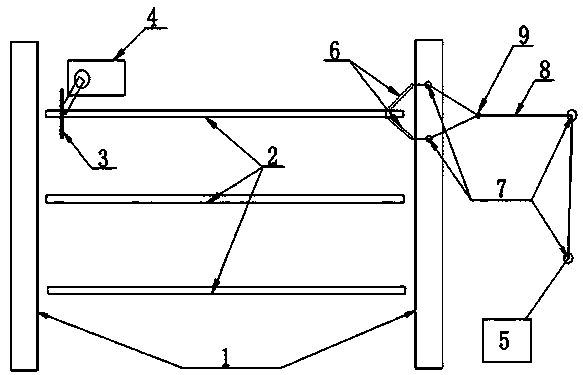

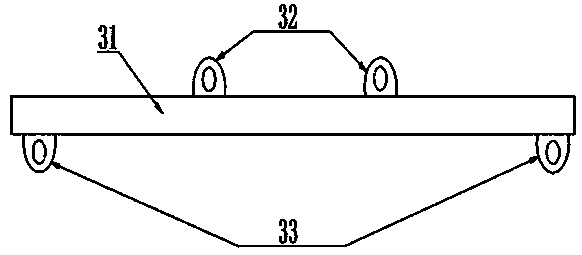

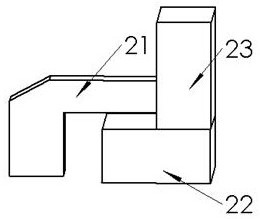

Movable wall lifting mechanism

InactiveCN105735655AInhibit sheddingGuaranteed installation progressBuilding material handlingMechanical engineeringBuilding construction

The invention discloses a movable wall lifting mechanism. The movable wall lifting mechanism comprises a warping device, a supporting device, a fixing device and a walking device, wherein the warping device comprises a wall lifting part and a handheld part; a right angle or an obtuse angle is formed between the wall lifting part and the handheld part; the fixing device is glidingly arranged on the handheld part along a connection shaft; a locking device is arranged on the fixing device; the walking device comprises the connection shaft; a first walking wheel is rotationally arranged at one end of the connection shaft; a second walking wheel is rotationally arranged at the other end of the connection shaft; the connection shaft is perpendicularly connected with the wall lifting part; the supporting device is arranged on one side close to the fixing device and comprises a supporting part and a clamping part; a right angle or an obtuse angle is formed between the supporting part and the clamping part; and the supporting part is connected with the connection shaft. The mechanism is relatively simple in structure and relatively low in processing and manufacturing costs; and the number of operation workers is reduced, the wall lifting and the wall body mounting position adjustment in a wall body mounting process are realized, the working efficiency is improved, the construction cost is reduced, and the potential safety hazards are avoided.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

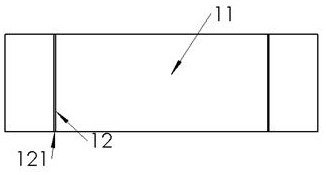

a pipe connector

ActiveCN104989898BGuaranteed installation progressGuaranteed installation qualityPipe-jointsEngineeringMechanical engineering

