Distributed ink jetting digital printing method and system of supporting variable data

A digital printing and distributed technology, applied in the input/output process of data processing, printing, electronic digital data processing, etc., can solve problems such as optimization of variable data printing, improve transmission speed, and improve reading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

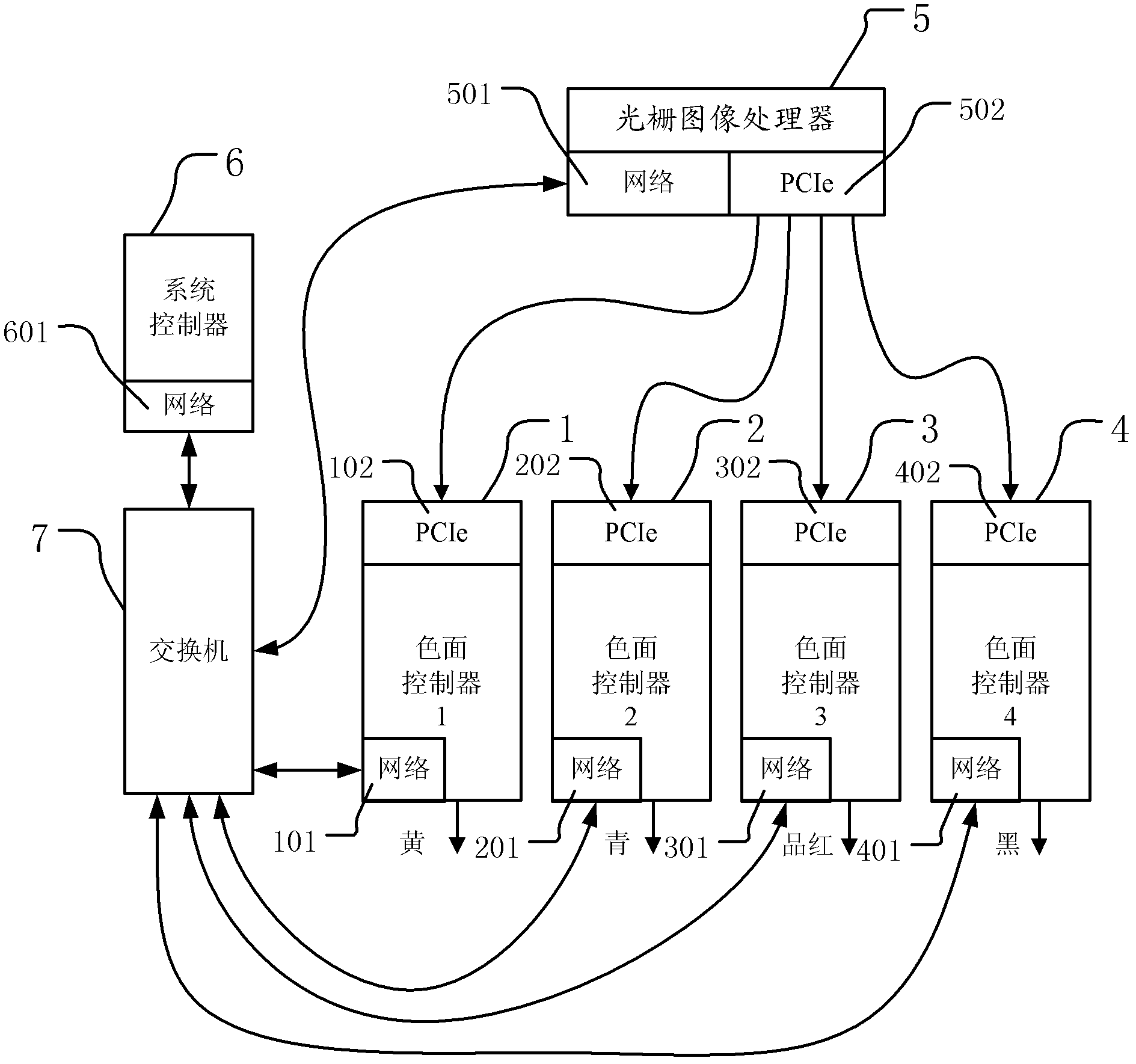

[0036] The invention provides a distributed inkjet digital printing method and system supporting variable data.

