Falling Prevention Structure For Socket In Electric Power Tool

An electric tool and detachment prevention technology, which is applied in the field of detachment structure, can solve the problems of supporting parts detachment and sleeve detachment prevention, and achieve the effects of improved reliability, reliable detachment prevention assembly, and simple formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described below based on the drawings.

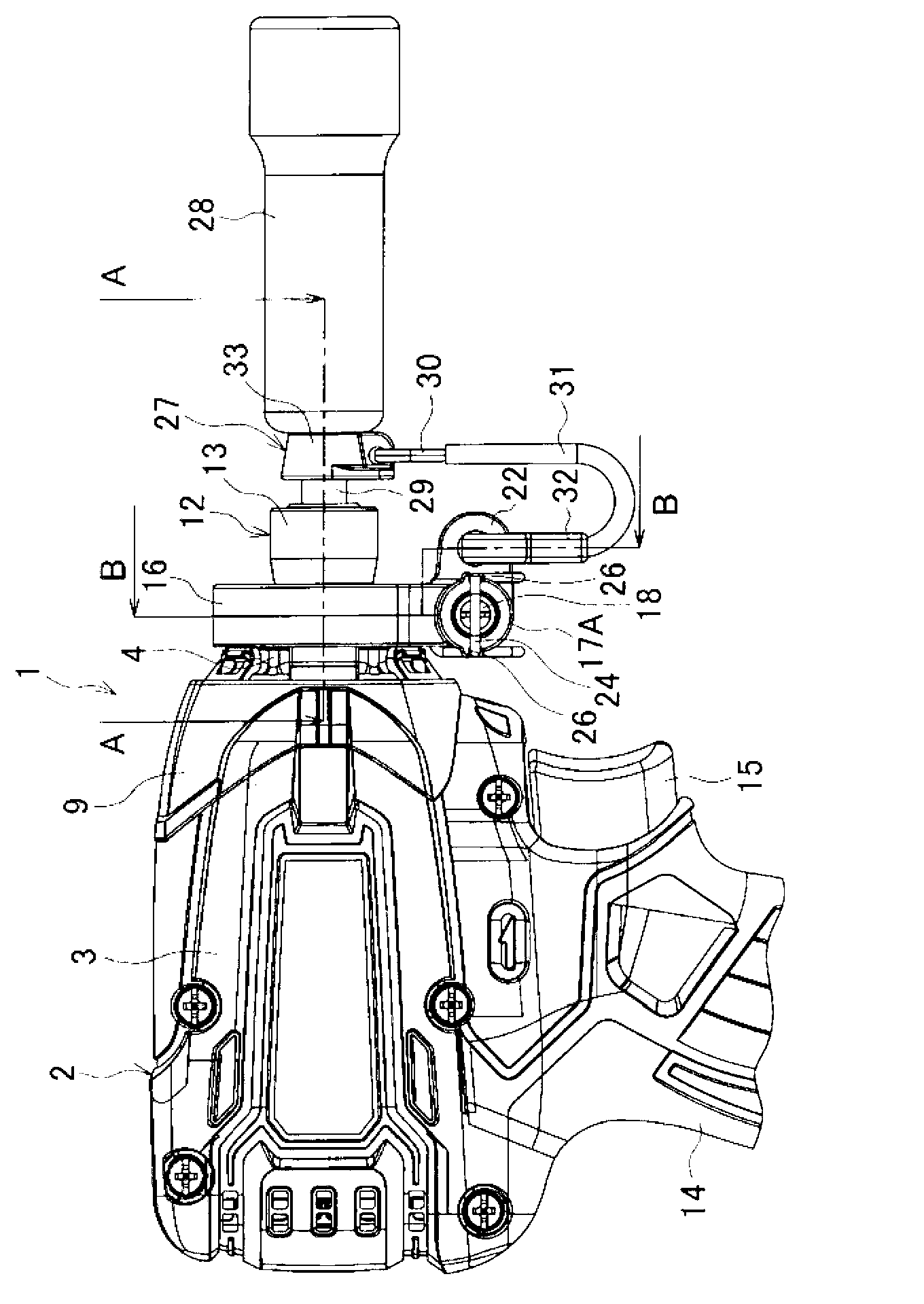