Owner:JIANGXI HUIFENG PIPE IND

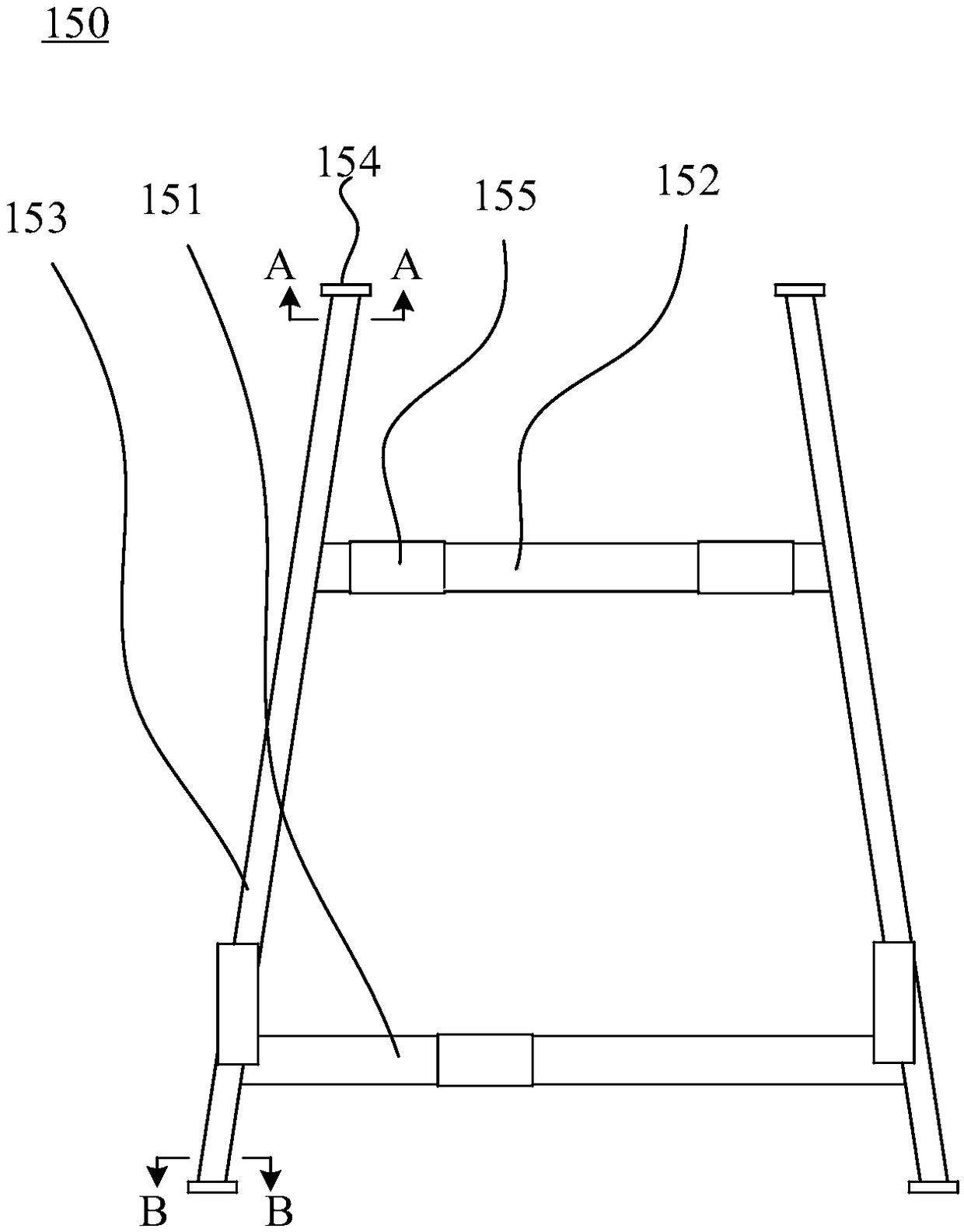

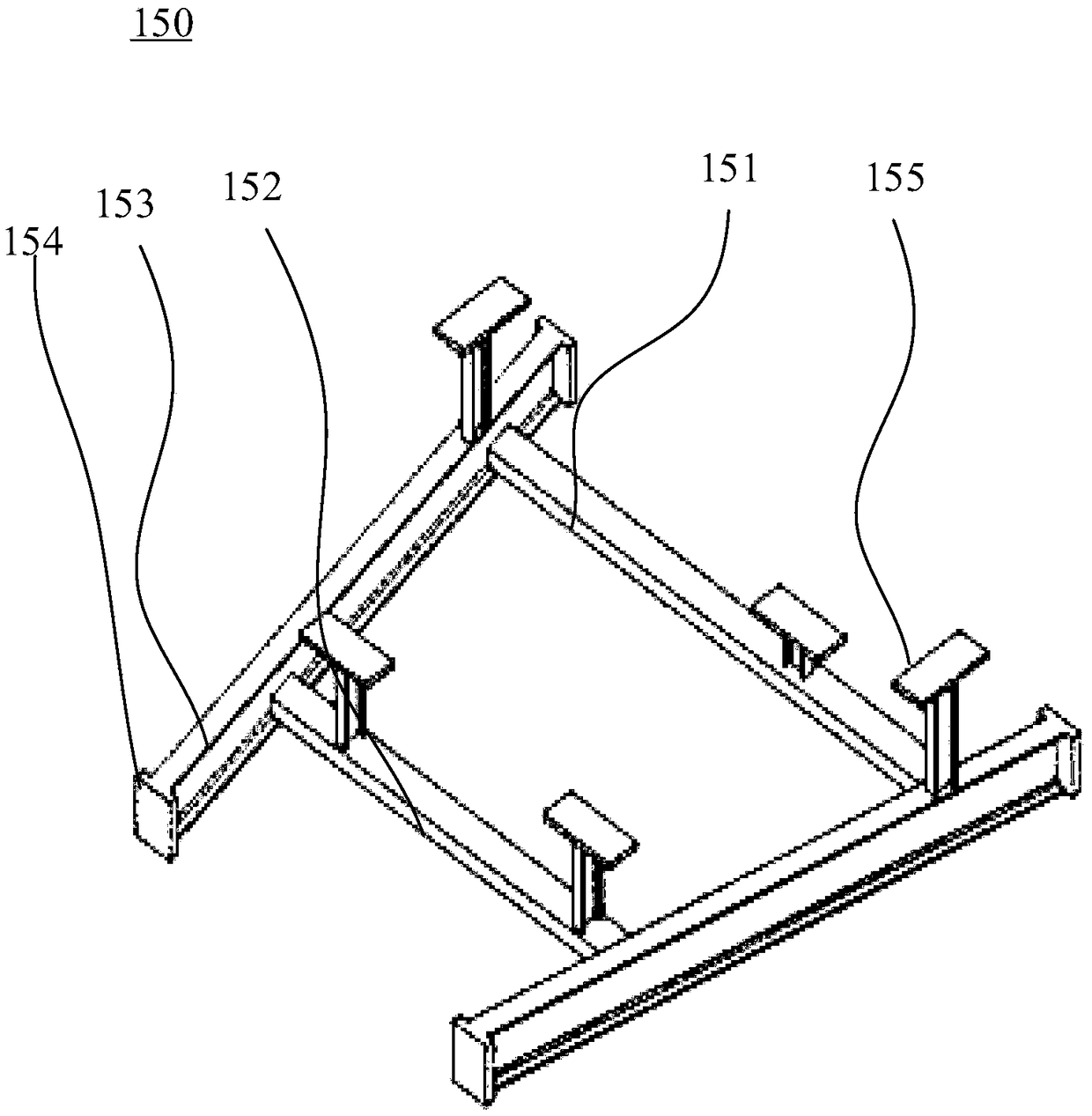

Steam turbine chassis and steam turbine

PendingCN109026208AGuaranteed installation accuracyShorten the processing cycleMachines/enginesEngine componentsMachiningGas turbines

The invention provides a steam turbine chassis and a steam turbine and belongs to the technical field of steam turbines. The steam turbine chassis comprises a first table board, a second table board,a third table board, a fourth table board and a supporting assembly. The supporting assembly comprises two steel angles symmetrically arranged on the two sides of the center line of the chassis in a splayed mode, a first cross beam and a second cross beam, wherein the first cross beam and the second cross beam are arranged between the two steel angles. The first table board is detachably connectedwith the ends of the ends of the two steel angles. The second table board and the second table board are detachably connected with the two steel angles correspondingly. The fourth table board is arranged between the second table board and the third table board. The fourth table board is detachably connected with the second table board and the third table board. According to the steam turbine chassis, the first table board, the second table board and the third table board are detachably connected with the supporting assembly to form the assembly type gas turbine chassis; the machining cycle ofthe steam turbine chassis is shortened; the installation difficulty of the table boards is reduced; and thus, the steam turbine chassis is simple and practical in machining and installation process,safe and reliable, and the center of the steam turbine chassis can be adjusted conveniently.

Owner:CHINA CHANGJIANG ENERGY CORP GROUP

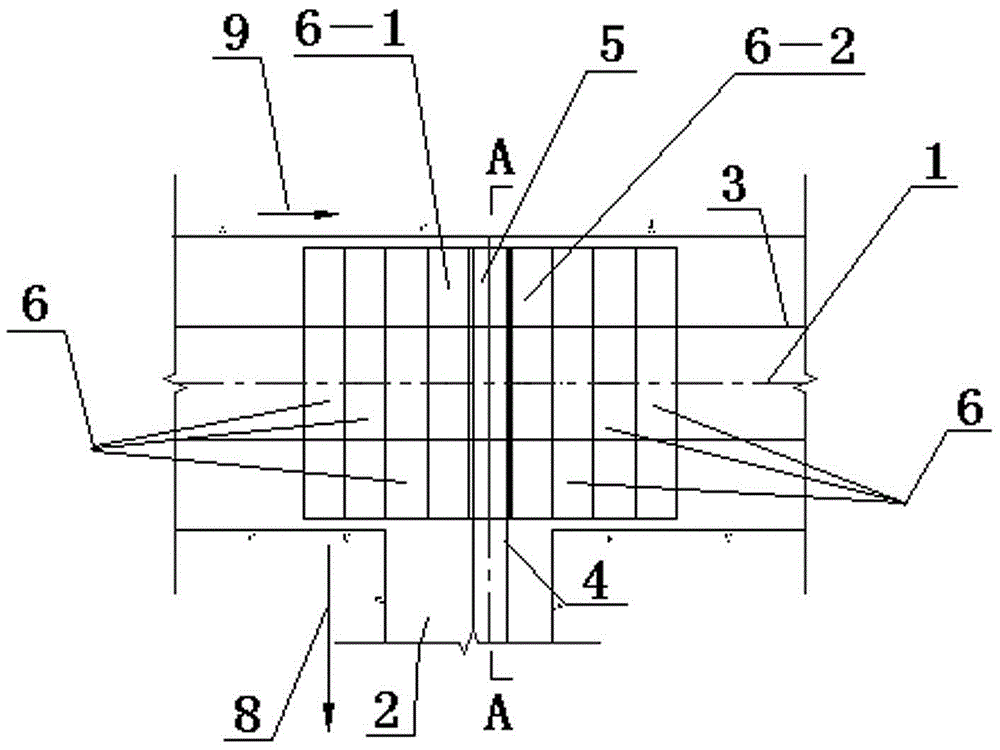

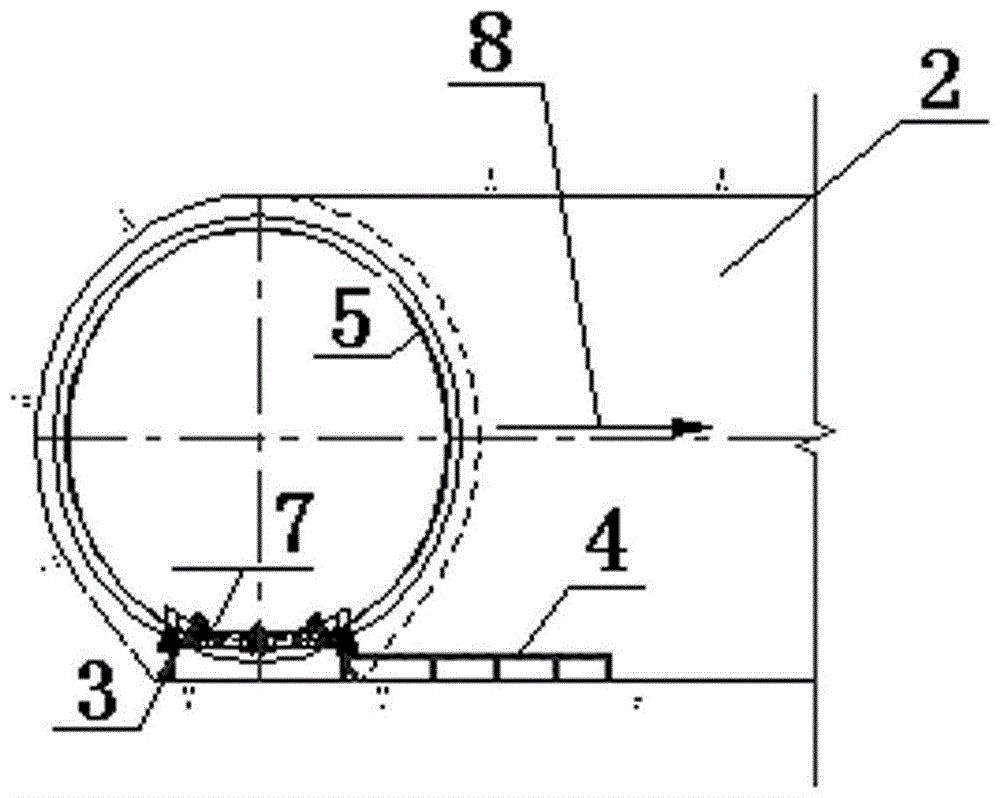

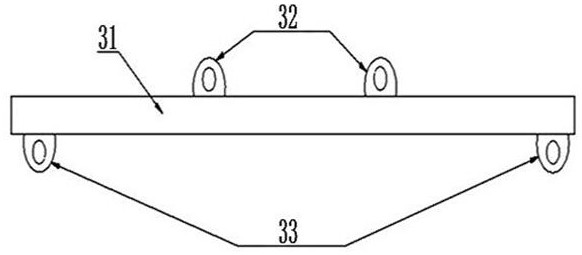

Method for assembling super-large-diameter pressure steel pipes in whole joints

ActiveCN104930260BSimple and fast operationThe method is scientific and reasonablePipe laying and repairMetallurgyPenstock

The invention discloses a method for assembling whole adjusters of super-large diameter pressure steel pipes. The method comprises the steps that the adjusters of the pressure steel pipes are conveyed to mounting positions; a universal wheel type trolley is adopted to support the whole weight of the adjusters of the pressure steel pipes; one-time seam pressing and rounding are carried out on the adjusters of the pressure steel pipes, front pressure steel pipes and back pressure steel pipes; after the pressure steel pipes mounted subsequently are effectively located and spot-welding reinforced positions of front and rear circular seams of the adjusters of the pressure steel pipes are removed, the mounting circular seams of the adjusters of the pressure steel pipes are in clearance fit with the adjacent front pressure steel pipes and back pressure steel pipes; the universal wheel type trolley and the adjusters of the pressure steel pipes are shifted laterally towards the mounting axes of the pressure steel pipes overall; construction channels are reserved by the pressure steel pipes and the adjusters of the pressure steel pipes at this moment; after all the pressure steel pipes are mounted, the universal wheel type trolley is used for enabling the adjusters of the pressure steel pipes to overall return to pre-mounting positions along the shifting trail; and then welding is carried out. Mounting cost expenses can be reduced, the mounting progress can be accelerated, and mounting quality can be guaranteed.

