Patents

Literature

43results about How to "Guaranteed workload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

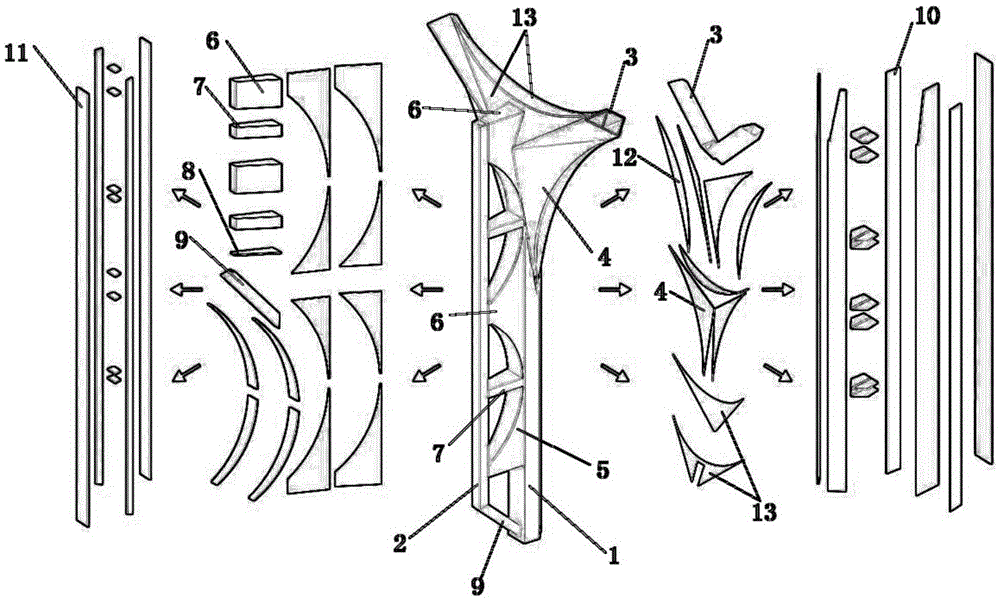

Assembly ship building unit element, modularization designing method

InactiveCN1948081AImprove build qualityGuaranteed Build QualityVessel partsModular designComputer module

A modular design method for building all units and assembling them together includes such steps as 3D modeling of ship body, 3D arrangement modeling for assembling, dividing it into functional or regional units or modules, providing the interfaces between units or modules, designing and drawing them, and integrating them together in frame mode while preserving the interfaces between them.

Owner:DALIAN SHIPBUILDING IND

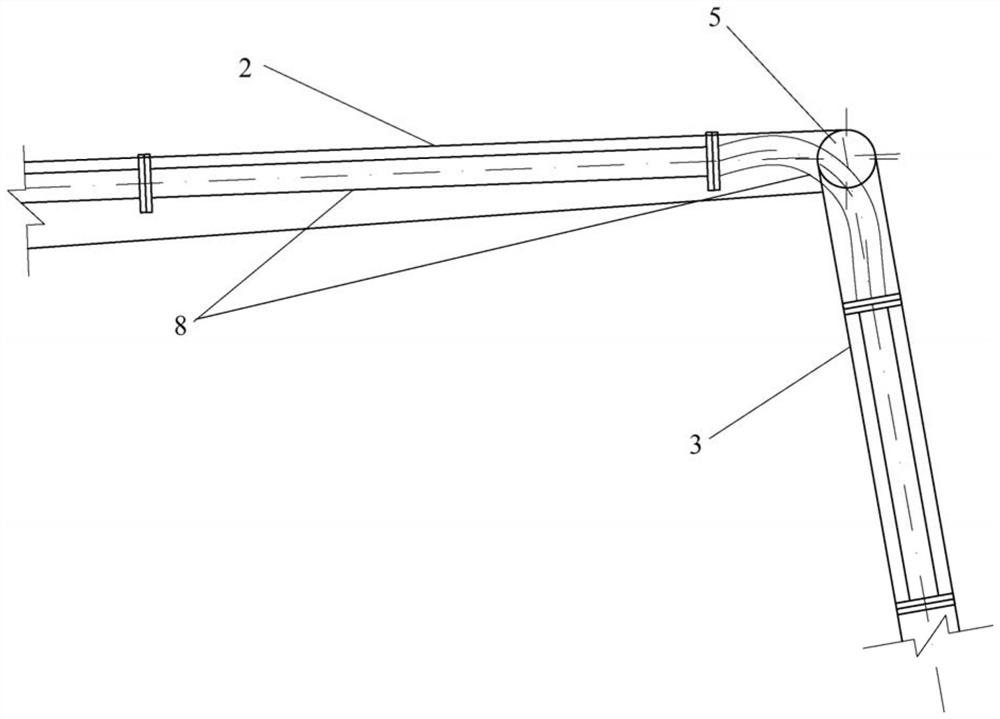

Tube truss manufacture process

The invention provides a tube truss manufacture process which comprises the steps as follows: blanking of steel tubes, positioning of intersecting points of tube fitting, welding of tube fitting, calibrating of members, pre-assembling, and disassembling of the pre-assembled truss, wherein all the manufacturing and processing links are carried out in sequence. The manufacture process has the advantages as follows: the assembly precisions of intersecting ends and intersecting holes are high; the size deviation is small; a truss body can be assembled quickly; the workload of calibration is small; formation of physical appearance is good; workload and time for polishing are greatly reduced; the quality of construction and formation can be guaranteed; smoothness and progression of all manufacture links are guaranteed; total construction period is guaranteed; material cost of manufacturing of the tube truss can be saved; inputs of manpower and goods and materials are saved; and economical effects of production are improved.

Owner:河北二十冶建设有限公司

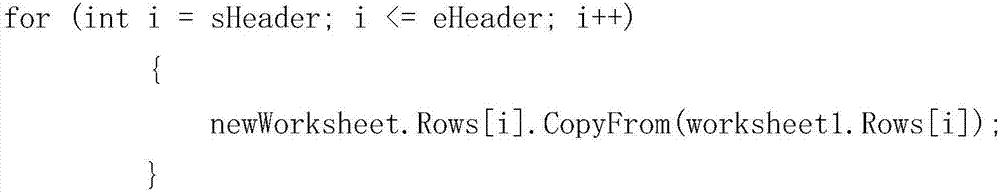

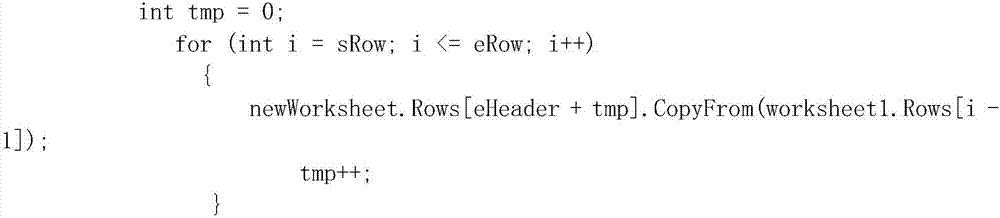

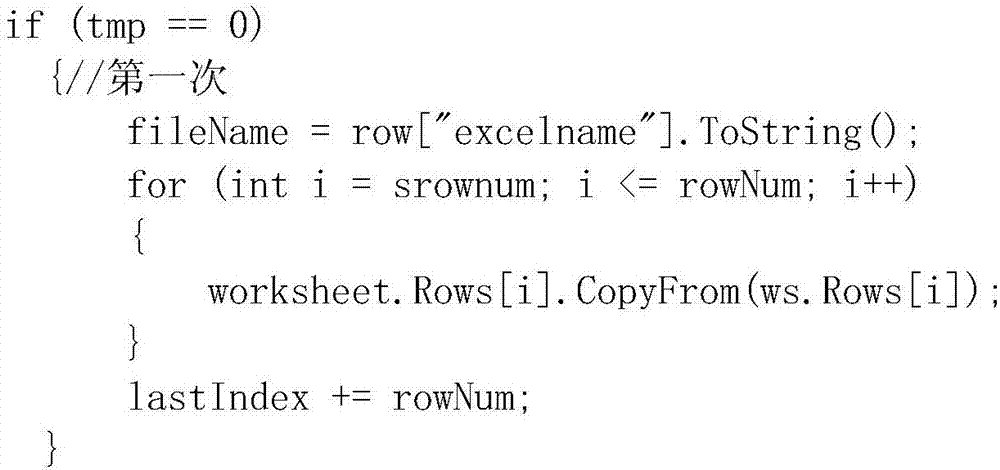

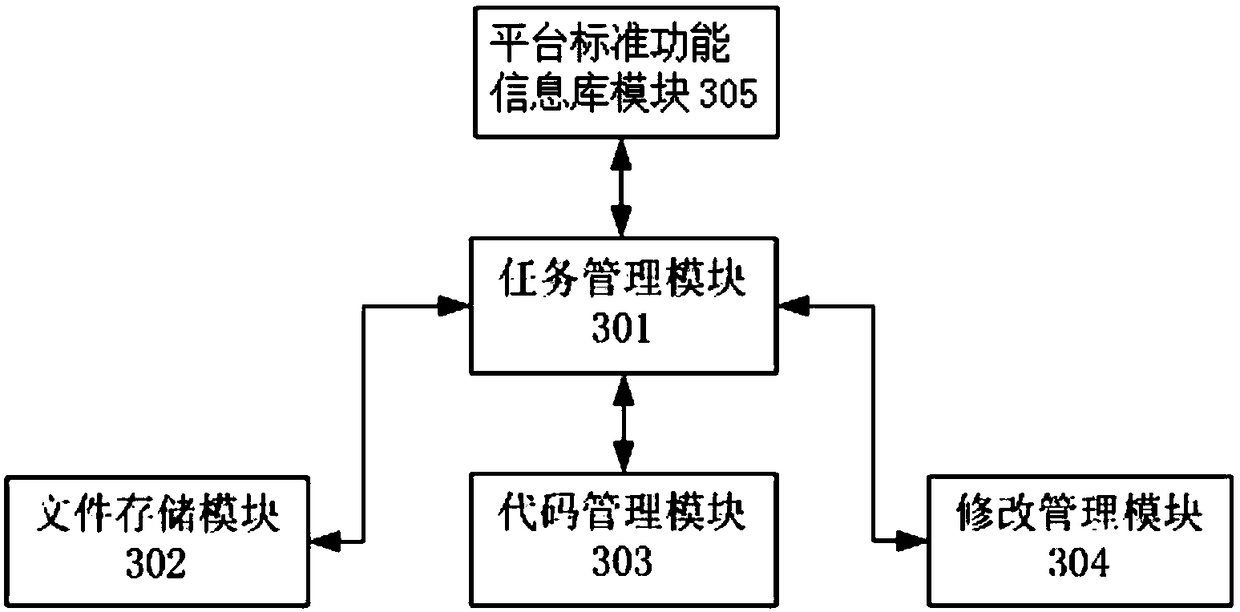

Multi-user synchronous editing processing system for same file, and processing method

ActiveCN108009243AImprove securityEnsure safetyDatabase management systemsVisual data miningData fileDocumentation

The invention discloses a multi-user synchronous editing processing system for the same file, and a processing method. The multi-user synchronous editing processing method comprises steps that a datafile is automatically analyzed and split and analyzed into a plurality of same small files via a template file; a plurality of users edit the file at the same time online, distribute authority for thesplit file for different users, enable all users to online edit file content and hand in the same; the file contents are merged and downloaded; multi-file handing in states are traced; the pluralityof files are merged into a file and contents edit by different users are completely reserved; and then the file is loaded and checked. According to multi-file handing in state trace, and file merge and reservation of contents edit by different users, synchronous edit on various terminals can be achieved; and table contents of each terminal can be checked only by editing users, so safety of important information can be ensured; and the system simplifies a process, reduces work load, shortens reporting time and improves information safety.

Owner:YUNNAN POWER GRID +1

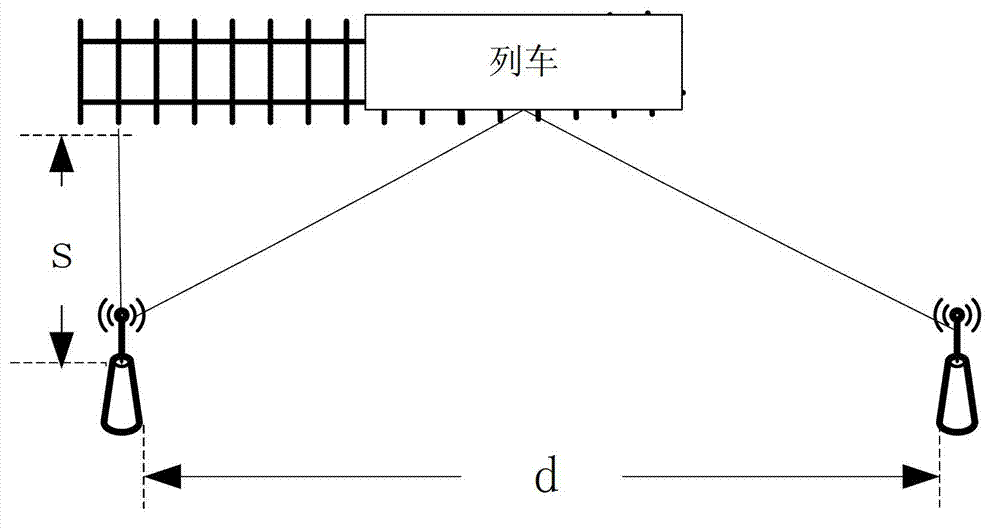

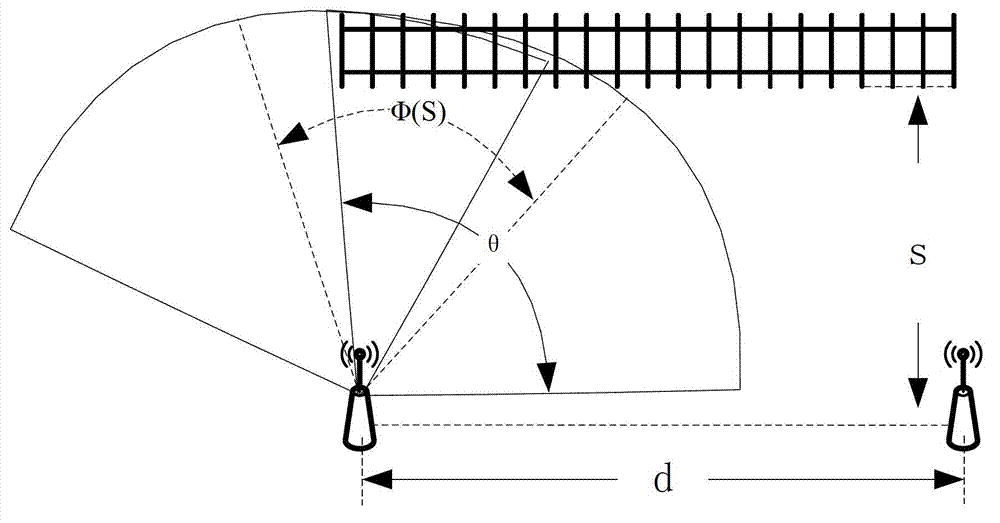

Setting method of CDMA (code division multiple access) wireless communication network in high-speed rail environment

ActiveCN103118372AGuaranteed performanceReduce performanceNetwork planningTime division multiple accessE communication

The invention discloses a setting method of a CDMA (code division multiple access) wireless communication network in high-speed rail environment. The CDMA wireless communication network comprises a base station set. Each base station comprises more than two signal sources equal in communication coverage radius. Antenna included angle of the base station signal sources meets the conditions that the included angle of the signal sources in the same base station is smaller than phi(S):phi(s)=theta-2*tan<-1>tau*v / s, the theta refers to 5dB lobe angle of the base station signal source antennas, the s refers to a definite distance of the base station signal source antennas from a rail in an actual scene, the tau refers to regulated CDMA system switching time, and the v refers to maximum train speed. Different stations can be set by the method according to different transmission environments before planning and construction, certain relation among azimuth, station spacing and the distance from the rail is guaranteed, construction efficiency can be improved effectively, late optimization work is reduced effectively, and network quality is improved effectively.

