Brake automatic compensation device

An automatic compensation and brake technology, applied in the direction of the slack adjuster, etc., can solve the problems of manual adjustment, manual adjustment of the brake pad positioning device, etc., and achieve the effect of simple use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

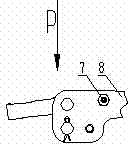

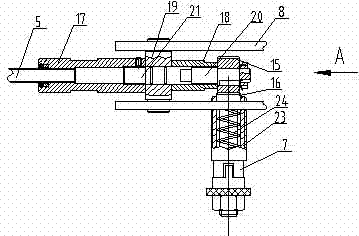

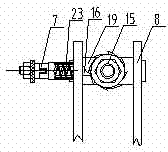

[0018] Such as figure 1 , figure 2 with image 3 A brake automatic compensating device shown includes a hinged shaft 19 hinged on the brake lever 8, a connecting shaft 21 is vertically arranged on the hinged shaft 19, the connecting shaft and the hinged shaft are clearance fit, and both ends of the connecting shaft are A threaded sleeve is provided, that is, a first threaded sleeve 17 and a second threaded sleeve 18. The first threaded sleeve 17 is provided with an internal thread matching the brake rod, and the end of the second threaded sleeve 18 is fixed with a ratchet movable tooth 15. A threaded sleeve 23 is also arranged on the lever corresponding to the ratchet movable tooth 15, and a return spring 24 is arranged in the threaded sleeve 23. The ratchet fixed tooth 16 is sleeved in the threaded sleeve 23, and the top of the screw sleeve 23 is provided with a limiter to prevent the ratchet from Fixed tooth 16 breaks away from screw sleeve, and ratchet movable tooth 15 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com