Diversion tank cover grasping cover pressing device

A diversion groove cover and cover pressure technology, which is applied in the directions of using a cover to tightly cover the container, packaging, transportation and packaging, can solve the problems of high labor intensity, time-consuming and labor-intensive, low production efficiency, etc., and achieve the maintenance of lifting motion. Stable, ingenious structural design, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

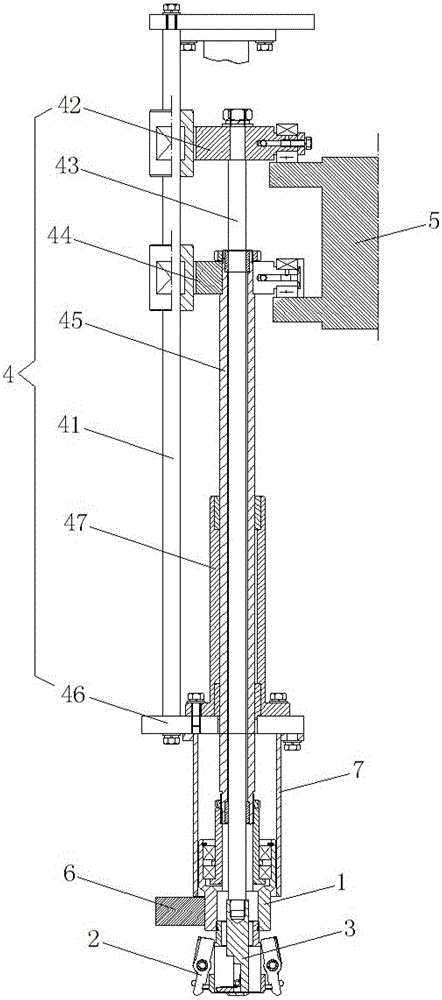

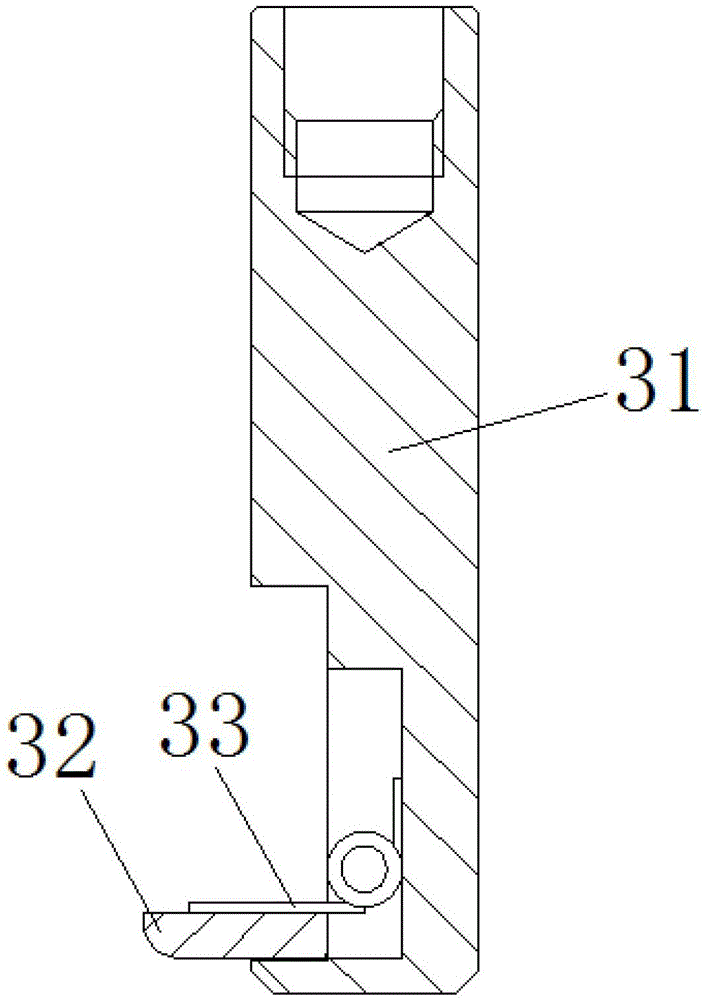

[0029] See Figure 1 to Figure 3 , the diversion tank cover grasping and capping device of the present embodiment includes a connecting sleeve 1, a cover claw 2, a guide mechanism 3, a lifting mechanism 4, a motor, a cam 5, a tendon plate 6 and a cap removal cover 7.