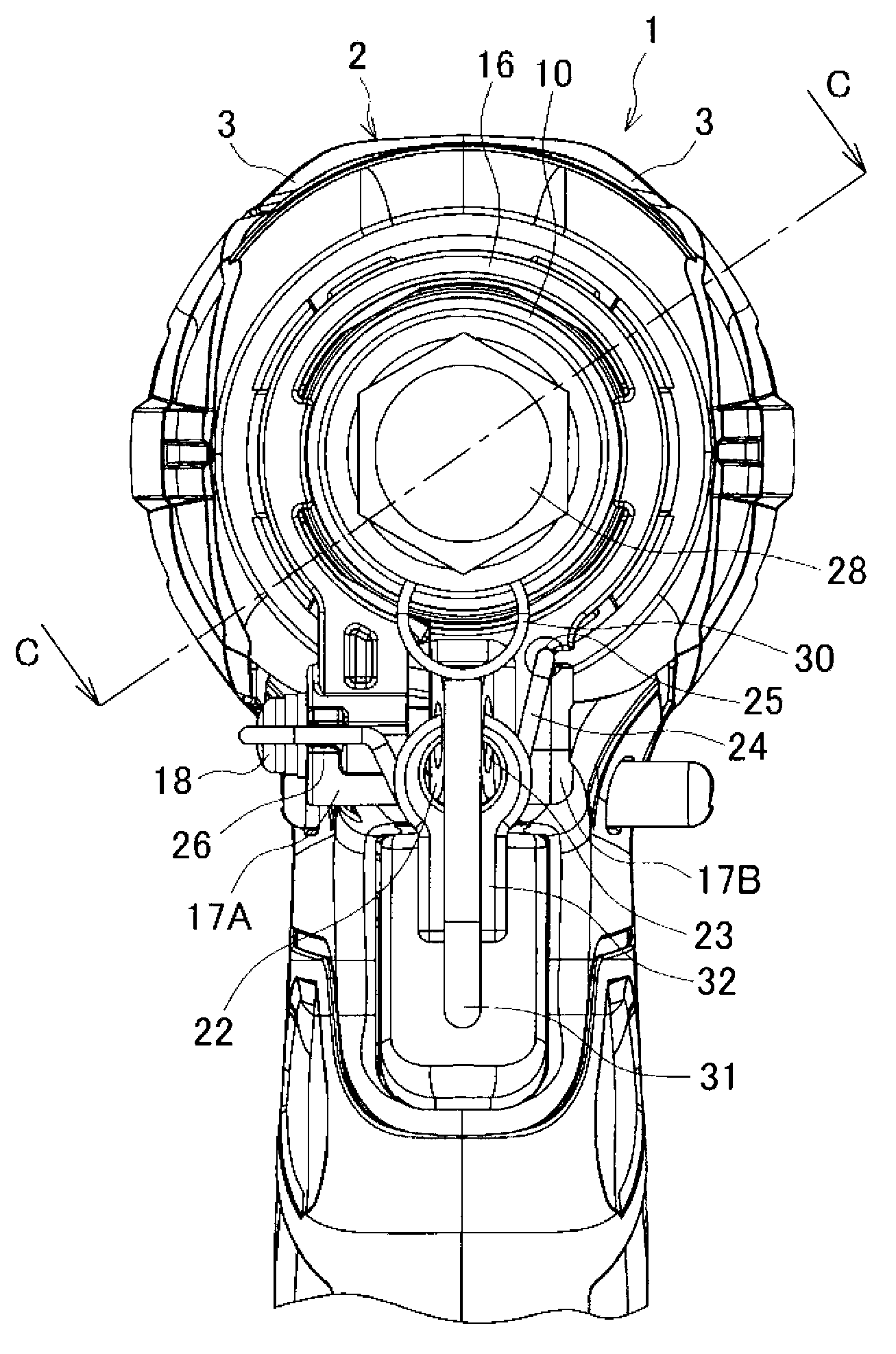

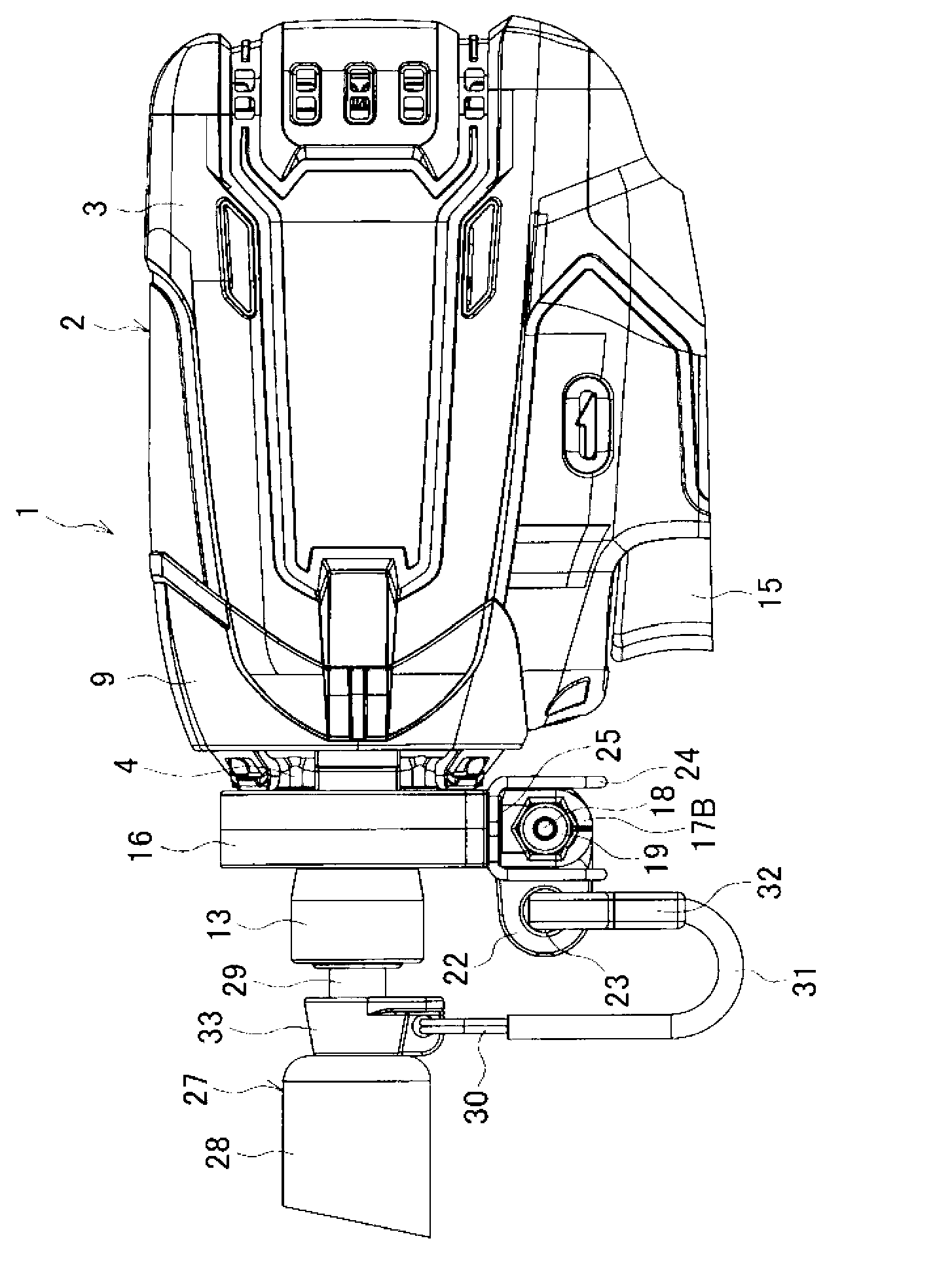

[0024] Figure 1-7 An example of the sleeve detachment prevention structure is shown. Reference numeral 1 denotes an impact screwdriver as an electric tool, and the impact screwdriver 1 includes: a synthetic resin main body case 2 formed by assembling left and right halves of the case 3 and housing a motor; The hammer case 4 made by the system is assembled in the front of the above-mentioned main body case 2 ( figure 1 The right side in the middle), and the main shaft 5, the striking mechanism 6, and the anvil 7 as the output shaft are accommodated as the front housing. The striking mechanism 6 is a well-known structure in which the hammer 8 repeatedly locks and disengages from the anvil 7 as the torque of the anvil 7 increases to strike (impact) in the rotational direction.

[0025] The hammer case 4 is a cylindrical body, and its rear part is inserted into the main body case 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com