Multipurpose joint base

A joint seat and mandrel technology, applied in the direction of wrench, screwdriver, manufacturing tools, etc., can solve the problems of inconvenient use, complex structure, high processing cost, etc., and achieve the effect of accurate positioning and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

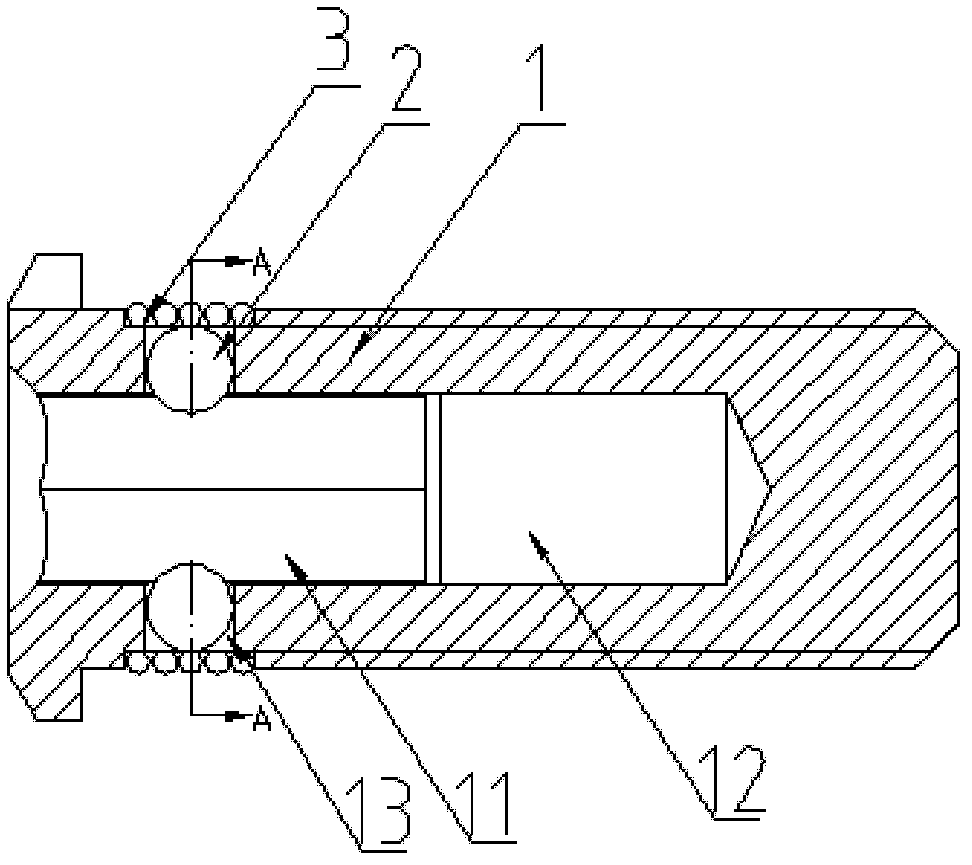

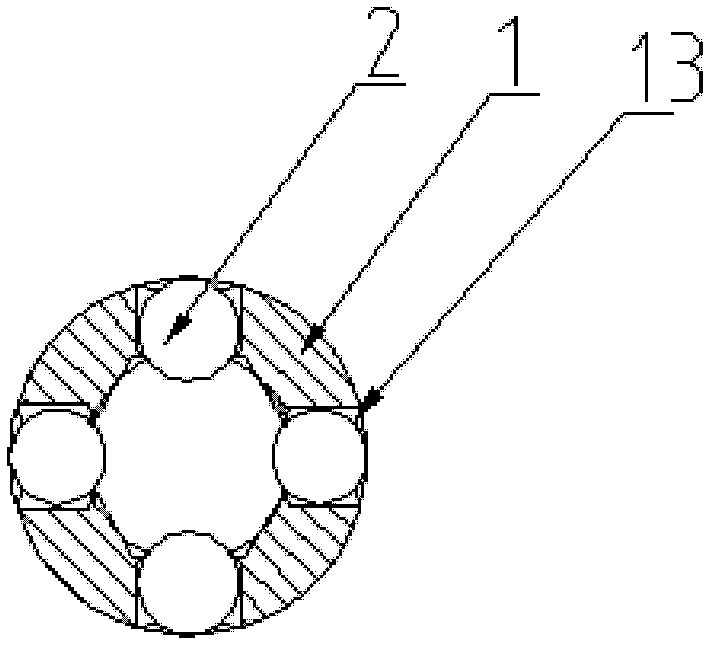

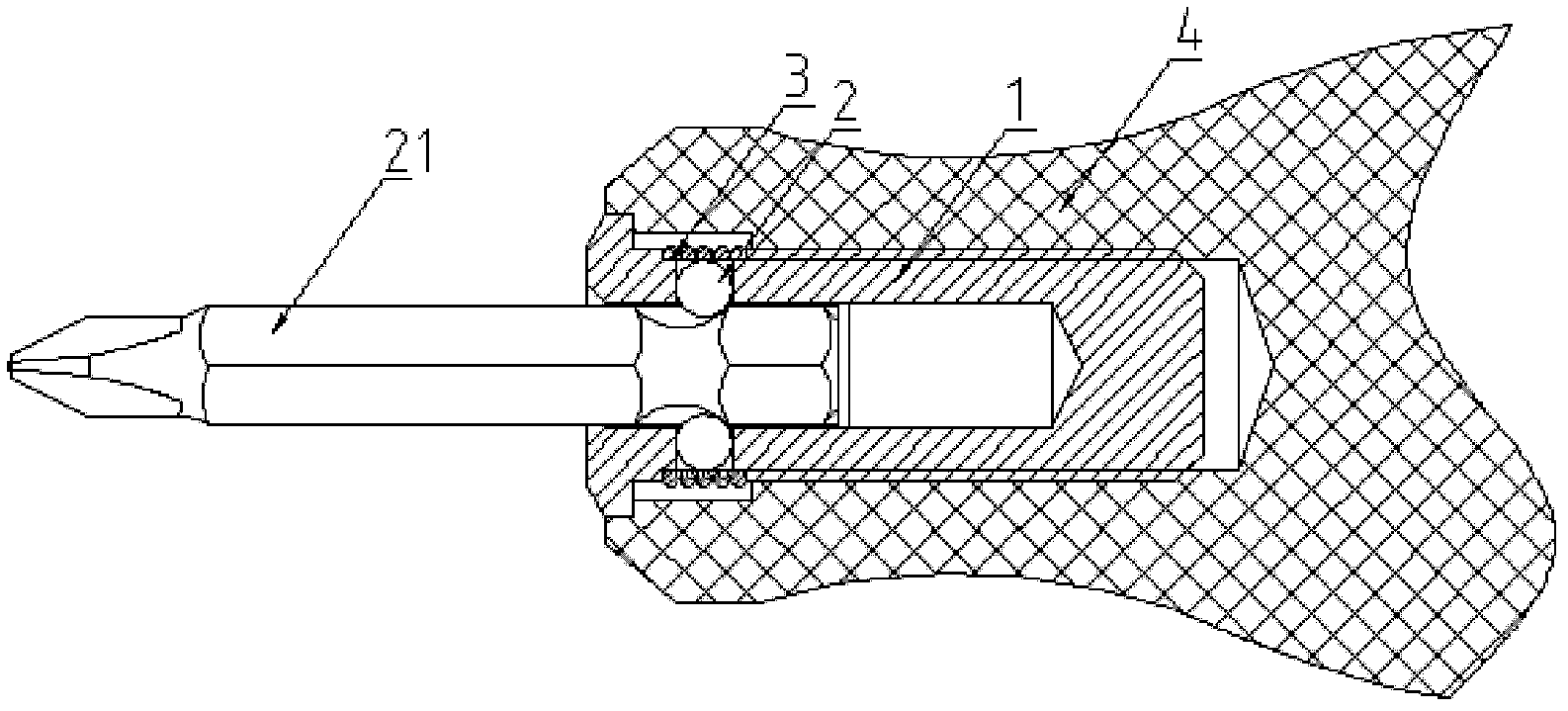

[0043] Embodiment: A multi-purpose joint seat, including a mandrel 1 and a first sphere 2, and the inner side of the mandrel 1 from one end to the other end is sequentially provided with an axial installation groove 11 (generally a hexagonal groove, which is convenient to be inserted with the workpiece 21) tools), the mandrel 1 is provided with at least one radial first hole 13, the first hole 13 communicates the mounting groove 11 in the mandrel 1 with the outside of the mandrel 1, and the ball is placed on the mandrel In the first hole 13 of 1, the side of the ball close to the installation groove 11 of the mandrel 1 can partially extend into the installation groove 11 without falling off, and a first elastic member 3 is also provided, and the first elastic member 3 axially stops. It is dynamically and tightly sleeved on the outside of the mandrel 1, and the inner side of the first elastic member 3 is tight against the side of the sphere facing away from the installation groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com