Owner:CHINA INFOMRAITON CONSULTING & DESIGNING INST CO LTD

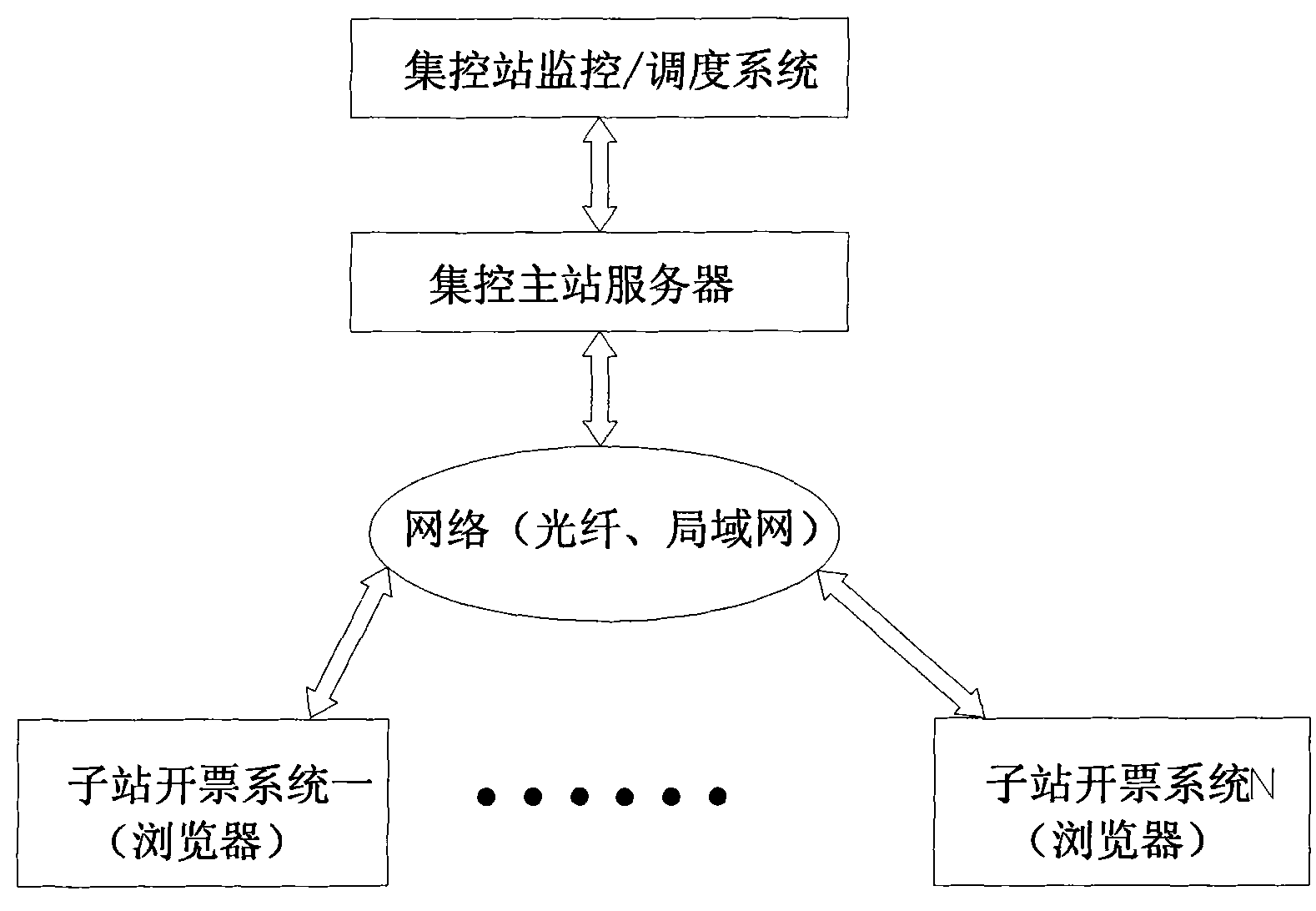

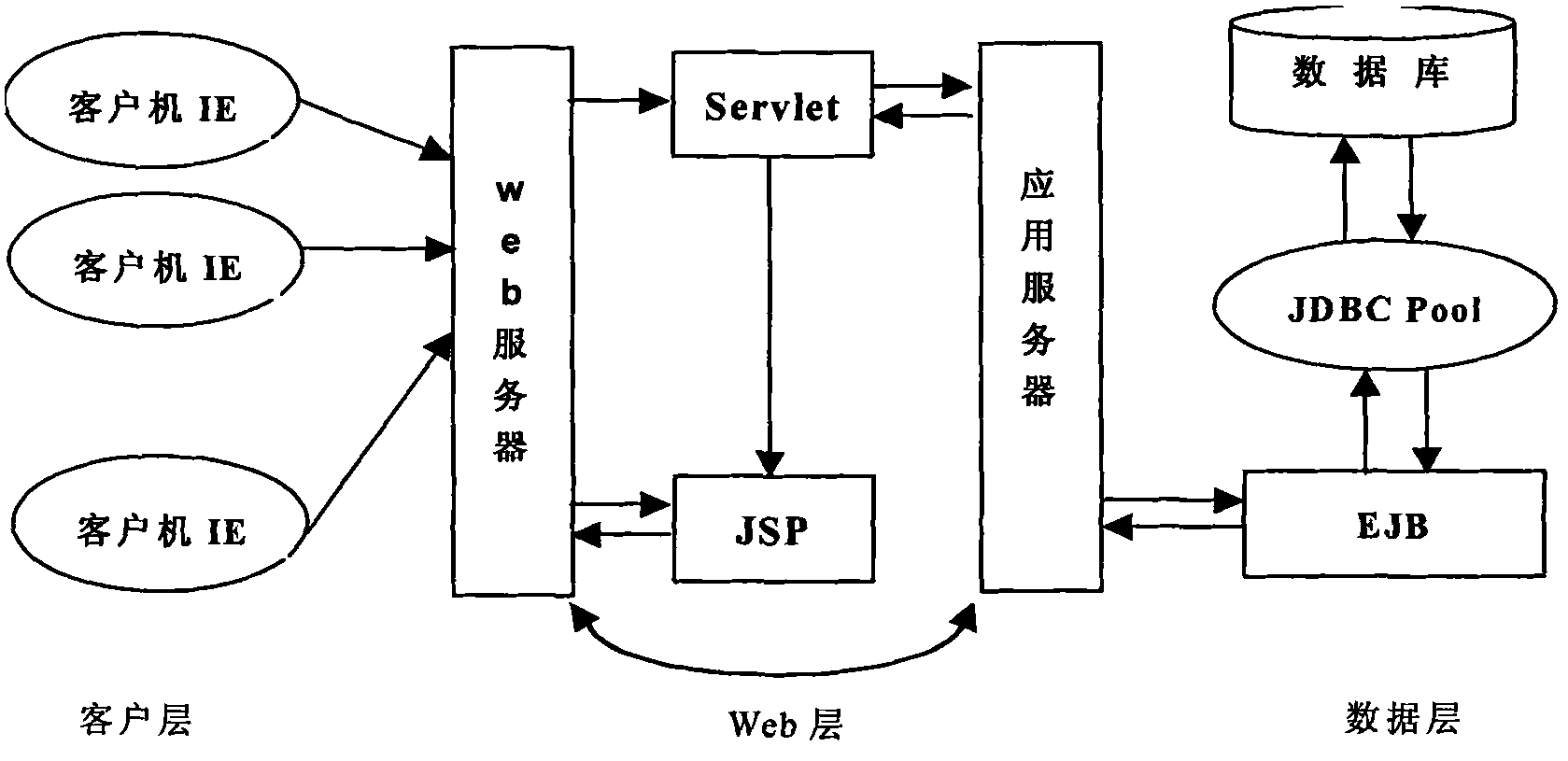

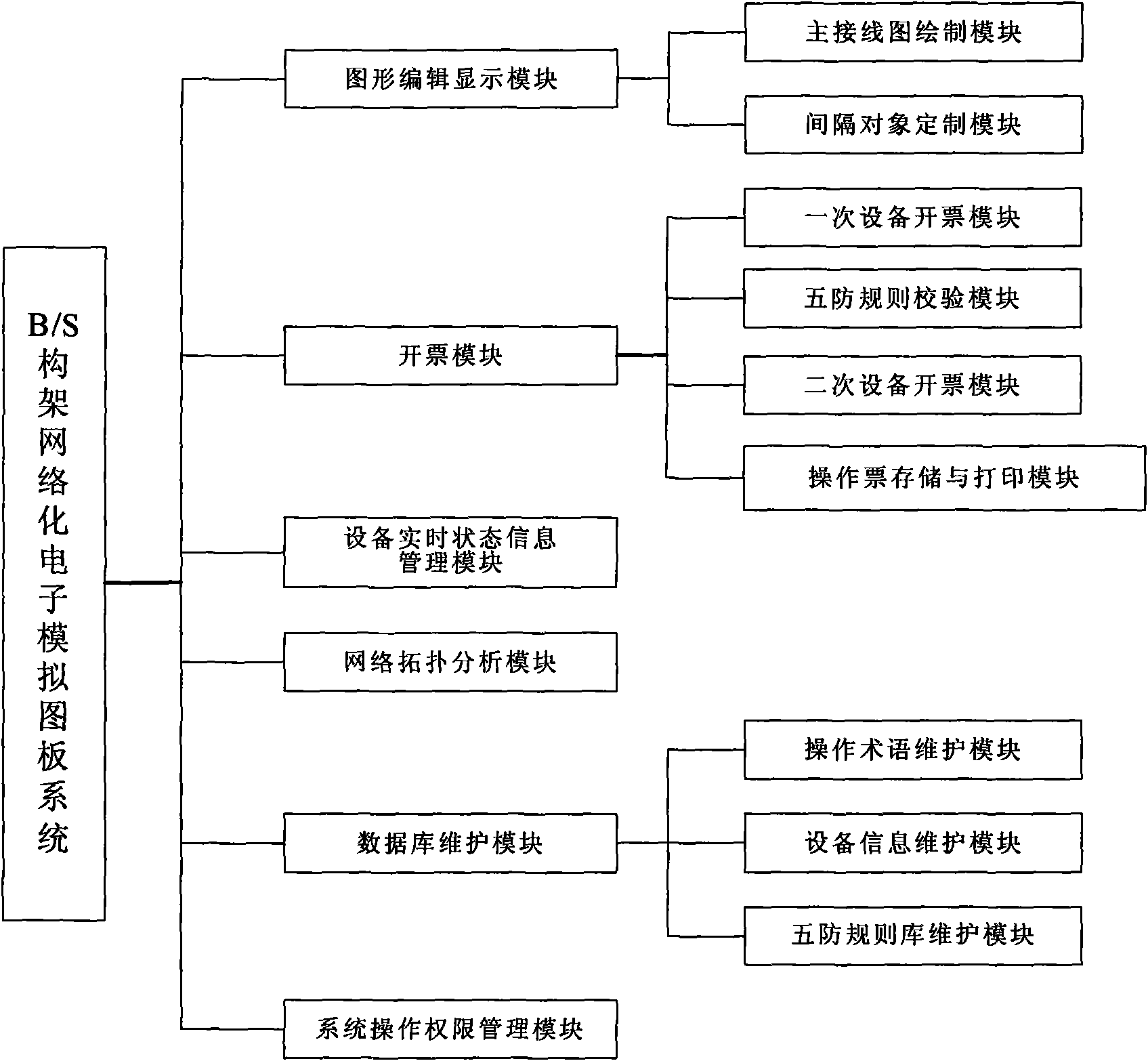

Operating method of B/S framework networked electronic simulation drawing board system

InactiveCN102064602AGuaranteed workloadReduce workloadCircuit arrangementsInformation technology support systemSafety controlNetwork topology

The invention discloses an operating method of a browser / server (B / S) framework networked electronic simulation drawing board system, which relates to a safety control method used when a power supply system operates electrified equipment. On the premise of ensuring correct and reliable billing, remote interaction of a field and a centralized control center is realized. The system is communicated with each field and the centralized control center; the centralized control center is provided with a monitoring system, a dispatching system and a main station server; the system is provided with a browser device which can be moved to each field; a communication device is communicated with a plurality of browser devices; and an application server is provided with a graphic edition and display module, a billing module, an equipment real-time status information management module, a network topology analysis module, a database maintenance module and a system operation authority management module. The operating method mainly comprises the following operating steps of: 1) transmitting an operation order billing request; 2) generating an operation order; 3) transmitting the generated operation order to a browser through the communication device; and (4) performing field operation through field operating personnel according to the operation order received by the browser.

Owner:JIANGSU ELECTRIC POWER COMPANY YANGZHOU POWER

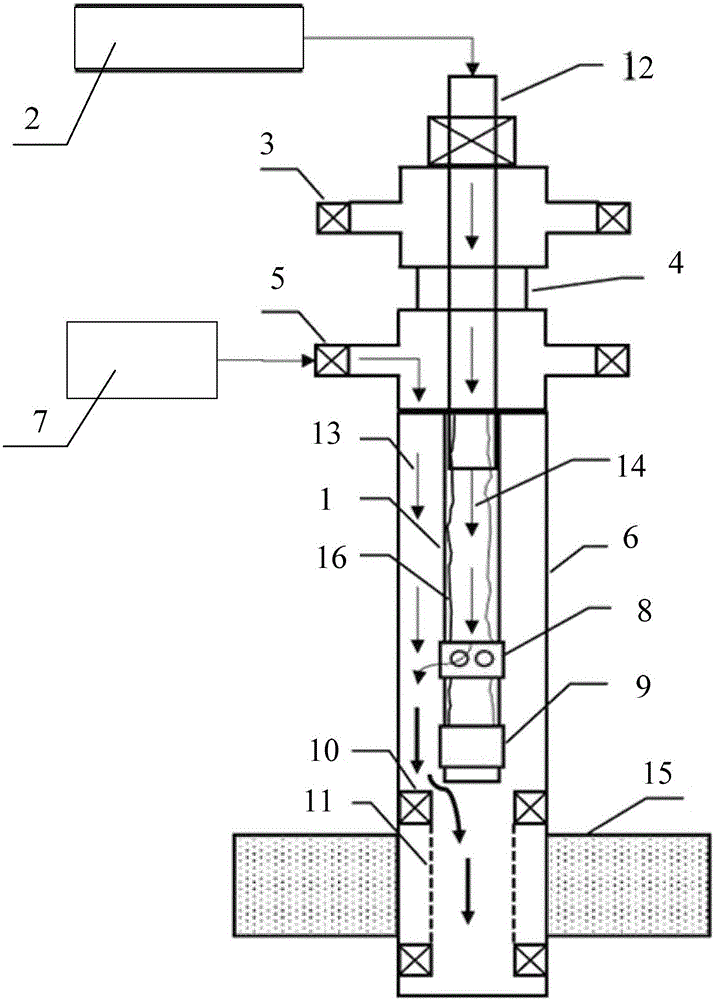

Hot fluid injection blockage relieving and production increasing process for immovable string

InactiveCN105735956AAvoid affecting the heat injection effectShorten the working cycleFluid removalProcess engineeringINCREASED EFFECT

The invention discloses a hot fluid injection blockage relieving and production increasing process for an immovable string. Hot fluid is injected into a stratum through thickened oil extraction equipment, and then well soaking, blowing and pump exhausting and production are conducted. According to the provided hot fluid injection blockage relieving and production increasing process for the immovable string, the operation cycle can be greatly shortened, the operation cost can be greatly reduced, pump starting and production can be timely conducted according to the condition of the output ratio of liquid, gas and oil during blowing, and the situation that the heat injection and production increasing effect is influenced due to operation of a movable string is avoided.

Owner:CHINA NAT OFFSHORE OIL CORP +1

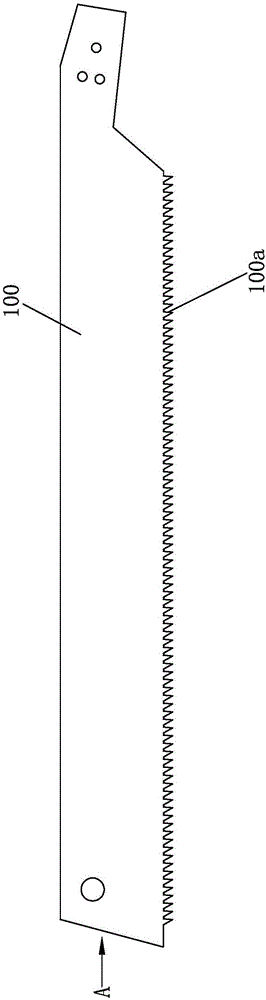

Handle saw web and sawtooth machining process

InactiveCN106180895AReduce workloadReduce wearMetal sawing tool makingGear grindingNumerical control

The invention discloses a sawtooth processing technology of a handle saw blade, which is characterized in that it comprises the following steps: step a: shaping the saw blade (100); step b: punching out a set of edges on the saw blade (100) The saw teeth (100a) arranged in the lengthwise direction of the saw blade; step c: use a CNC gear grinding machine to grind both sides of each saw tooth (100a) to form a cutting edge; step d: deburring and polishing. The upper and lower sides of (100) are deburred and polished; step e: divide the teeth, in this step, the second punch press is used to press the saw blade (100), so that all the saw teeth (100a) on a piece of saw blade (100) ) to complete the tooth division at one time. This process method effectively simplifies the process, greatly improves the processing efficiency and precision, effectively eliminates the cumulative error, and reliably reduces the processing cost. The waste produced after stamping can also generate a certain economic value, thus effectively overcoming the existing process method. disadvantages, has good practicality.

Owner:CHONGQING MINGYOU STEEL PROD MFG CO LTD

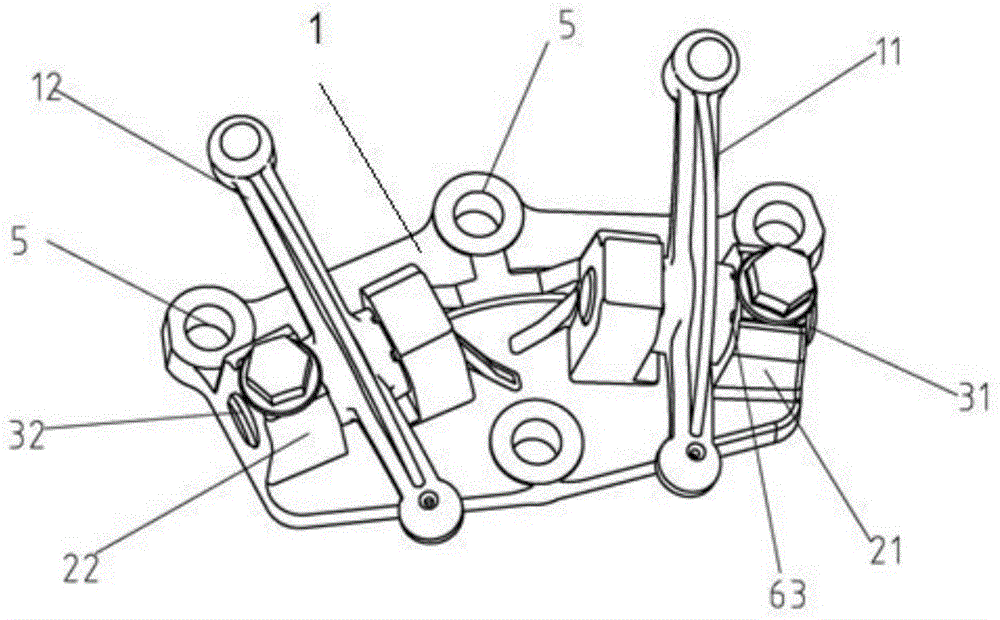

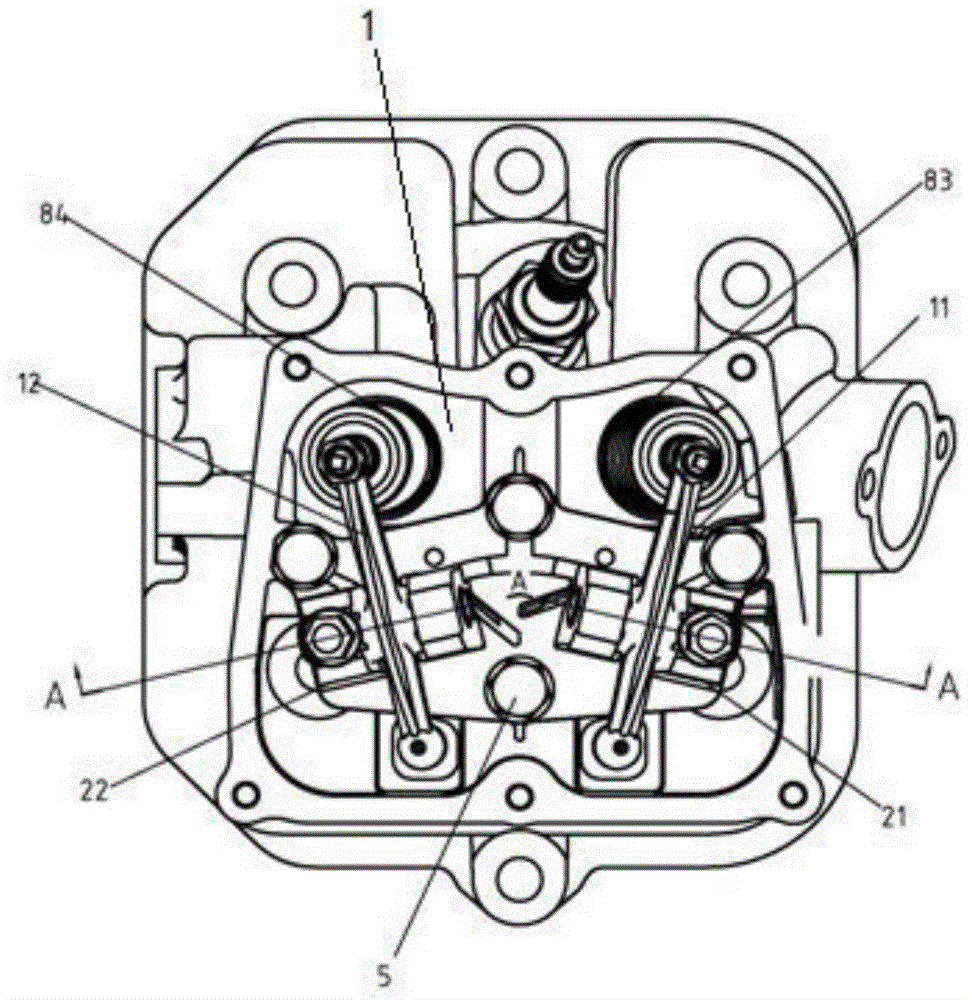

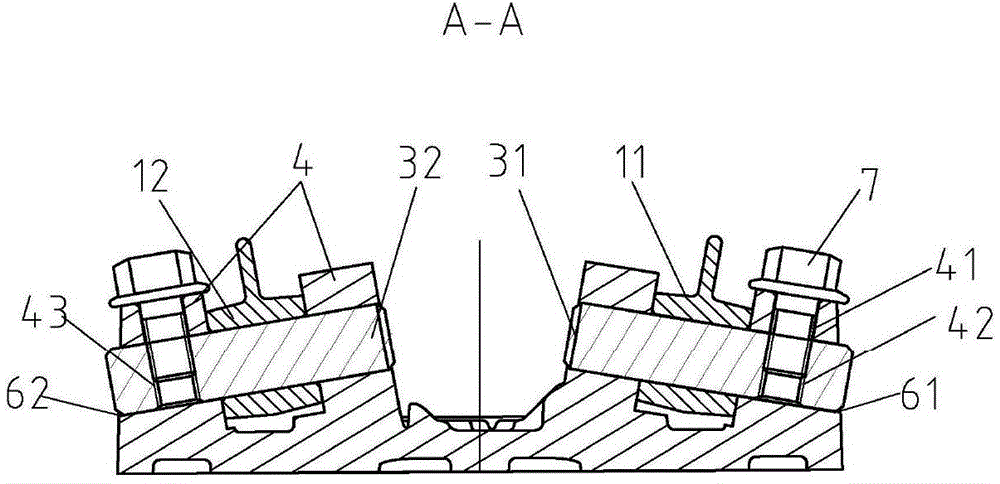

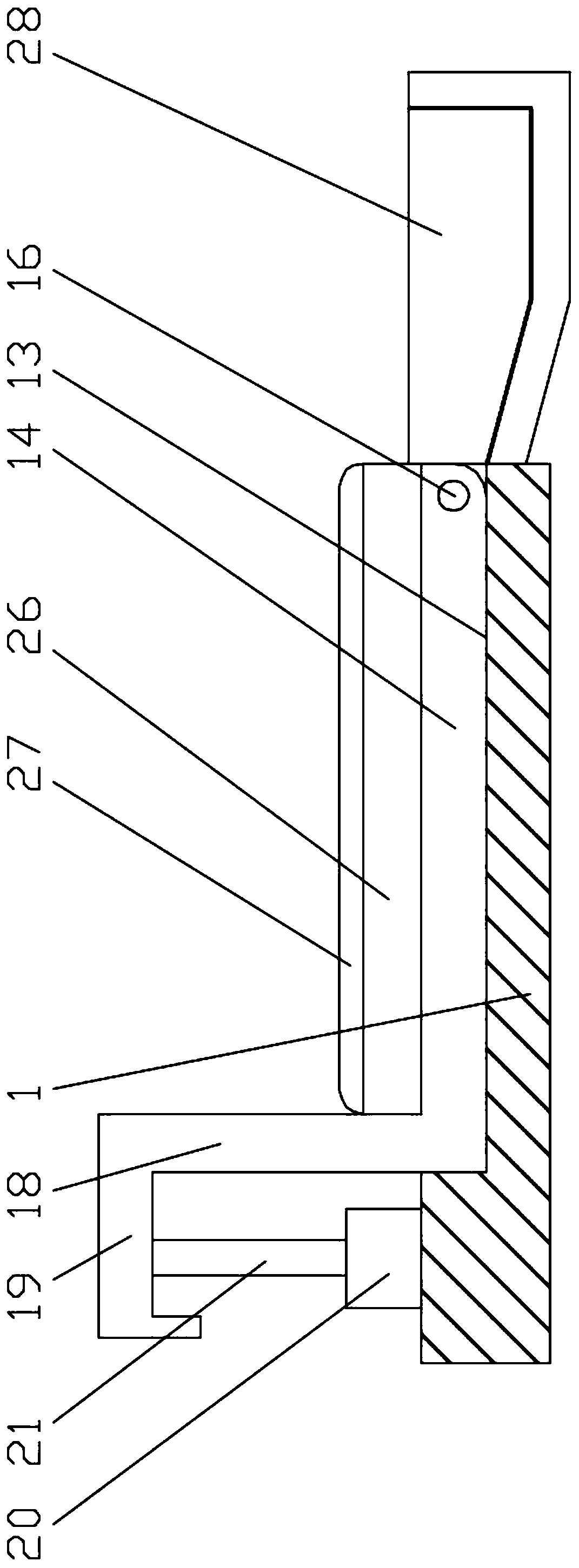

Valve rocker mounting mechanism and gasoline engine thereof

ActiveCN104832237AReduce wearReduce structural complexityValve arrangementsMachines/enginesExhaust valveCylinder head

The invention discloses a valve rocker mounting mechanism. The valve rocker mounting mechanism comprises a valve rocker mounting seat, wherein an intake valve rocker seat and an exhaust valve rocker seat are arranged on the valve rocker mounting seat, the intake valve rocker seat is used for mounting an intake valve rocker, and the exhaust valve rocker seat is used for mounting an exhaust valve rocker; the intake valve rocker and the exhaust valve rocker are hinged to the intake valve rocker seat and the exhaust valve rocker seat by an intake valve rocker shaft and an exhaust valve rocker shaft; the intake valve rocker is used for driving a contact surface, which corresponds to the top of an intake valve rod, to be respectively vertical to the corresponding axis of the intake valve rod, and the exhaust valve rocker is used for driving a contact surface, which corresponds to the top of an exhaust valve rod, to be respectively vertical to the corresponding axis of the exhaust valve rod; an included angle is formed between the axis of an axle hole of the intake valve rocker seat and a junction surface of the valve rocker mounting seat and a cylinder head, and an included angle is formed between the axis of an axle hole of the exhaust valve rocker seat and the junction surface of the valve rocker mounting seat and the cylinder head; an included angle is formed between the axis of an axle hole of the intake valve rocker shaft and the axis of an axle hole of the exhaust valve rocker shaft, and the intake valve rocker seat and the exhaust valve rocker seat are symmetrically arranged on the valve rocker mounting seat. The valve rocker mounting mechanism and a gasoline engine thereof, which are provided by the invention, have the advantages that the power transferred by the valve rockers can be highly efficiently utilized, the abrasion of the contract surfaces is reduced, and the workload of a valve driving mechanism is reduced.

