Linear motor for pump

A technology for linear motors and pumps, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of limited effective thrust, consumption, and large inertial force of linear motors, and achieve continuous thrust and work efficiency. Simple, high speed and acceleration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

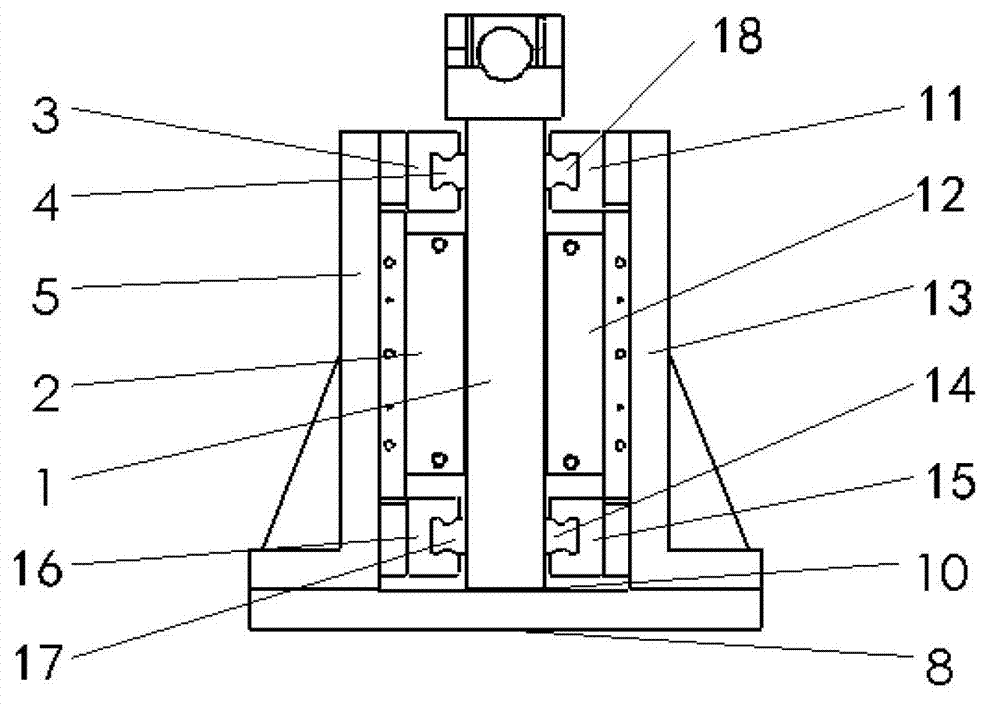

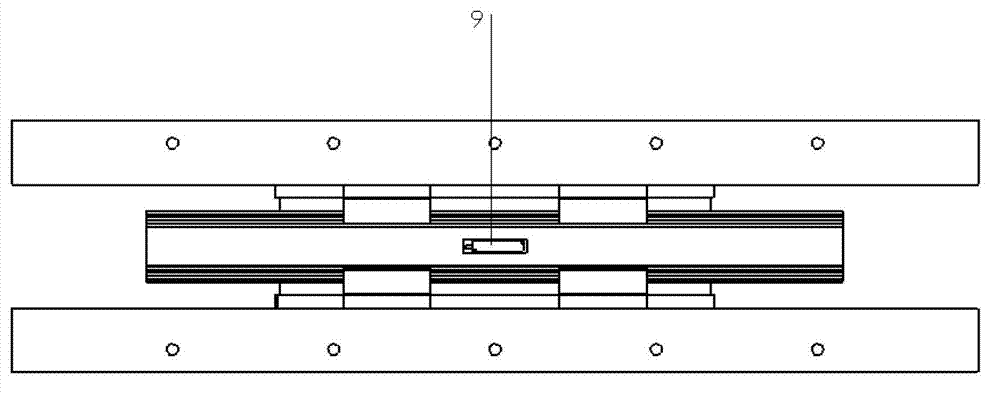

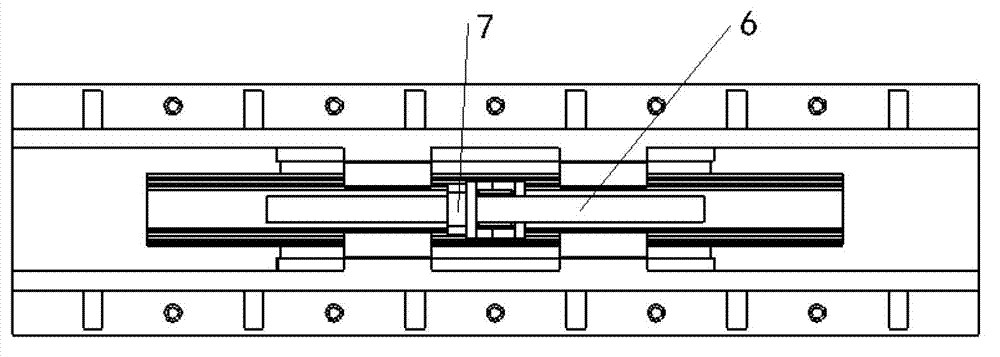

[0022] Such as Figure 1-3 Shown, a kind of pump linear motor of the present invention, its specific embodiment is as follows:

[0023] Including the stator and the mover 1, the linear motor adopts a moving iron symmetrical structure, that is, the two primary coils 2 and 12 are used as the stator, the permanent magnet yoke group is used as the mover 1, and the two primary coils 2 and 12 are symmetrically arranged on the mover 1 The two sides of the primary coils 2 and 12 are connected to the UVW three-phase alternating current to generate a traveling wave magnetic field, and the mover 1 generates a thrust relative to the stator under the combined action of the two traveling wave magnetic fields; among them, the two primary The coils 2 and 12 are respectively installed on the stator mounting plates 5 and 13 on both sides of the mover 1, and the upper and lower ends of the two primary coils 2 and 12 are respectively provided with sliders 3, 11, 15 and 16, and the slider 3 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com