Septic tank sludge treatment vehicle with control arm

A sludge treatment vehicle and control arm technology, which is applied to chemical instruments and methods, waterway systems, cleaning hollow objects, etc., can solve problems such as inability to clean sludge, increase risks, and cluttered pipelines, so as to optimize the space inside the vehicle and equipment, increased efficiency and safety, and the effect of increased automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

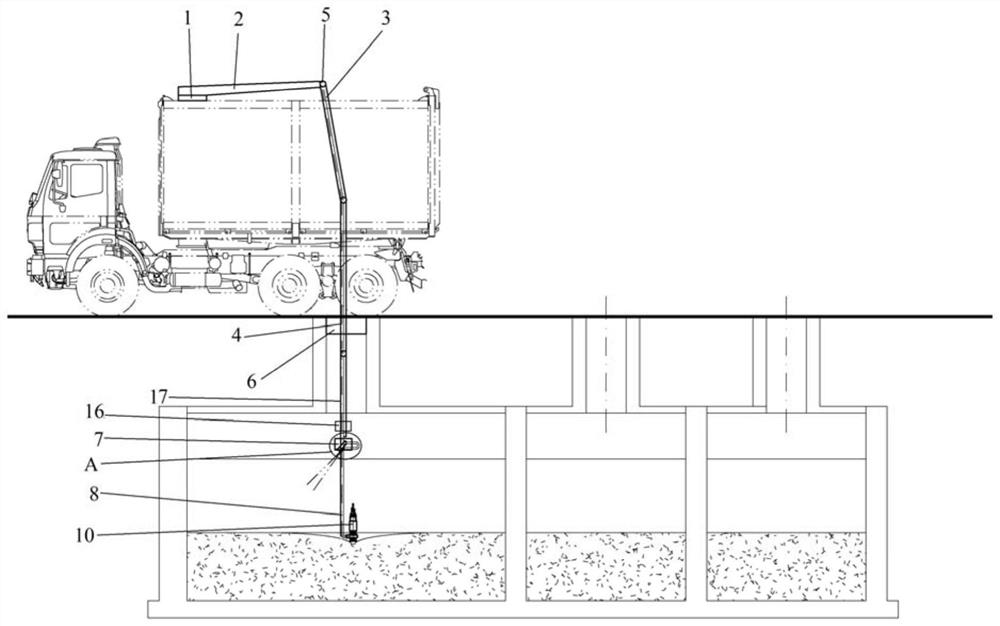

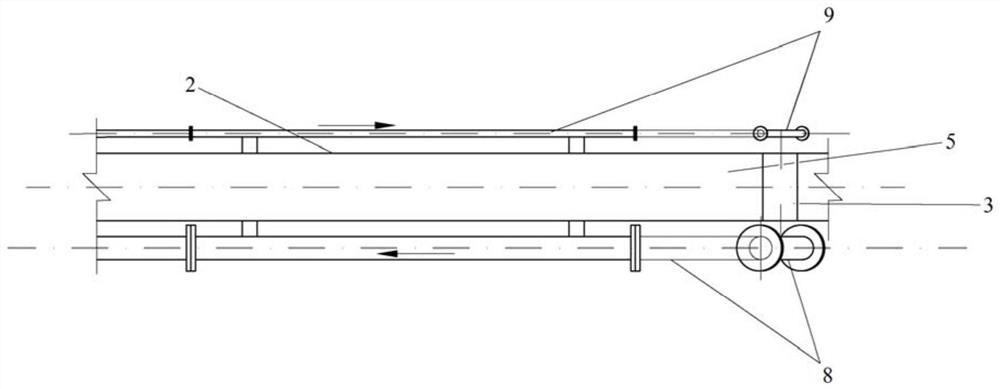

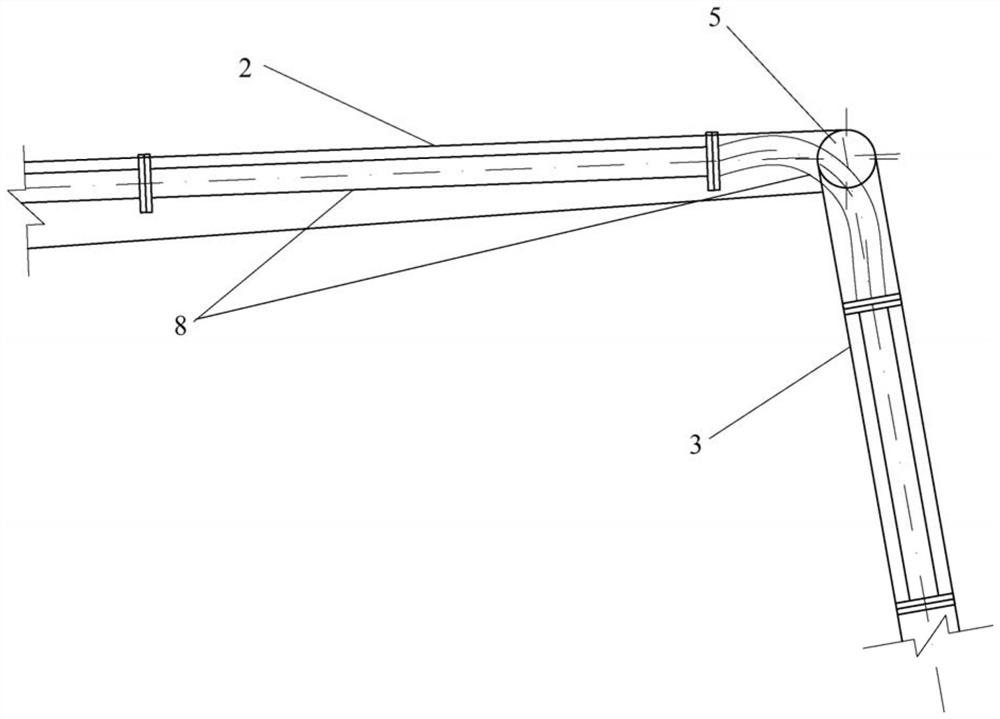

[0022] The present invention will be further described below with reference to the accompanying drawings and examples.

[0023] Combine Figure 1 to 5 This embodiment provides a septic tank sludge treatment vehicle with a control arm, including at least a vehicle body and a control cabinet, a gate residue press, a stacked machine, a generator, a distribution cabinet, a vacuum tank, and a control cabinet. The mixing box also includes a control arm and a monitoring device 16, the excavation device 7, and the contigable device 10, which are sequentially located on the control arm, and all of which are connected to the control cabinet; the control arm includes the first A robot arm 2, the second robot arm 3, the third robot arm 4, and the fourth robot arm 17, and the four are connected to the shaft 5, wherein the first mechanical arm is connected to the turntable 1 fixed to the vehicle body; There is also a water pipe 9 and a sewage tube 8 on the control arm, which is fixed to both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com