Owner:SUZHOU ERMA MECHNICAL & ELECTRICAL

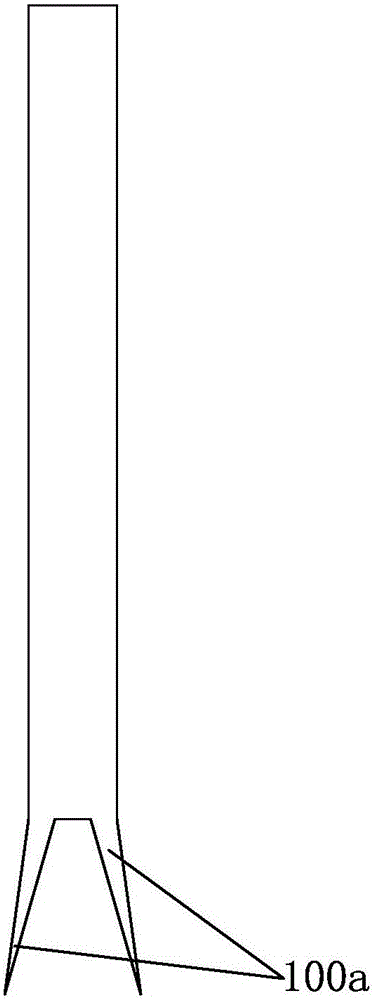

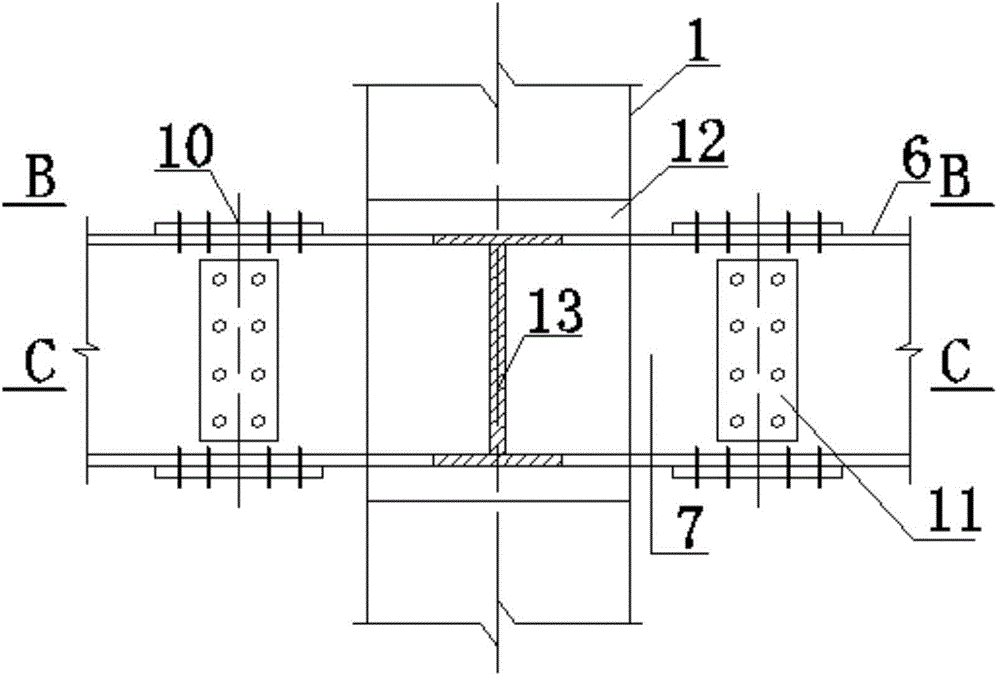

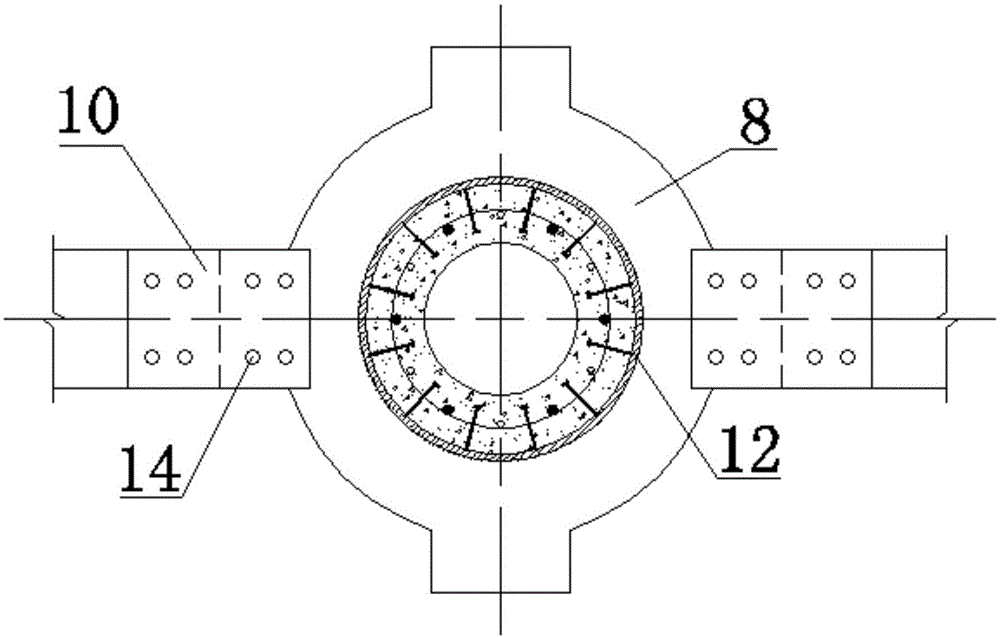

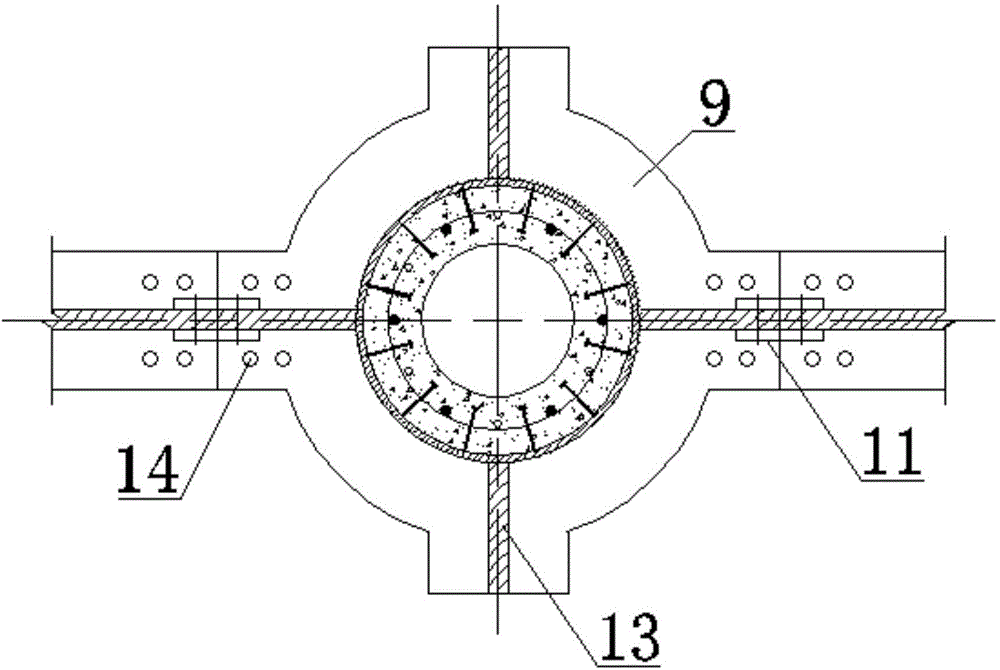

Assembling type frame structure

The invention discloses an assembling type frame structure which comprises tubular columns and steel beams. The tubular columns are connected with the steel beams through nodes. The tubular columns and the steel beams are prefabricated parts. The tubular columns are made by a pre-tensioning prestress centrifugal shaping process. The height of each tubular column is as high as three layers or four layers. The assembling type frame structure has the advantages that the prefabricated tubular columns are used, the assembling degree of the frame structure is increased, the three layers or four layers are prefabricated together, tubular column longitudinal rib connecting times are reduced, connecting node construction measures of tubular columns between layers are simplified, mixed reinforcement is used, and tubular column ductility property is enhanced; compared with a steel frame, the assembling type frame structure is capable of lowering manufacturing cost and increasing fireproof and corrosion resistant performance; the prefabricated components are standardized and modularized, large-scale component production by factories is benefited, and work load of a design link is reduced greatly at the same time; compared with traditional frame structures, the frame structure is good in integrity; the frame structure is spliced on a construction site, construction speed is increased, labor intensity is lowered, and structural quality is guaranteed.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +1

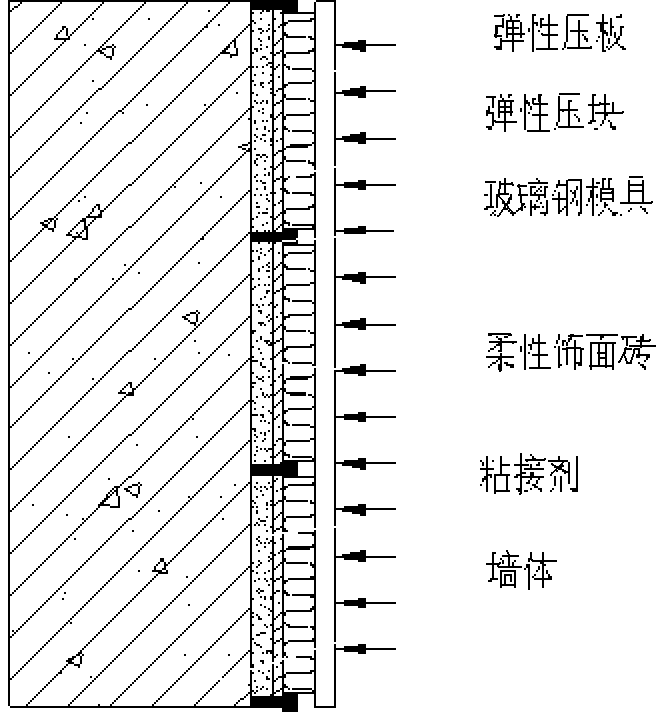

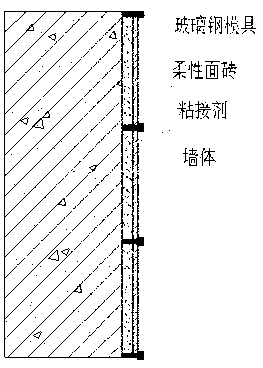

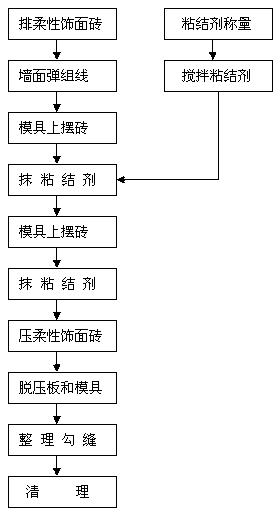

Method for constructing flexible facing brick

The invention discloses a method for constructing a flexible facing brick. The method comprises the following steps of: providing a glass-reinforced plastic mold corresponding to the specifications of the flexible facing brick, and snapping lines on a wall face; placing the flexible facing brick in a concave groove of the glass-reinforced plastic mold; plastering a cementing agent to the back face of the flexible facing brick; pasting the whole mold to a specified position of the wall face according to the positions of the lines on the wall face; pressing the flexible facing brick by using an elastic pressing plate matched with the glass-reinforced plastic mold; sequentially removing the elastic pressing plate and the glass-reinforced plastic mold; and carrying out joint pointing and surface cleaning. When the flexible facing brick is laid by adopting the method disclosed by the invention, the disadvantages existing when the flexible facing brick is laid by traditional construction methods can be overcome, and the requirements on good bonding strength, high flatness, high construction speed and low cost are met.

Owner:ENERGY EFFICIENCY TECH

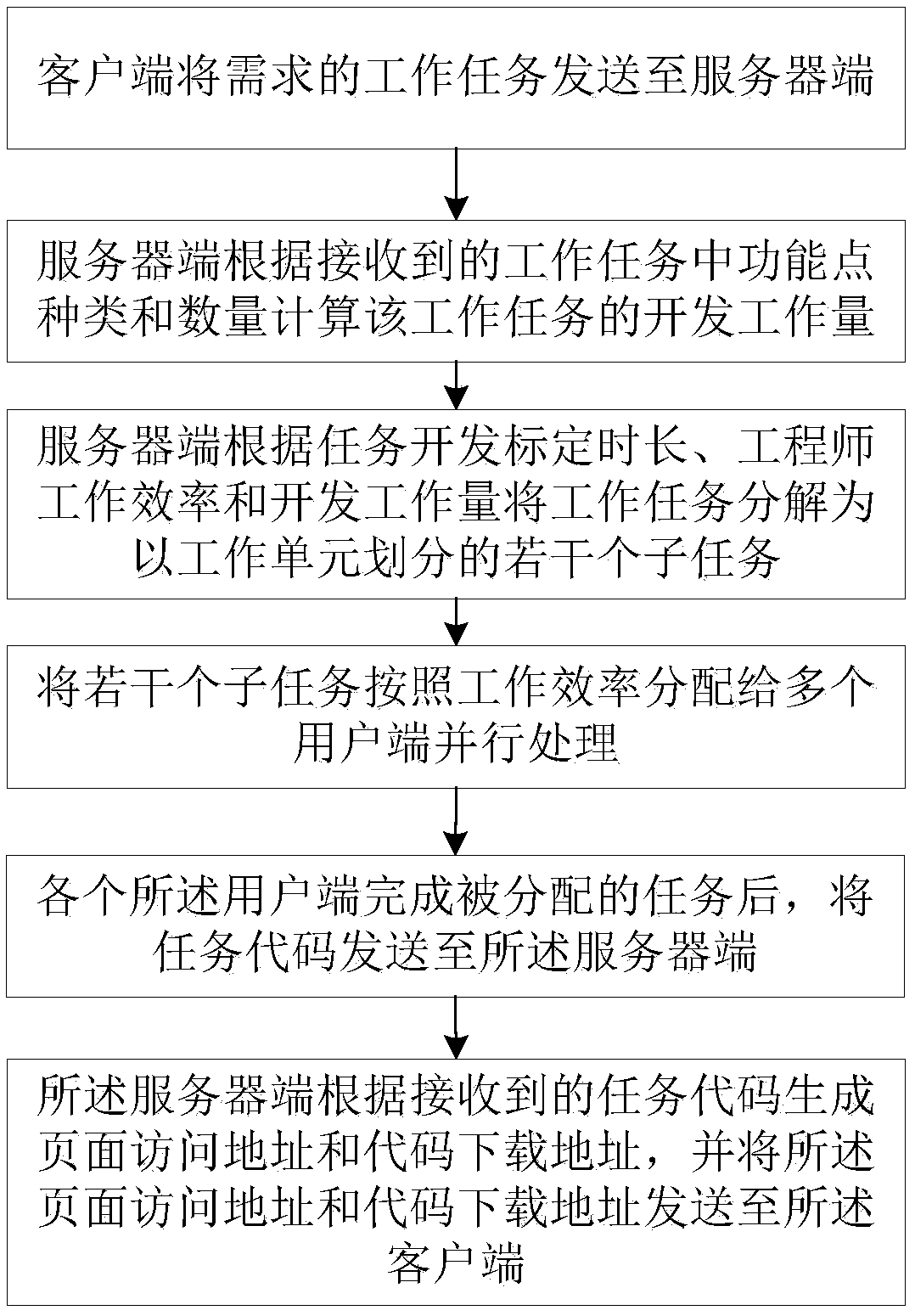

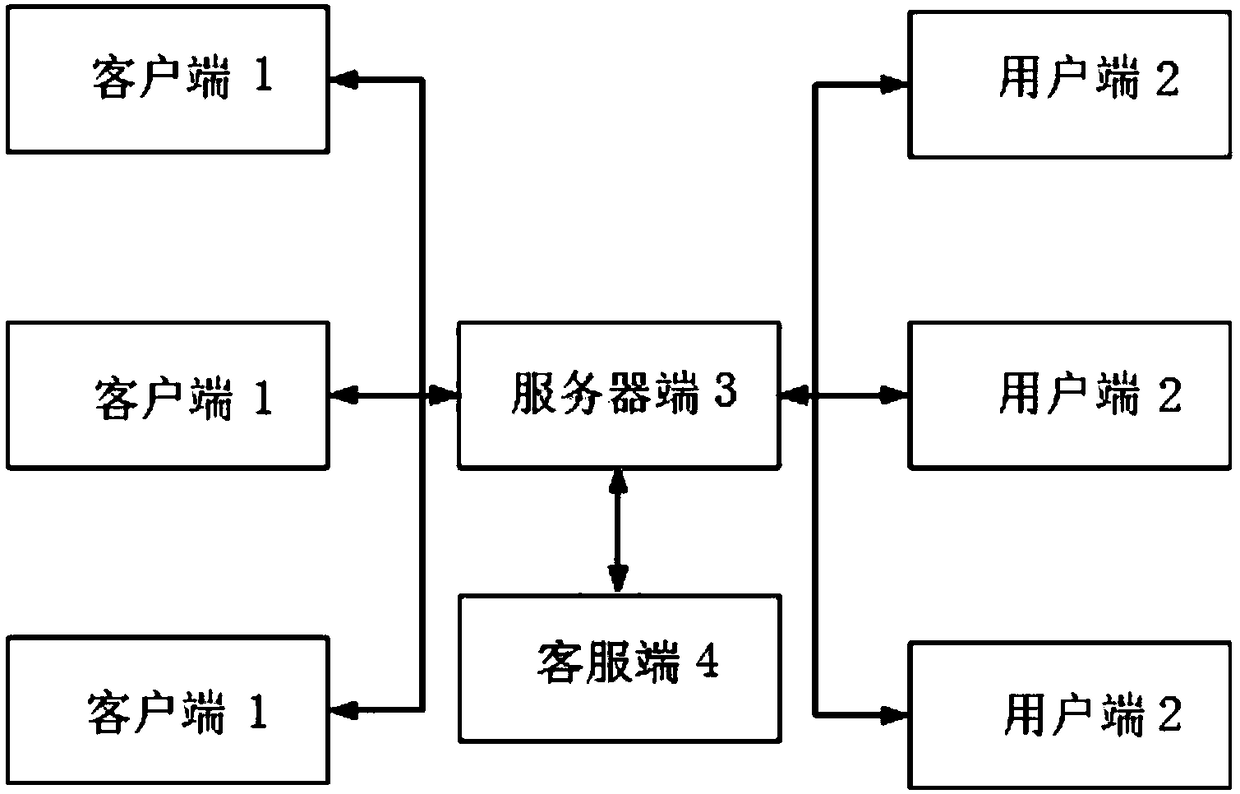

Development method and system based on functional metrology

The invention relates to the technical field of computer, in particular to a development method and a system based on functional metering. The client sends the required work tasks to the server through the client; the server calculates the development workload of the work task according to the received number of function points in the work task; the server divides the task into several sub-tasks according to the task development and demarcation time, the engineer's work efficiency and the development workload; a plurality of sub-tasks are assigned to a plurality of client terminals for parallel processing according to work efficiency; after each of the client terminals completes the assigned task, the task code is sent to the server terminal; the server generates a page access address anda code download address according to the received task code, and sends the page access address and the code download address to the client. The number of function nodes in the task is used to calculate the development workload of the whole task, so that the task can be quantified and the subsequent assignment can be facilitated. Tasks are assigned according to the efficiency of the Engineer, and each Engineer shall not assign more tasks than the total development workload that can be completed within the specified time.

Owner:武汉空心科技有限公司

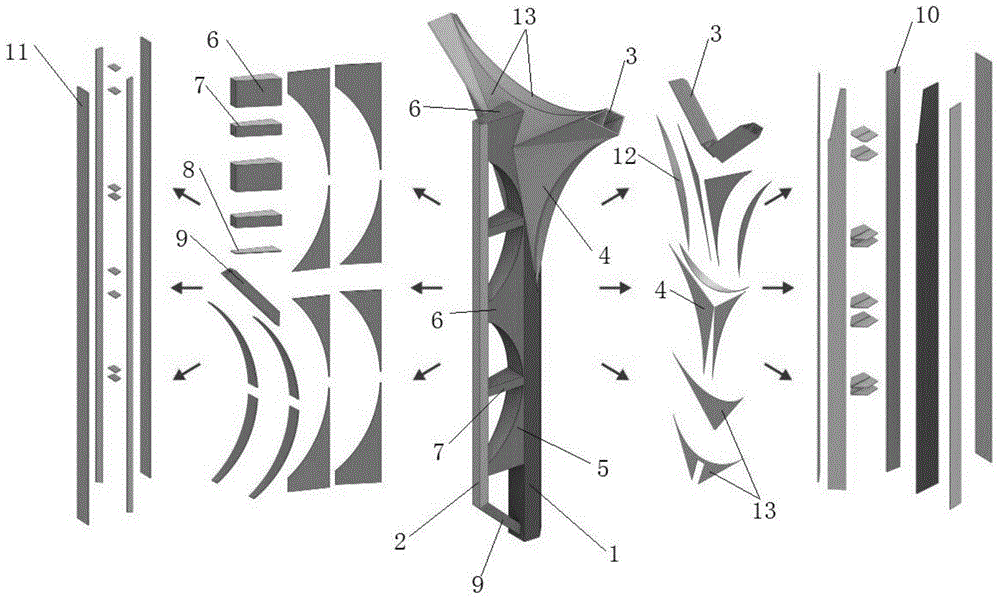

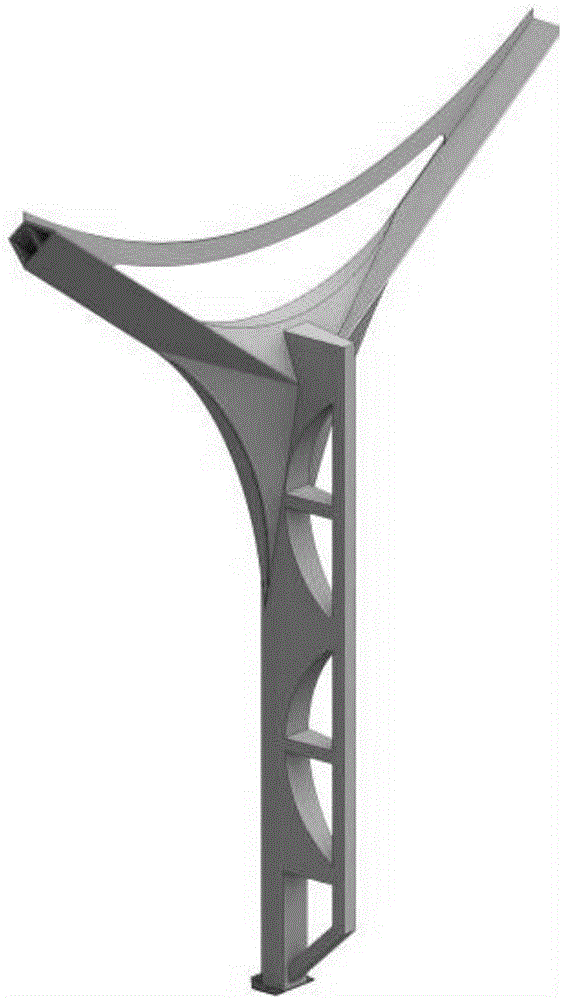

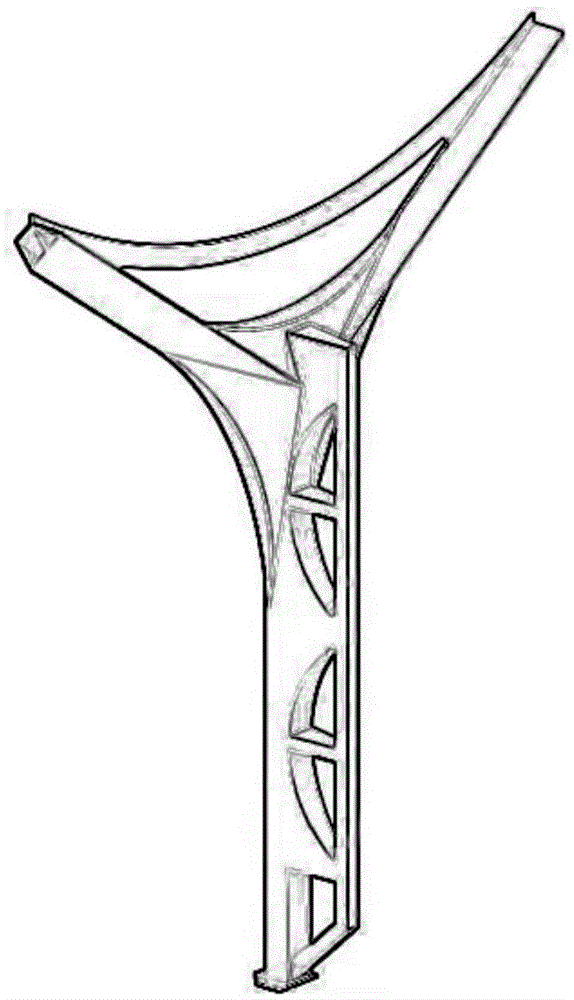

Y-shaped steel column and manufacturing method thereof

ActiveCN104389379AGuaranteed shape accuracySimplify the difficulty of subsequent constructionStrutsPillarsChinese charactersManufactured material

The invention discloses a Y-shaped steel column and a manufacturing method thereof. The Y-shaped steel column comprises a Y-shaped trunk and a front end part which is connected with the Y-shaped trunk, wherein the Y-shaped trunk comprises a box-shaped column of which the cross section takes the shape of a Chinese character ri, and inverted splayed steel plates mounted on the box-shaped column which takes the shape of the Chinese character ri; the front end part comprises a box-shaped column of which the cross section is square-shaped, and front-end steel plates which are connected with the square-shaped box-type column horizontally; the front part forms a shape consisting of two letters B which are arranged up and down after being connected; the inverted splayed steel plates and the front-end steel plates consist of specially-shaped components of different shapes; inclined support components connected with the box-shaped column which takes the shape of the Chinese character ri are further arranged at the bottom of the square-shaped box-type column. The Y-shaped steel column reflects perfect combination of art and construction engineering, by reasonably disassembling the Y-shaped steel column and due to detailed design of constitutional units, the later construction difficulty is relieved, the structure of the column is simplified to the maximum extent while the bearing property of the column is ensured, the raw materials are saved, and the effective building use area is increased.

