Auxiliary centering device for automatically producing sheet metal in stamping mode

A technology of centering device and sheet material, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of inability to realize automatic centering of two blanks, and inability to realize free adjustment of distance, and achieves simple structure and easy use. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in further detail in conjunction with accompanying drawing now.

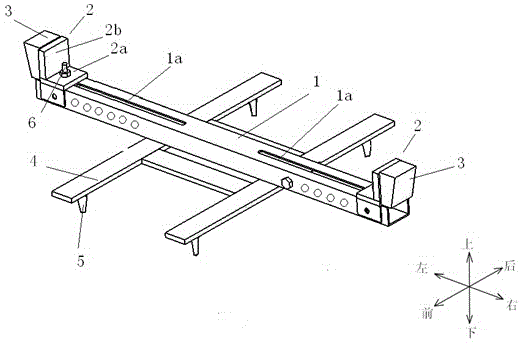

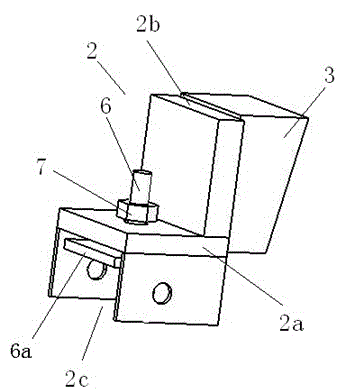

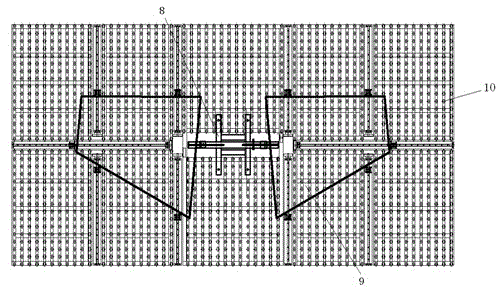

[0014] Such as figure 1 with figure 2 The shown auxiliary centering device for stamping automatic production sheet includes a base 4, a guide seat 1 fixed on the base 4, and a positioning device is respectively installed on the left and right parts of the guide seat 1, and the base The bottoms of the four tops of 4 are each provided with a tapered pin 5 with a large diameter at the upper end and a small diameter at the lower end. The top surfaces of the left and right parts of the guide seat 1 are respectively provided with a T-shaped first chute 1a along the longitudinal direction, and the two positioning devices are all composed of a positioning bracket 2 and a bolt 6. L-shaped, composed of a horizontal plate 2a and a vertical plate 2b, the lower part of the positioning bracket 2 is provided with a "┌┐"-shaped second chute 2c, the top of the second chute 2c is the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com