Directional cover pressing device for flow guide groove cover

A diversion groove cap and capping technology, which is applied to flange-type bottle caps and other directions, can solve the problems of inability to adapt to automation, large-scale production, high labor intensity, low production efficiency, etc., and achieves ingenious structural design and improved production efficiency. , to meet the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

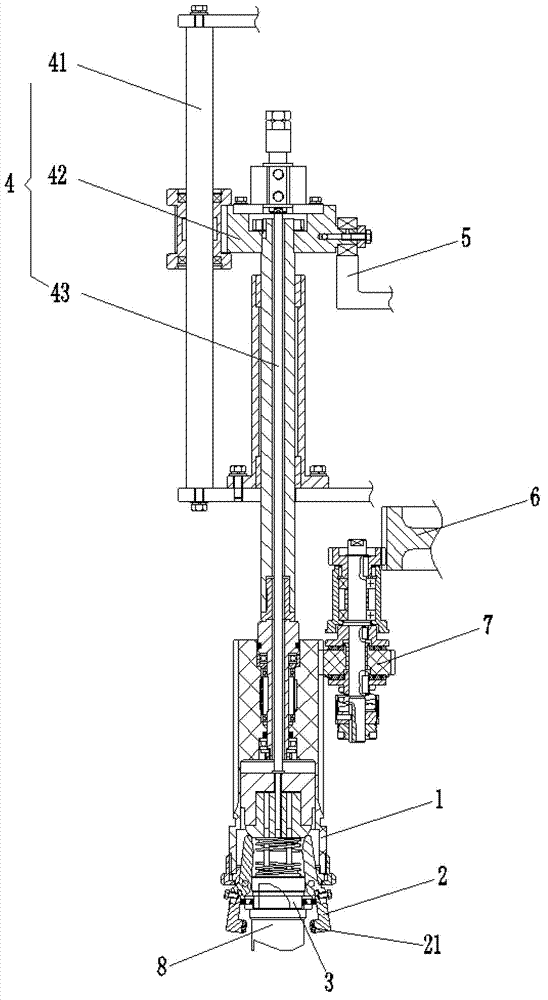

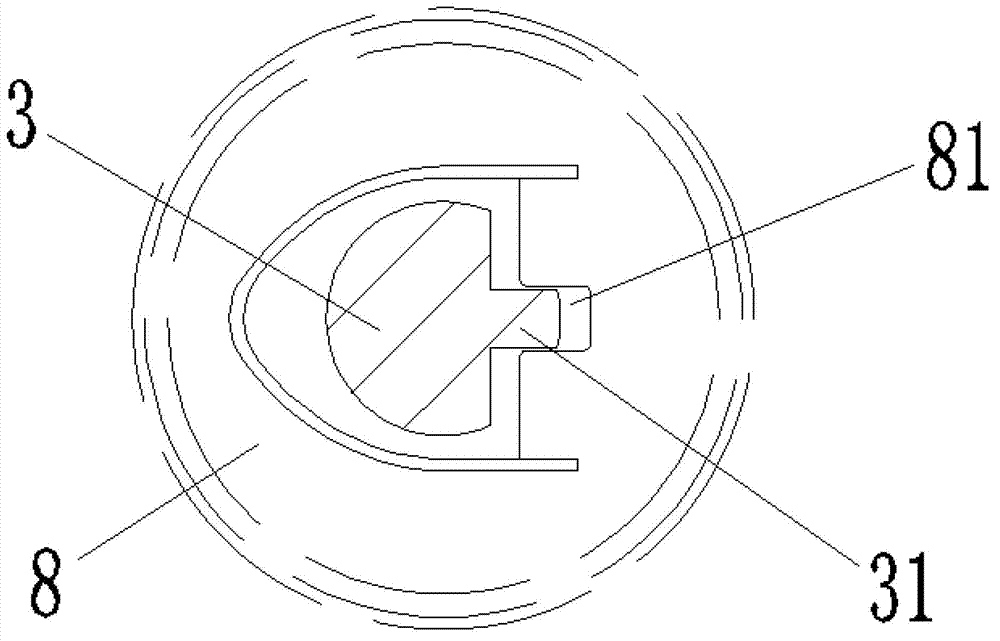

[0027] See figure 1 , The orientation capping device of the diversion tank cover of the present embodiment includes a cover claw seat 1, a cover claw 2, an orientation block 3, a lifting mechanism 4, a lifting driving mechanism and a rotating driving mechanism. Get the bottom of cover pawl seat 1 and lifting mechanism 4 to be rotatably connected. Get the lid claw 2 and be fixed on the bottom of getting the lid claw seat 1. The orientation block 3 is fixed on the bottom of the lifting mechanism 4 and is located in the cover pawl 2 . The lifting drive mechanism drives the lifting mechanism 4 to drive the lid claw seat 1 to perform lifting motion. The rotation drive mechanism drives the cover claw seat 1 to rotate.

[0028] The lifting mechanism 4 includes a lifting bracket 41 , a lifting block 42 and a lifting link 43 . The lifting block 42 is slidably connected with the lifting bracket 41 in the vertical direction. The top of the lifting link 43 is fixed on the lifting blo...

Embodiment 2)

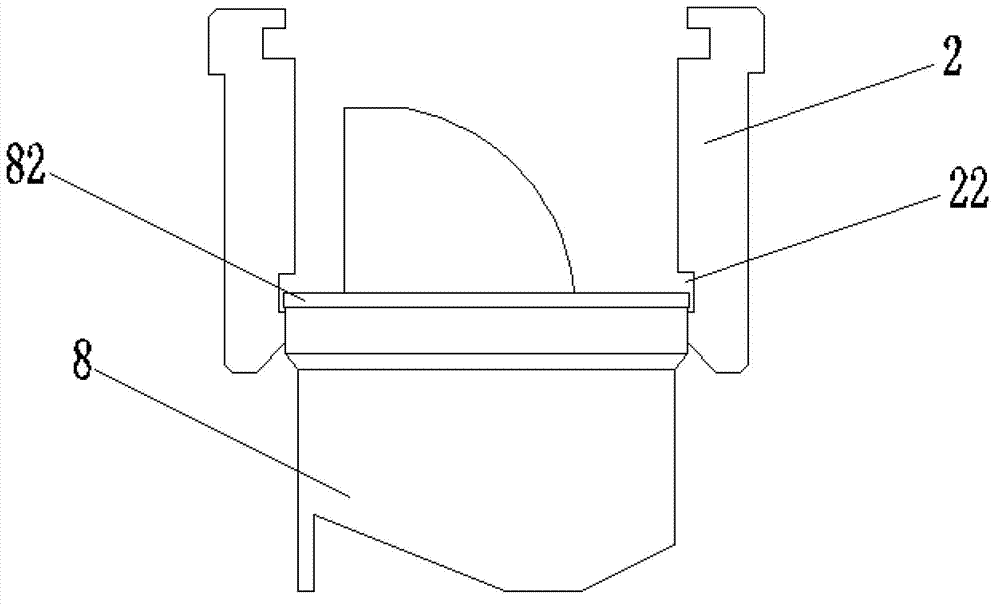

[0034] See image 3 , this embodiment is basically the same as Embodiment 1, the difference is that the cover claw 2 is provided with an inner hook groove 22 that cooperates with the outer wall flange 82 of the diversion tank cover 8 .

Embodiment 3)

[0036] This embodiment is basically the same as Embodiment 1, the difference is that: the cover claw 2 is provided with an outer hook groove that can cooperate with the inner wall flange of the diversion tank cover 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com