Owner:JIANGSU HUNING STEEL MECHANISM

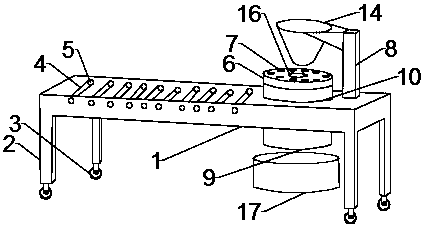

Automatic apple packaging machine

InactiveCN106742374AImprove efficiencyReduce workloadPackaging automatic controlPackaging fruits/vegetablesEngineeringWorkload

The invention discloses an automatic apple packaging machine which comprises an operating platform, wherein landing legs are connected with four corners of the operating platform; universal wheels are mounted below the landing legs; transmission idler wheels are mounted on the left side of the interior of the operating platform; middle shafts are mounted in the transmission idler wheels; a packaging cylinder is mounted on the right side of the interior of the operating platform; leakage holes are uniformly formed in the packaging cylinder; a transformation disc is mounted below the packaging cylinder; a packaging bag storage room is connected with a position below the transformation disc; a support rod is mounted on the right side of the packaging cylinder; and a feeding device is connected with the right side of the support rod. According to the automatic apple packaging machine, as the packaging cylinder is arranged, ten apples can be simultaneously packaged, the packaging efficiency is improved, and the workload of a packaging worker is reduced; as the transmission idler wheels are arranged, the packaged apples can be transmitted to a next working procedure, and the carrying quantity of the worker is reduced; as the transformation disc is arranged, a sealed product can be transmitted to transformation idler wheels; and the automatic apple packaging machine is simple and practical and excellent in application prospect.

Owner:CHENGDU JUZHI IND DESIGN

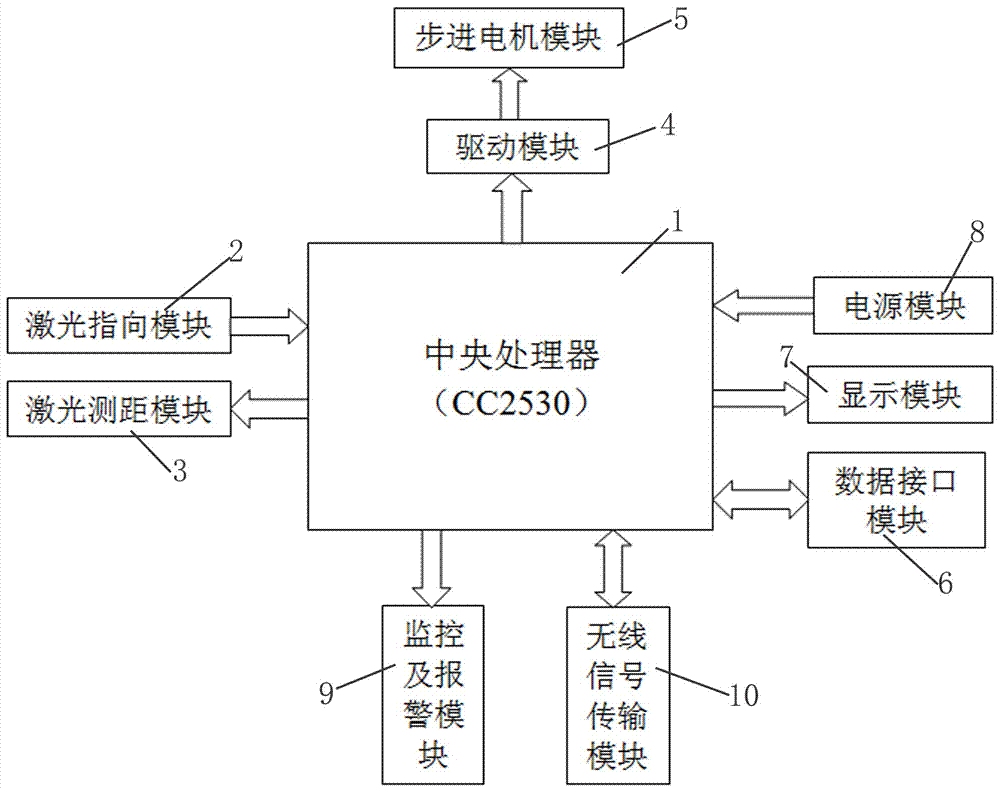

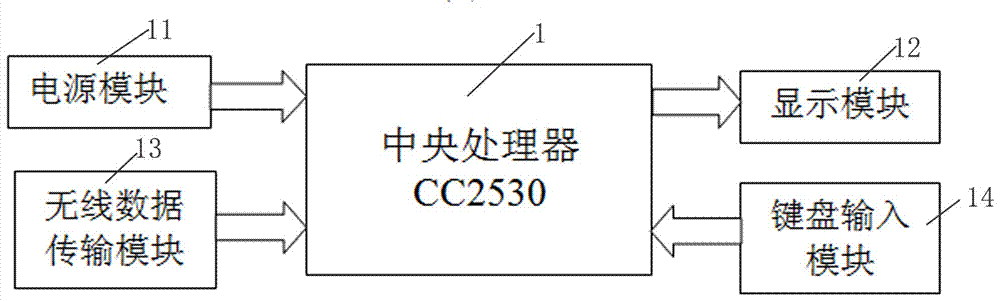

Tunnel advanced detection monitoring alarming method and apparatus based on laser range finding

InactiveCN107329143ASimple systemEasy to operateElectromagnetic wave reradiationAutomatic controlDistance parameter

The invention relates to the technical field of automatic control, specifically to a tunnel advanced detection monitoring alarming method and apparatus based on laser range finding. The method includes the steps of a, preparation step including setting tunnel advanced water probing safety driving distance, sending a signal for adjusting the angle of a laser range finder, and aligning the laser range finder with a measurement target, b, starting step including receiving the properly adjusted signal of the laser range finder, and starting and stopping the laser range finder, c, determination step including receiving the actual distance parameter measured by the laser range finder, comparing the actual distance parameter with the tunnel advanced water probing safety driving distance set in step a, and determining whether to sent an alarm signal according to the comparison result, giving off an alarm signal when the measured distance parameter is smaller than the tunnel advanced water probing safety driving distance set in step a and locking the power supply of the tunnel driving working face, and d, information storage step including measuring, recording and storing the tunnel drilling footage of each working shift, each day and each month.

Owner:SHANXI COKING COAL GROUP

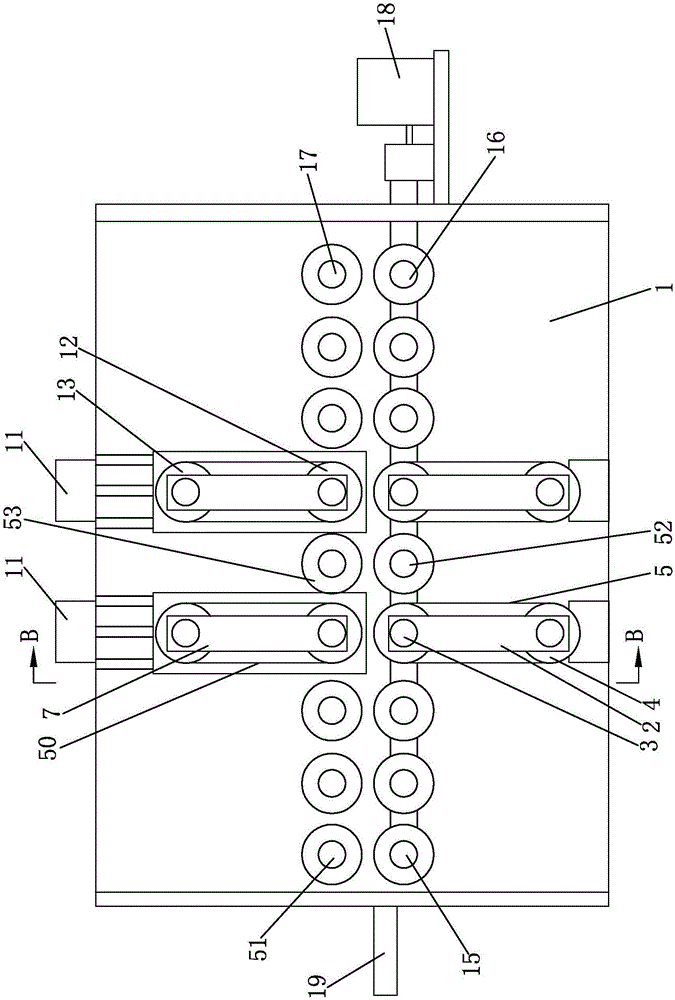

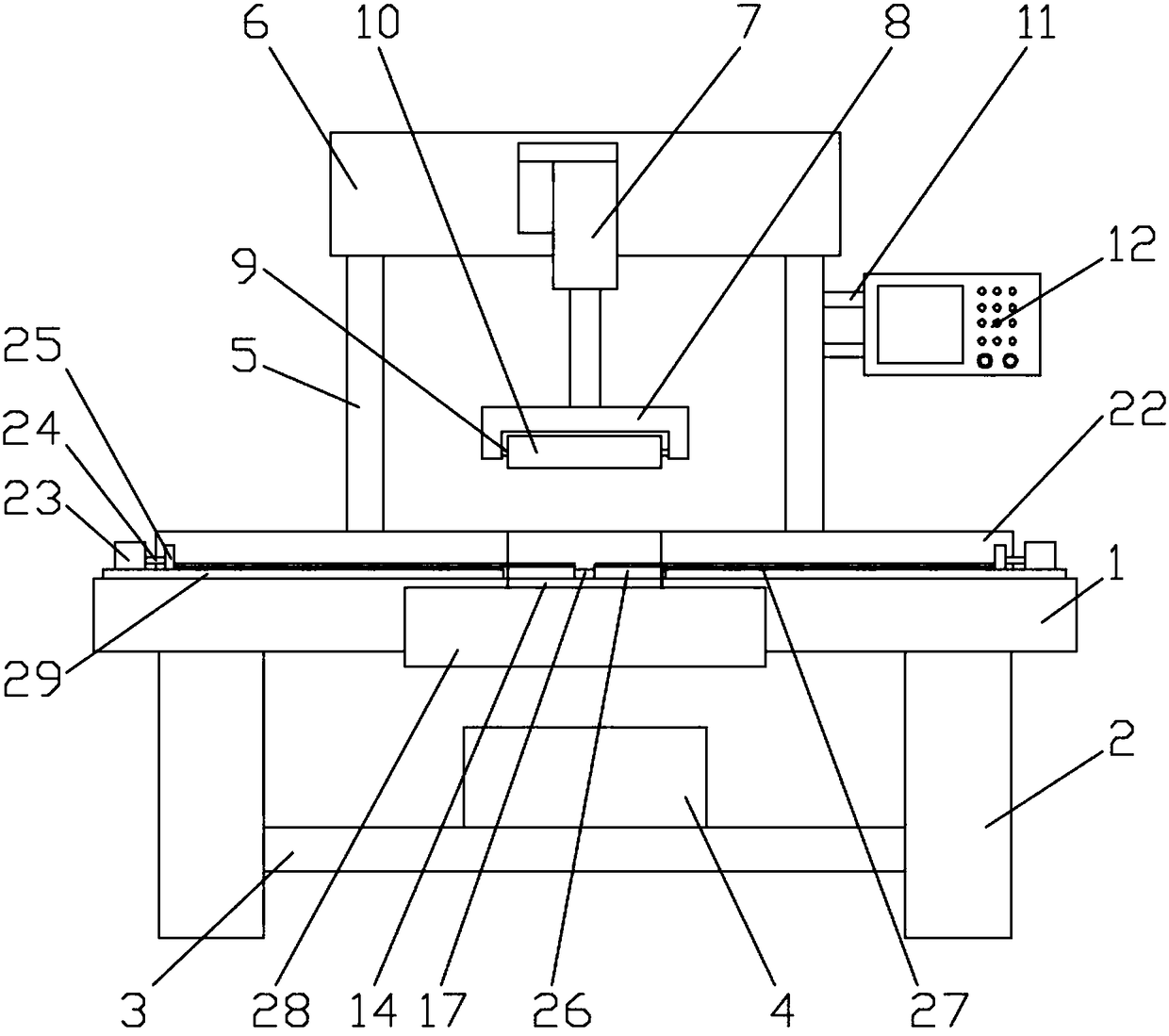

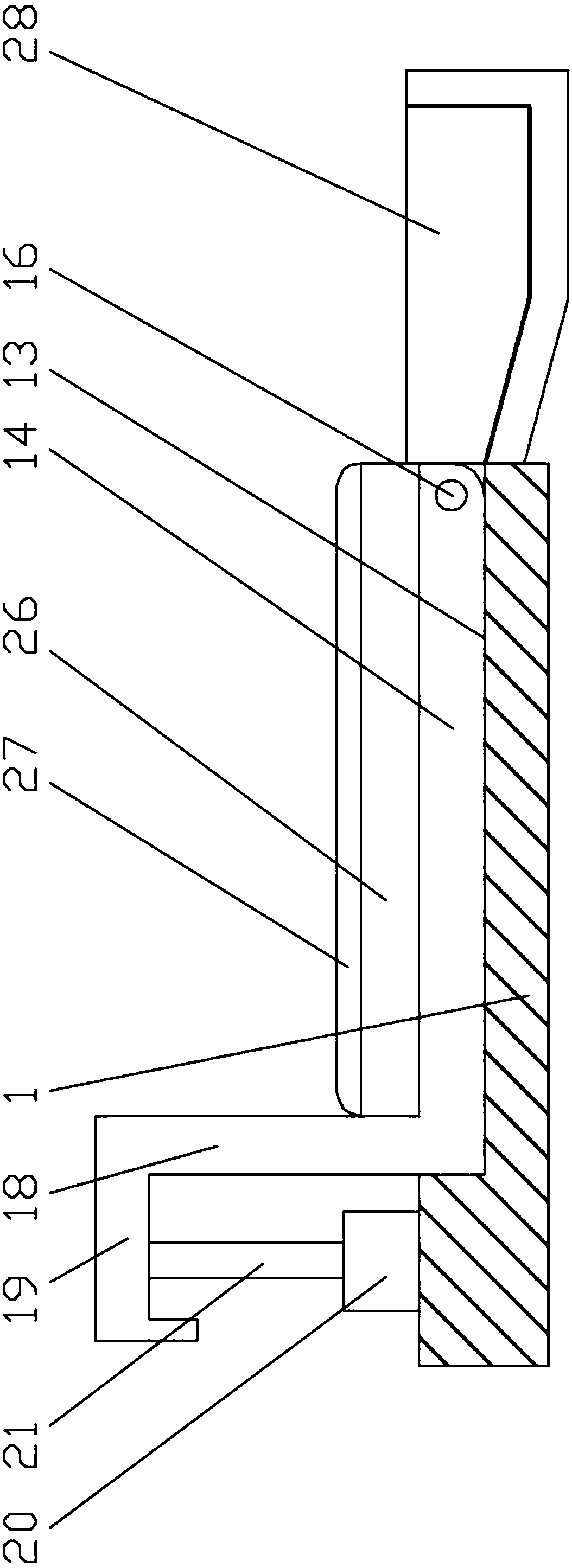

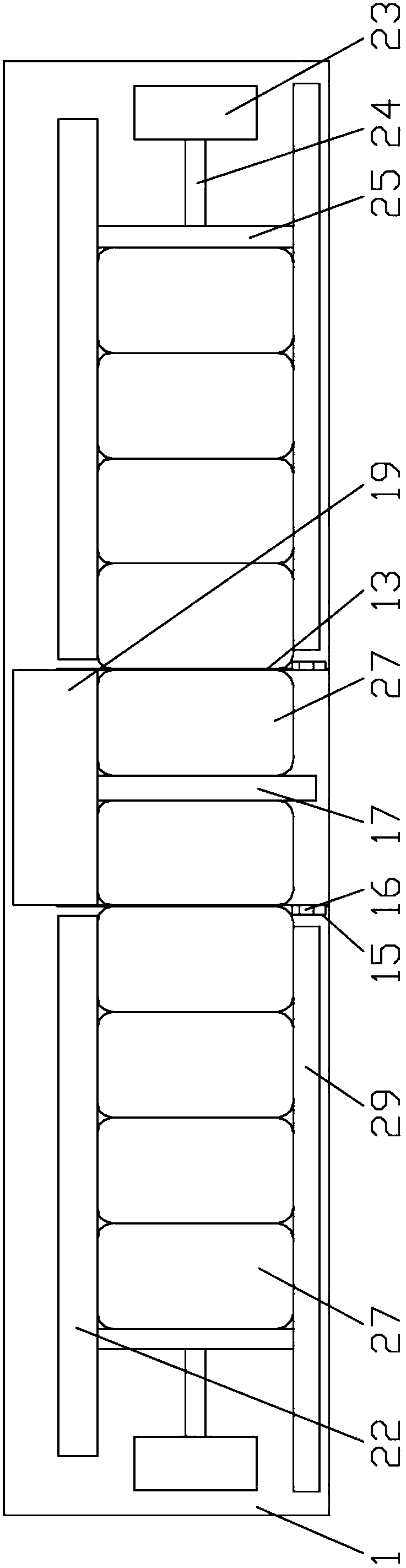

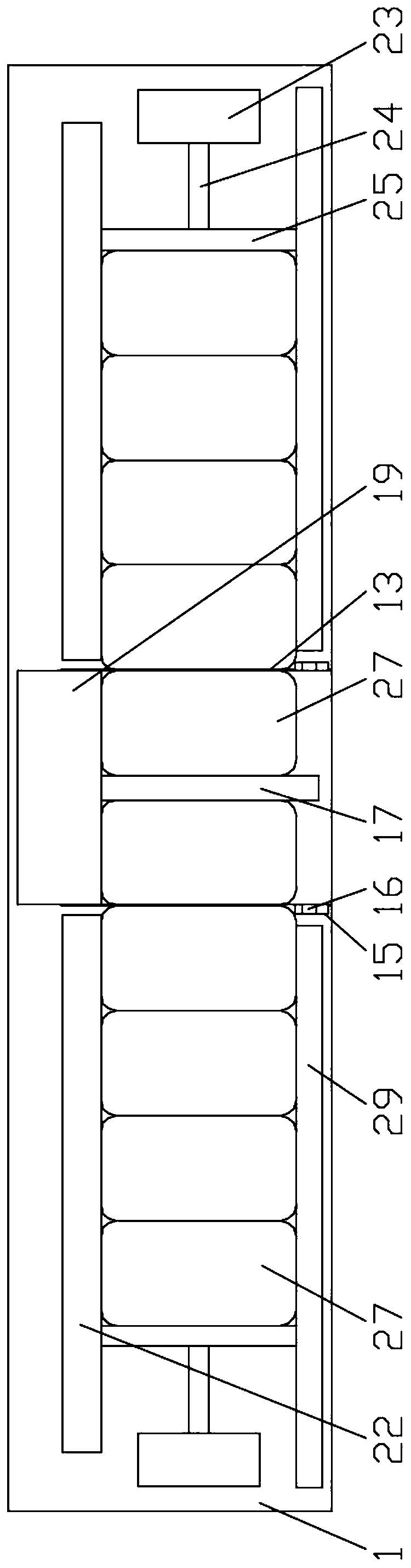

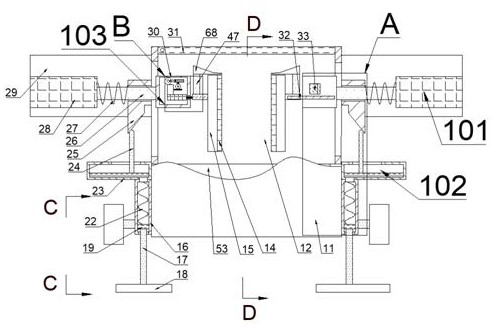

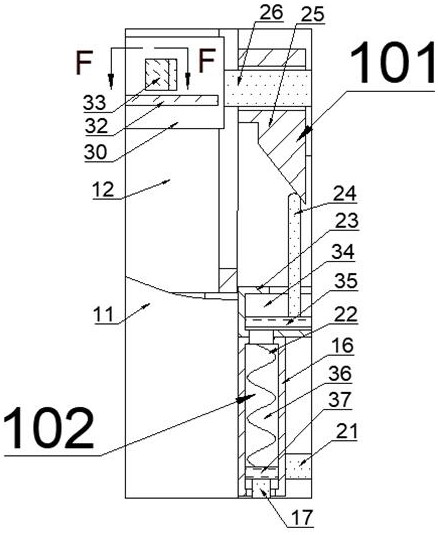

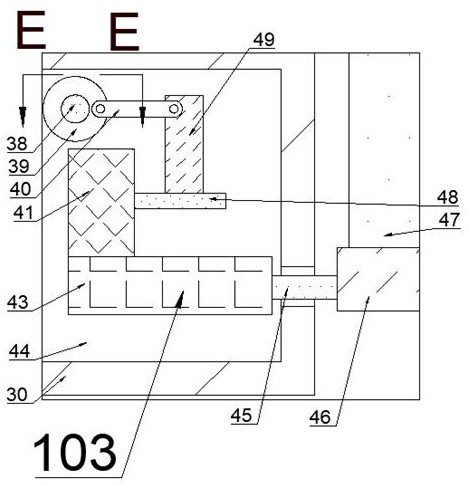

Mobile phone assembly machine

The invention discloses a mobile phone assembly machine. The mobile phone assembly machine comprises a stand; support legs are arranged at four corners of the lower surface of the stand; workers set alifting travel of a push rod type electric lifting column and the pressure to the surface of a back cover of a mobile phone through a numerical control system; a lifting end of the push rod type electric lifting column is descended to enable a pressing plate to press the back cover of the mobile phone to guarantee the buckling effect; the assembly work of two mobile phones can be synchronously finished at each time, so that the working efficiency is improved, and the assembly time is saved; after assembly is finished, a first extension rod is elongated to push a horizontal plate to upwards move, so that an assembly plate is inclined, and the assembled mobile phones slide into a discharge basket; after discharge is finished, a second extension driving motor drives a second extension rod toelongate by a certain distance, so that a main body of the mobile phone nearest the assembly plate moves to the upper side of the assembly plate for assembly; and materials are synchronously fed on two sides, so that the assembly work is automatically finished, the workload of workers on this post is saved, the assembly quality is guaranteed, and the yield of defective products is reduced.

