Method for constructing flexible facing brick

A technology of flexible finishing and construction method, applied in the field of exterior wall decoration and building interior, can solve problems such as poor adaptability of materials and construction methods, inability to guarantee flatness, affecting construction speed, etc. The effect of shortening construction period and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

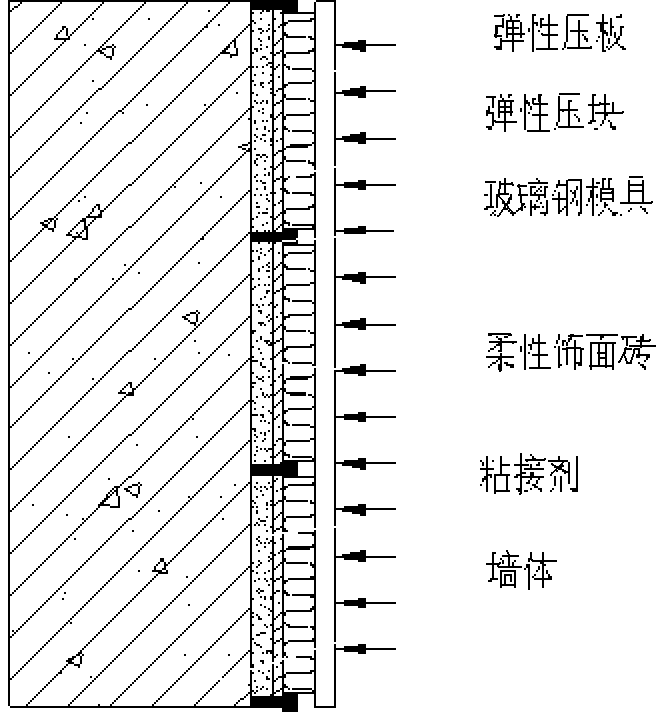

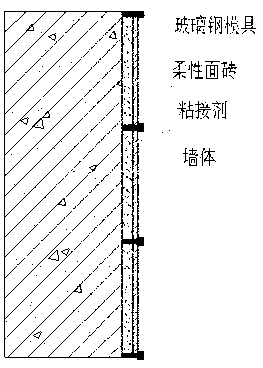

[0019] The size and shape of the FRP mold can be adjusted according to the specifications of the flexible facing brick, and it can be staggered or opposite. Its frame is an "L"-shaped section, and the middle division is a "convex"-shaped section, which can hold flexible facing tiles and adhesives. The height of the section is the sum of the thickness of the flexible facing brick and the thickness of the adhesive. The plastering thickness of the adhesive can be effectively controlled.

[0020] The elastic pressing plate is composed of an elastic pressing block and an elastic back plate. The elastic pressing block can be made of rubber or other elastic polymer materials such as polyurethane. The elastic back plate can be ABS thin plate, or other elastic polymer material plate; its specification is consistent with the selected glass fiber reinforced plastic mold.

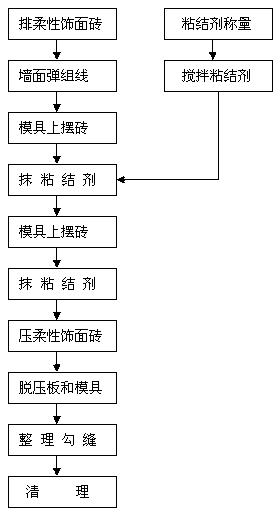

[0021] The present invention is realized through the following steps:

[0022] Step 1) Stretch the wire on the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com