Auxiliary frame for electric drill machining

An auxiliary frame and electric drill technology, applied in metal processing equipment, workbenches, manufacturing tools, etc., can solve problems such as affecting the installation progress, failing to meet processing requirements, trouble, etc., to ensure processing accuracy, reduce vibration and jitter, ensure The effect of installation progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

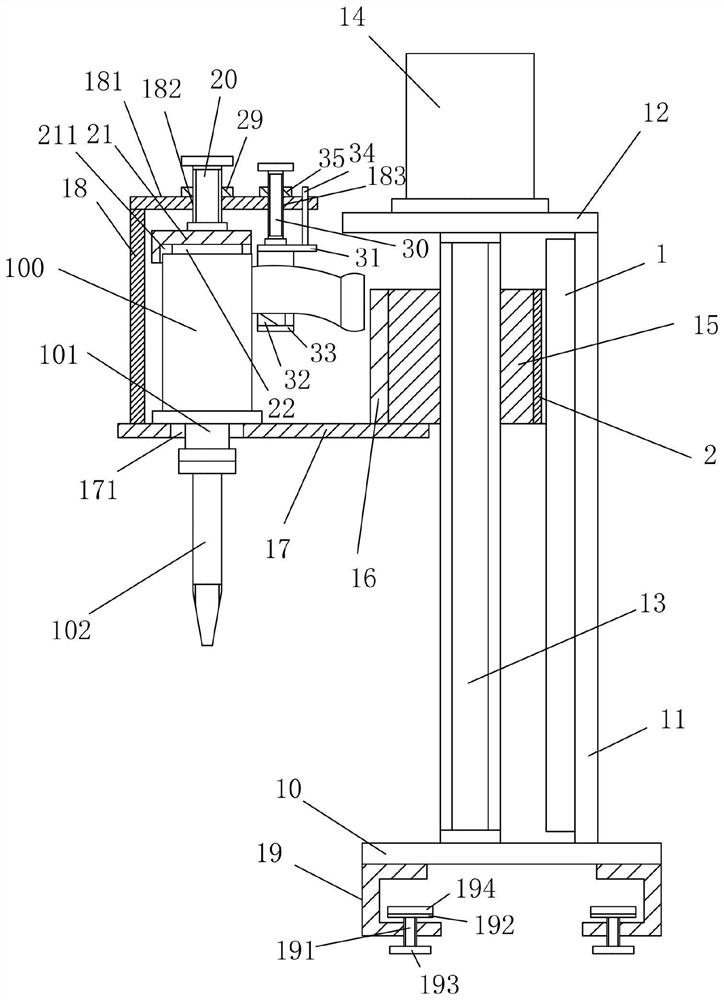

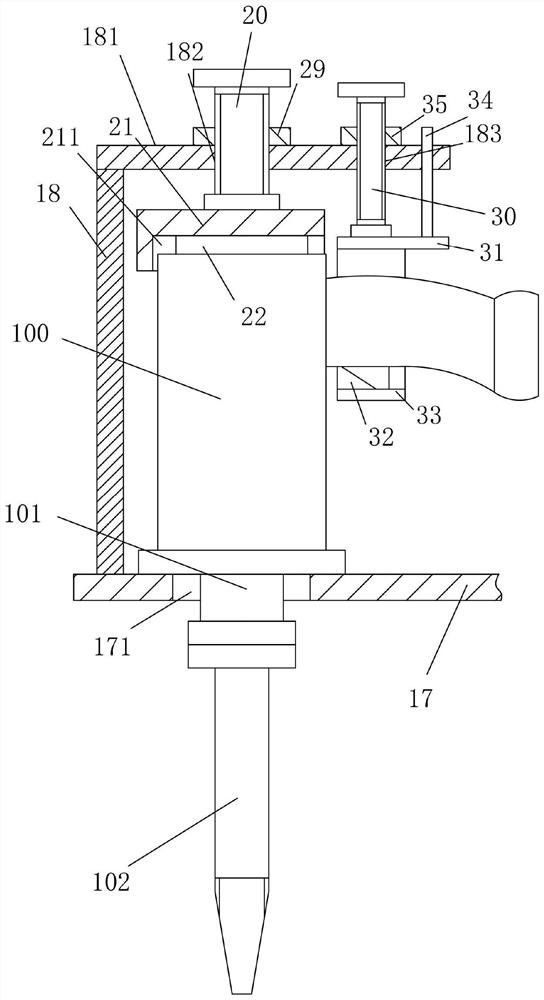

[0019] Examples, see e.g. Figures 1 to 2 As shown, a kind of auxiliary frame for electric drill processing includes a fixed base plate 10, the top surface of the fixed base plate 10 is fixed with a vertical support plate 11, and the upper horizontal plate 12 is fixed on the top surface of the vertical support plate 11, vertically The top of lifting screw rod 13 is hinged on the upper horizontal plate 12 by bearing, and the bottom end of vertical lifting screw rod 13 is hinged on the fixed base plate 10 by bearing, and the top surface of upper horizontal plate 12 is fixed with lifting motor 14, and the lifting motor 14 The output shaft is a spline shaft, and the spline shaft is inserted into the spline hole at the top of the vertical lifting screw 13. The lifting motor 14 drives the vertical lifting screw 13 to rotate, and the vertical lifting screw 13 is screwed with a lifting adjustment block. 15. A connection fixing plate 16 is fixed on the outer side wall of the lifting ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com