Owner:四川永润欣科技有限公司

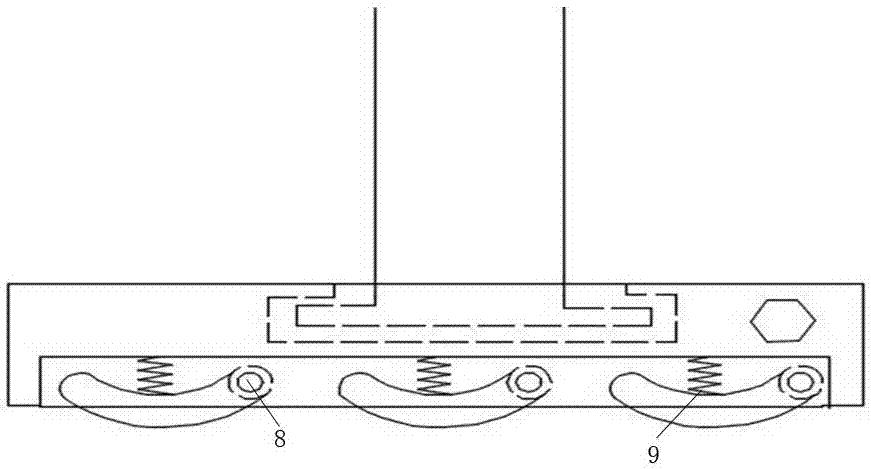

Mine conveyor belt sweeping device

The invention discloses a mine conveyor belt sweeping device. A sweeping belt, a pair of clamping plates, at least one supporting rod, a support and at least one spring are included, wherein the sweeping belt is blocky and is obliquely and upwardly arranged; the free end of the sweeping belt is in contact with a belt of a conveyor; the clamping plates are arranged in parallel, located on the two sides of the sweeping belt, and are used for clamping the sweeping belt; the supporting rod is obliquely and upwardly arranged, and the upper end of the supporting rod is in threaded connection with the clamping plates; the support is vertically arranged below the supporting rod, and is in threaded connection with the middle portion of the supporting rod; the spring is fixedly and vertically arranged below the supporting rod, and is in threaded connection with the lower end of the supporting rod; the spring is used for pulling the lower end of the supporting rod, so that the supporting rod rotates upwards with the middle portion of the supporting rod as a supporting point, then the upper end of the supporting rod drives the sweeping belt to apply force upwards, the sweeping belt is forced to be attached to the belt of the conveyor, and then coal slag remaining on the belt of the conveyor is wiped out. The mine conveyor belt sweeping device guarantees that a whole belt lane is clean andsanitary, lots of falling coal is reduced, the workload of a driver on the station and a maintaining bench worker is reduced, and manpower and material resources are saved.

Owner:SHAANXI SHAANXI COAL HANCHENG MINING CO LTD

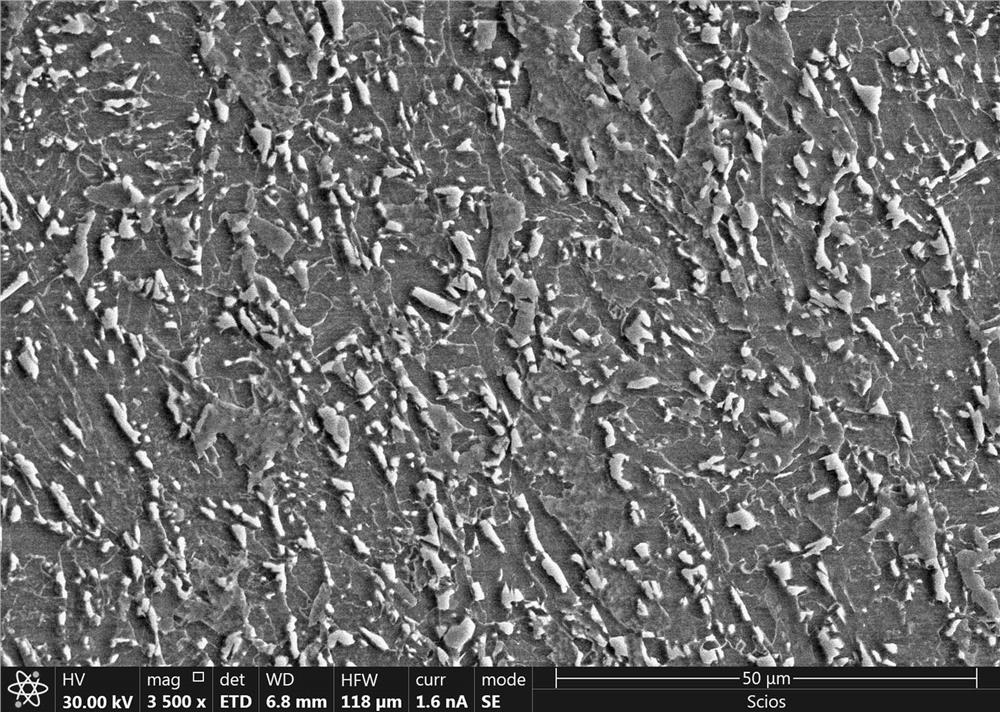

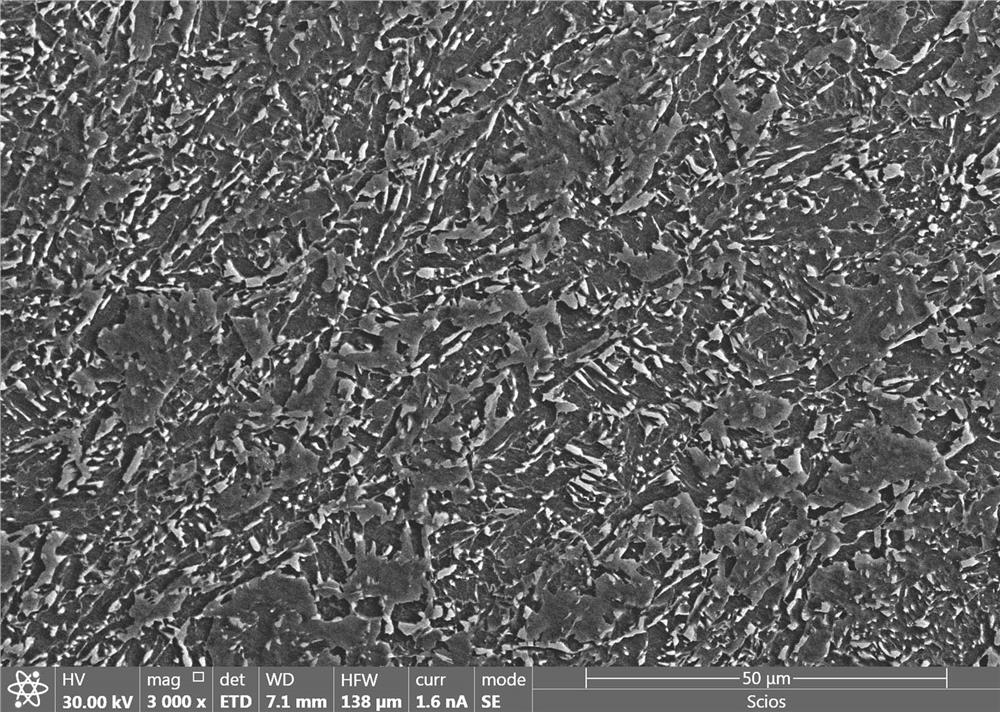

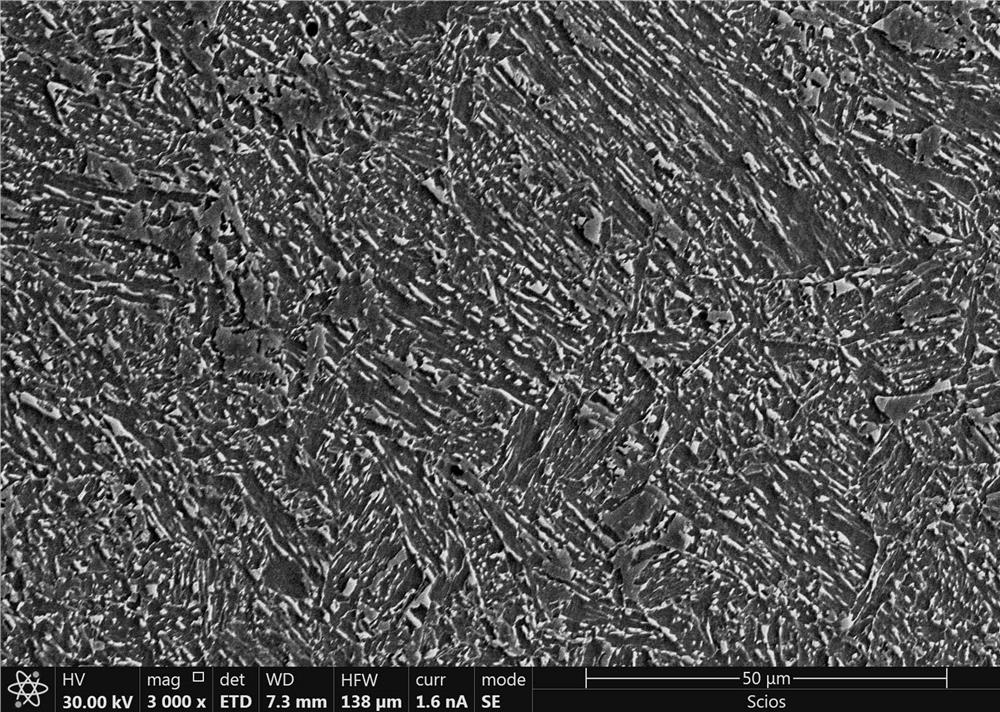

A kind of 500mpa grade strong and tough weathering bridge steel and preparation method thereof

ActiveCN111057945BGuaranteed welding effectGuaranteed toughnessRefining (metallurgy)Weather resistance

The invention relates to a 500MPa grade strong and tough weather-resistant bridge steel, which belongs to the field of metallurgy technology, and its chemical composition is: C 0.04-0.06, Si 0.25-0.35, Mn 1.20-1.30, Cr 0.4-0.5, Ni 0.30-0.40, Cu 0.27‑0.37, Mo 0.2‑0.7, P<0.015, S<0.006, Nb 0.020‑0.030, V 0.015‑0.025, Ti 0.007‑0.017, Al 0.015‑0.040, the balance being Fe and unavoidable impurities. Its preparation method includes the steps of smelting into molten iron, refining, vacuum treatment, protective continuous casting, and thermomechanical rolling. Through the design of components and processes, acicular ferrite + bainitic ferrite + M-A components are obtained. Composite structure to achieve a good match of high strength, toughness, weather resistance and weldability.

Owner:YANSHAN UNIV

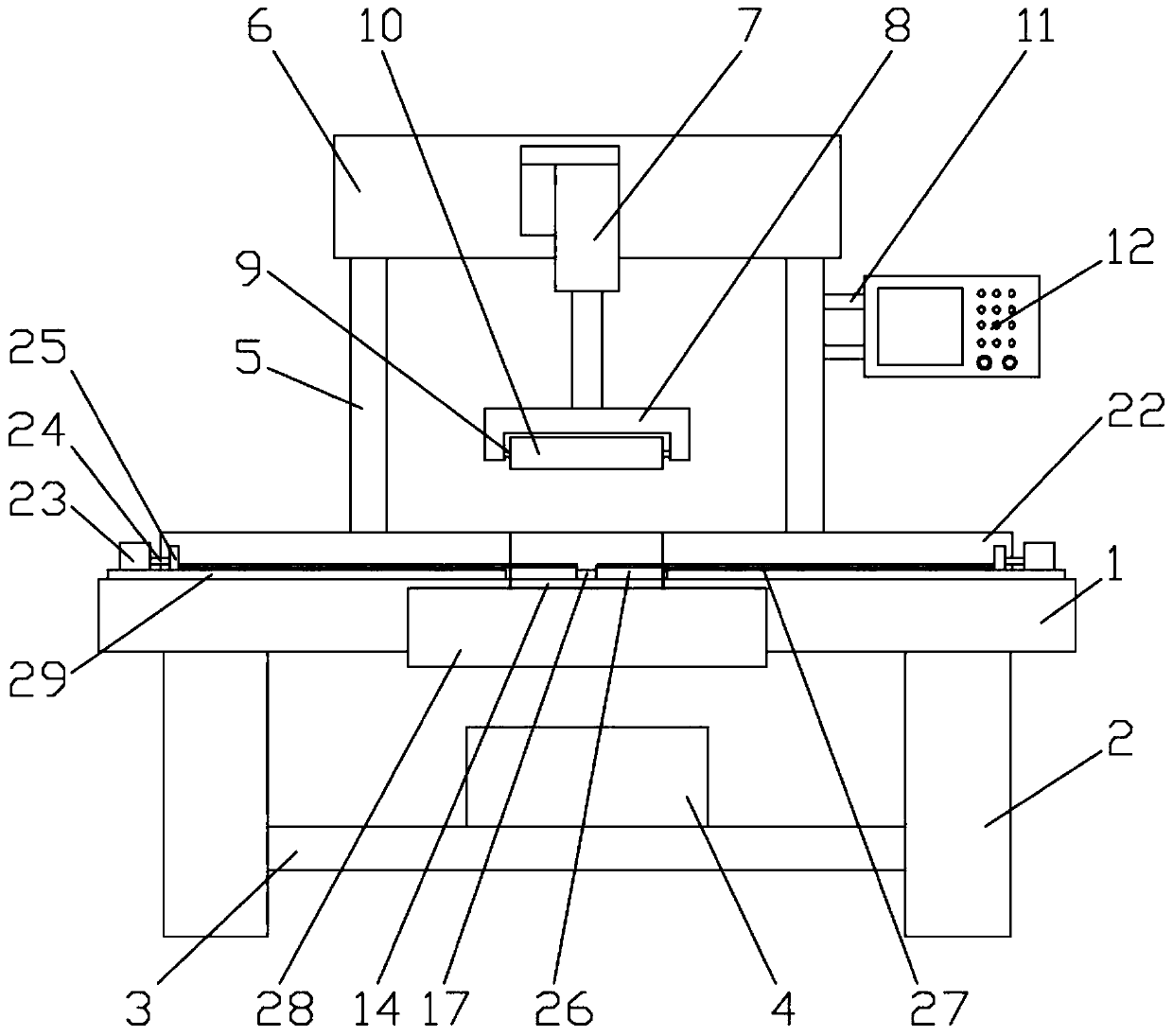

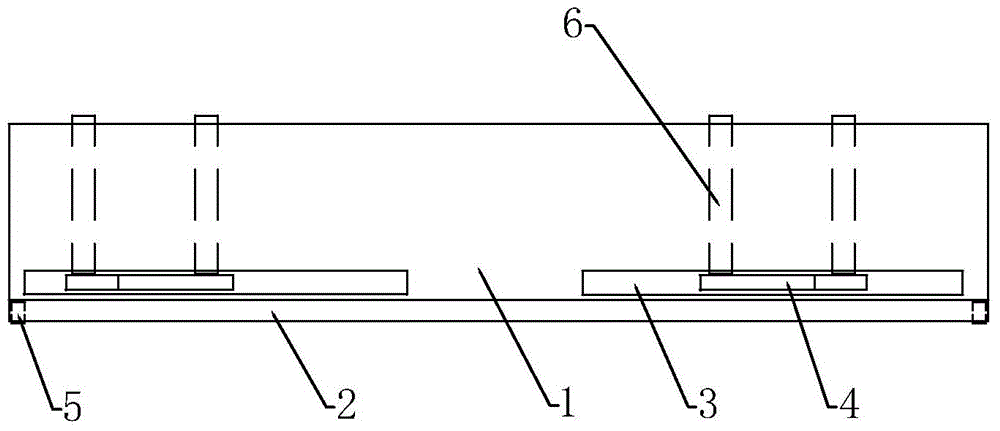

A mobile phone assembly machine

ActiveCN108381456BGuaranteed workloadReduce workloadMetal working apparatusMetal-working hand toolsElectric machineryEngineering

The invention discloses a mobile phone assembly machine. The mobile phone assembly machine comprises a stand; support legs are arranged at four corners of the lower surface of the stand; workers set alifting travel of a push rod type electric lifting column and the pressure to the surface of a back cover of a mobile phone through a numerical control system; a lifting end of the push rod type electric lifting column is descended to enable a pressing plate to press the back cover of the mobile phone to guarantee the buckling effect; the assembly work of two mobile phones can be synchronously finished at each time, so that the working efficiency is improved, and the assembly time is saved; after assembly is finished, a first extension rod is elongated to push a horizontal plate to upwards move, so that an assembly plate is inclined, and the assembled mobile phones slide into a discharge basket; after discharge is finished, a second extension driving motor drives a second extension rod toelongate by a certain distance, so that a main body of the mobile phone nearest the assembly plate moves to the upper side of the assembly plate for assembly; and materials are synchronously fed on two sides, so that the assembly work is automatically finished, the workload of workers on this post is saved, the assembly quality is guaranteed, and the yield of defective products is reduced.

Owner:四川永润欣科技有限公司

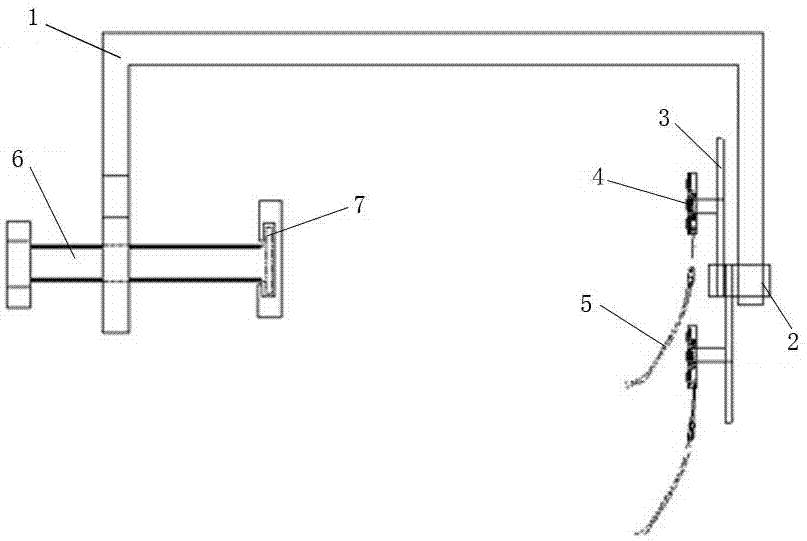

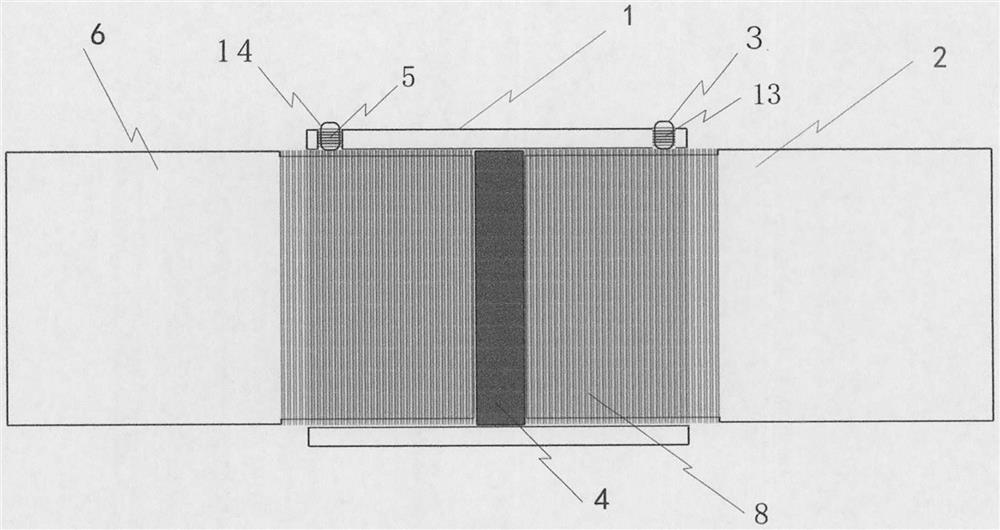

Test clamp of 10kV switch cabinet current transformer

PendingCN106990377AReduce test wiring timesIncrease contact areaElectrical measurementsPower flowElectrical and Electronics engineering

The invention relates to a test clamp of a 10kV switch cabinet current transformer. The test clamp comprises a connecting lever. A double-arm type wire clamp is fixed on the front end of the connecting lever. A contact is arranged on the head of the wire clamp and is connected with a test cable. A screw handle is installed on the back end of the connecting lever. The test clamp is of an inverted U-type structure. The U-type connecting lever is molded through the highly insulative and easy-to-process bakelite in an integrated manner, so the U-type connecting lever has certain mechanical intensity and the insulation characteristic. The double-arm type wire clamp on the front end of the connecting lever is capable of simultaneously clamping two primary wiring ends of the current transformer, so wiring testing frequency is reduced. The wire clamp is equipped of multiple rows of copper contacts. One end of the wire clamp is fixed on a moving shaft and the other end is supported by the spring. Thus, contact area with a primary wiring plate of the current transformer is increased; the contact is good, it is ensured that heavy current can pass and fastening performance of the wire clamp is improved; and the test clamp can be reliably fixed and prevented from falling off.

