Bidirectional balanced flow distributor

A flow distributor and equalization technology, which is applied in the direction of fluid circulation arrangement, refrigeration components, refrigerators, etc., can solve the problems of unbalanced flow distribution of each branch, influence on heating performance, etc., and achieve the solution of uneven flow distribution and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

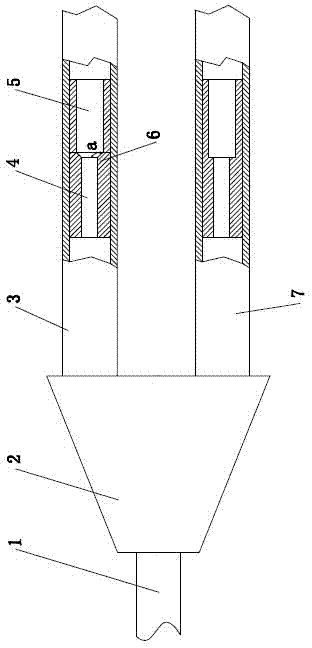

[0022] Such as figure 1 As shown, it is a two-way balanced flow distributor, including a splitter head 2, an inlet pipe 1, more than two connecting pipes and more than two resistance adjustment pipes; one end of the splitter head 2 is provided with an inlet port , the other end of the splitter head 2 is provided with more than two outlet ports, and each of the outlet ports communicates with the inlet port respectively; the outlet of the inlet pipe 1 communicates with the inlet port of the splitter head 2; the number of the connecting pipes The number of the outlet ports of the splitter head 2 is the same, and each connecting pipe is connected with the outlet port of the respective splitter head 2; In the connecting pipe and fastened, the outer wall of the resistance adjusting pipe is tightly matched with the inner wall of the connecting pipe; in this embodiment, the splitter head 2 has two outlet ports, so two connecting pipes and two resistance adjusting pipes are provided; ...

Embodiment 2

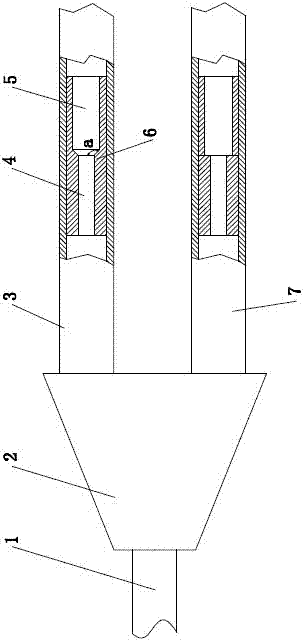

[0027] Such as figure 2As shown, a two-way balanced flow distributor includes a splitter head 2, an inlet pipe 1, more than two connecting pipes and more than two resistance adjustment pipes; one end of the splitter head 2 is provided with an inlet port for splitting The other end of the head 2 is provided with more than two outlet ports, and each outlet port is communicated with the inlet port respectively; the outlet of the inlet pipe 1 is communicated with the inlet port of the splitter head 2; The number of outlets of the head 2 is the same, and each connecting pipe is respectively connected with the outlet of the respective splitter head 2; the number of the resistance adjusting pipes is the same as that of the connecting pipes, and each resistance adjusting pipe is respectively arranged in the respective connecting pipes And fasten, the outer wall of the resistance adjusting pipe is sealed with the inner wall of the connecting pipe; in this embodiment, the splitter 2 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com