Owner:GEZHOUBA GRP NO 2 ENG

A LED display module flatness adjustment device

The invention relates to the field of LED displays, and more particularly, to a device for adjusting the flatness of LED display modules. A flatness adjustment device for an LED display module, comprising a fixing piece, an adsorption piece, a first adjusting piece and a second adjusting piece, the fixing piece is fixedly connected to the LED box, and the second adjusting piece is screwed to the fixing piece , the first adjusting part is screwed to the second adjusting part, the absorbing part is arranged in the first adjusting part, and the absorbing part is magnetically connected with the display module. The present invention designs a new type of display module flatness adjustment device with simple and reliable structure and convenient use. Through the cooperation of the fixing part, the first adjusting part and the second adjusting part, the standard quantification of the initial installation can be realized, and at the same time, it can be easily realized. The installation position of the display module can be adjusted up and down, and each display module can be adjusted up and down independently. The adjustment is flexible and convenient, and the efficiency is high, which can better ensure the installation progress and display effect.

Owner:GUANGDONG VTRON TECH CO LTD

Elevator leveling position control device and method

ActiveCN105173935BGuaranteed uptimeSolve the problem of larger leveling errorsElevatorsControl systemPosition control

The invention relates to a control device and method of the elevator flat floor position. An elevator comprises a shaft, an elevator car, and a drive device driving the elevator car to move, and the elevator car and the drive device are arranged in the shaft. The control device of the elevator flat floor position comprises at least one ranging sensor arranged on the top or bottom of the shaft, baffles opposite to the ranging sensors, and a control system electrically connected with the ranging sensors. The baffles are fixed to the elevator car. The control system is electrically connected with the drive device. The ranging sensors are fixed to the shaft and matched with the baffles fixed to the elevator car. Thus, installing and adjusting are convenient, the installing convenience is improved, the production efficiency is high, and the installing progress of the elevator project is guaranteed. The real-time and accurate measurement is carried out on the position distance of the elevator car through the ranging sensors, the running of the elevator car is controlled through the control system, and the problem that the longer running time of the elevator is, the larger the generated flat floor error becomes is solved. The running of the elevator is safer, and the accuracy of the elevator flat floor position is guaranteed.

Owner:HITACHI ELEVATOR CHINA

An anti-glare LED wall washer lamp and its construction method

ActiveCN110195833BAdjust the projection angleAvoid scatterMechanical apparatusLighting support devicesLED lampMaterials science

The invention discloses an anti-dazzling LED wall-washer lamp. The anti-dazzling LED wall-washer lamp comprises a mounting rack, a mounting device, a lamp box, a light-projecting device and an adjusting device, wherein the opening of the lamp box is upwards arranged, rotating posts are fixed at two ends of the lamp box, and the rotating posts are rotatably connected with two ends of the mounting rack; the light-projecting device comprises a mounting plate fixed in the lamp box, LED lamps fixed on the mounting plate, and a light-pervious plate fixed at the opening of the lamp box; the adjustingdevice comprises an adjusting groove formed in the outer side wall of one end of the mounting rack, an adjusting cover arranged in the adjusting groove, an elastic arc plate fixed on the adjusting cover, clamping grooves formed in the inner wall of the adjusting groove, and a drive part arranged in the adjusting cover and used for controlling the elastic arc plate to deform; the rotating post atone end of the lamp box penetrates through the inner side wall of the adjusting groove and is fixed to the adjusting cover; and at least two clamping grooves are available, and the clamping grooves are uniformly distributed around the axis of the adjusting groove. The anti-dazzling LED wall-washer lamp has the effect that the projecting angle of the wall-washer lamp is adjustable, and thus the mounting progress is guaranteed.

Owner:安徽华新光电饰业有限公司

Large support grouting device and grouting method thereof

PendingCN113529577AGuaranteed installation progressSimple structureBridge structural detailsFoundation engineeringUltimate tensile strengthGrout

The invention discloses a large support grouting device and a grouting method thereof. The technical problems that in the prior art, the grouting efficiency is low, grouting is not compact and full, and the levelness is insufficient are solved. The grouting device mainly comprises a side template and a grouting template. The grouting method is a secondary grouting method, during primary grouting, high-strength mortar is poured in a side formwork before the support is installed, then the high-strength mortar is pressed through a mud jacking formwork to achieve the high-strength mortar compact level, and after the strength of the high-strength mortar reaches the standard, the formwork is dismantled, the support is installed, and gravity type grouting is directly adopted in the secondary grouting process. The grouting device is simple in structure, scientific and reasonable in design, convenient to use, low in operation difficulty, low in grouting cost, low in grouting environment requirement in the grouting process, high in grouting construction speed, good in effect, high in grouting efficiency and compact, full and horizontal in grouting, and the grouting quality and the overall progress of support installation can be effectively guaranteed.

Owner:CHINA MCC5 GROUP CORP

Pipe cable pay-off cart

The invention discloses a pipe cable pay-off cart. The pipe cable pay-off cart comprises a base, a cable containing frame, at least one cable containing rod, a handrail and a rotating mechanism; a roller is arranged at one end of the base; the cable containing frame comprises a first circular ring and a second circular ring which are parallel to each other; the cable containing frame is verticallyarranged on the base; each cable containing rod comprises a first connecting rod, the two ends of each first connecting rod are each fixedly connected with a fixing clamp, and each fixing clamp is fixed between the outer wall of the first circular ring and the inner wall of the second circular ring; the handrail is an inverted-U-shaped rod, the inverted-U-shaped rod is obliquely arranged on the base, the bottom end of the inverted-U-shaped rod is fixedly connected with the other end of the base, a side rod on one side of the inverted-U-shaped rod is located on one side of the cable containingframe, a side rod on the other side of the inverted-U-shaped rod is located on the other side of the cable containing frame, and opposite screw holes are formed in the side rods on two sides of inverted-U-shaped rod; and the rotating mechanism is rotatably arranged between the side rods on the two sides of the inverted-U-shaped rod, and the rotating mechanism is connected with the first connecting rods through the second connecting rods. The pipe cable pay-off cart is ingenious in structural design, easy to machine and manufacture, safe and stable.

Owner:JINCHUAN GROUP LIMITED

Autoclaved aerated concrete equipment mould box turnover shaft and crank arm shaft seat positioning tool

PendingCN114872181AGuaranteed placement accuracyGuaranteed accuracyPassive housesAuxillary shaping apparatusCrankAutoclaved aerated concrete

The invention relates to an autoclaved aerated concrete equipment mould box turnover shaft and crank arm shaft seat positioning tool, which is used for positioning a mould box turnover shaft and a crank arm shaft seat before welding, and comprises a bottom plate used for placing an autoclaved aerated concrete equipment mould box, a mould box limiting block, a mould box turnover shaft positioning tool and a mould box crank arm shaft seat positioning tool; the mold box limiting block is used for limiting the position of the mold box on the tool; the mold box turnover shaft positioning tool is used for positioning a mold box turnover shaft before welding, and the precision of the mold box turnover shaft is guaranteed; and the mold box crank arm shaft seat positioning tool is used for ensuring the precision of the mold box crank arm shaft seat and positioning the crank arm shaft seat before welding.

Owner:DONGYUE MACHINERY GRP

A detachable geocell

ActiveCN106013035BGuaranteed installation progressUniform pressureRoadwaysSoil preservationGeocellsEngineering

The invention discloses a detachable geocell. The detachable geocell comprises a connecting base and a basal cell. The basal cell comprises a fixing base. Clamping grooves are evenly distributed in the peripheral sides of the fixing base. A mounting groove is formed in the surface of the other end of the fixing base. The peripheral side of the mounting groove is connected with the clamping grooves in a cut-through mode. Connecting plates are mounted in the clamping grooves. Clamping heads are arranged at one ends of the connecting plates, mounted in the clamping grooves and placed between a pressure pad and a bottom cap. Three mounting columns are arranged on each connecting plate in the direction from the clamping head to the other end of the connecting plate at equal intervals. A columnar groove is formed in the surface of one end of each mounting column, and two connecting grooves are symmetrically formed in the peripheral side of each mounting column. Four connecting grooves are evenly distributed in the peripheral side of the connecting base. The connecting base is fixedly connected with the basal cell through the connecting grooves. Through the array type composite structure, the geocell is divided into a plurality of blocks with the same compartment area, so that pressure of fillers in grids to the inner walls of the geocell is uniform, the mounting service life of the geocell is greatly prolonged, and the mounting process of a whole project is ensured.

