A single-stage excitation unit with external magneto-rheological damping

A magnetorheological damping, single-stage technology, applied in the field of manufacturing, can solve the problems of high manufacturing cost and limited number of coil turns, and achieve the effect of eliminating the restriction of magnetic circuit and flow channel design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

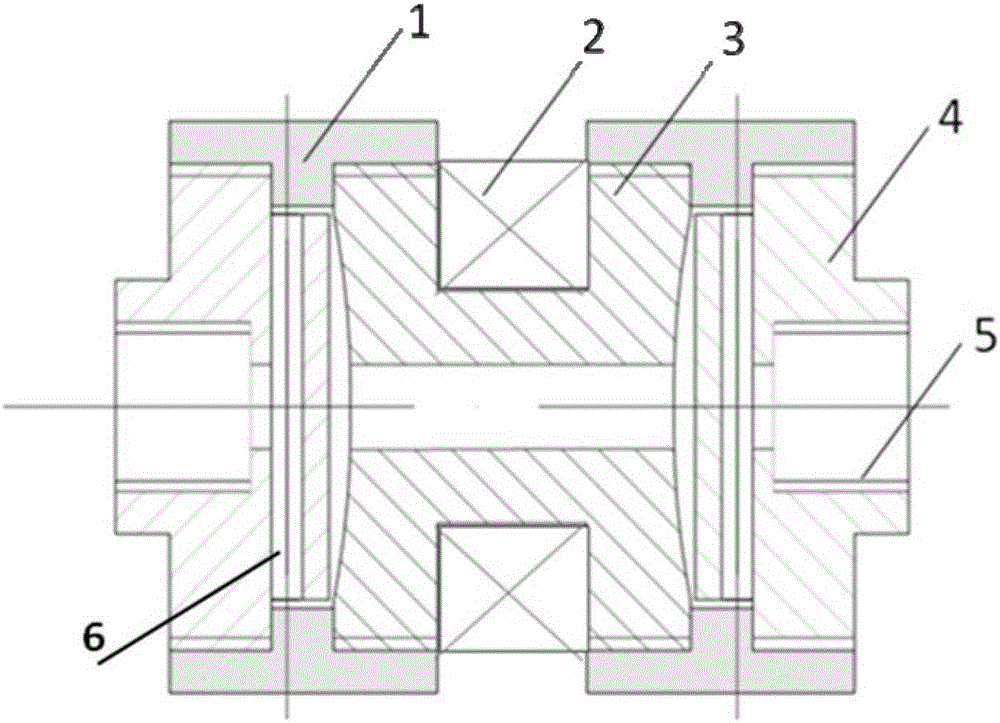

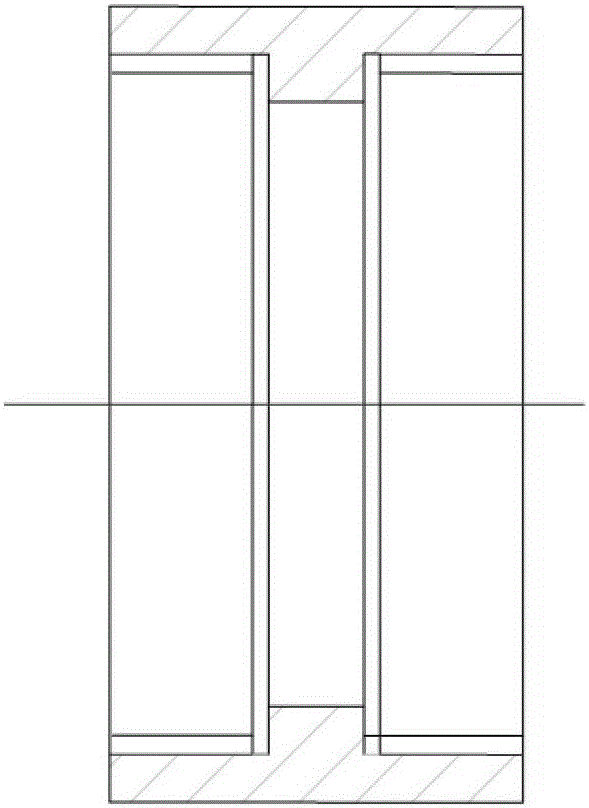

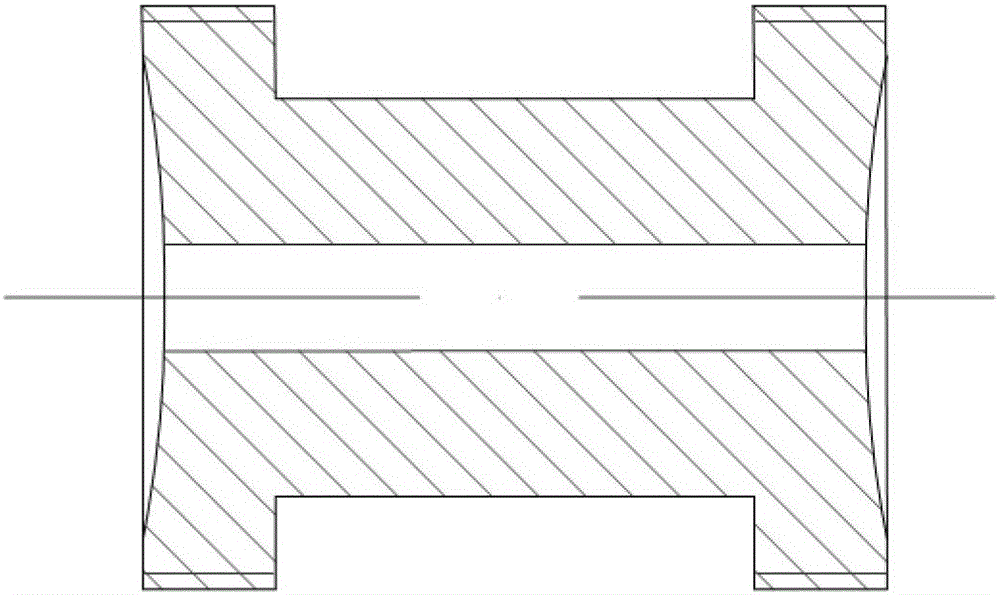

[0026] The end cover 4 and the I-shaped magnetic core 3 of the single-stage excitation unit of the external magnetorheological seat damper are made of 1J79 permalloy, the coil 2 is wound with polyimide high-temperature resistant enameled wire, and the copper sleeve 1 is made of stainless steel 304 manufacture. The copper sleeve 1 will connect the I-shaped magnetic core 3 and the end cover 4 together through threads, the quick connector threaded hole 5 is installed with a quick connector, and the excitation unit is connected with the magneto-rheological seat shock absorber cylinder through the pneumatic tube together.

Embodiment 2

[0028] The end cap 4 and the I-shape magnetic core 3 of the single-stage excitation unit of the external magnetorheological seat damper are made of 1J117 soft magnetic alloy, the coil 2 is wound with polyurethane high-temperature-resistant enameled wire, and the copper sleeve 3 is made of brass. The copper sleeve 1 will connect the I-shaped magnetic core 3 and the end cover 4 together through threads, the quick connector threaded hole 5 is installed with a quick connector, and the excitation unit is connected with the magneto-rheological seat shock absorber cylinder through the pneumatic tube together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com