Owner:YINGKOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

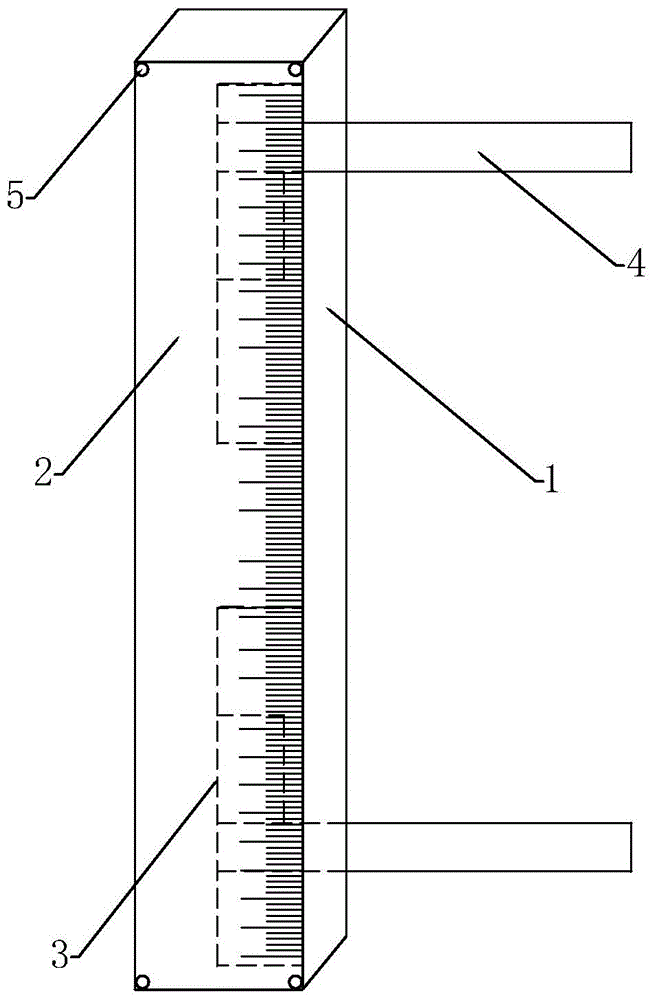

Polycrystal minority carrier lifetime detection back lineation measuring tool

InactiveCN104972450AQuality assuranceLower requirementOther workshop equipmentWorkloadMechanical engineering

The invention relates to a polycrystal minority carrier lifetime detection back lineation measuring tool. The polycrystal minority carrier lifetime detection back lineation measuring tool comprises a wood base, wherein the front end of the wood base is connected with a dividing ruler bonded with the wood base; grooves are respectively formed in one side of the front part of the wood base corresponding to the upper and lower ends of the dividing ruler; right-angled rulers are respectively arranged in the grooves in a vertical sliding manner; and first fastening screws for fixing the right-angled rulers are respectively arranged at the two ends of the bottom edges of the right-angled rulers corresponding to the back part of the wood base. The polycrystal minority carrier lifetime detection back lineation measuring tool has the advantages of reasonable structure, convenience, practicability, simple operation, time and labor saving, precise lineation, low workload and capability of improving the working efficiency.

Owner:SHANDONG DAHAI NEW ENERGY DEV

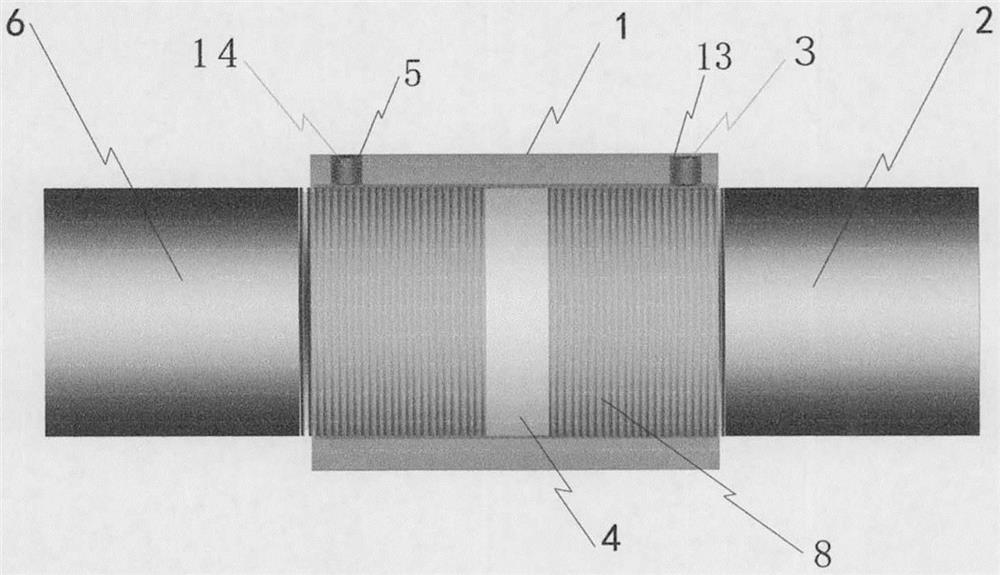

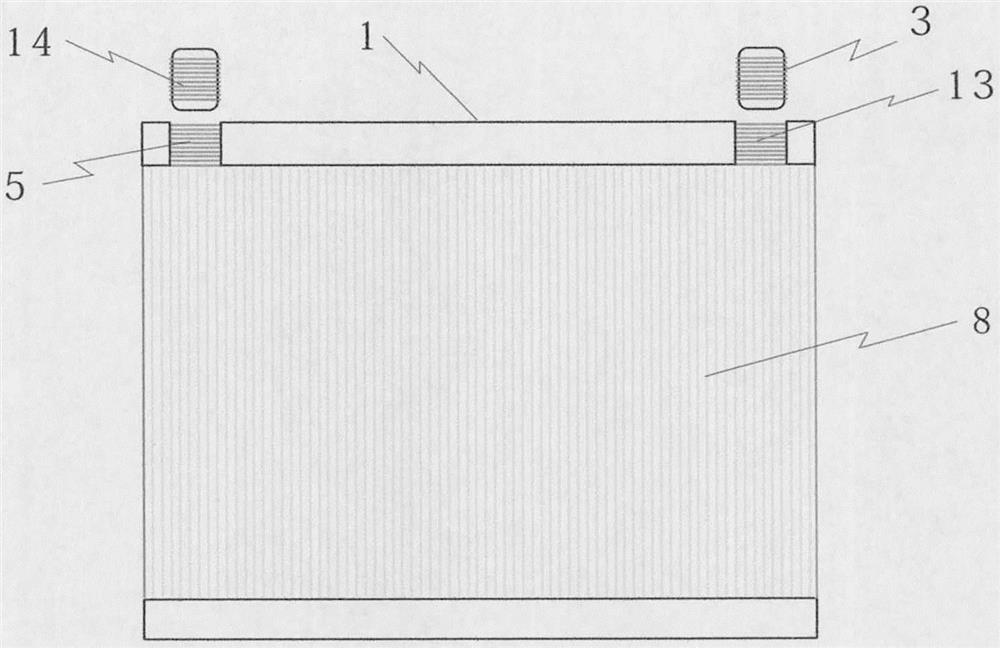

Pipeline thread airtight connection method and device

PendingCN112833265AImprove practicalityEasy to operateScrew threaded jointsEmbedded systemThreaded pipe

The defects that in the pipeline installation process, time cost, material cost and labor cost are high, pipeline sealing reliability is poor, and pipelines made of different materials can only be installed through different installation methods are mainly overcome. A pipeline thread airtight connection method is achieved by a pipeline thread airtight connection device and is completed by combining the pipeline thread airtight connection device, sealing gaskets, external thread pipes and set screws. The pipeline thread airtight connection method is characterized in that when the external thread pipes are screwed with the pipeline thread airtight connection device, the external thread pipes which are oppositely screwed into the pipeline thread airtight connection device are in airtight butt joint through the sealing gaskets, or the external thread pipes are in airtight connection with the pipeline thread airtight connection device. The pipeline thread airtight connection method is further characterized in that the external thread pipes and the pipeline thread airtight connection device are fastened together through the set screws, so that the long-term effect of pipeline airtight connection is ensured. The technical scheme is suitable for installation of water supply and heating pipelines of industry, agriculture, commerce, buildings, municipal administration, life, indoor parts and outdoor parts and is very wide in application.

Owner:黄锦林

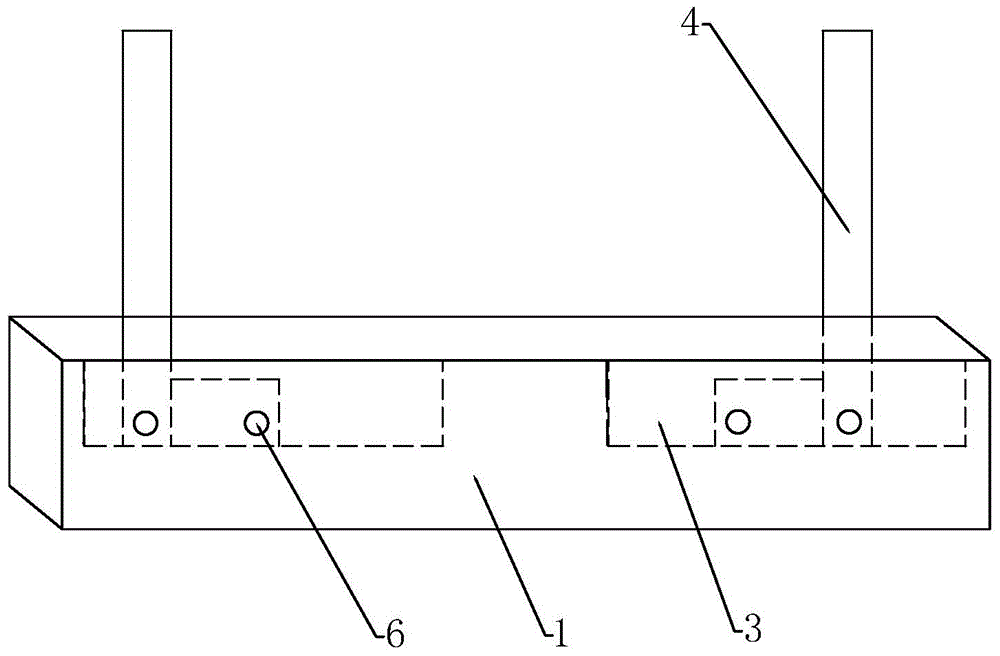

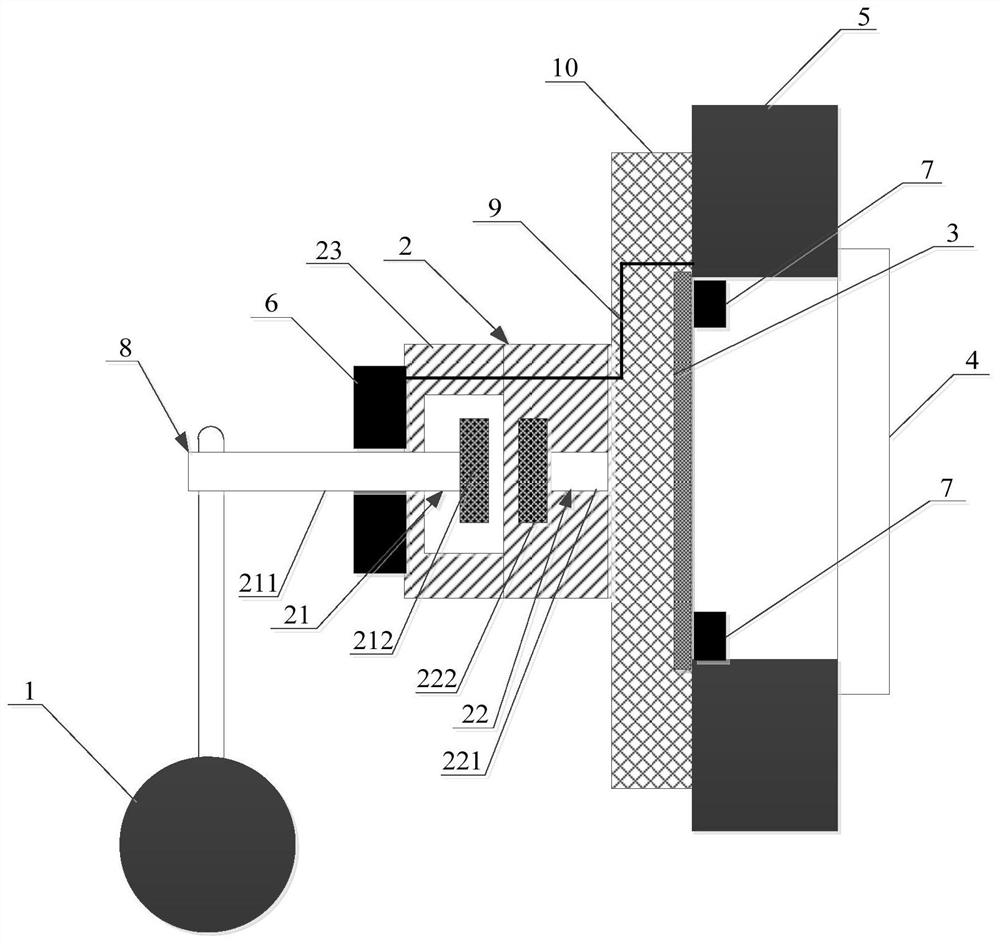

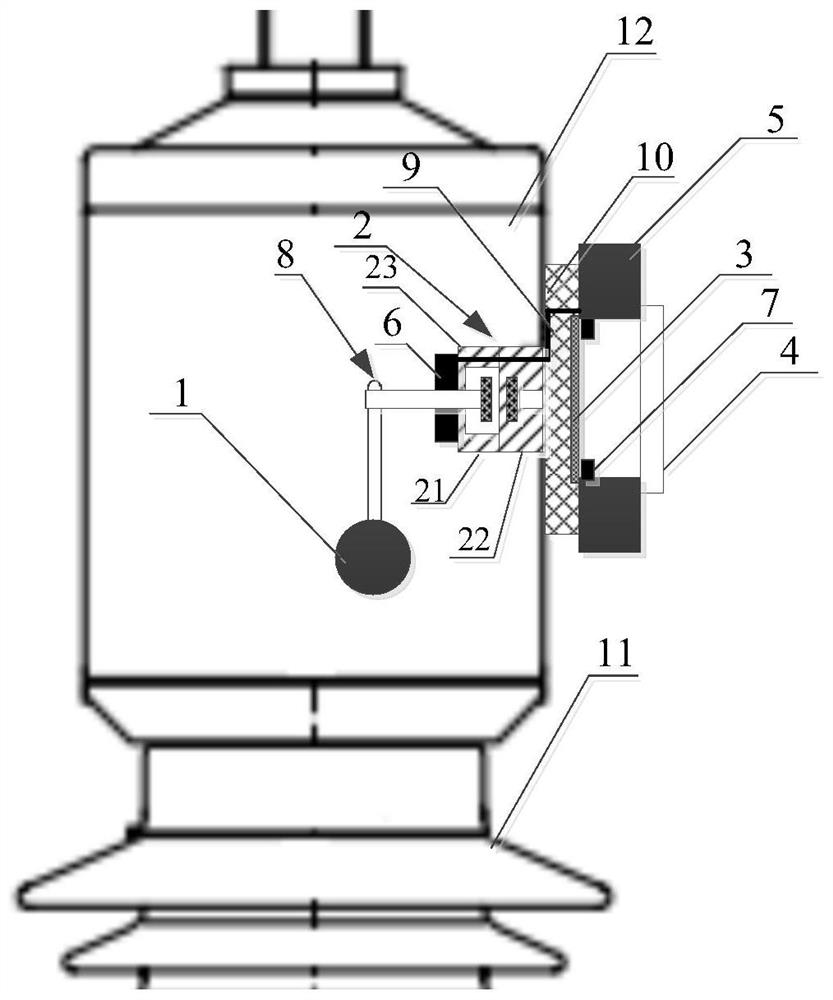

An Intelligent Oil Level Gauge for Transformer Bushing

ActiveCN108871491BGuaranteed accuracyGuaranteed workloadLevel indicators by floatsCommunication unitData information

The invention provides an intelligent oil level gauge for a transformer bushing, comprising: a measuring piece, a transmission mechanism, a pointer dial, a protective cover and a controller; a pressure temperature sensor is arranged on the surface of the transmission mechanism, and an oil level measurement sensor is arranged on the surface of the pointer dial , the controller sends each of the acquired data to an external monitoring device and sends an alarm signal to the monitoring device when any one of the data is abnormal. The invention uses the magnetic field force between the pointer dial and the transmission mechanism to feed back the displacement change of the measuring piece as the oil level changes to the pointer dial, and automatically reads the oil level information through the oil level measuring sensor arranged on the outer surface of the pointer dial , to ensure the accuracy of oil level measurement, and use the communication unit in the controller to transmit the data information obtained by the oil level measurement sensor to the external monitoring equipment, which reduces the cost of on-site operation and maintenance and provides the work of on-site operation and maintenance personnel It provides great convenience and ensures the safe and reliable operation of the power grid.