Owner:ANHUI HUIFENG NEW SYNTHETIC MATERIALS CO LTD

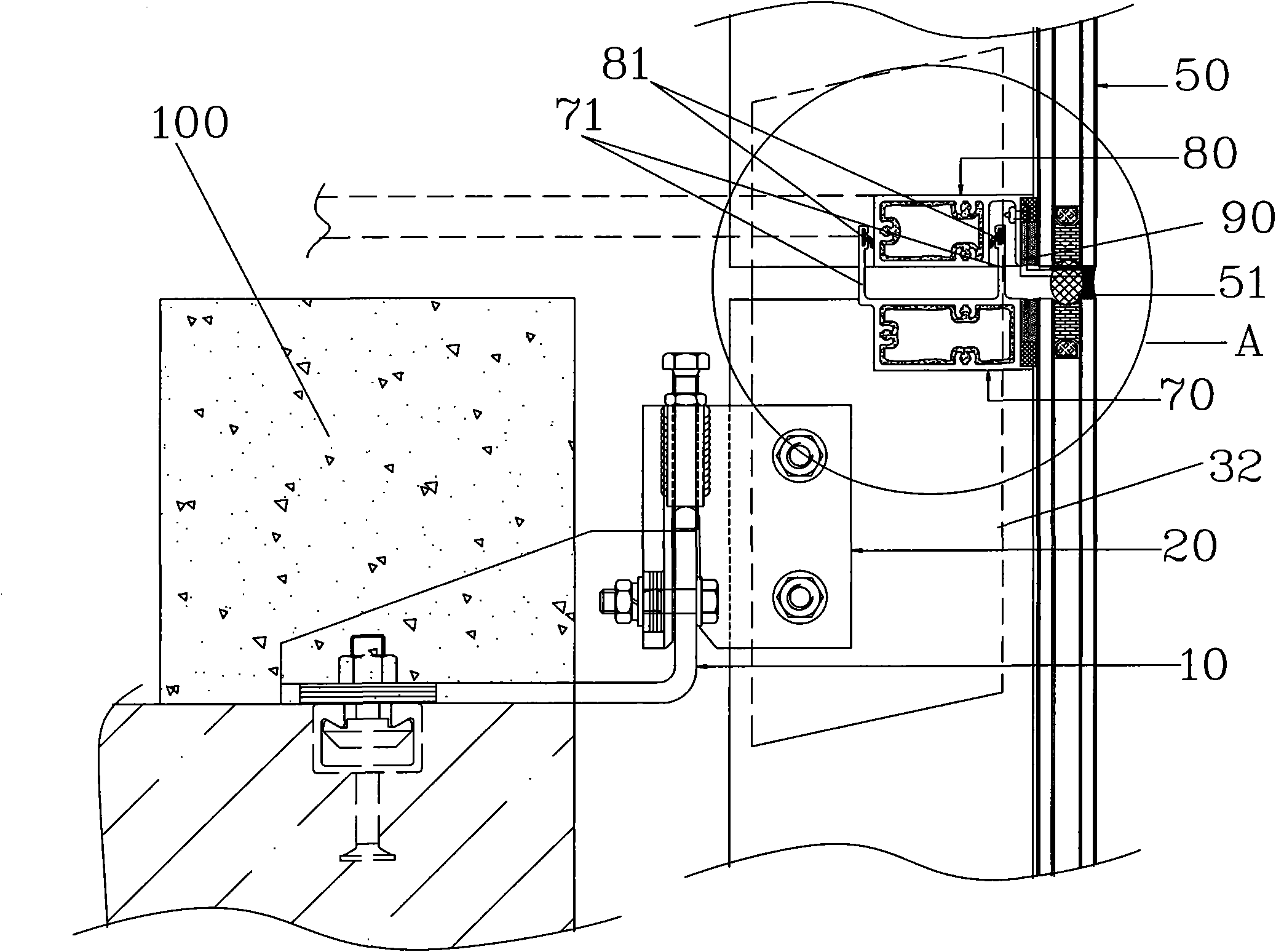

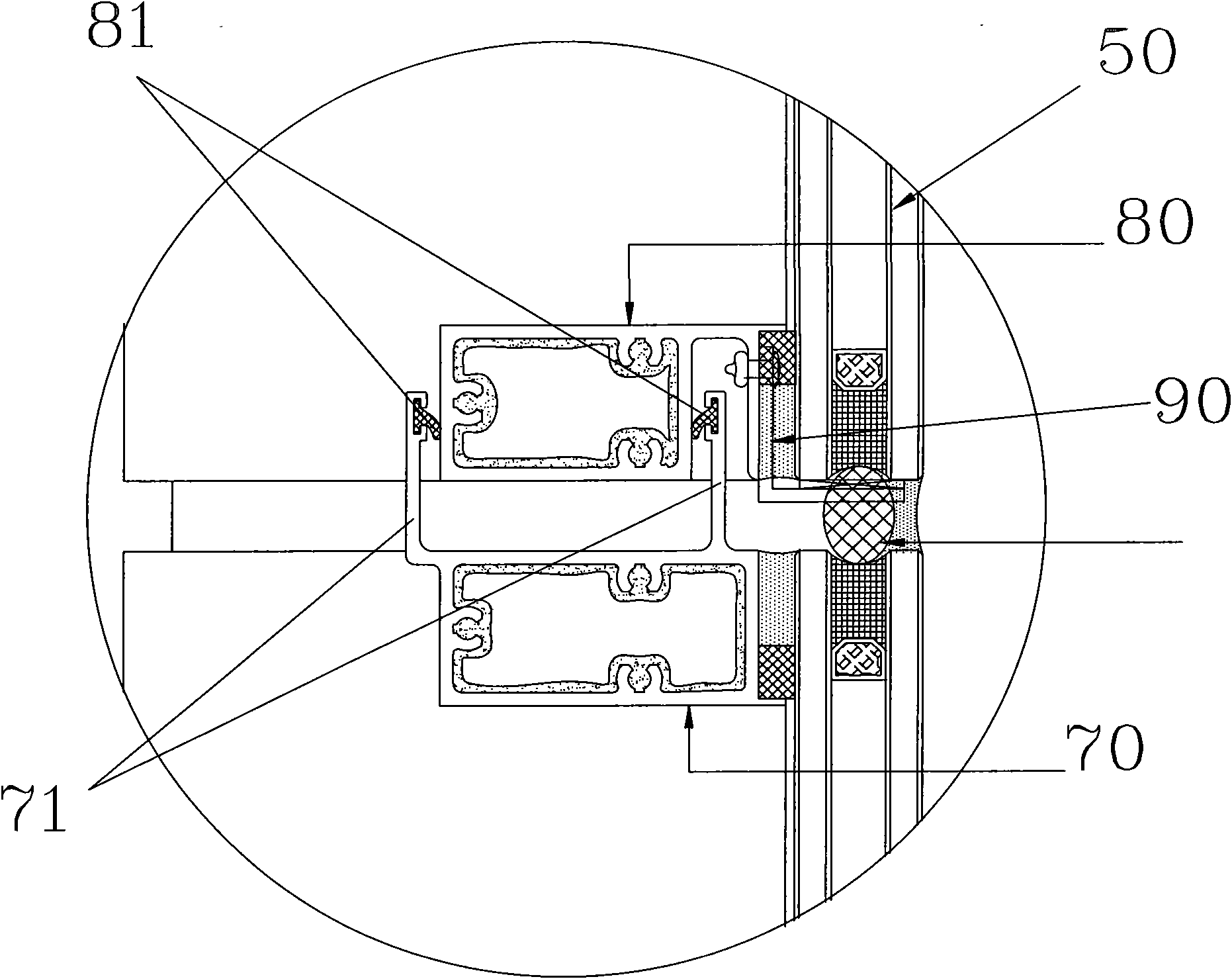

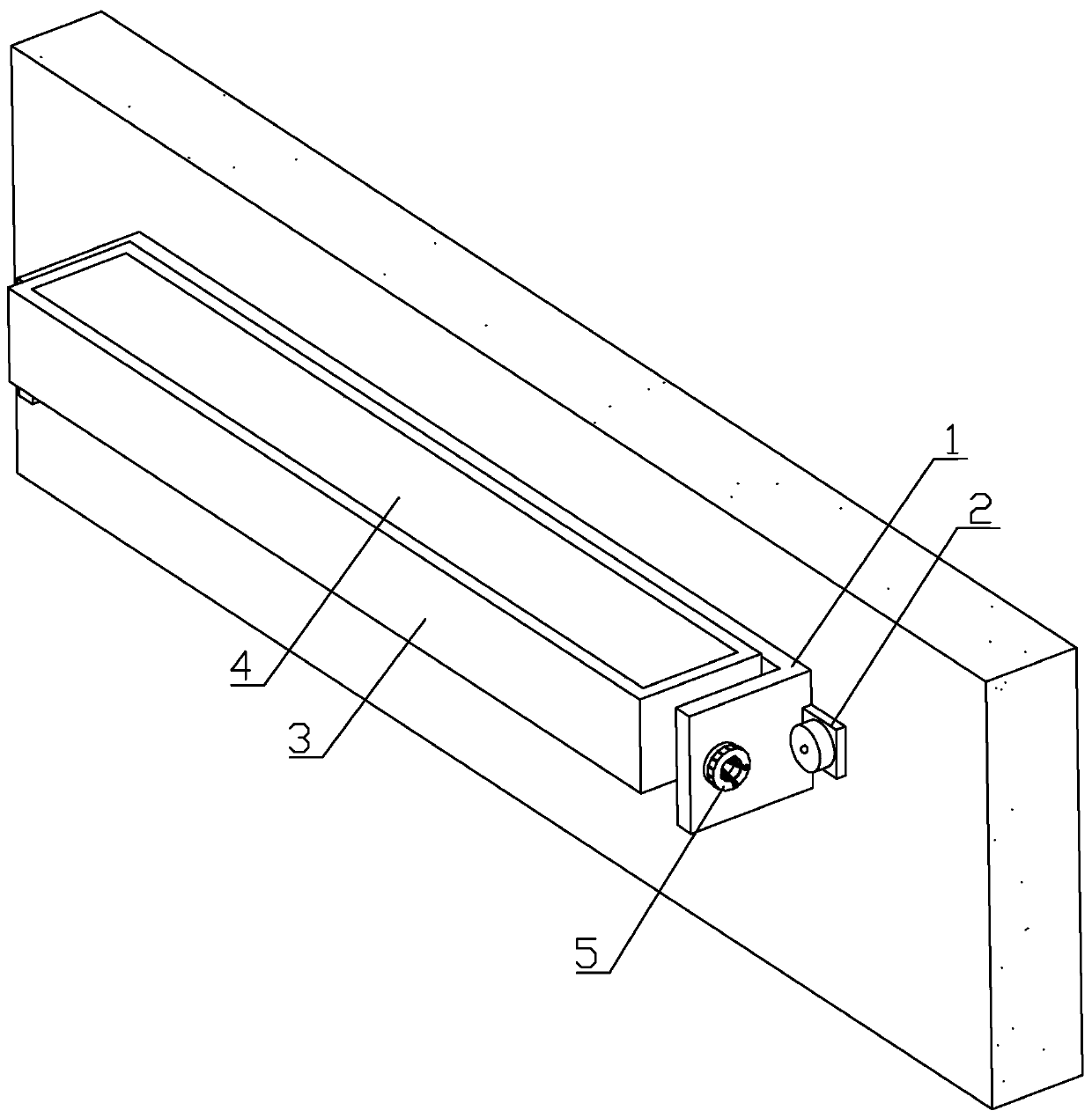

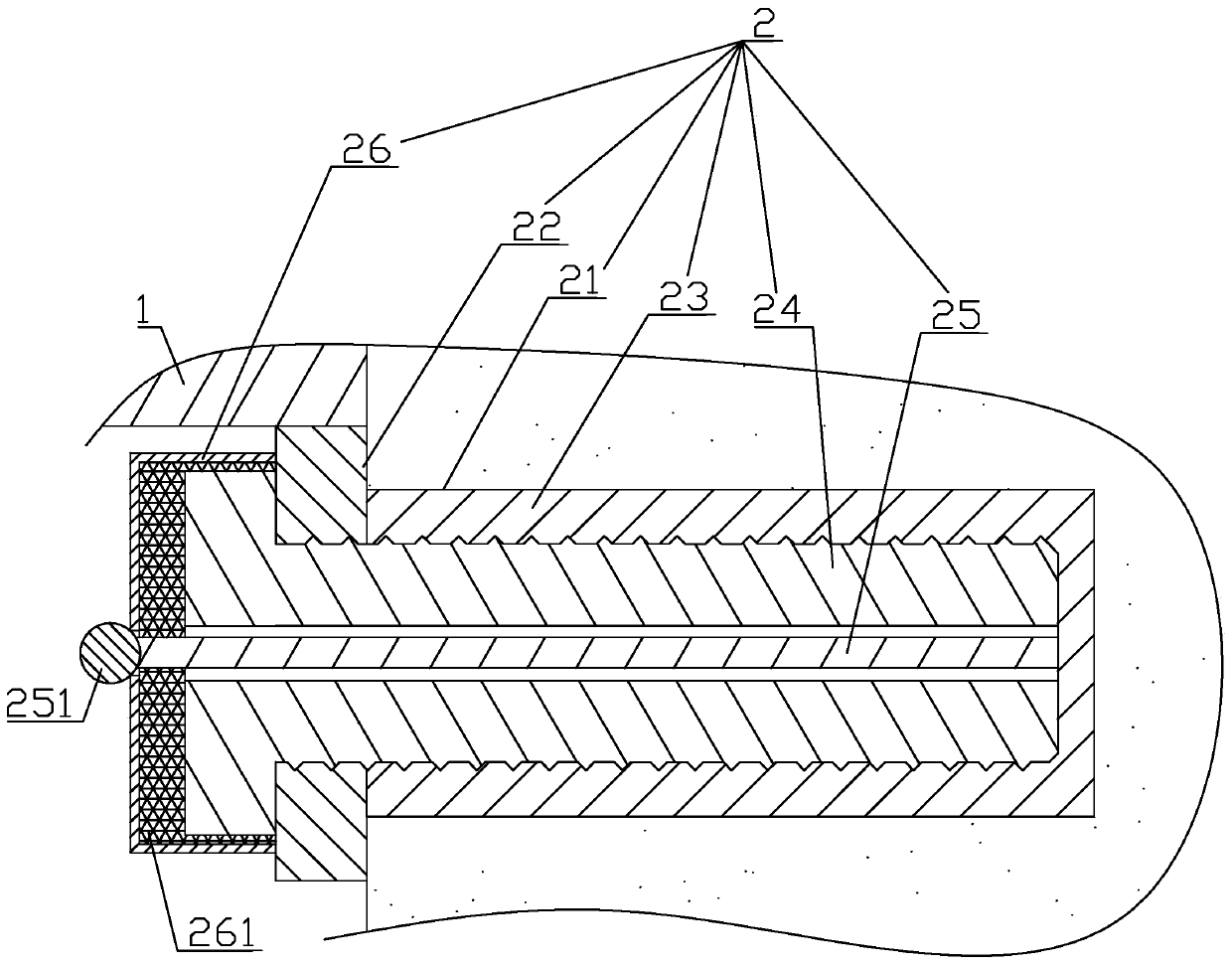

Building curtain wall structure

The invention relates to a building curtain wall structure which comprises a supporting seat connected with a fixing body and a plurality of sections fixedly connected with curtain wall plane materials, wherein each section has a frame structure formed by connecting an upper transverse material, a lower transverse material, a negative vertical material and a positive vertical material; the upper transverse material and the lower transverse material are arranged oppositely; the negative vertical material and the positive vertical material are arranged oppositely; the upper transverse material and the lower transverse material between upper and lower adjacent sections are connected with each other; the negative vertical material and the positive vertical material between left and right adjacent sections are connected with each other; the negative vertical material and the positive vertical material are provided with core sleeves respectively; the core sleeves are fixedly connected to the supporting seat through pendants; and a gap between adjacent curtain wall plane materials is provided with sealing gum. In the building curtain wall structure, a unit curtain wall form is combined with a frame curtain wall form, deficiencies are made up and advantages are complemented, so that the structural installation of the entire building curtain wall is easy and safe, the installation progress and quality of the curtain wall can be ensured, and the construction cost is relatively low.

