High-precision multi-dimensional adjusting device

A multi-dimensional adjustment and high-precision technology, applied in medical science, internal bone synthesis, internal fixator, etc., can solve the problems of component fit gap error, cumbersome adjustment, long adjustment time, etc., saving valuable time, reducing the number of parts, Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

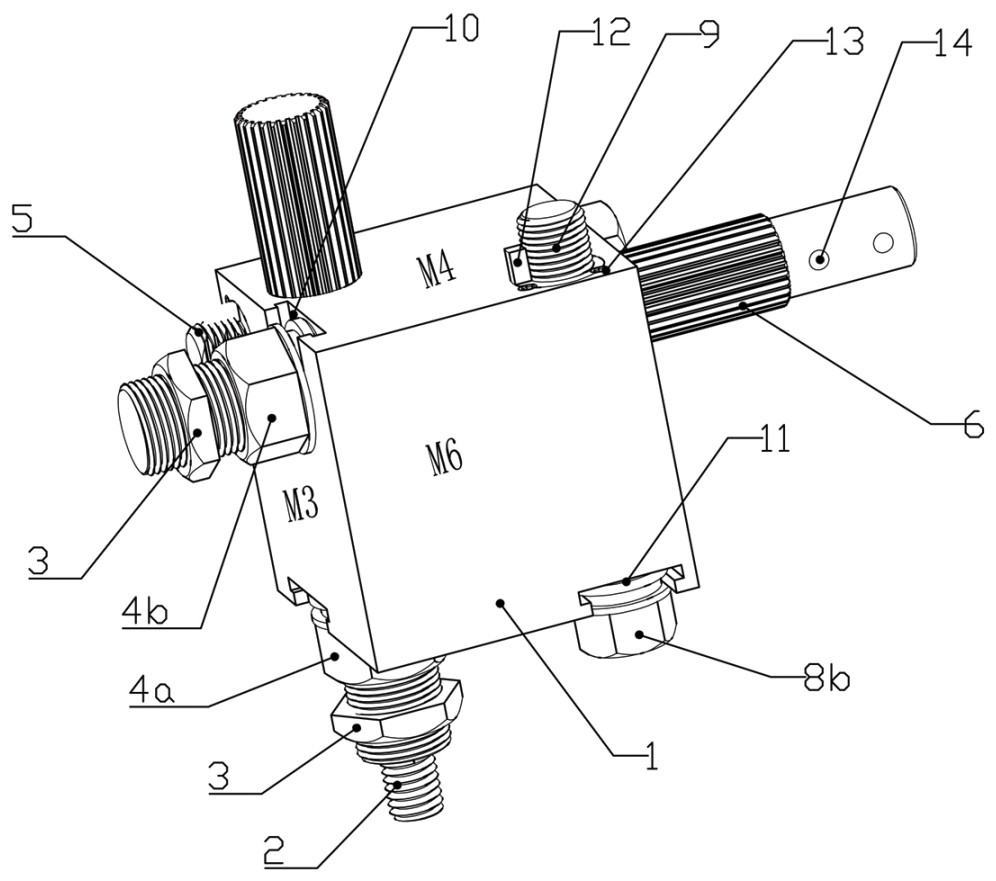

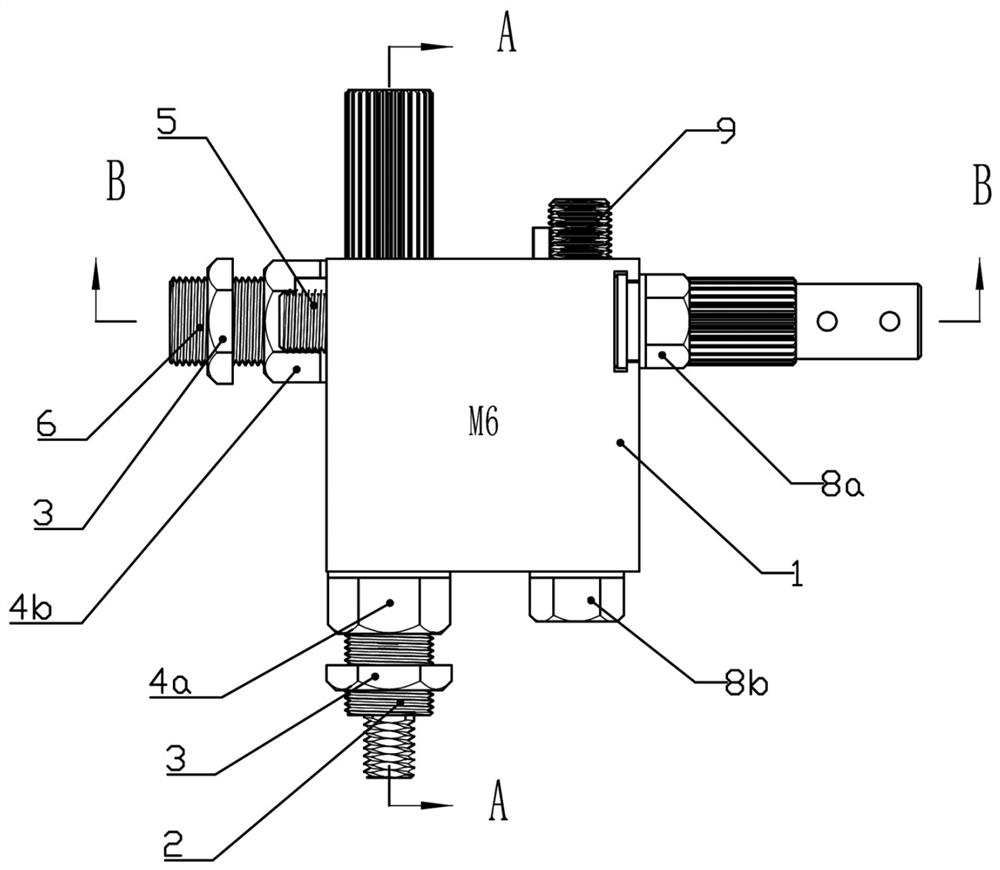

[0042]Example 1: Such asfigure 1 The four-dimensional adjustment device shown in the figure shows that the device includes a four-dimensional control seat 1, a lead screw gear shaft 1, a positioning nut 3, an axial non-shedding nut 4a, an axial non-shedding nut 2 4b, and a rack wire Bar one 5, screw gear shaft two 6, eccentric adjusting sleeve 7, steering non-shedding nut one 8a, steering non-shedding nut two 8b, rack screw two 9, and patch plates. Specifically, you can also passFigure 3-Figure 6 Learn the structure of the device and the cooperating relationship of the components from multiple sides and inside.

[0043]The specific structure of the four-dimensional control seat 1 involved in the device can be found inFigure 7-14, The drawings show in detail the relationship between the sides and internal holes of the four-dimensional control seat 1. It can be seen from the figure that the four-dimensional control seat 1 includes two shaft holes, namely a vertical shaft hole 15a and a t...

Embodiment 2

[0054]Embodiment 2: On the basis of embodiment 1, an eccentric adjusting sleeve is further fitted in the vertical connection hole. The specific structure of the eccentric adjusting sleeve 7 is attachedFigure 18 As shown in the figure, it can be seen that the inner cavity of the tube body 71 is an eccentric