Efficient grinding method for tipping tooth tops of side-edge-free roughing broaches

A technology for grinding broach teeth and teeth, which is applied to broaches, broaching machines, metal processing equipment, etc., can solve the problems of reducing the number of regrinding times of knives, reducing the service life, and increasing the cost of use, so as to achieve the purpose of grinding The effect of shortening the time, reducing the production cost and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

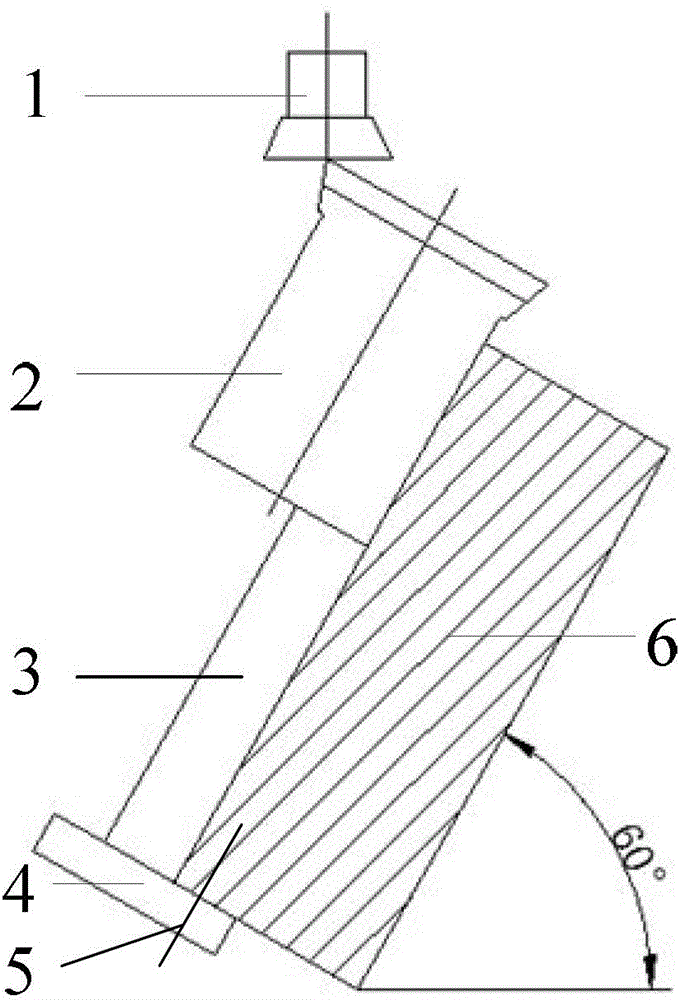

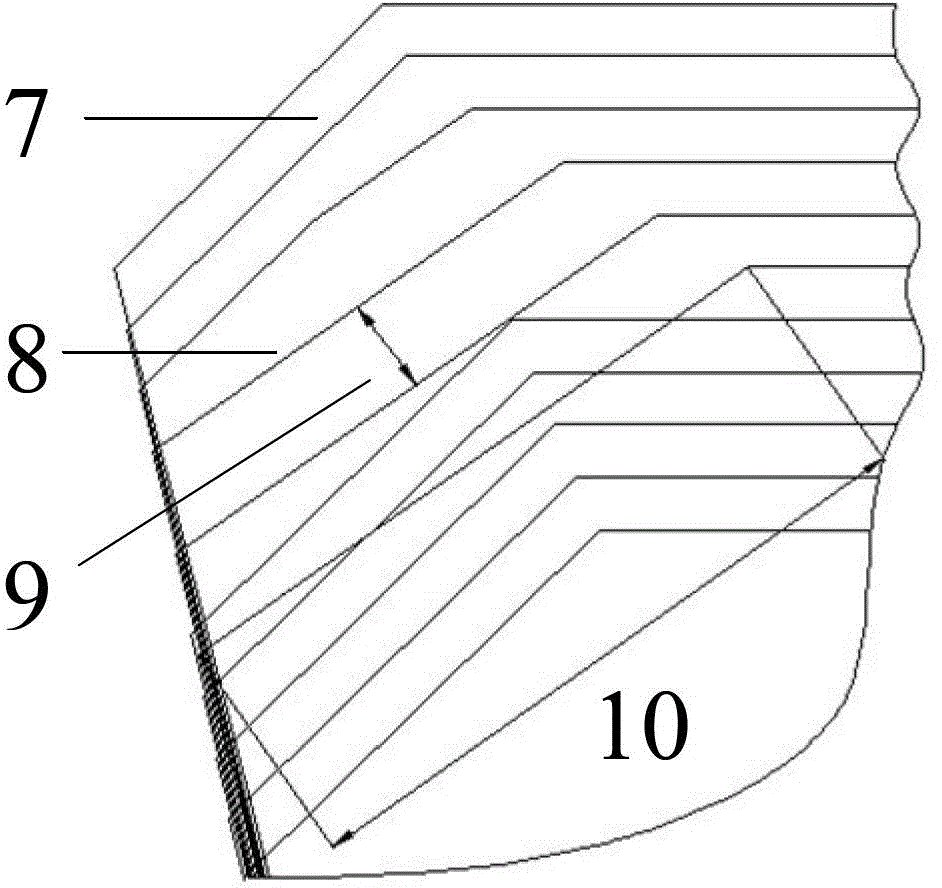

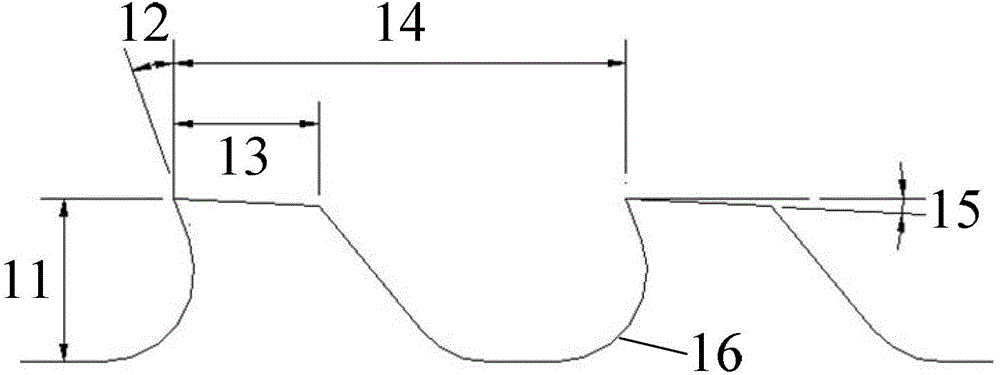

[0028] The invention is a high-efficiency grinding method for tooth tip chipping of a rough broach without a side edge, which is used for the tenon and groove broaching of a heavy-duty gas turbine rotor disk. In the triangular area at the tip of the cutter tooth, the subsequent cutter teeth are ground according to the shape of the chipping cutter tooth after grinding, and the grinding allowance is gradually reduced. The last three subsequent teeth of the broach are kept without grinding to ensure the broach Knife shape line, so as to change the local envelope of grinding broach teeth to achieve efficient grinding without side edge rough broach tooth chipping. The length of the triangular area at the tip of the chipped tooth of the grinding broach is no more than 5% of the width of the tooth, and the maximum depth is no more than 3% of the tooth height.

[0029] Please refer to figure 1 with figure 2 According to the present invention, the high-efficiency grinding method of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com