Multifunctional electric automation equipment installation base

A technology for electrical automation and equipment installation, which is applied in mechanical equipment, non-rotational vibration suppression, cooling/ventilation/heating transformation, etc. It can solve the problems of easily damaged electrical automation equipment, the inability to adjust the position of the equipment in height, and the inability to adjust the position of the equipment by rotation , to achieve the effect of ensuring stability and protection, improving heat dissipation and cooling effect, and ensuring service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

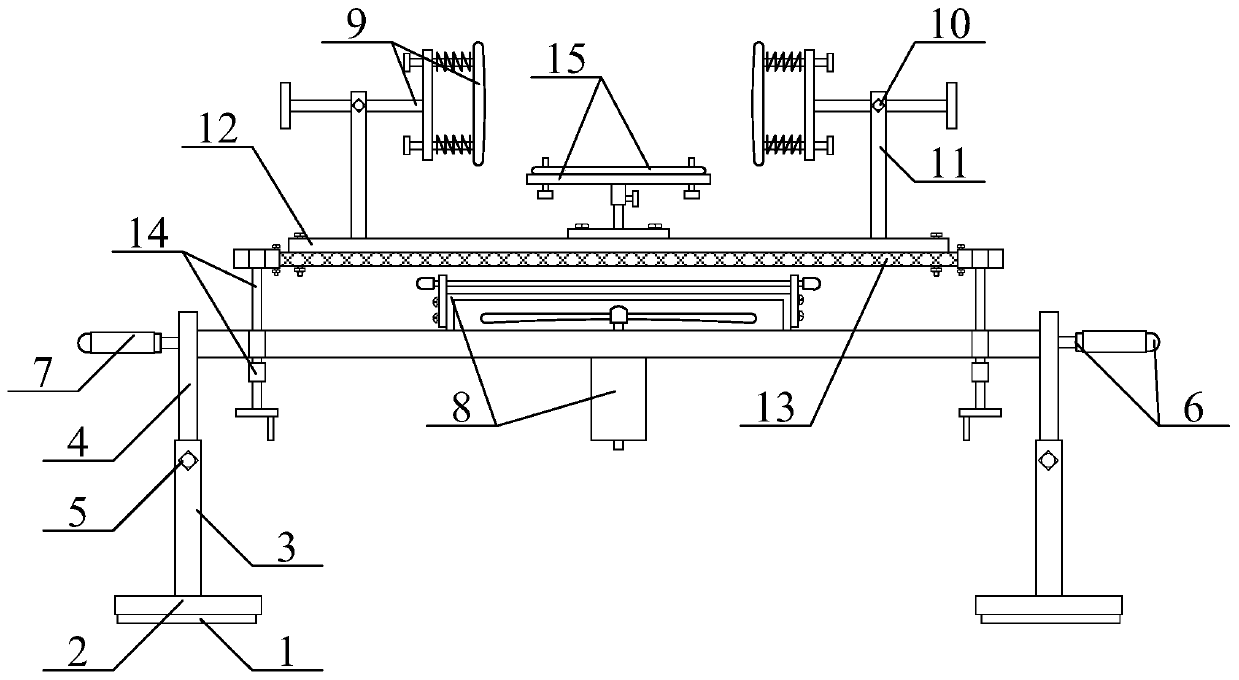

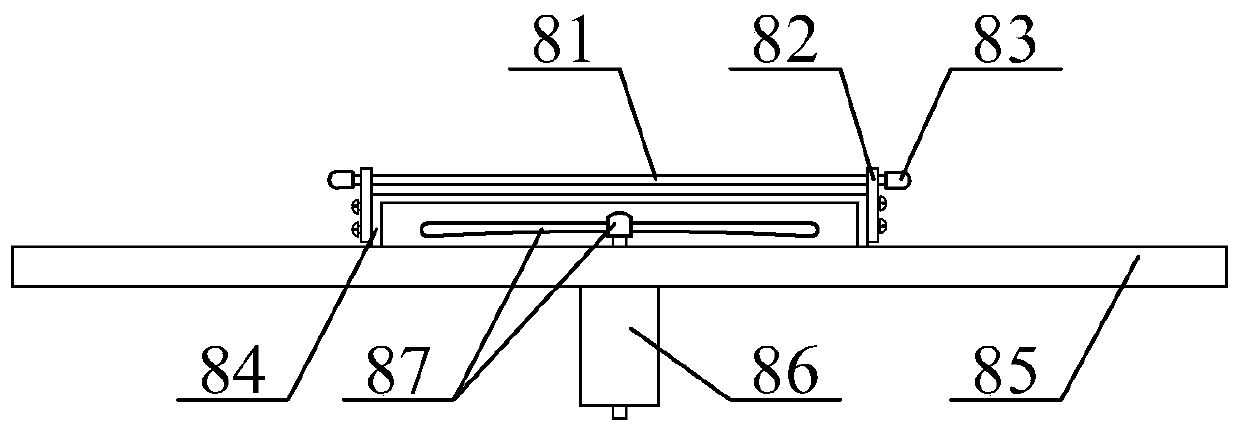

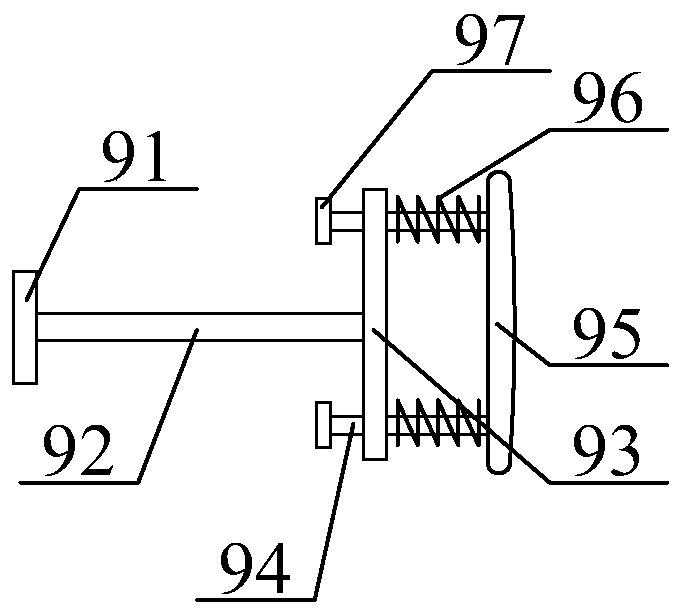

[0045] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a multi-functional electrical automation equipment installation base includes an anti-skid pad 1, a support base 2, a fixed pipe 3, a telescopic rod 4, an adjustment bolt 5, an auxiliary handle 6, a protective cover 7, and an auxiliary cooling fan 8 for cooling equipment. , the anti-injury buffer clamping frame 9, the fixing bolt 10, the support liner 11, the connection liner 12, the hollow seat 13, the height auxiliary adjustable equipment mounting seat structure 14 and the auxiliary equipment rotation adjustment fixed base structure 15, the described The anti-skid pads 1 are respectively transversely glued to the middle position of the upper surface of the support base 2; the inner middle positions of the support base 2 are respectively threaded to the lower end of the fixed pipe 3; the longitudinal upper parts of the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com