Owner:DONGGUAN FANGDA NEW MATERIAL CO LTD

Anti-dazzling LED wall-washer lamp and construction method thereof

ActiveCN110195833AAdjust the projection angleAvoid scatterMechanical apparatusLighting support devicesPulp and paper industryLED lamp

The invention discloses an anti-dazzling LED wall-washer lamp. The anti-dazzling LED wall-washer lamp comprises a mounting rack, a mounting device, a lamp box, a light-projecting device and an adjusting device, wherein the opening of the lamp box is upwards arranged, rotating posts are fixed at two ends of the lamp box, and the rotating posts are rotatably connected with two ends of the mounting rack; the light-projecting device comprises a mounting plate fixed in the lamp box, LED lamps fixed on the mounting plate, and a light-pervious plate fixed at the opening of the lamp box; the adjustingdevice comprises an adjusting groove formed in the outer side wall of one end of the mounting rack, an adjusting cover arranged in the adjusting groove, an elastic arc plate fixed on the adjusting cover, clamping grooves formed in the inner wall of the adjusting groove, and a drive part arranged in the adjusting cover and used for controlling the elastic arc plate to deform; the rotating post atone end of the lamp box penetrates through the inner side wall of the adjusting groove and is fixed to the adjusting cover; and at least two clamping grooves are available, and the clamping grooves are uniformly distributed around the axis of the adjusting groove. The anti-dazzling LED wall-washer lamp has the effect that the projecting angle of the wall-washer lamp is adjustable, and thus the mounting progress is guaranteed.

