Bidirectional rollover-type dumper box with linked bottom plate and side plates

A rollover type, dump truck technology, applied in the direction of inclined bearing motion vehicles, vehicles with loading ramps, etc., can solve the problems of burial, prone to overturning, only limited to one side unloading, etc., to achieve high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

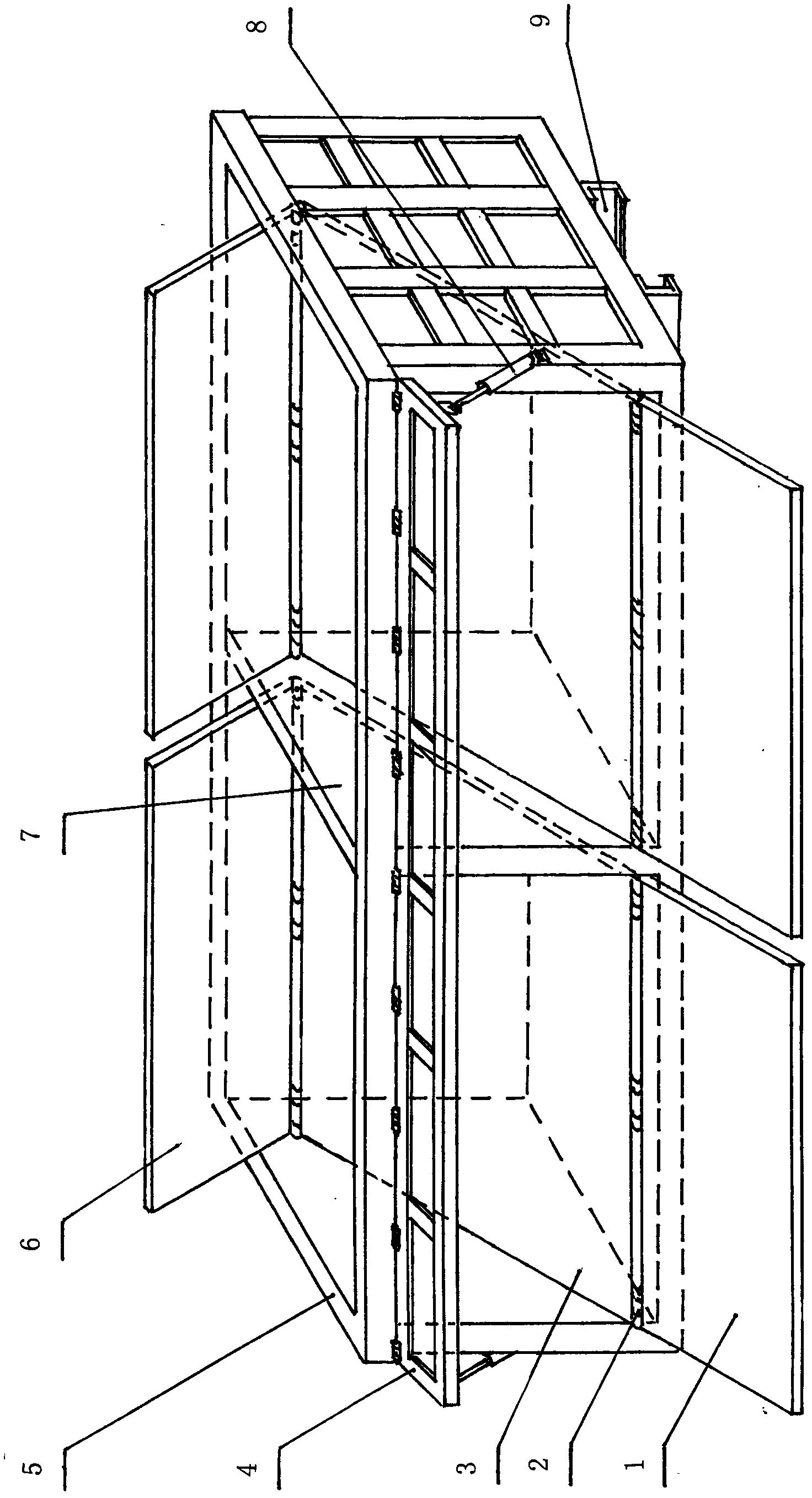

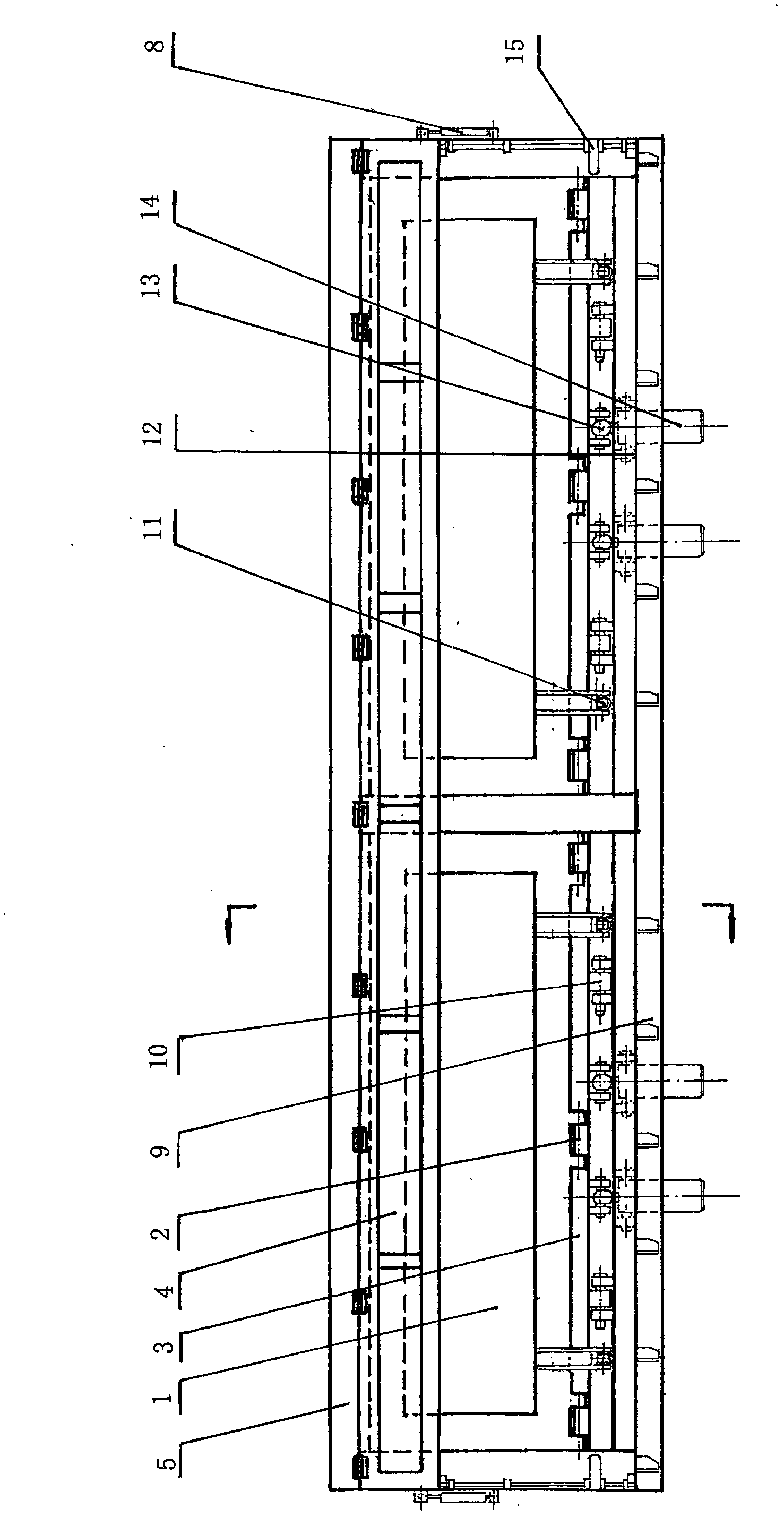

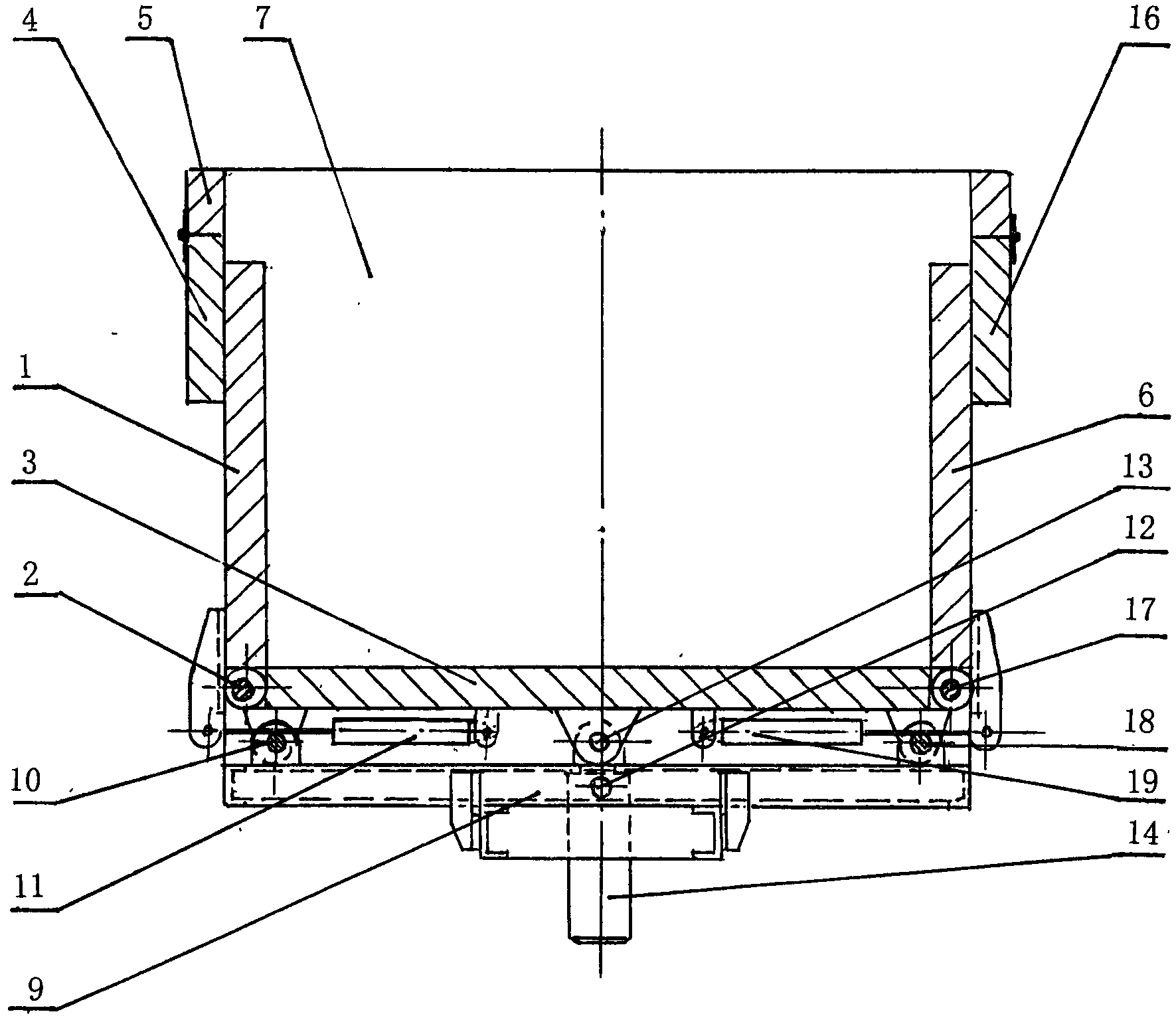

[0022] The two-way rollover dump truck box with the linkage of the bottom plate and the side plate is composed of the box body, the movable bottom plate and the left and right movable side panels, and the opening and closing mechanism of the movable bottom plate and the left and right movable side panels. Frame 9, the carriage frame 5 that is made up of upper left and right frame strips, front and rear box plates and middle partition 7, is installed on the left and right baffles 4, 16 under the left and right frame strips at the top of the carriage frame 5, and is located in the carriage frame 5 The movable bottom plate 3 of cavity, the left and right movable side plates 1,6 are formed.

[0023] The lifting and lowering mechanism of the movable floor 3 is the removable hinged movable floor 3 by the left and right bearings 10, 18 and the sub-frame 9, the head and the upper support 13 at the bottom of the movable floor 3 are hinged, And the lifting oil cylinder 14 that the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com