Owner:CHINA ELECTRIC POWER RES INST +2

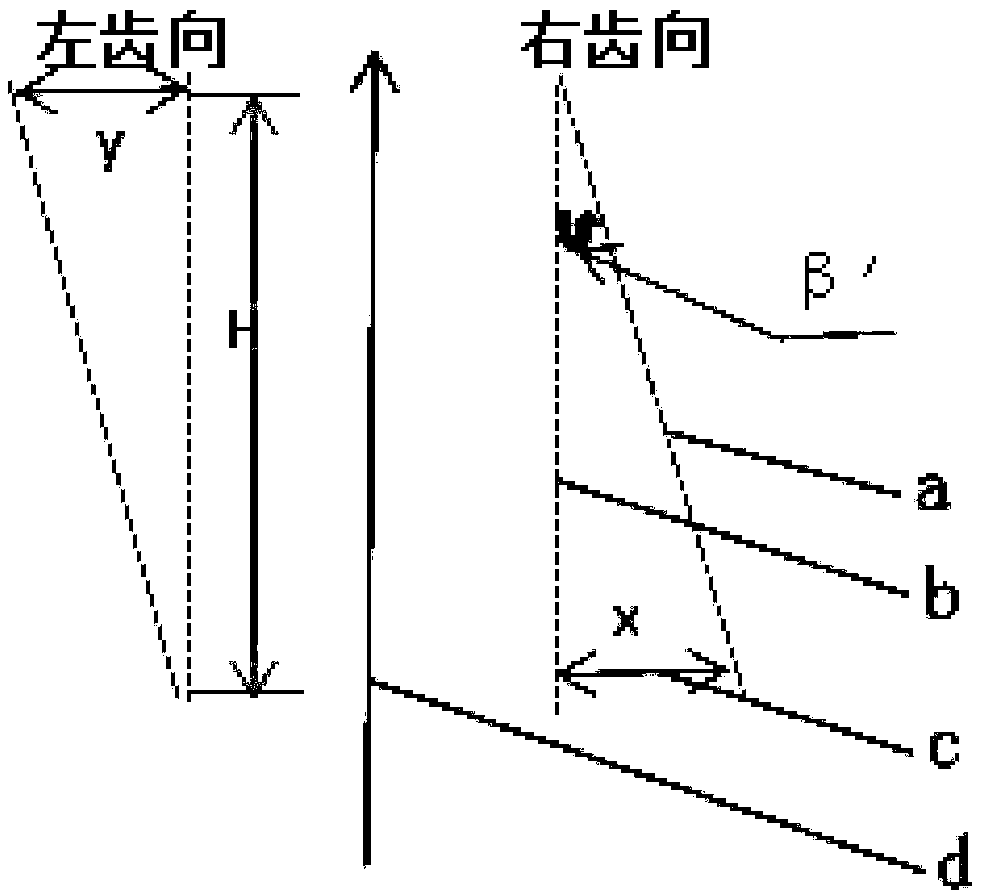

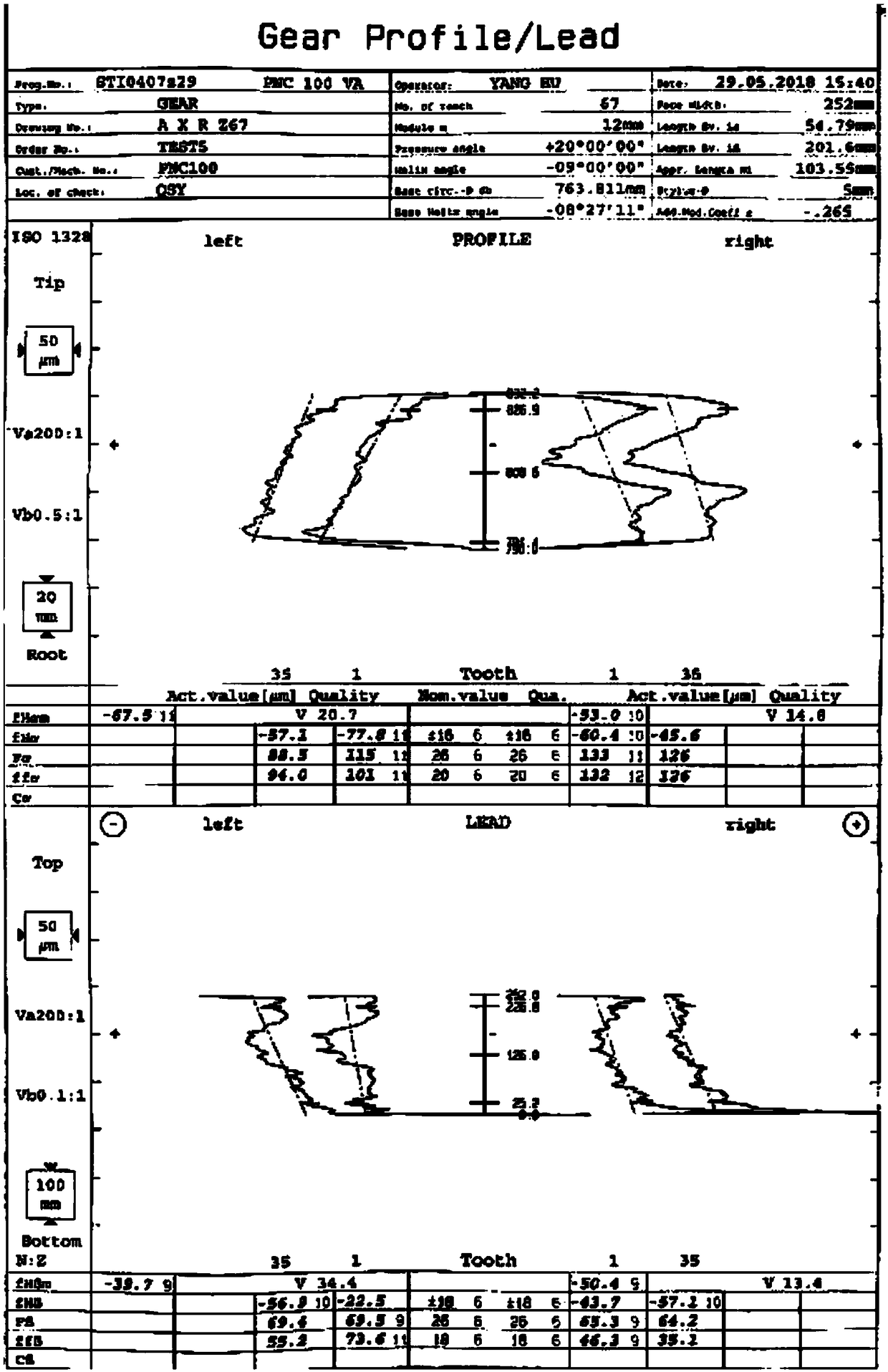

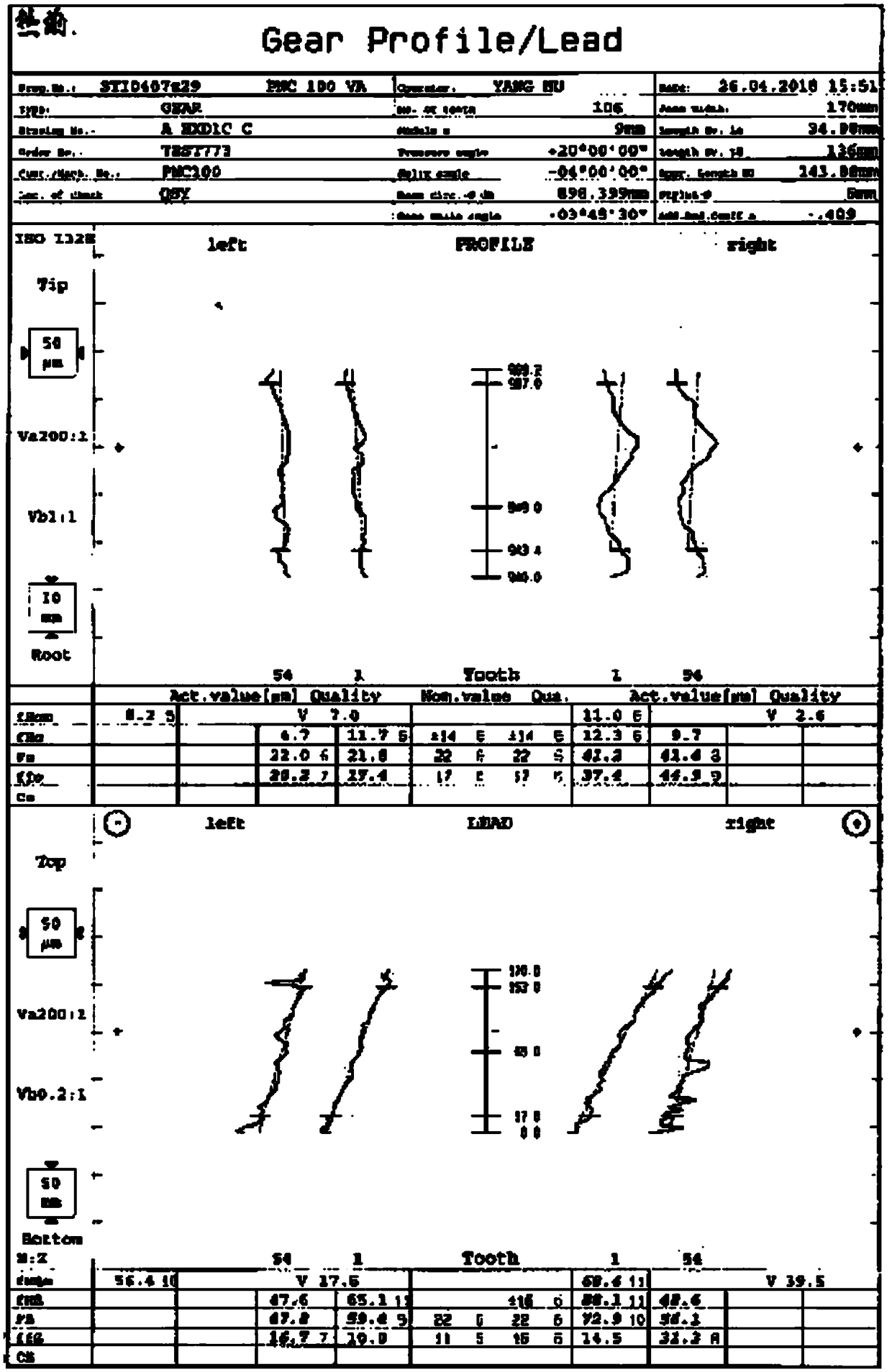

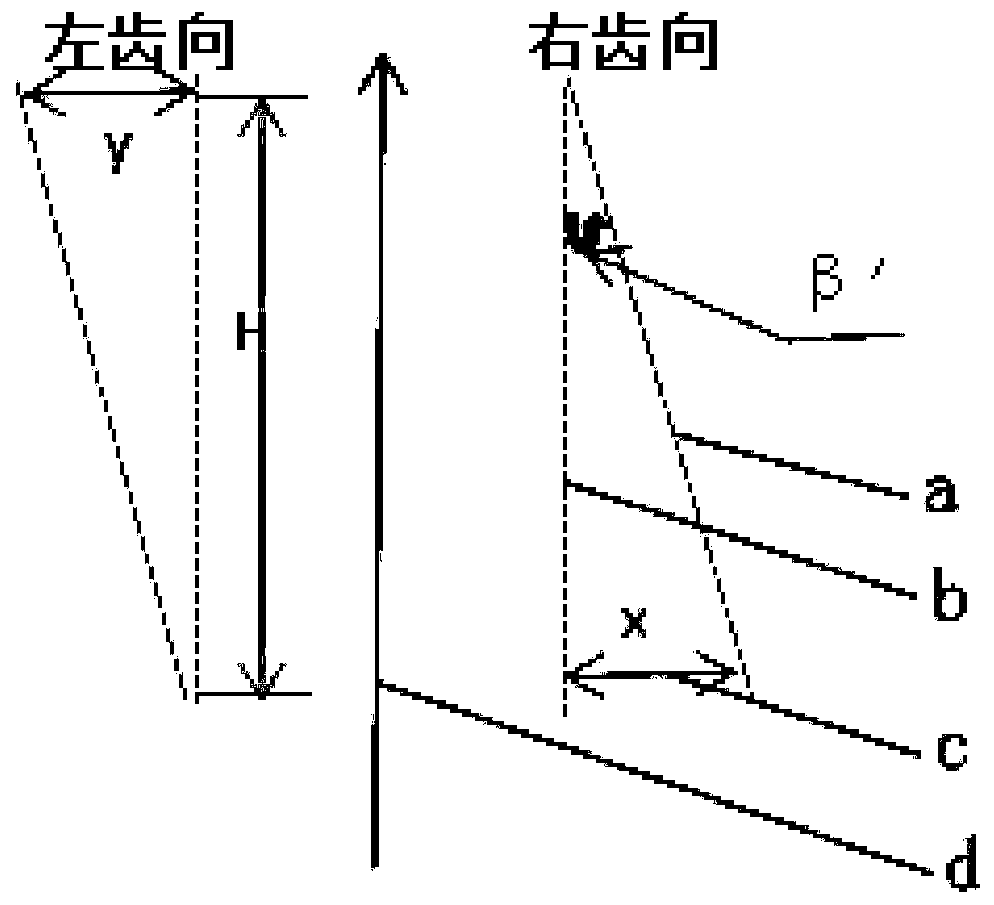

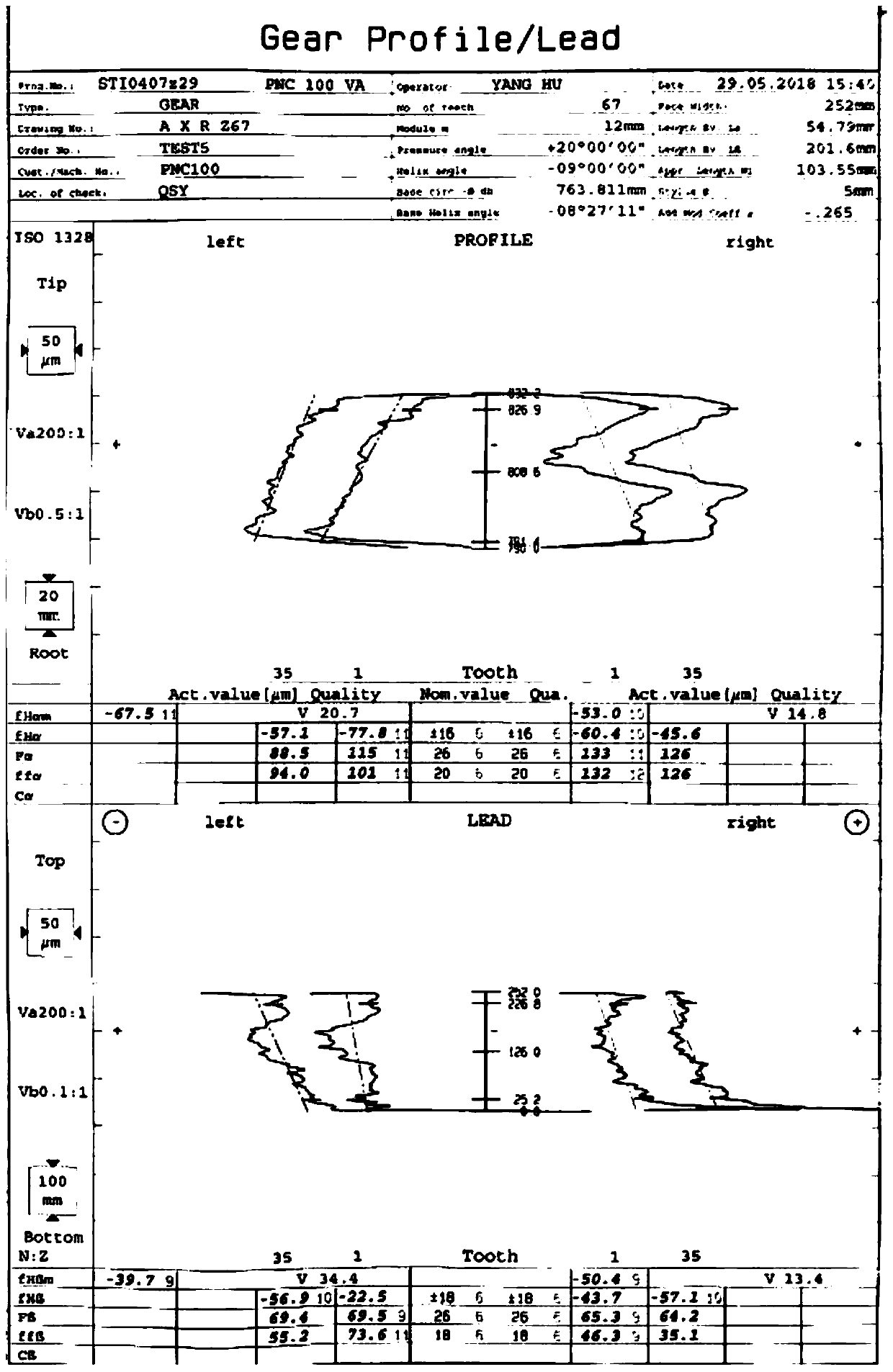

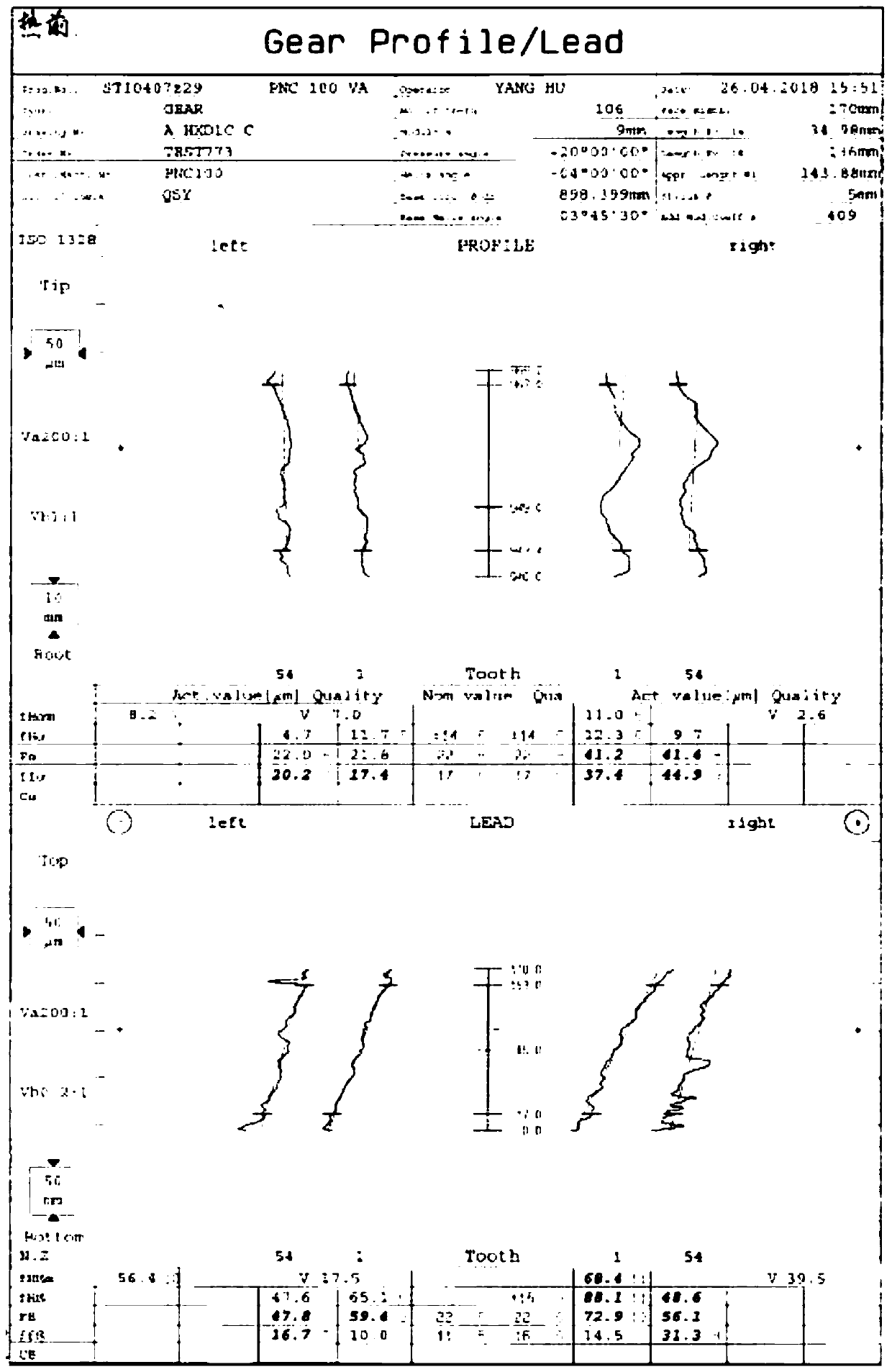

Processing method for reducing carburizing and quenching deformation of helical gear

InactiveCN109136517AReduce defective rateReduce the amount of cuttingSolid state diffusion coatingFurnace typesHobbingHelix angle

The invention provides a processing method for reducing the carburizing and quenching deformation of a helical gear. The method includes the following steps that a helix angle variable beta' for reverse deformation is reserved for helix gear machining before carburizing and quenching of the gear, that is to say, the machining helix angle of the helical gear before the carburizing and quenching process is equal to a value obtained by subtracting the helix angle margin beta' for revere deformation on the basis of a design helix angle beta; the helix angle variable beta' is set according to the design helix angle beta of the gear, the tooth-direction effective analysis range H of the gear and a tooth-direction heat treatment deformation amount M in the gear hobbing or gear shaping process. Inthe method, based on the reverse deformation rule, the distortion generated by heat treatment is offset by the helix angle variable. The helix angle meets process requirements after carburizing and quenching of the gear, it is guranateed that the upper and lower section deformation will not be out of tolerance after carburizing and quenching in subsequent finish machining of the tooth-direction gear, the workload of subsequent finish machining is reduced, and the cutting amount of a carburized layer is reduced.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

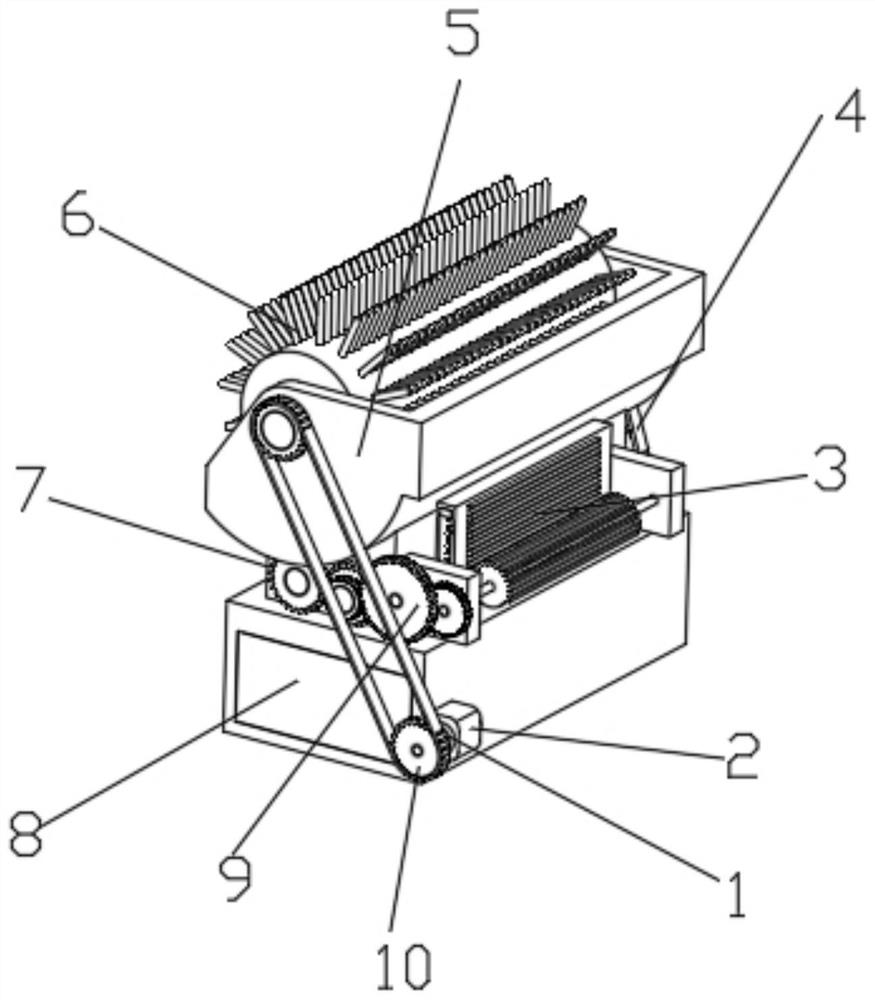

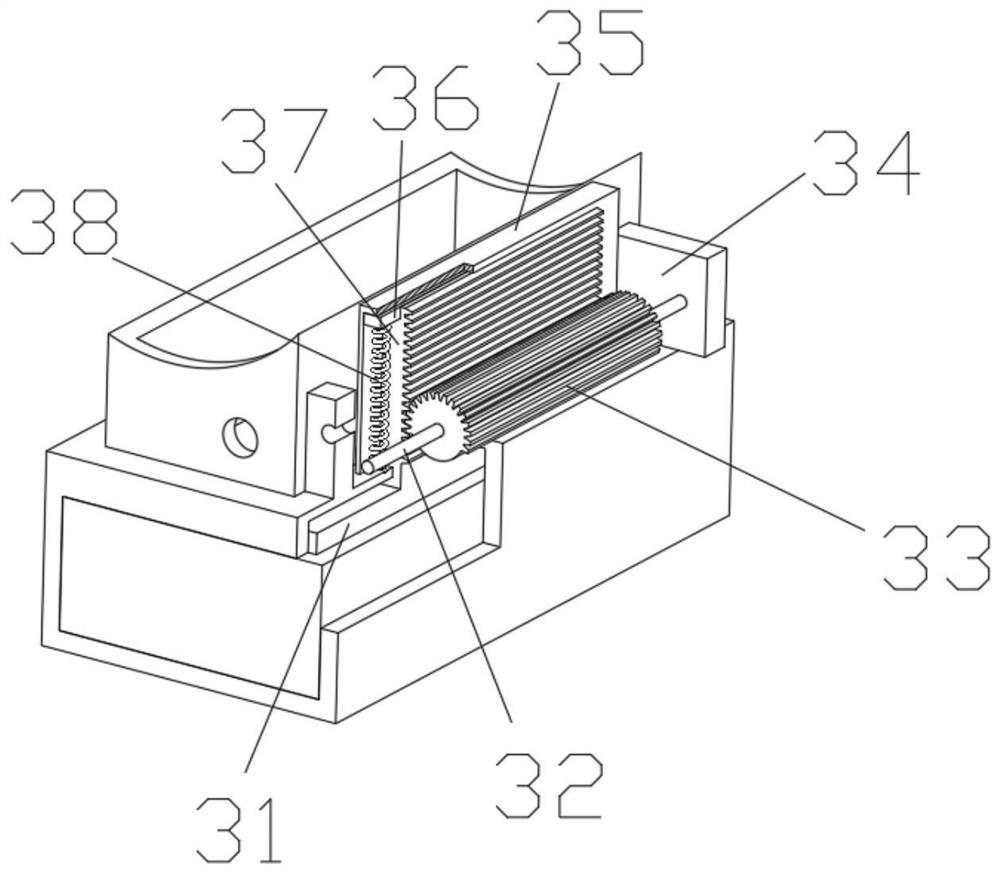

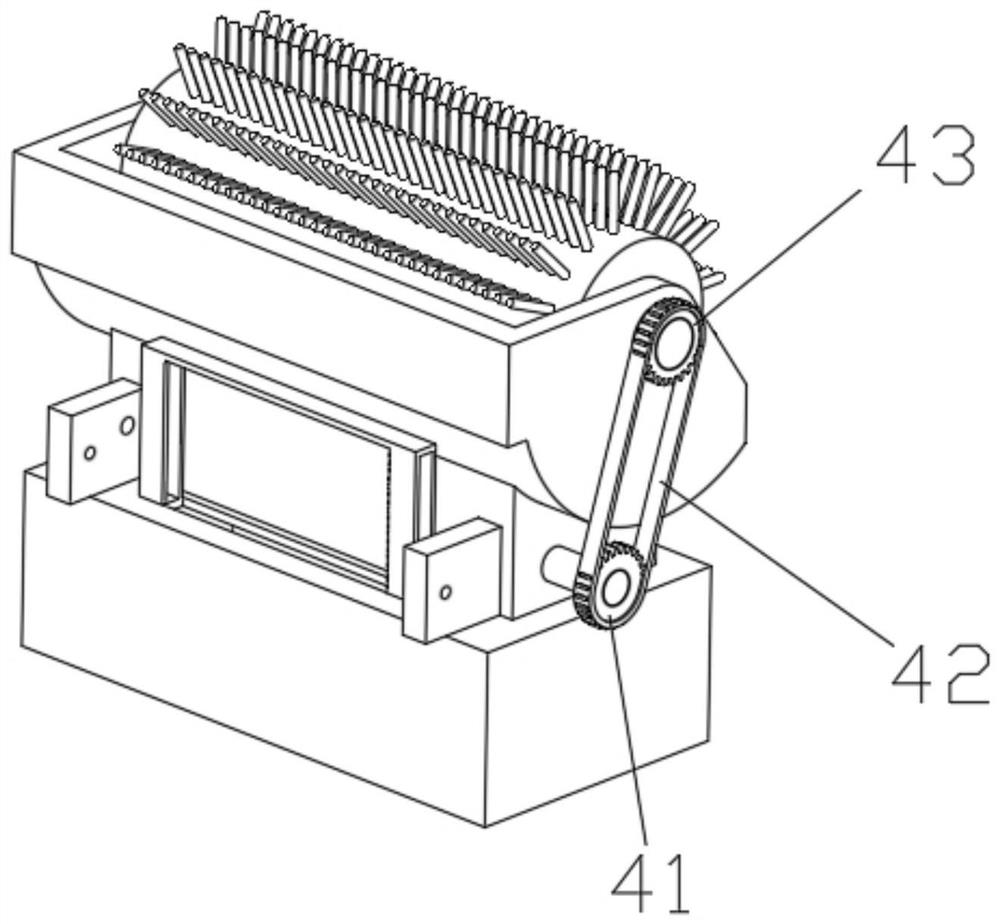

A multifunctional construction equipment cleaning and maintenance equipment

ActiveCN112222027BAffect cleaning effectEasy maintenanceSolid waste managementCleaning using toolsStructural engineeringBrush