Owner:安徽华新光电饰业有限公司

Hoisting method of cable-stayed suspended tubular busbar

ActiveCN110386543BGuaranteed installation progressEnsure a successTotally enclosed bus-bar installationsLoad-engaging elementsBusbarTransformer

The invention discloses an inclined pulling hanging type tubular busbar hoisting method. According to the hoisting operation steps, a special hanging beam is manufactured, and the special hanging beamis manufactured according to the distance of hanging holes in a civil engineering n-shaped framework and the total length and the weight of a tubular busbar; the left end of the tubular busbar is hoisted in a combined manner, and a crane is used for hanging the special hanging beam to sequentially connect an insulator chain and a hanging hardware fitting for hoisting; the right end of the tubularbusbar is hoisted in a combined manner, a winch mill is used for dragging a traction steel wire rope to sequentially connect a steel wire rope, the insulator chain and the hanging hardware fitting for hoisting; hanging holes in the crane side are hoisted and connected; hanging holes in the winch mill side are hoisted and connected, and the tubular busbar hoisting process is finished; levelness adjustment is conducted; and sling dismounting is conducted. According to the inclined pulling hanging type tubular busbar hoisting method, through manufacturing and using of the special hanging beam, ahoisting machine is reasonably arranged on the construction site, the hoisting work of a 500 KV transformer substation tubular busbar is safely and rapidly finished, the inclined pulling hanging typetubular busbar hoisting method can be used for installing of similar transformer substation tubular busbars, and a basic guarantee is provided for later tubular busbar hoisting.

Owner:POWER CHINA HENAN ENG CO LTD

Pipeline connector

ActiveCN104989898ASimple structureReasonable designPipe-jointsStructural engineeringMechanical engineering

Owner:JIANGXI HUIFENG PIPE IND

Axial positioning device for steam turbine low-pressure end outer vapor seal

ActiveCN100504038CAchieve radial adjustmentAchieve axial adjustmentLeakage preventionMachines/enginesRadial positionEngineering

The invention relates to a steam turbine vapor lock axial location device, in particular to the axial location device for the vapor lock outside the low-pressure side of a steam turbine and the vapor lock of a rotor. The vapor lock axial location device used outside of the low-pressure side of the steam turbine comprises a dummy bearing, a dummy shaft, a shaft sleeve, an anchor ear and a positioning arm; the dummy bearing comprises a left bearing and a right bearing which are arranged on a cylinder, the two ends of the dummy shaft are transversely placed on the dummy bearings, a left shaft sleeve and a right shaft sleeve and the anchor are sleeved on the dummy shaft, the left shaft sleeve and the right shaft sleeve are arranged at both sides of the anchor ear respectively, the anchor and the shaft sleeve can make axial movement along the dummy shaft; the positioning arm comprises a positioning arm and a locating plate, one end of the positioning arm is connected with the end face of the anchor ear, the other end is provided with a movable locating plate, the positioning arm is vertical to the axis lead of the dummy shaft. The invention can adjust the axial direction and the radial position to simulate the low-pressure rotors of different sets, precisely locate the axial position of the vapor lock outside the low-pressure end and the rotor vapor lock; also, the invention has simple structure and strong versatility.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

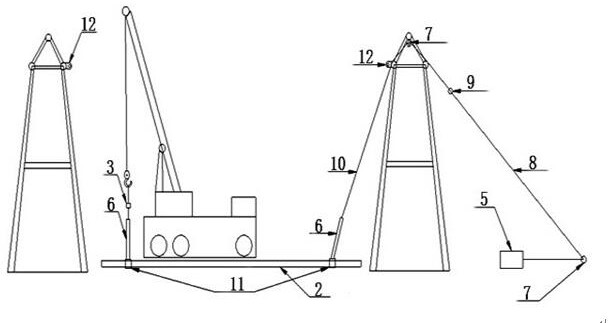

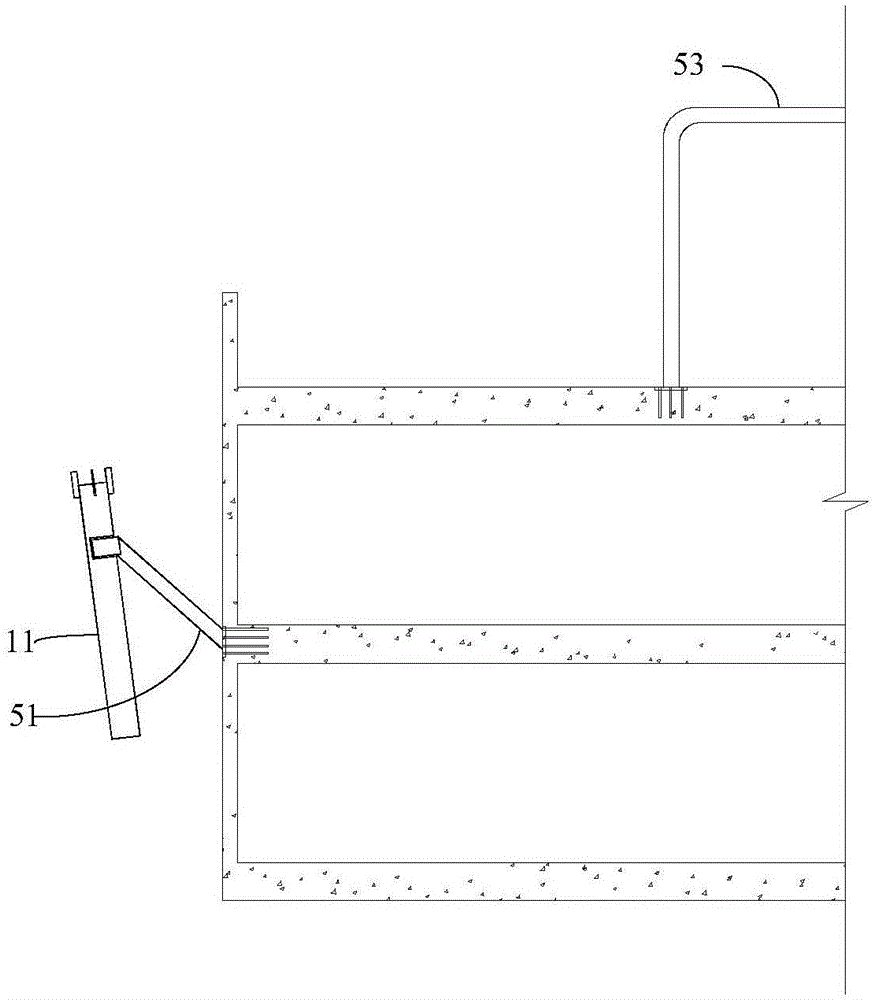

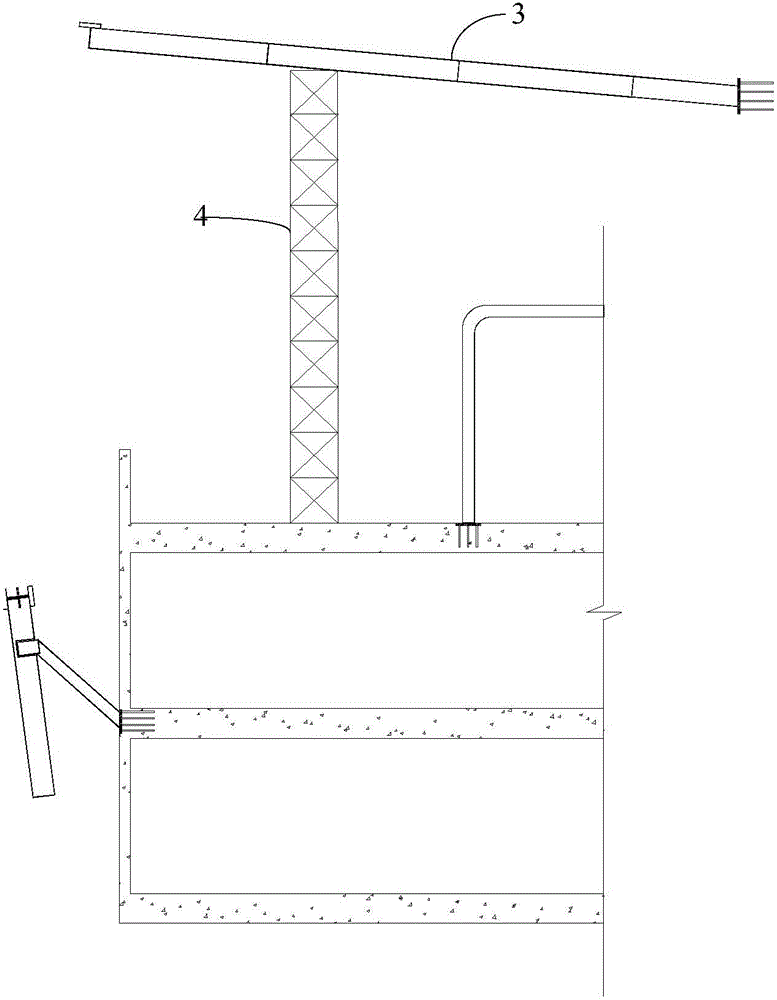

Construction method of overall embedded hoisting of large cantilever beam with front support and rear tension

ActiveCN103410335BReduce construction costsGuaranteed installation progressArched girdersPortal framesCantilevered beamBuilding construction

Owner:NANTONG BAJIAN GRP CO LTD

New type base for mast type mechanical equipment

A new type of foundation for flagpole mechanical device consists of three kinds of level prestress connection system as top and bottom single hole, top single and bottom double hole as well as middle and bottom single hole; concrete shearing-proof and displacement-proof structure, integrated positioning structure, the same tilting torque for one set of foundation, vertical connection structure being set on bottom frame cross beam on top mechanical device and being set in different structure size as per requirement of vertical force.

