Flatness adjusting device for LED display module

A display module and adjustment device technology, applied in the direction of identification devices, instruments, etc., can solve the problems of low accuracy, low efficiency, inflexibility, etc., and achieve the effects of ensuring installation progress, flexible and convenient adjustment, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

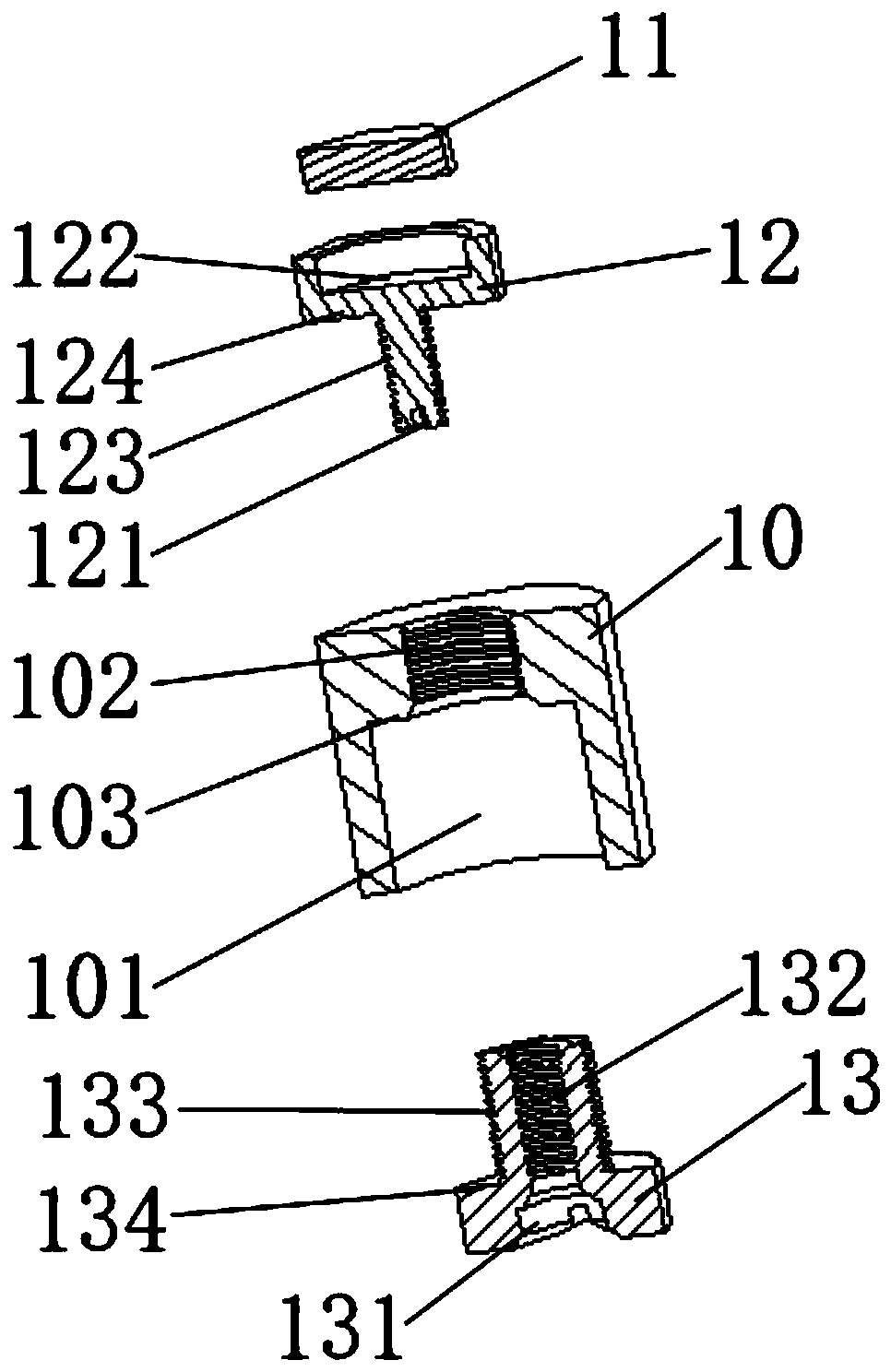

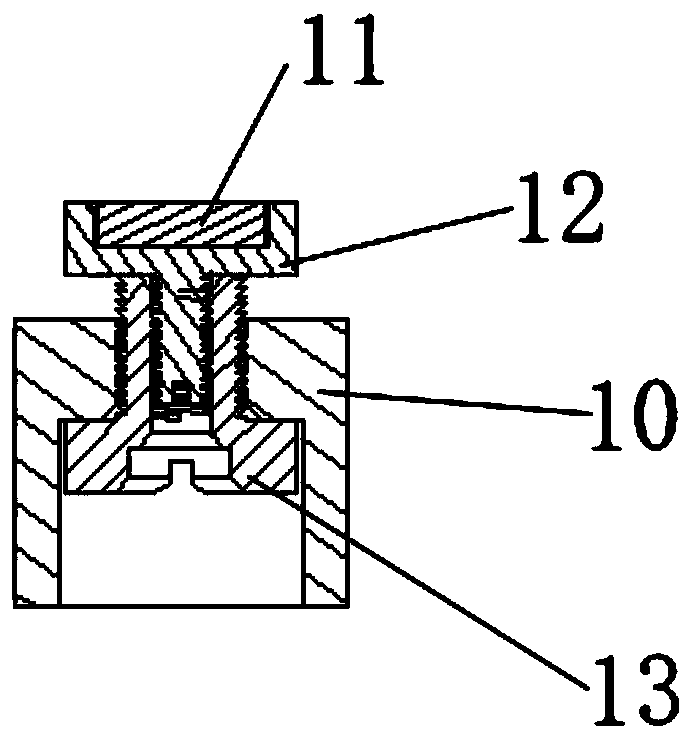

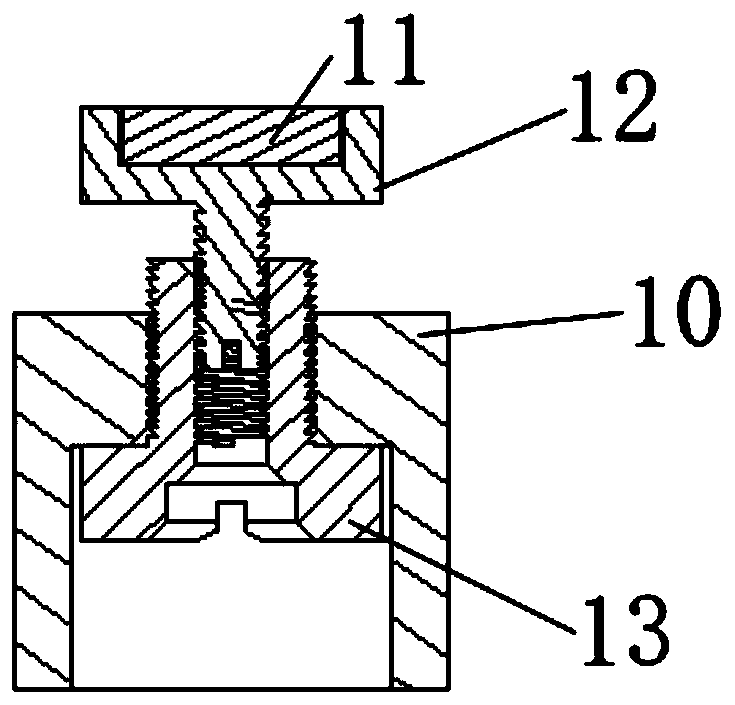

[0019] Such as Figure 1 to Figure 4 As shown, a flatness adjustment device for an LED display module includes a fixing member 10, a suction member 11, a first adjusting member 12, and a second adjusting member 13. The fixing member 10 is fixedly connected to the LED box 3, and the second adjusting member 13 is threadedly connected with the fixing part 10, the first adjusting part 12 is threadedly connected with the second adjusting part 13, the suction part 11 is arranged in the first adjusting part 12, and the suction part 11 is magnetically connected with the display module 2.

[0020] In this embodiment, the fixing member 10 is fixed on the LED box 3, the second adjusting member 13 is screwed to the fixing member 10, and the second adjusting member 13 is screwed into the fixing member 10. When adjusting the height, the second adjusting member 13 can Move up and down along the threaded hole in the fixing member 10; the first adjusting member 12 is screwed into the second adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com