A Y-shaped steel column and its manufacturing method

A type of steel and box-shaped column technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of difficult processing of bending and torsion components, large component cross-sections, high requirements for installation and positioning accuracy of Y-shaped space modeling, and achieve simplified construction. The effect of reducing the self-weight of the structure and saving the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

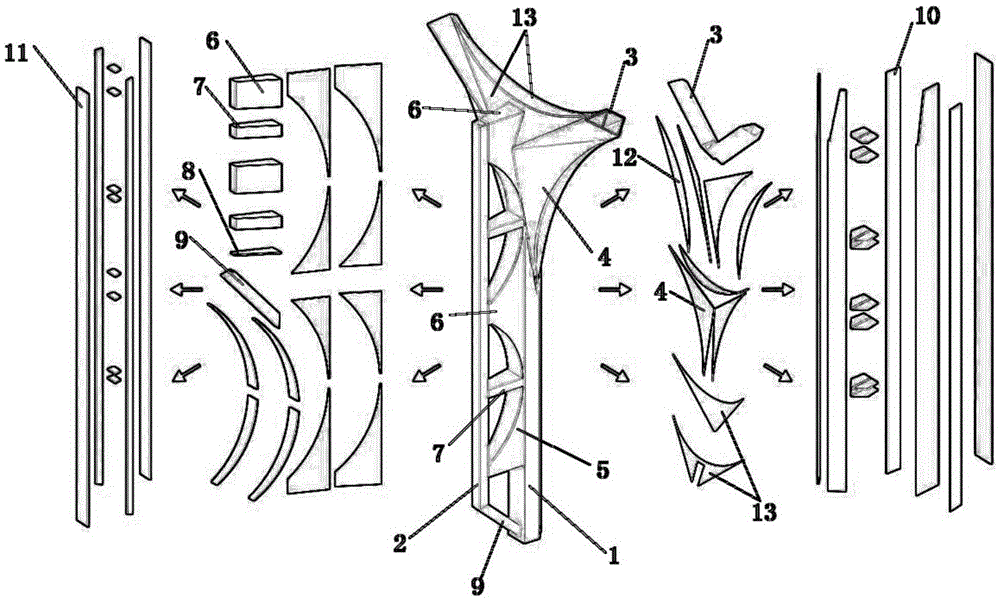

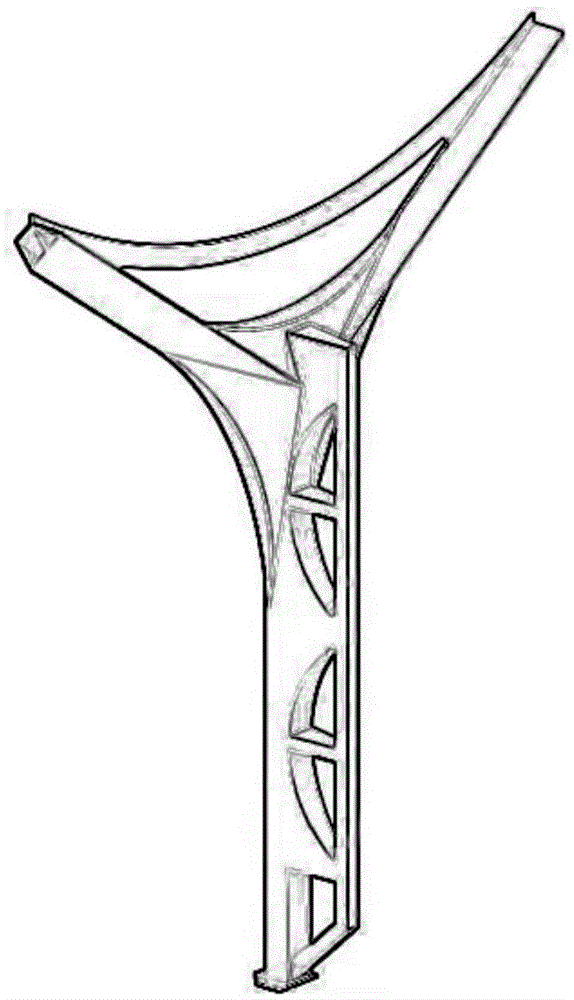

[0023] Example 1: Such as Figure 1 to Figure 2 The Y-shaped steel column shown includes a Y-shaped backbone and a front end connected to the Y-shaped backbone. The Y-shaped backbone includes a box-shaped column 1 with a Japanese-shaped cross section and an inverted splayed-shaped column installed on the Japanese-shaped box-shaped column. Steel plate, the front end includes a box-shaped column 2 with a cross-section and a front-end steel plate connected horizontally with the box-shaped column. After the front end is connected, it is two B-shaped up and down; Column 2 is composed of 4 steel plates, and the wall thickness of each steel plate 11 of a Japanese-shaped box-shaped column is 35mm. is 30mm.

[0024] The inverted splayed steel plate is mainly composed of an inverted splayed part 3 and a triangular arc part 4 supporting the inverted splayed part 3. The outside of triangular arc surface part one 4 is bonded with blade type part 12, and inverted splayed part 3 upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com