Owner:北京九鼎同方技术发展有限公司

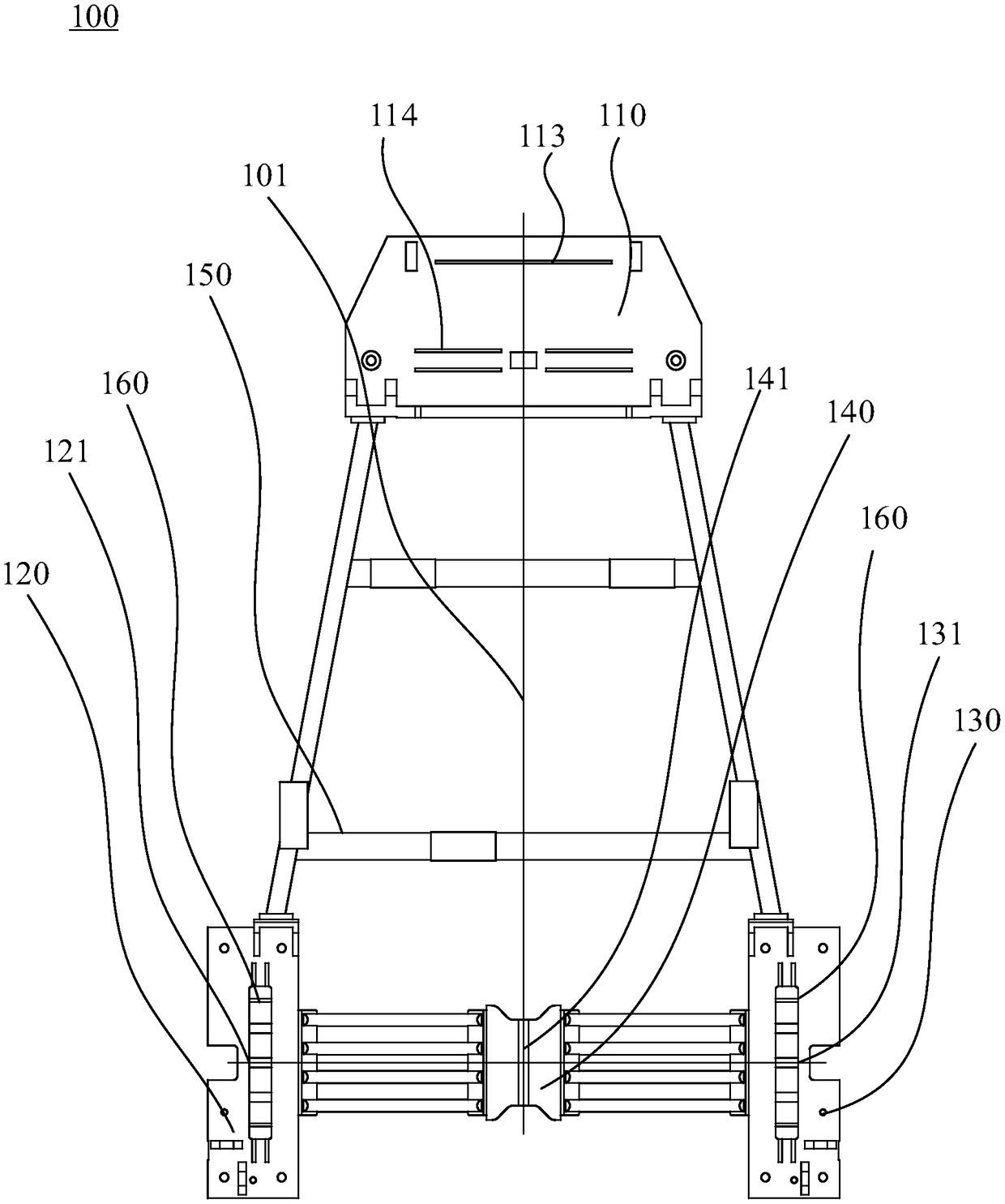

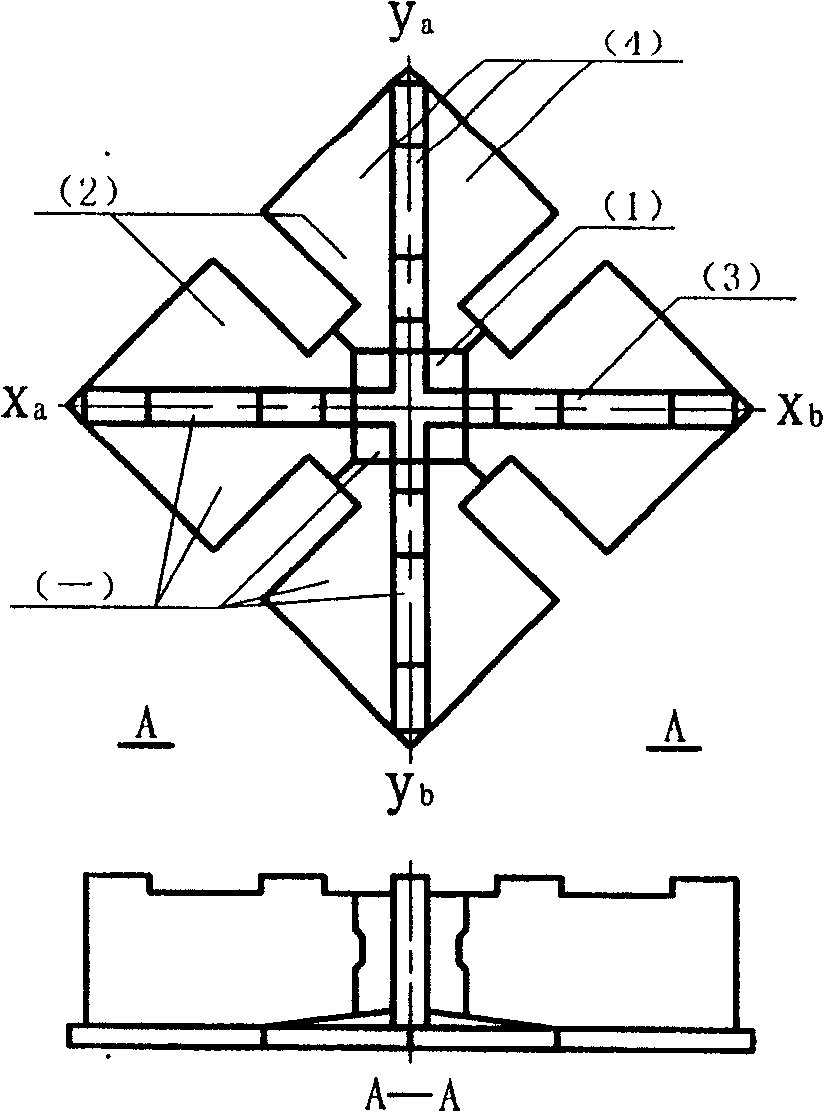

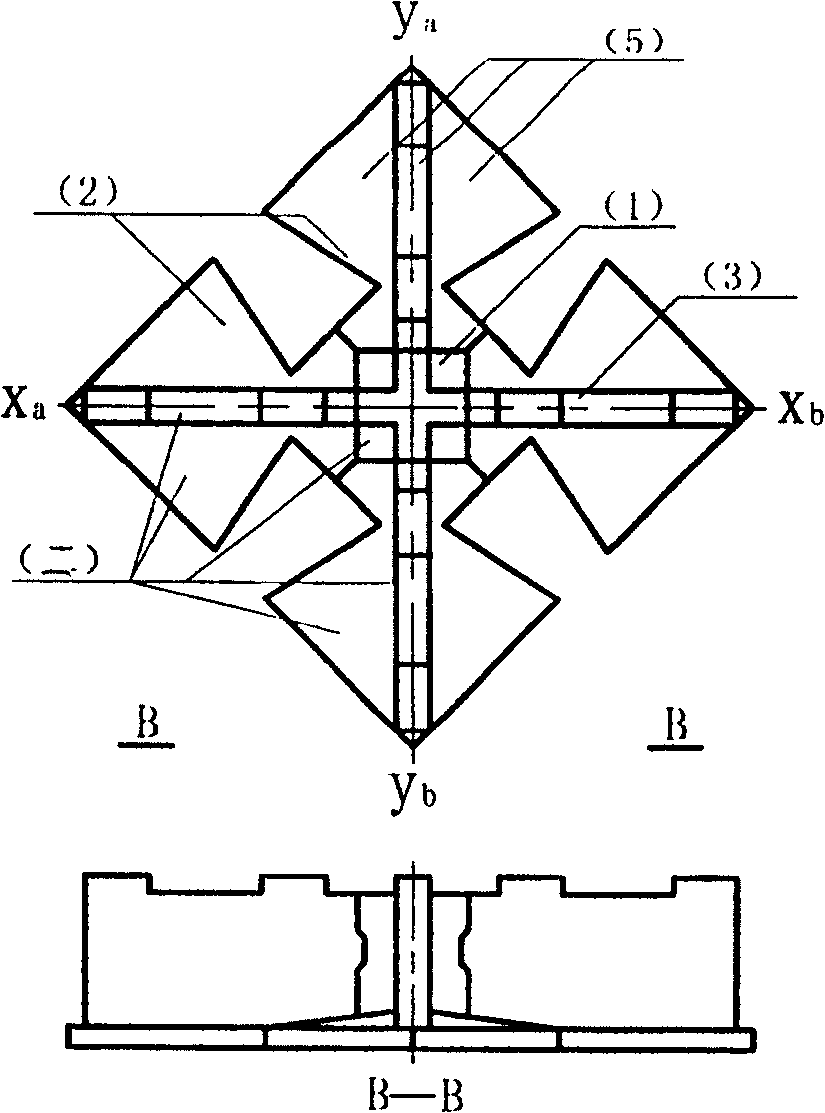

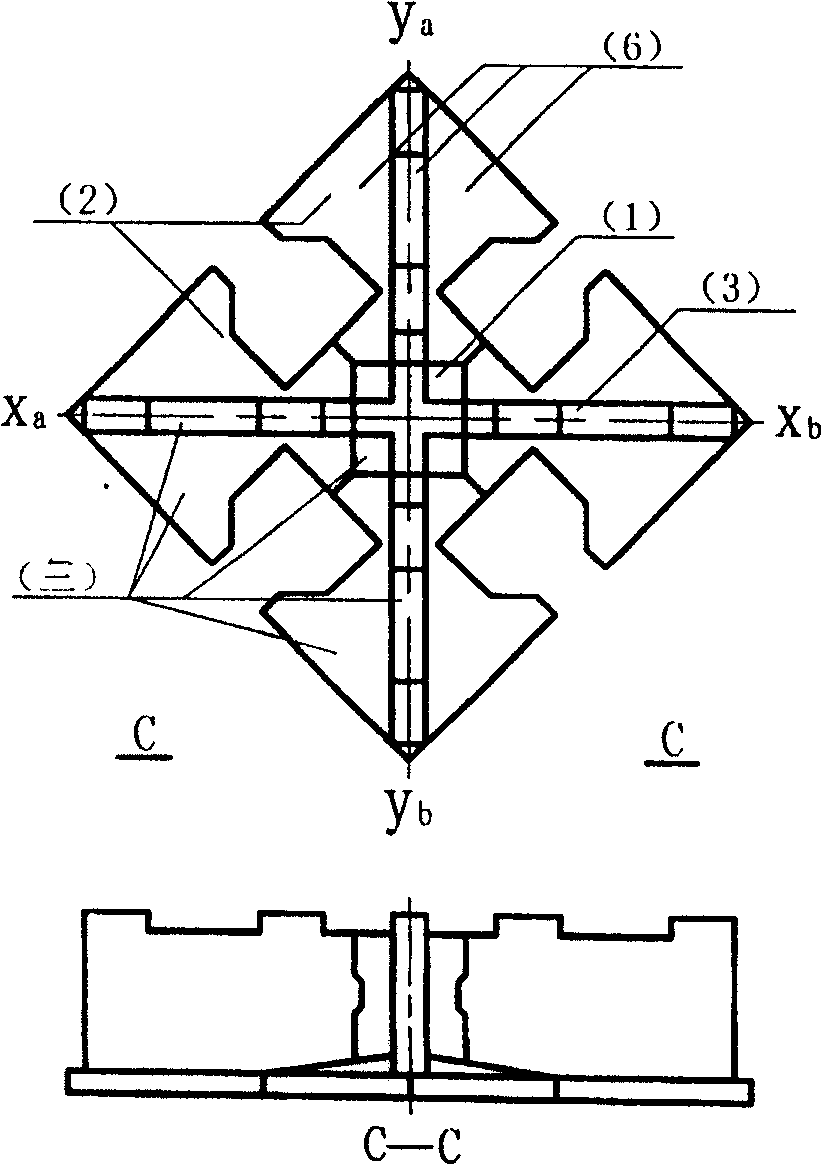

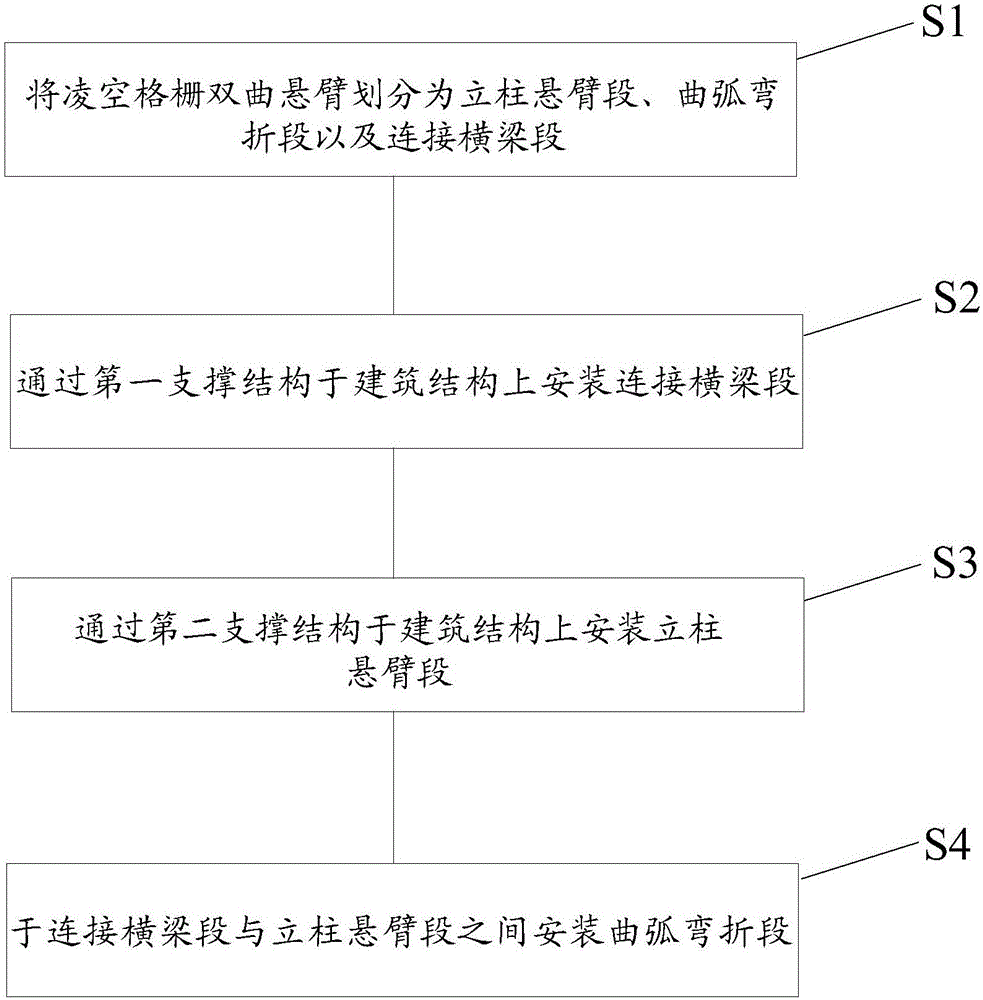

Mounting structure of soar-grille hyperbolic cantilever and mounting method of soar-grille hyperbolic cantilever

ActiveCN106088332AGuaranteed installation qualityGuaranteed installation progressBuilding material handlingEngineeringCantilever

The invention discloses a mounting structure of a soar-grille hyperbolic cantilever and a mounting method of the soar-grille hyperbolic cantilever. The mounting method includes: dividing the soar-grille hyperbolic cantilever into a column cantilever section, a curve bending section and a connection beam section; mounting the connection beam section on an architectural structure through a first support structure; mounting the column cantilever section on the architectural structure through a second support structure; mounting the curve bending section on the space between the connection beam section and the column cantilever section. The soar-grille hyperbolic cantilever is divided into the column cantilever section, the curve bending section and the connection beam section for mounting, and the first support structure and the second support structure are arranged on the architectural structure for auxiliary mounting, so that the mounting method is simple and independent in step, on-site assembly with fewer auxiliary processes can be achieved, and mounting quality and progress of a project are guaranteed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com