Handle saw web and sawtooth machining process

A processing technology and saw blade technology, applied in the field of handle saw blade sawtooth processing technology, can solve the problems that powder cannot be recycled, reduce the precision of handle saw blade, shorten the service life of grinding wheel, etc., so as to reduce the workload and structure of grinding wheel. Simple, low processing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

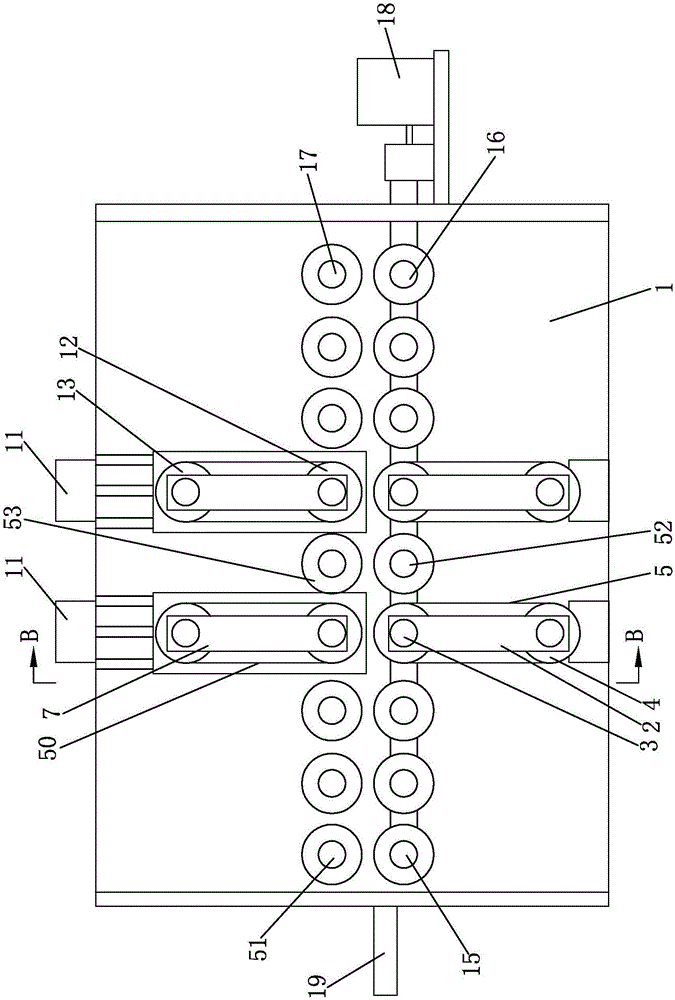

[0041] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

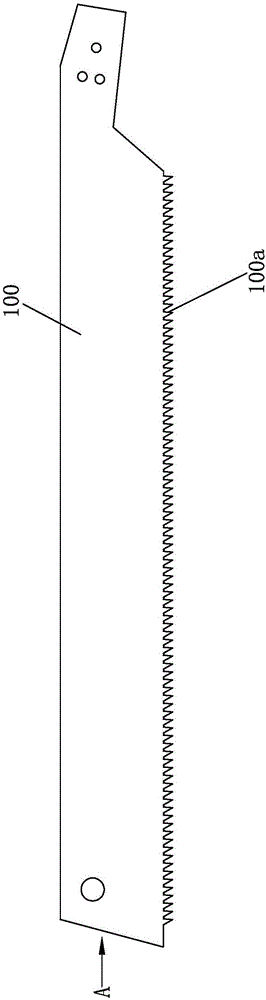

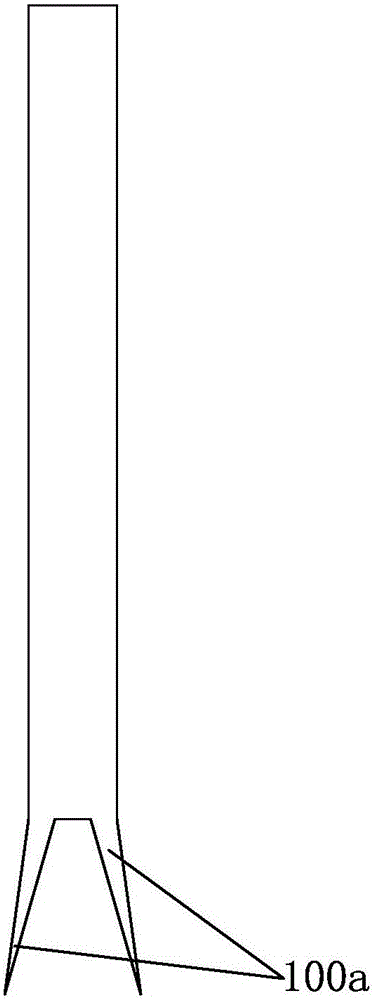

[0042] Such as figure 1 , 2 , Shown in 3, 4 and 5, a kind of handle saw blade sawtooth processing technology is characterized in that comprising the following steps:

[0043] Step a: The saw blade 100 is formed, specifically, the saw blade is flattened, and the specific process steps are the same as the existing process steps.

[0044] Step b: Use the first punch to punch out a group of saw teeth 100a arranged along the length direction of the saw blade on the saw blade 100. These saw teeth 100a are on the same plane, and a stamping head of the first punch is fixed with a A mould, the shape of which matches the shape of the sawtooth 100a.

[0045] Step c: Grinding both sides of each sawtooth 100a with a CNC gear grinding machine to form a cutting edge. When grinding the gear, it is automatically controlled by the program of the CNC gear grinding machine, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com