Die-casting method and die-casting machine adopting same

A die-casting machine and die-casting mold technology, applied in the field of die-casting machines, can solve the problems of product bubble shrinkage and mold cavity air discharge, and achieve the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

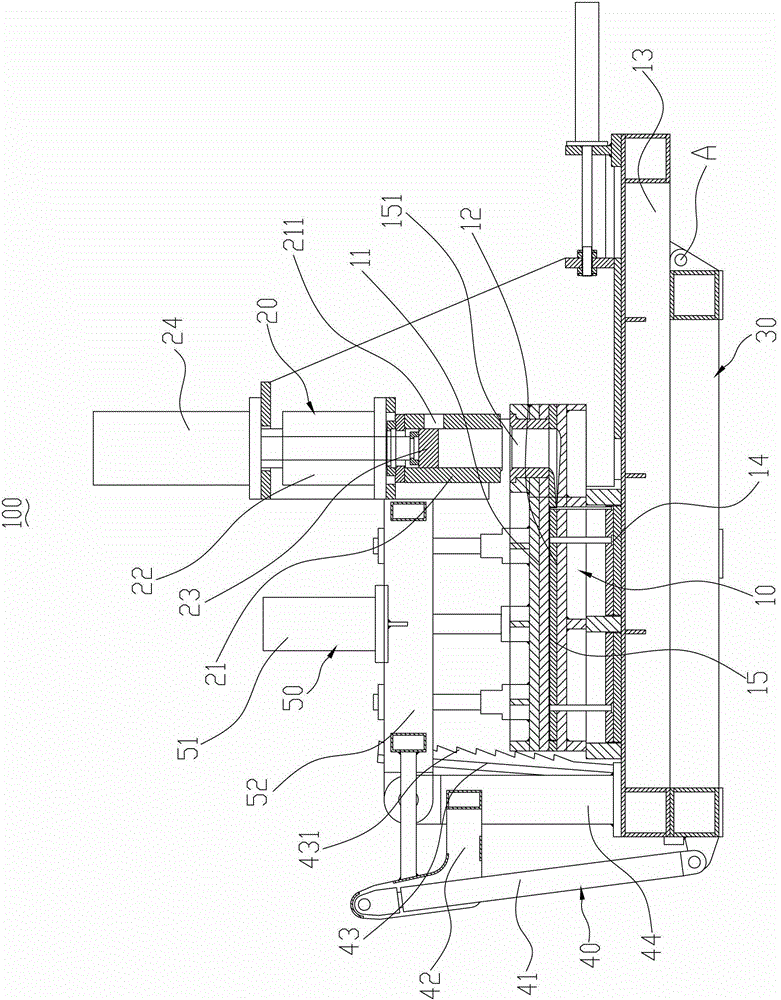

[0031] Please check figure 1 , a die-casting machine 100 of the present invention is mainly used for producing large-scale die-casting parts, such as door panels made of copper and aluminum. The die-casting machine 100 includes a die-casting mold 10 , a pressing mechanism 20 , a support base 30 , a lifting mechanism 40 , a mold opening mechanism 50 and a turning mechanism (not shown).

[0032] The die-casting mold 10 includes an upper mold assembly 11 , a lower mold assembly 12 , a base 13 and an ejector 14 . The upper mold assembly 11 is covered on the lower mold assembly 12 , and a cavity 15 is formed between the upper mold assembly 11 and the lower mold assembly 12 . The mold cavity 15 is used to form a die casting. The feed port 151 of the cavity 15 is located at one end of the cavity 15 . The lower mold assembly 12 is disposed on the base 13 . The ejector device 14 is used to eject the die casting from the mold cavity 15 . The ejector device 14 is accommodated in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com