cavity 75, and the end of the tube body 71 is provided with a recess 72 formed by a side gap, and the gear section of the screw gear shaft is matched with this Give way to slot 72. One side of the relief groove area 72 has a straight groove bottom surface 73 and the other side has an arc groove bottom surface 74.

[0055]The function of the eccentric adjusting sleeve is to improve the reasonable gap between the gear and the rack. It can prevent the loosening of the gap caused by the meshing of the gear and the rack, further reducing the matching gap between the components, and improving the adjustment accuracy. In order to ensure the installation stability of the eccentric adjusting ...

Embodiment 3

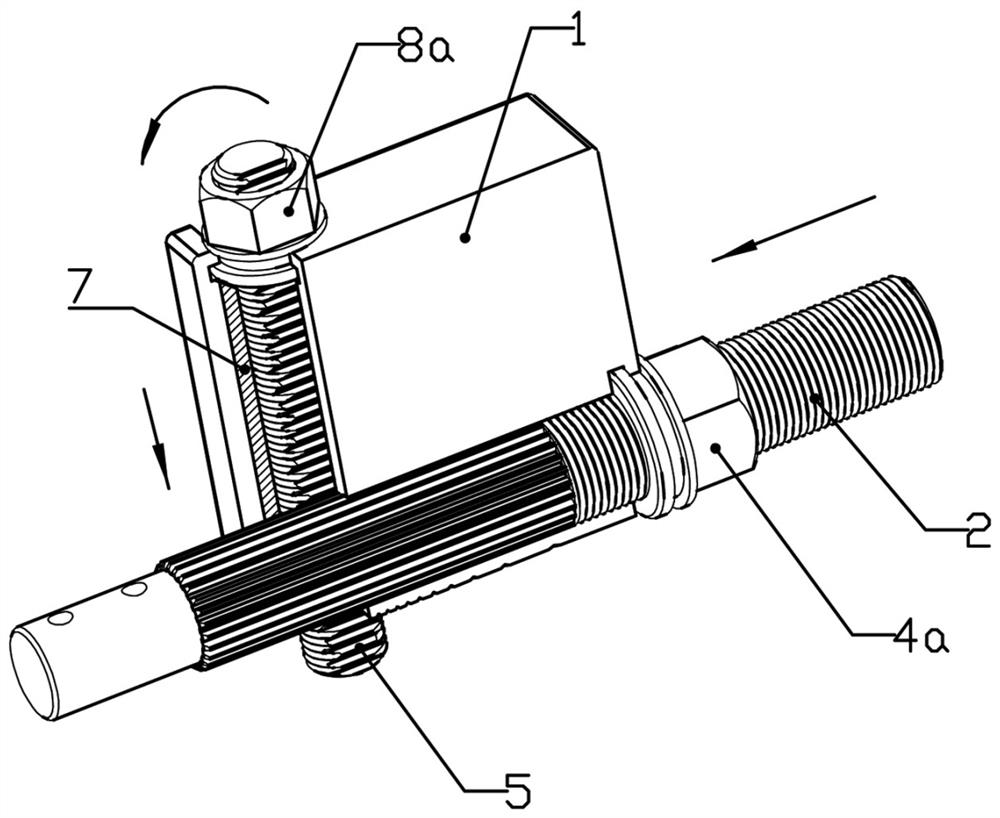

[0056]Embodiment 3: A high-precision two-dimensional adjustment device, which includes a base, a screw gear shaft, an axial non-shedding nut, a rack screw, a steering non-shedding nut, and the like. For details, seefigure 2 As shown, the base includes a shaft perforation along a linear dimension, and there is another perforation perpendicular to the shaft perforation, and the two perforations intersect, which is called a hanging hole.

[0057]The screw gear shaft, the axial non-shedding nut, the rack screw and the steering non-shedding nut, etc. are the same as or similar to the first embodiment. Specifically, the screw gear shaft includes a thread section at the first section and a gear section at the tail section. The screw gear shaft is matched and sleeved on the shaft after perforation, and the gear section is located at the intersection of the two perforations, and the nut does not fall off in the axial direction. The threaded section of the screw gear shaft, the nut and the shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com