Spring cylinder

The technology of a spring cylinder and a spring seat is applied in the field of spring cylinders, which can solve the problems of high pressure and short service life, and achieve the effects of preventing rotation, enhancing the bearing force and having a reliable mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

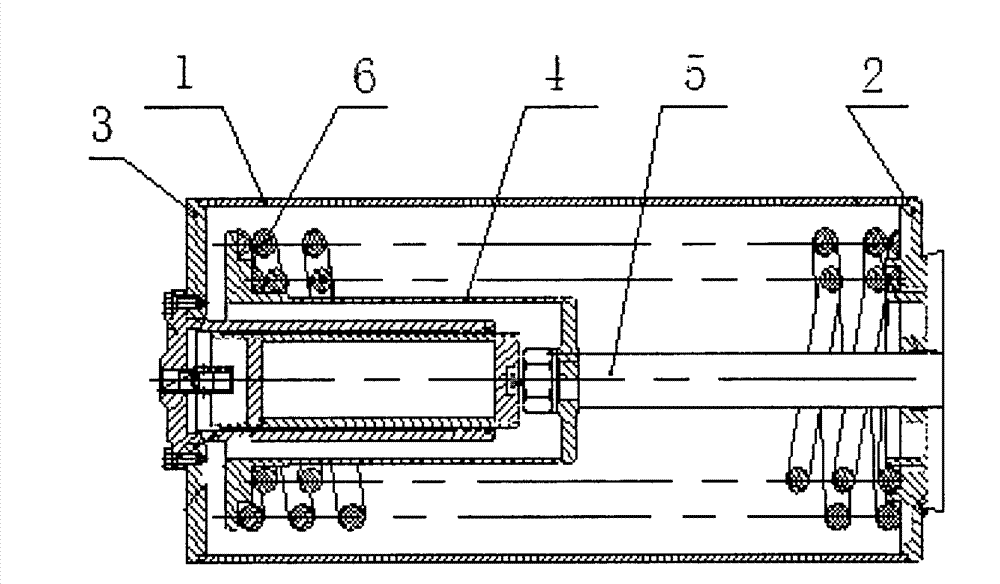

[0010] Such as figure 1 A kind of spring cylinder shown, comprises cylinder body 1, and described cylinder body 1 two ends are respectively provided with cylinder body end cover 2 and spring end cover 3, and described cylinder body 1 inner left end is provided with spring seat 4, and described spring The right end of the seat 4 is affixed to the piston rod 5, and the outer layer of the spring seat 4 is provided with a return spring 6; there are two return springs 6, and the two return springs 6 are arranged in the opposite direction of rotation; the cylinder end The cover 2 and the spring end cover 3 are sealed and welded to the cylinder body 1 respectively.

[0011] The structure of the present invention is simple, and the two return springs 6 are arranged in the opposite direction of rotation, and are arranged in the spring seat 4; The limited circumferential displacement effectively prevents the rotation of the piston rod 5 and the deviation of the return spring during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com