A dry-type integral earth-taking device for foundation pillar piles

A soil-taking device and dry-type technology, which is applied in earth drilling, percussion drilling, rotary drilling, etc., can solve problems such as easy damage to equipment, dirty and messy construction sites, and low working efficiency of drilling rigs, and achieve Improve drilling efficiency and avoid mud cross flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

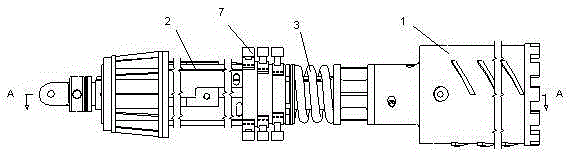

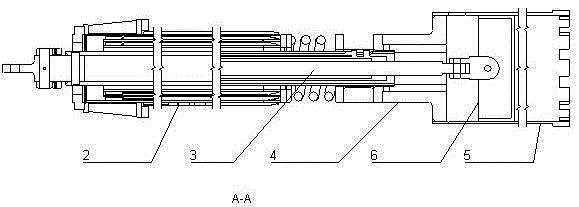

[0016] Such as figure 1 with figure 2 As shown, a dry-type integral soil fetching device for foundation piles includes a cylinder 1 connected to the lower end of the drill pipe 2, and also includes: a hydraulic cylinder 3 whose cylinder end is fixedly connected to the drill pipe. Inside the rod 2, the end of the piston 6 leads into the cylinder 1, and the piston 6 is slidably connected in the cylinder 1.

[0017] The cylinder body 1 has an aspect ratio greater than 2:1.

[0018] In the dry-type integrated soil extraction device for pile pits on soft foundations, a hexagonal joint 3 is provided at the end connecting the cylinder body 1 and the drill pipe 2 , and a spring 4 is sleeved on the upper end thereof.

[0019] In the dry-type integrated soil fetching device for pile pits on soft ground, the outer surface of the cylinder body 1 is provided with threaded grooves.

[0020] In the dry-type integrated earth-taking device for pile pits on soft ground, the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com