The invention discloses a multi-functional construction equipment cleaning and maintenance equipment in the technical field of equipment cleaning equipment. The cleaning mechanism provided in the invention cleans the equipment and parts, and the brush filter comb removes impurities attached to the brush to avoid Impurities attached to the brush affect the subsequent cleaning of the parts. The outer shell and the inner core roller on the cleaning mechanism rotate in the opposite direction, so that the brush is retracted into the outer shell, and the brush is cleaned through the through hole. Surface impurities are removed to ensure the cleanliness of the equipment, so that the equipment can be better maintained and the service life of the equipment is extended. The self-cleaning manual cleaning of the present invention reduces the work burden of workers. The crushing device can crush impurities to avoid blocking the equipment. The impurity compression mechanism provided can regularly compress the impurities falling into the impurity storage tank, thereby greatly improving the storage capacity of the equipment for impurities and facilitating the transportation and treatment of impurities.

Owner:HANGZHOU FUYANG WEIWEN ENVIRONMENTAL PROTECTION TECH CO LTD

Tube truss manufacture process

Owner:河北二十冶建设有限公司

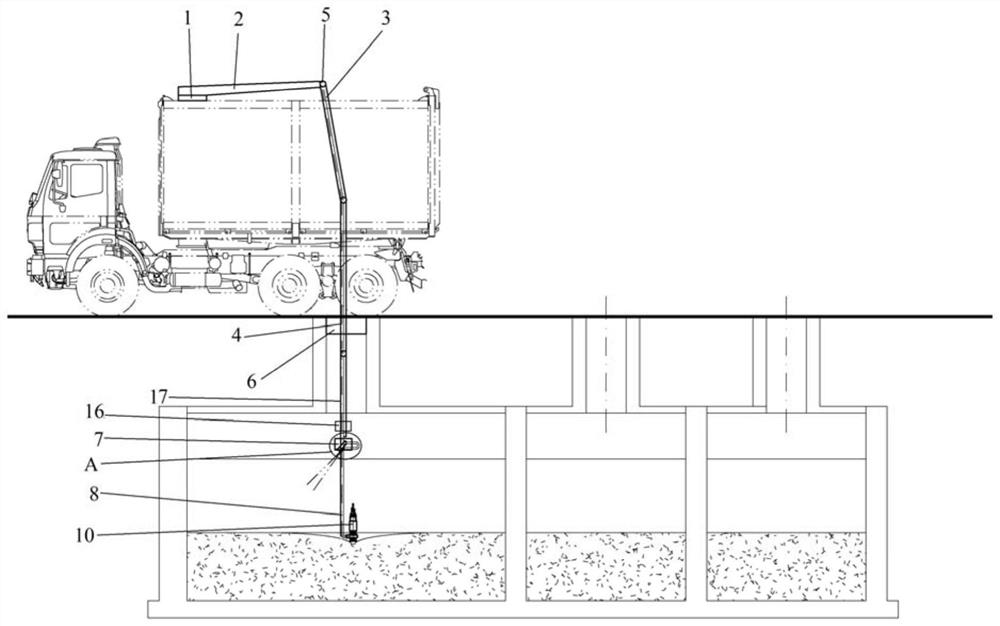

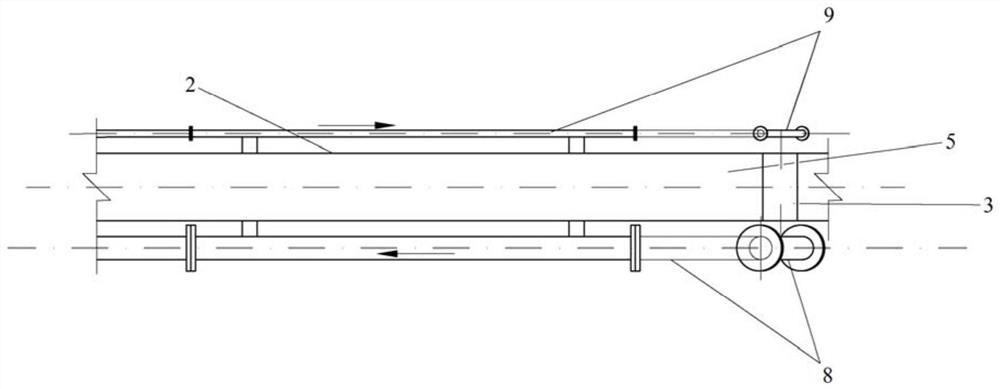

Septic tank sludge treatment vehicle with control arm

PendingCN113802684AAvoid cross flowAvoid cloggingHollow article cleaningClosed circuit television systemsSludgeControl arm

The invention provides a septic tank sludge treatment vehicle with a control arm. The septic tank sludge treatment vehicle at least comprises a vehicle body, a control cabinet, a grid residue presser, a screw press, an electric generator, a power distribution cabinet, a vacuum water tank and a stirring tank, and further comprises the control arm, a monitoring device, a flushing and digging device and a sewage suction device, wherein the control cabinet, the grid residue presser, the screw press, the electric generator, the power distribution cabinet, the vacuum water tank and the stirring tank are arranged in the vehicle body, and the monitoring device, the flushing and digging device and the sewage suction device are positioned on the control arm. According to the treatment vehicle, through cooperative operation of the control arm and an airtight device, the monitoring device, the flushing and digging device and the sewage suction device on the control arm, the automation degree of the septic tank sludge treatment vehicle is high, the number of workers is decreased, meanwhile, the airtight device prevents odor from overflowing, environmentally-friendly operation is achieved, the monitoring device monitors the cleaning degree in a septic tank in real time, the flushing and digging device performs multi-angle flushing, sludge in the septic tank is fully flushed, and the operation efficiency is improved.

Owner:BEAUTIFUL ORIENTAL ENVIRONMENTAL PROTECTION CO LTD

A protective treatment device for rail aluminothermic welding

InactiveCN111570907BAvoid the risk of burnsReduce difficultyShearing machinesShearing machine accessoriesCooling chamberEngineering

Owner:南京幸庄科技创新产业园管理有限公司

Machining method of reducing deformation of helical gear after carburizing and quenching

InactiveCN110408762AReduce defective rateReduce the amount of cuttingSolid state diffusion coatingFurnace typesHobbingHelix angle

The invention provides a machining method of reducing deformation of a helical gear after carburizing and quenching. The machining method comprises the following steps of machining a helix angle variable beta' of reserved reverse deformation on the helical gear before carburizing and quenching of the gear is carried out, and namely before carburizing and quenching process, a machining helix angleof the helical gear is equal to a designed helix angle beta minus a helix angle balance beta' of reverse deformation; and the helix angle variable beta' is set according to the designed helix angle beta of the gear, an axial effective analysis range H of the gear, and axial heat treatment deformation amount M in the processes of gear hobbling or gear shaping. According to the machining method of reducing deformation of the helical gear after carburizing and quenching, on the basis of the law of reverse deformation, the helix angle variable is used for offsetting the distortion amount generatedby heat treatment. The helix angle of the gear after carburizing and quenching meets process requirements, thus ensuring that the deformation of upper and lower sections is not out of tolerance in subsequent axial finish machining after carburizing and quenching of the gear, and therefore the workload of subsequent finish machining as well as the cutting amount of a carburized layer can be reduced.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

A Y-shaped steel column and its manufacturing method

ActiveCN104389379BGuaranteed shape accuracySimplify the difficulty of subsequent constructionStrutsPillarsManufactured materialStructural engineering

The invention discloses a Y-shaped steel column and a manufacturing method thereof, comprising a Y-shaped trunk and a front end connected to the Y-shaped trunk. The inverted eight-shaped steel plate on the column, the front end includes a box-shaped column with a cross-section and a front-end steel plate connected horizontally with the box-shaped column. After the front end is connected, it is two upper and lower. B shape; the inverted eight-shaped steel plate and the front-end steel plate are composed of special-shaped parts of different shapes; the bottom of the mouth-shaped box-shaped column is also provided with oblique support parts connected with the Japanese-shaped box-shaped column. The Y-shaped steel column described in the present invention embodies the perfect combination of art and construction engineering. Through reasonable splitting of the Y-shaped steel column and detailed design of the constituent units, the difficulty of subsequent construction is simplified, and the bearing capacity of the column is guaranteed. , which simplifies the structure of the column to the greatest extent, saves raw materials and increases the effective building area.

Owner:JIANGSU HUNING STEEL MECHANISM

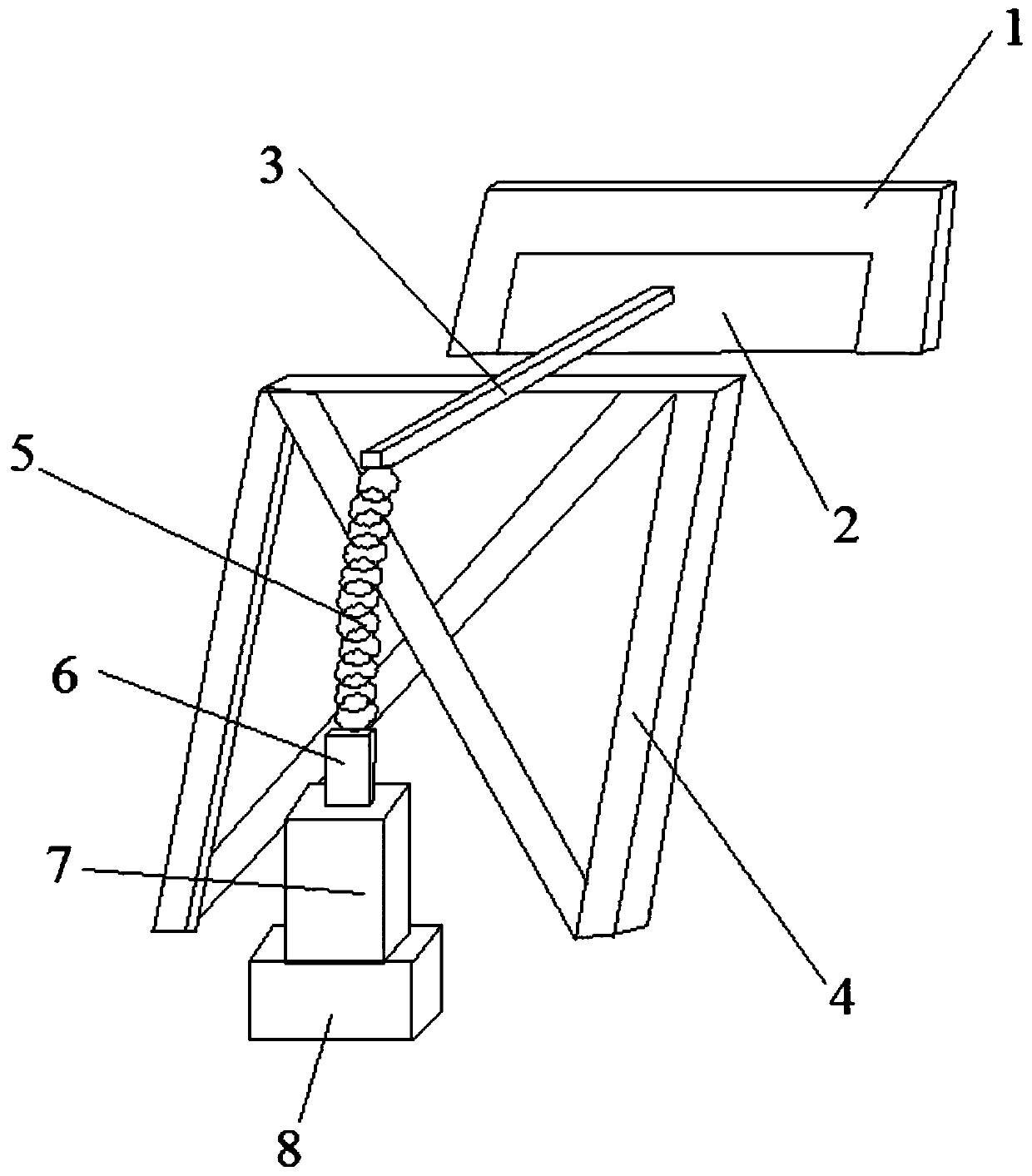

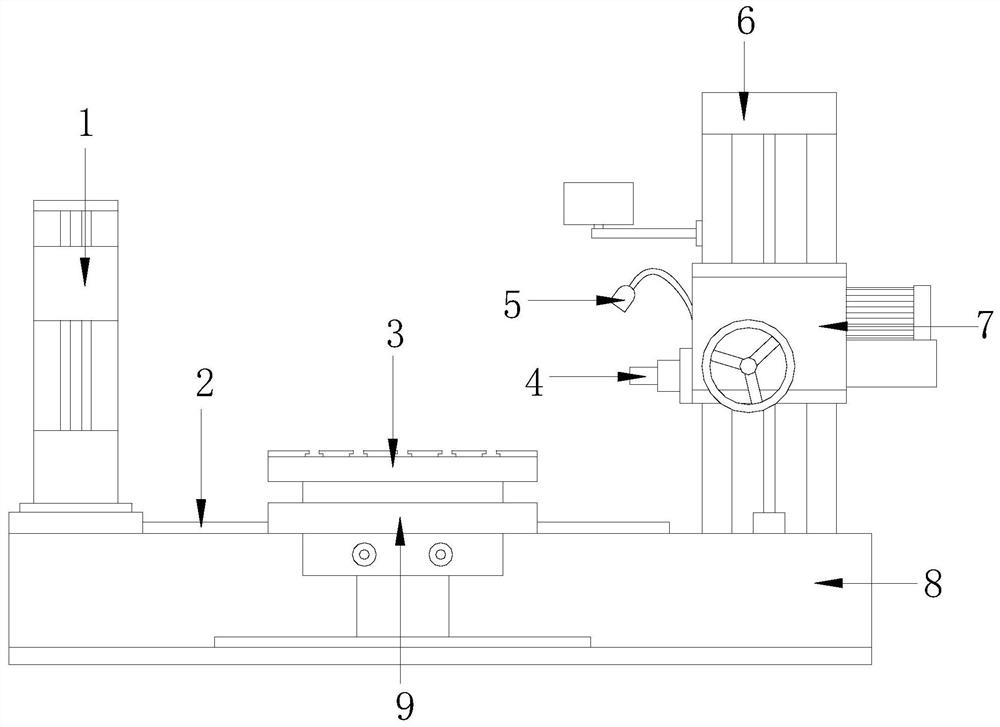

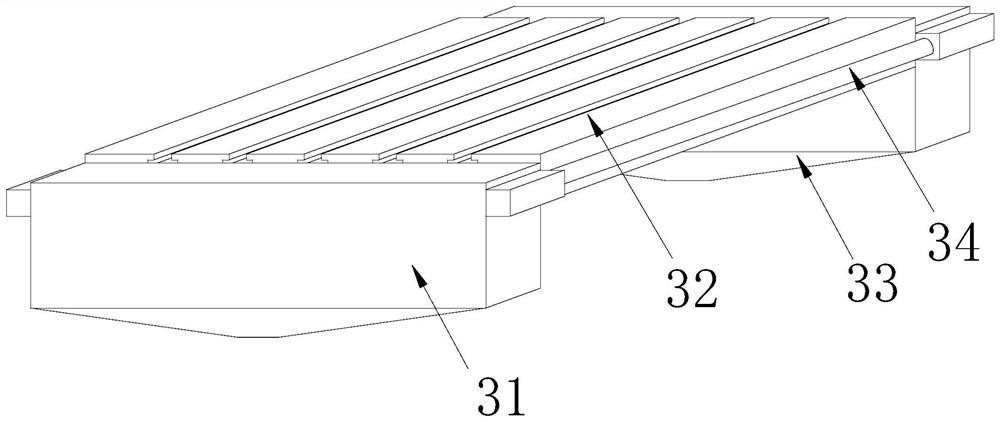

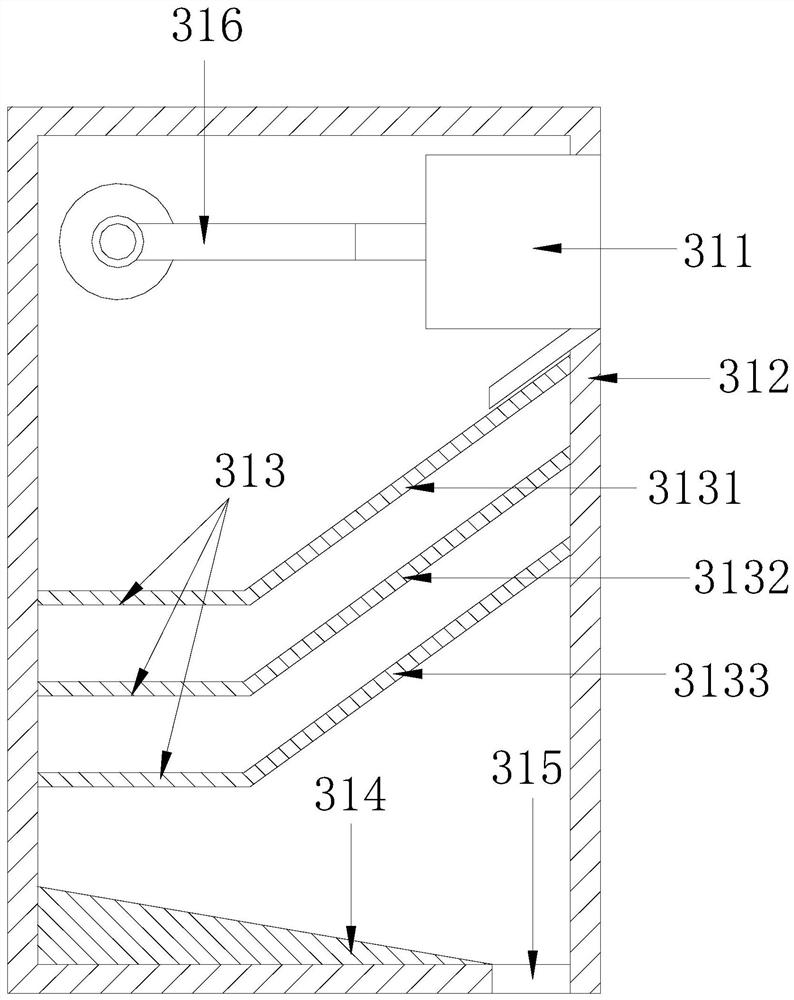

A horizontal boring machine

ActiveCN111168100BPrevent outflowImprove cleanlinessMaintainance and safety accessoriesBoring/drilling machinesMachineWater processing

The invention discloses a horizontal boring machine, whose structure includes a rear column assembly, a sliding assembly, a workbench, a spindle assembly, a lamp assembly, a front column assembly, a spindle box, a bed body, and a pallet rotating assembly. Compared with the technology, the beneficial effect of the present invention is: the spray liquid can be collected, the spray liquid can be avoided from dripping everywhere, the processing chips can be prevented from forming dirt and adhering to the equipment, the workload of the operator can be reduced, and the workbench can be guaranteed. The cleanliness is more conducive to the processing of workpieces. At the same time, the water treatment device can filter the spray liquid, so that the spray liquid can be recycled, energy saving and emission reduction, and the dust collection device uses the spindle processing rotation as the power source. Friction electrification absorbs processing chips, and at the same time scrapes the adsorbed processing chips, avoiding the accumulation of processing chips and causing the spindle to freeze, which is conducive to the normal rotation of the spindle, facilitates the collection of processing chips, prevents the processing chips from splashing around, and helps to improve the operator's productivity. job safety factor.

Owner:威海德尔瑞通科技信息有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com