[0030] The connecting sleeve 1 is rotatably connected with the bottom of the lifting mechanism 4 . Take the cover claw 2 and fix it on the lower part of the connecting sleeve 1. The guide mechanism 3 is fixed on the bottom of the lifting mechanism 4 and is positioned in the cover pawl 2 . The outer periphery of cam 5 is provided with track. The motor drives the lifting mechanism 4 to move along the orbit of the cam 5 periphery. The tendon plate 6 is frictionally connected with the outer wall of the connecting sleeve 1 .

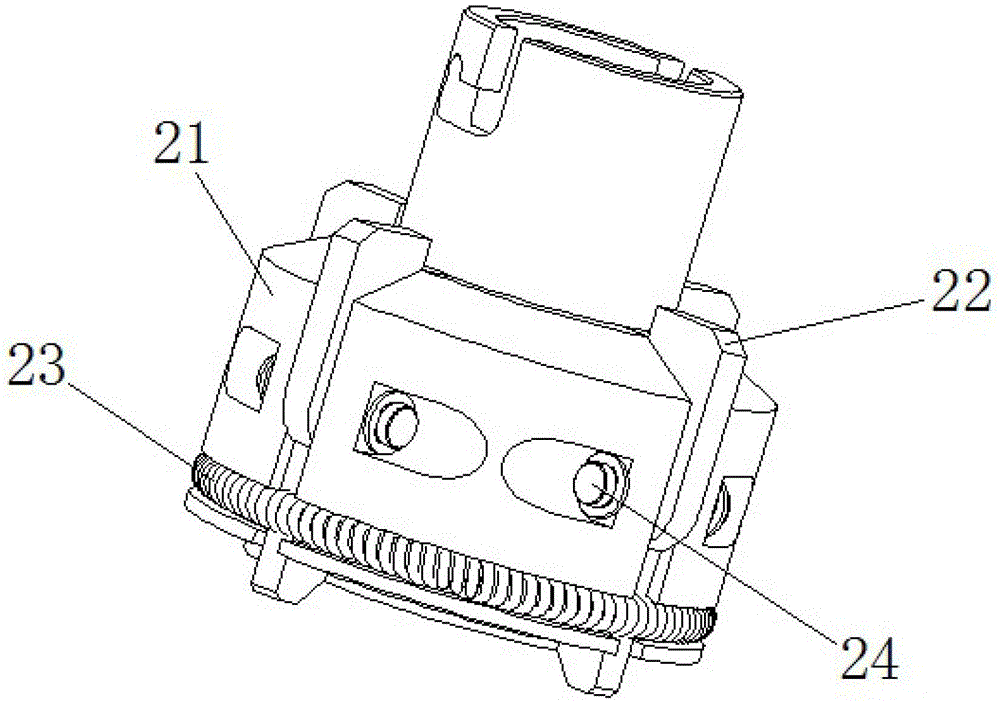

[0031] Get cover paw 2 and comprise paw seat 21, paw sheet 22, spring 23 and pin 24. A plurality of claw grooves are uniformly arranged on the outer periphery of the claw seat 21 , and a c...

Embodiment 2)

[0037] See Figure 4 , this embodiment is basically the same as Embodiment 1, except that the guide mechanism 3 includes an orientation block 34 . The orientation block 34 is provided with a protrusion 341 capable of matching with the notch 81 of the inner ring of the diversion tank cover 8 .

[0038] The guiding is completed when the protrusion 341 on the orientation block 34 cooperates with the notch 81 of the inner ring of the guide tank cover 8 .

Embodiment 3)

[0040] See Figure 5 , this embodiment is basically the same as Embodiment 2, except that: the orientation block 34 of the guide mechanism 3 is provided with a positioning groove 342 that can cooperate with the diversion groove 82 of the diversion groove cover 8 .

[0041] The guide is completed when the positioning groove 342 on the orientation block 34 cooperates with the flow guide groove 82 of the flow guide groove cover 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com