Pipeline thread airtight connection method and device

A connection device and connection method technology, which is applied in the direction of threaded connection, pipe/pipe joint/pipe fitting, passing components, etc., can solve the problems of high labor cost and time cost, slow pipeline installation speed, unsuitable for outdoor use, etc., to achieve practicality Performance enhancement, reduction of duplication and waste, and long-term airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

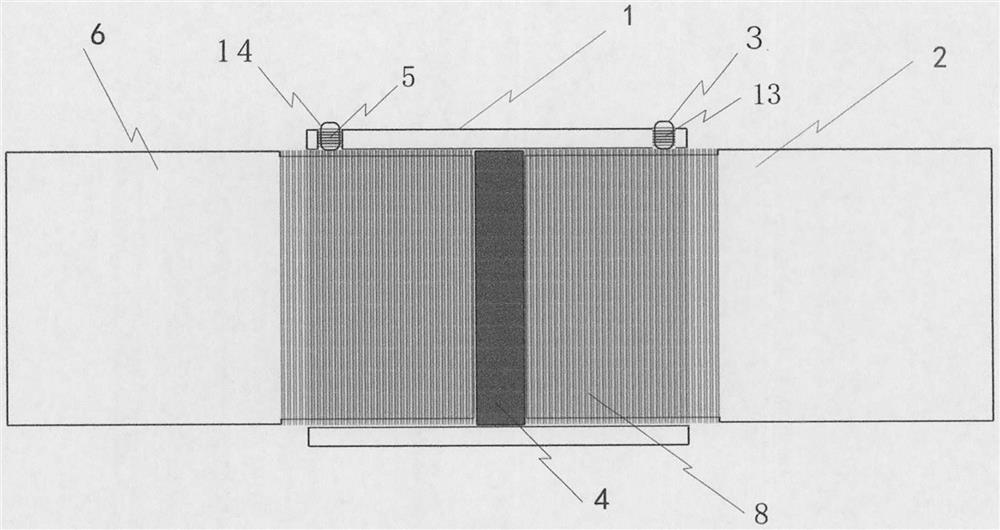

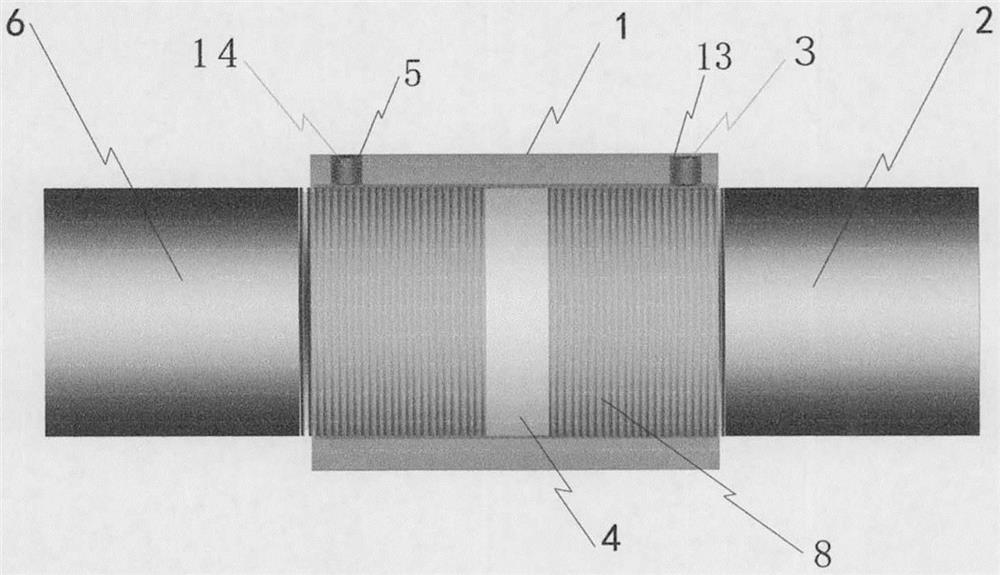

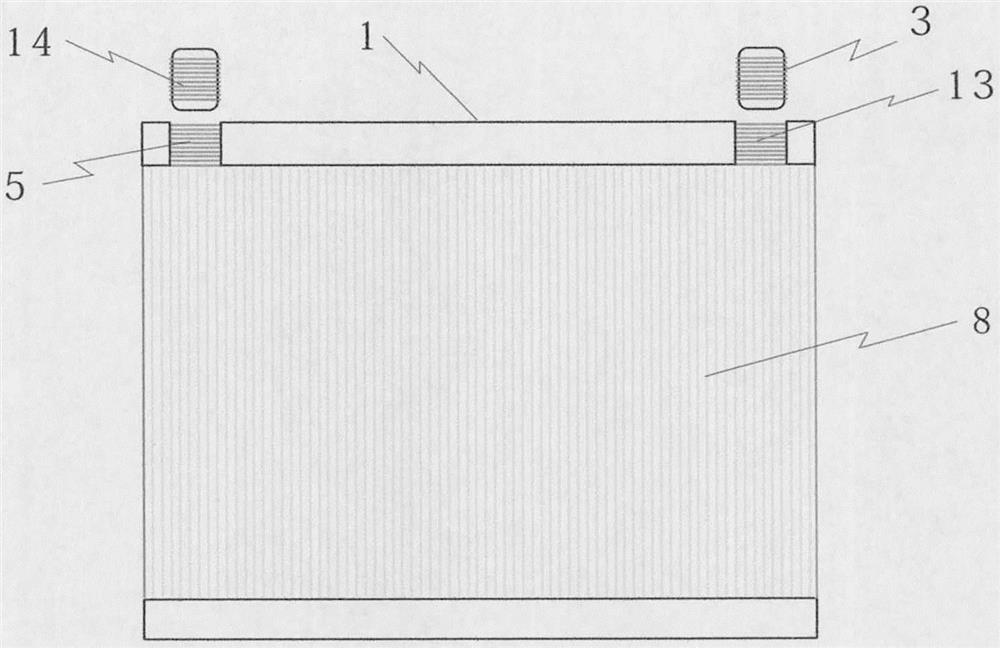

[0013] Example 1, image 3 An example of a pipeline threaded airtight connection device is given, the body 1 of the pipeline threaded airtight connection device is composed of a full internal thread channel 8, and radially passes through the pipeline thread airtight connection device body 1 from the full internal thread channel 8 The fixed screw holes 5, 13 are formed, and the full inner thread channel 8 is provided for the outer bellows 2, 6 ( Figure 4 ) for screwing, the fixed screw holes 5, 13 are provided with internal threads for the installation of set screws 3, 14, the installation is as follows figure 1 , figure 2 As shown, first, when the outer bellows 2, 6 are screwed into the full inner thread channel 8 of the pipeline threaded airtight connection device body 1, a sealing gasket 4 is placed between the flat openings of the outer bellows 2, 6 to ensure that the outer bellows After the bellows 2, 6 are airtightly connected by the sealing gasket 4, tighten the fixi...

Embodiment 2

[0014] Example 2, Figure 5 An example of a pipeline thread airtight connection device is given, the body 1 of the pipeline thread airtight connection device is composed of a half-inner thread channel 7, and radially passes through the pipeline thread airtight connection device body 1 from the half-inner thread channel 7 The fixed screw holes 5, 13 are formed, and the middle of the half inner groove channel 7 is provided with a circular boss 10, and the circular boss 10 is in the shape of a flat mouth for installing a sealing gasket 11, and the fixed screw holes 5, 13 for the installation of set screws 3, 14, such as Image 6 Among them, the outer bellows 2, 6 are oppositely screwed into the body 1 of the pipeline thread airtight connection device, and the sealing gaskets 11, 12 on the flat opening of the boss 10 in the half internal thread passage of the body 1 of the pipeline thread airtight connection device are docked After ensuring the airtight connection between the out...

Embodiment 3

[0015] Example 3, Figure 7 Provided is a union nut for a pipe threaded airtight connection device, which is composed of a nut 15 and a fixing screw hole 5, wherein the pipe connection and fixing methods are the same as those in Embodiment 2, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com