Mounting structure of soar-grille hyperbolic cantilever and mounting method of soar-grille hyperbolic cantilever

An installation method and a technology for installing structures, which are applied in building construction, building material processing, construction, etc., can solve the problems of high difficulty in stable control of super-long components, large slenderness ratio of components, and high height, so as to ensure installation quality and Progress, fewer auxiliary processes, steps and independent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

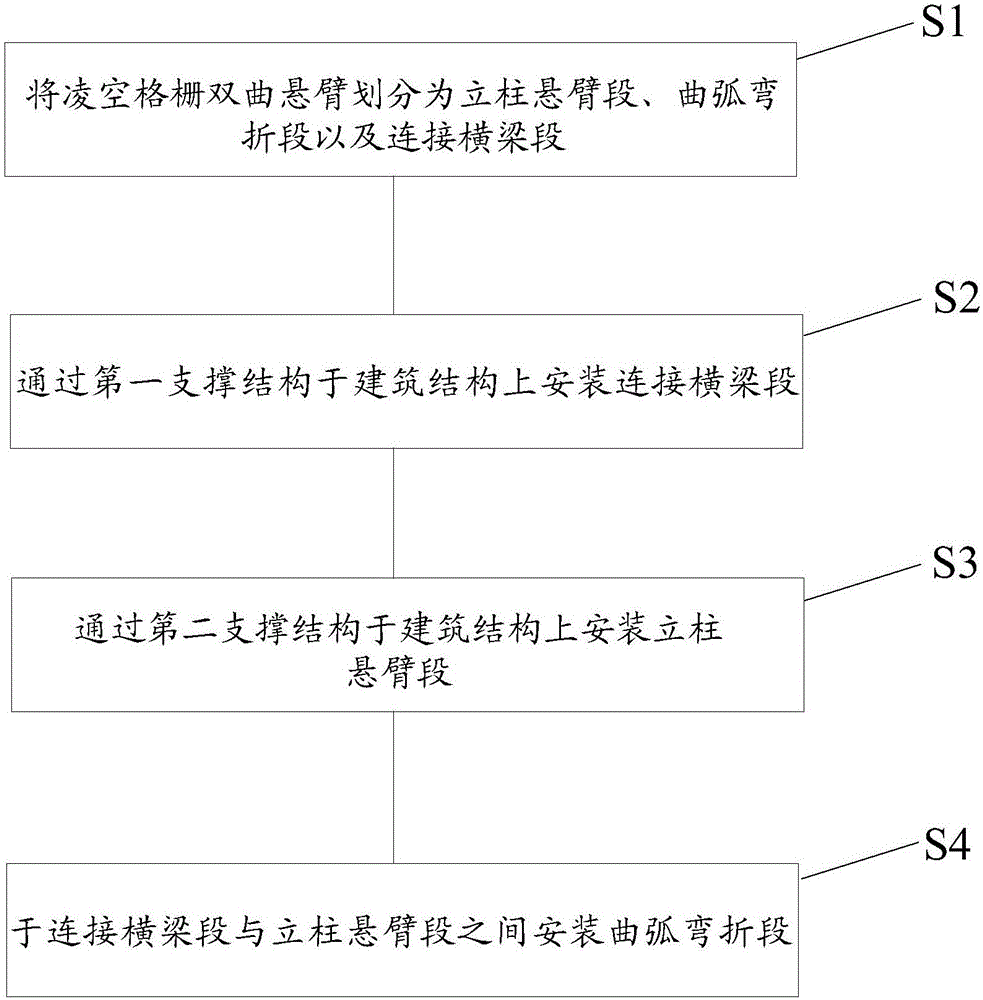

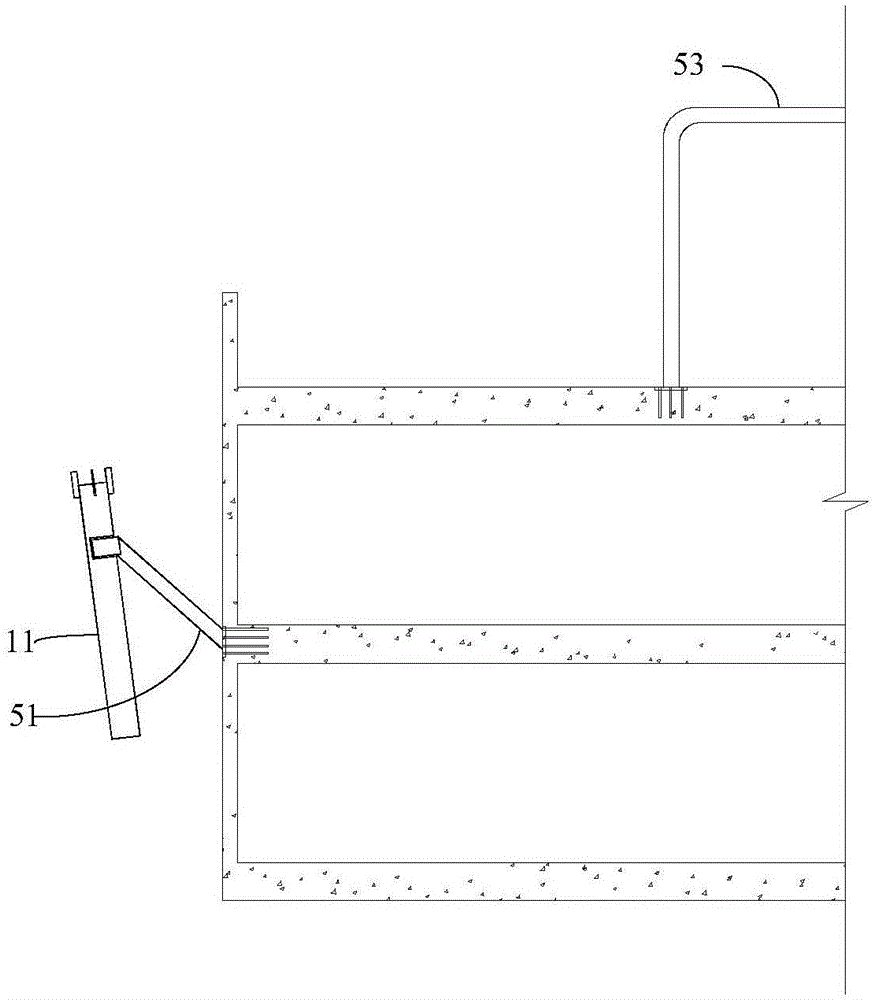

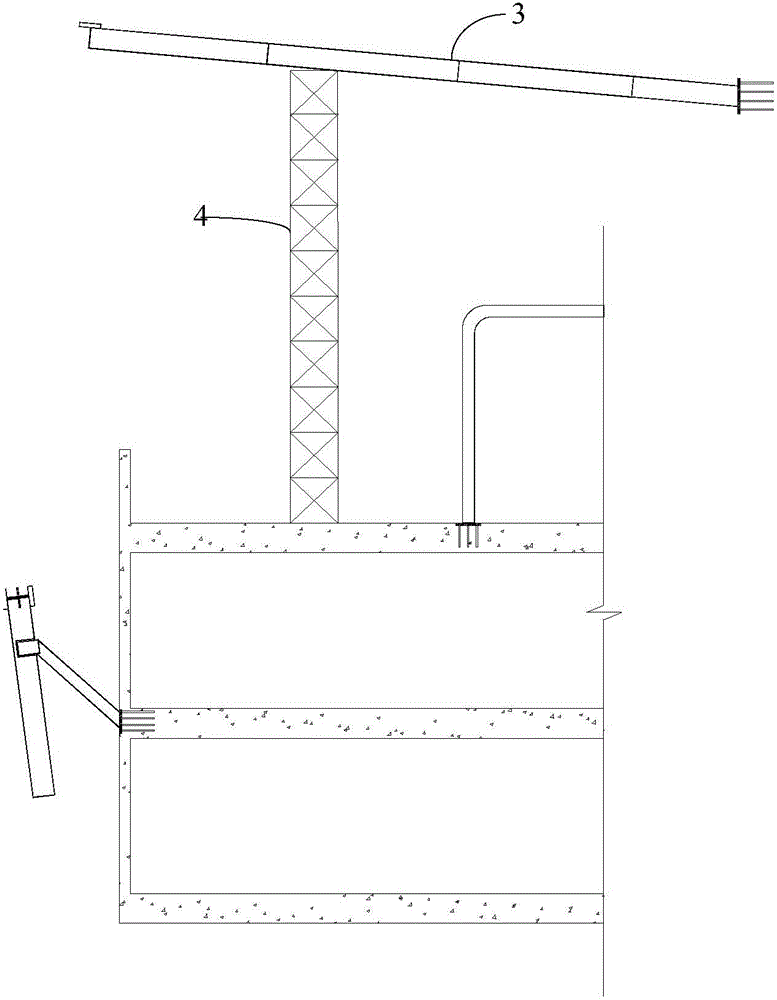

[0034] Please refer to figure 1 , Figure 2 to Figure 4 , figure 1 It shows a flow chart of the steps of the installation method of the volley grid hyperbolic cantilever of the present invention; Figure 2 to Figure 4 It shows the construction diagram of the installation method of the volley grid hyperbolic cantilever of the present invention.

[0035] The invention provides a method for installing a volley grid hyperbolic cantilever, comprising:

[0036] Step S1: Divide the volley grid hyperbolic cantilever into column cantilever section 1, curved arc bending section 2 and connecting beam section 3.

[0037] Specifically, when step S1 is executed, the volley grid hyperbolic cantilever is divided into the column cantilever section 1 arranged on the side of the building structure 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com