Rotary hydraulic system and construction machinery

A technology for hydraulic systems and construction machinery, applied in the hydraulic field, can solve the problems of affecting the control performance, brake lock, strong impact, etc., to prevent the car from slipping, reduce the impact feeling, and improve the control performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

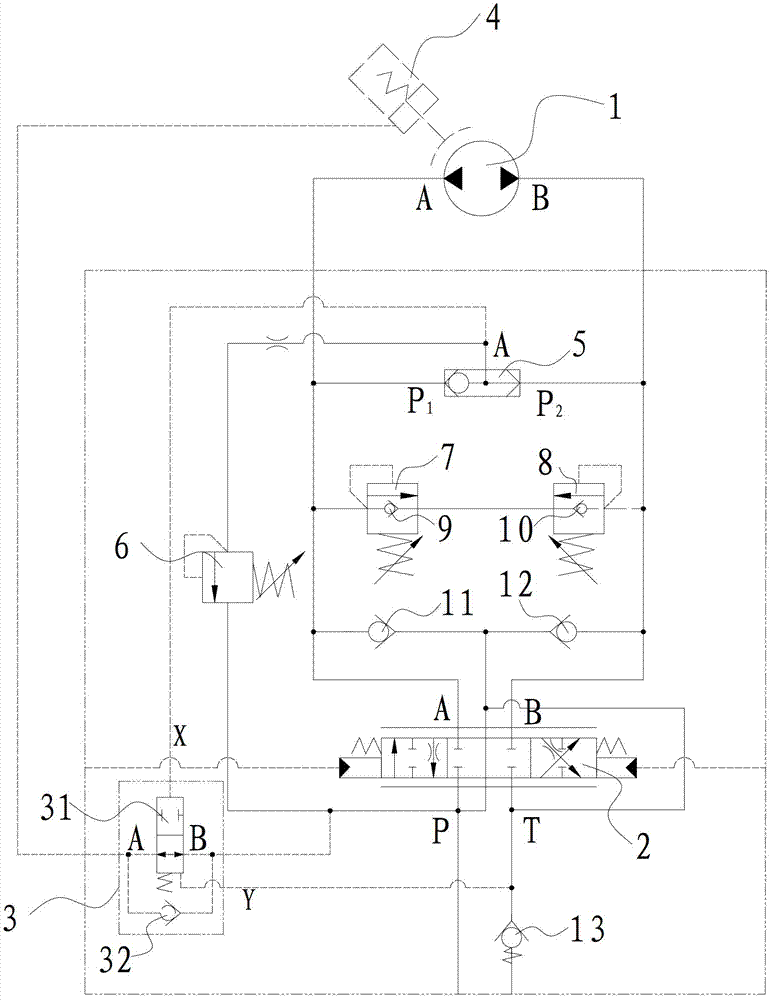

[0040] figure 1 It is the hydraulic schematic diagram of the rotary hydraulic system described in the embodiment of the present invention. As shown in the figure, the rotary hydraulic system described in this embodiment includes a rotary motor 1, a brake cylinder 4, a main valve 2, a shuttle valve 5 and a brake Dynamic anti-lock valve 3. The main valve 2 is a three-position six-way hydraulic pilot proportional valve. The brake anti-lock valve 3 includes a first check valve 32 and a hydraulic control reversing valve 31; 1 The port is connected with the A port of the rotary motor 1, and the B port of the main valve 2 is connected with the P port of the shuttle valve 5 at the same time. 2 It comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com