Banana gate mechanism free of insert core trace

A banana and glue-feeding technology, which is applied in the field of plastic product processing, can solve the problems of not being able to realize the waterproof performance of products, increase the use of raw materials, increase labor costs, etc., and achieve the effects of reducing labor processing costs, reliable operation safety, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

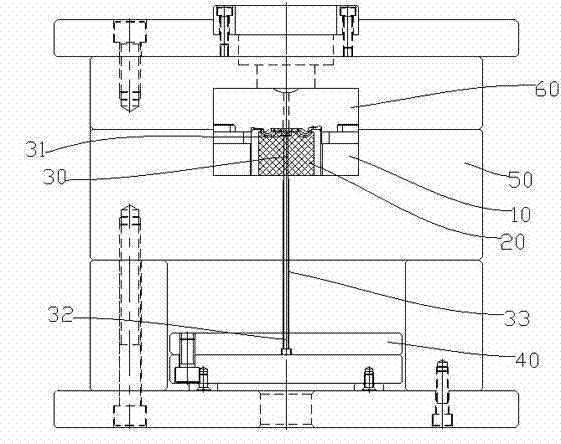

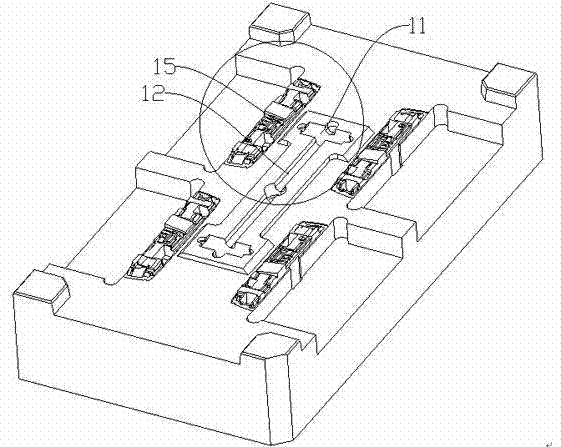

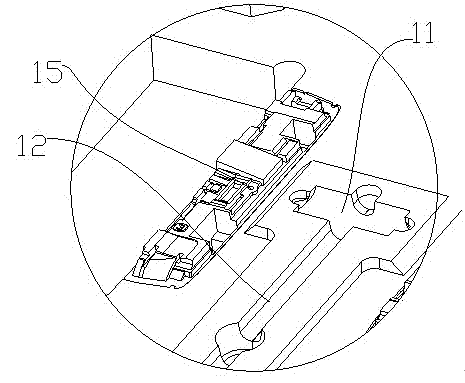

[0016] see Figure 1 to Figure 4 As shown, embodiments of the present invention include:

[0017] A banana glue-feeding mechanism without traces, comprising: a male mold core 10, a male-mould banana glue-feeding insert 20, a thimble 30, a thimble plate 40 and a movable template 50.

[0018] The male mold core 10 is fixed on the moving template 50, the male mold banana glue insert 20 is arranged in the installation hole 11 at the bottom of the male mold core 10, and the male mold banana glue insert 20 The top surface 21 of the top surface 21 has a banana-shaped groove 22 and a first product pouring groove 23, and the banana-shaped groove 22 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com