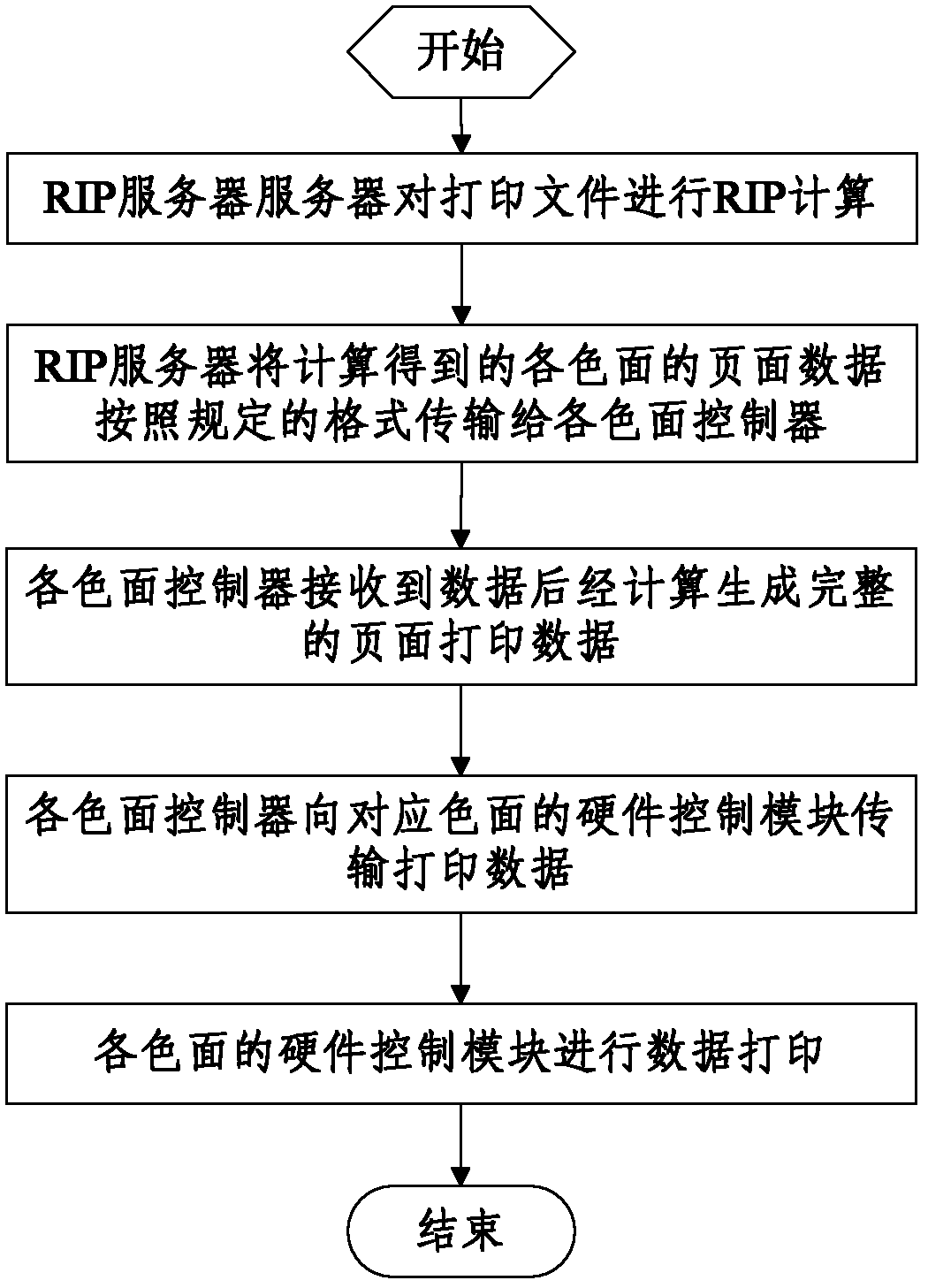

[0037] Such as figure 2 As shown, a distributed inkjet digital printing method supporting variable data includes the following steps:

[0038] (1) The RIP server performs RIP calculation on the print file;

[0039] (2) The RIP server transmits the calculated page data of each color plane to each color plane controller according to the specified format;

[0040] (3) After each color plane controller receives the data, it calculates and generates complete page printing data;

[0041] (4) Each color surface controller transmits printing data to the hardware control module corresponding to the color surface;

[0042] (5) The hardware control modules of each color face print data.

[0043] In this embodiment, the RIP serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com