Bilateral flat-plate type linear motor

A linear motor and flat-plate technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of large inertial force, consumption, and limited effective thrust of linear motors, etc., to facilitate heat dissipation, simple pipeline layout, and improve continuous Effects on Thrust and Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

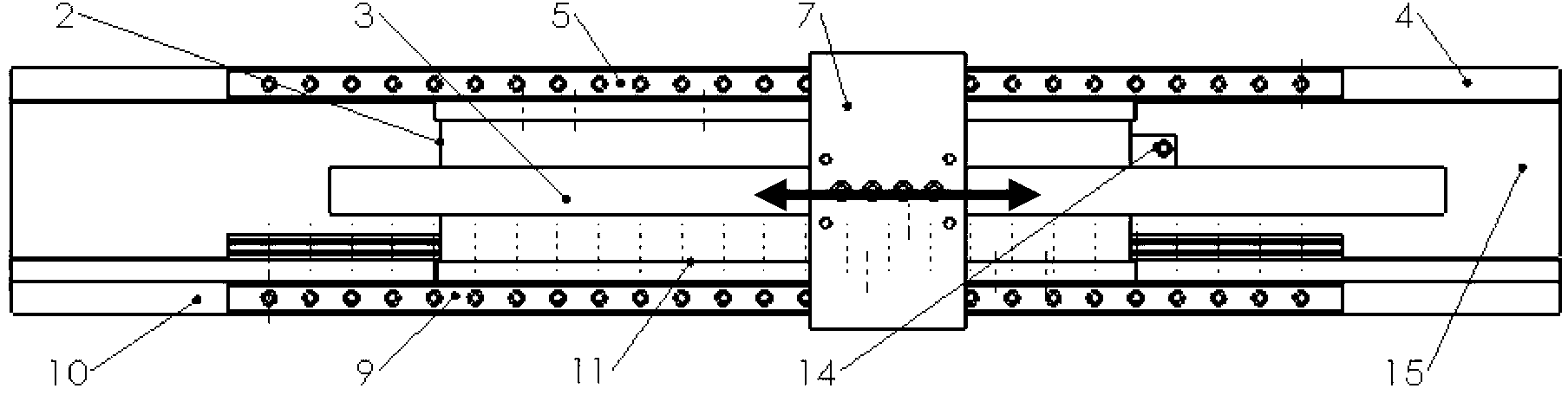

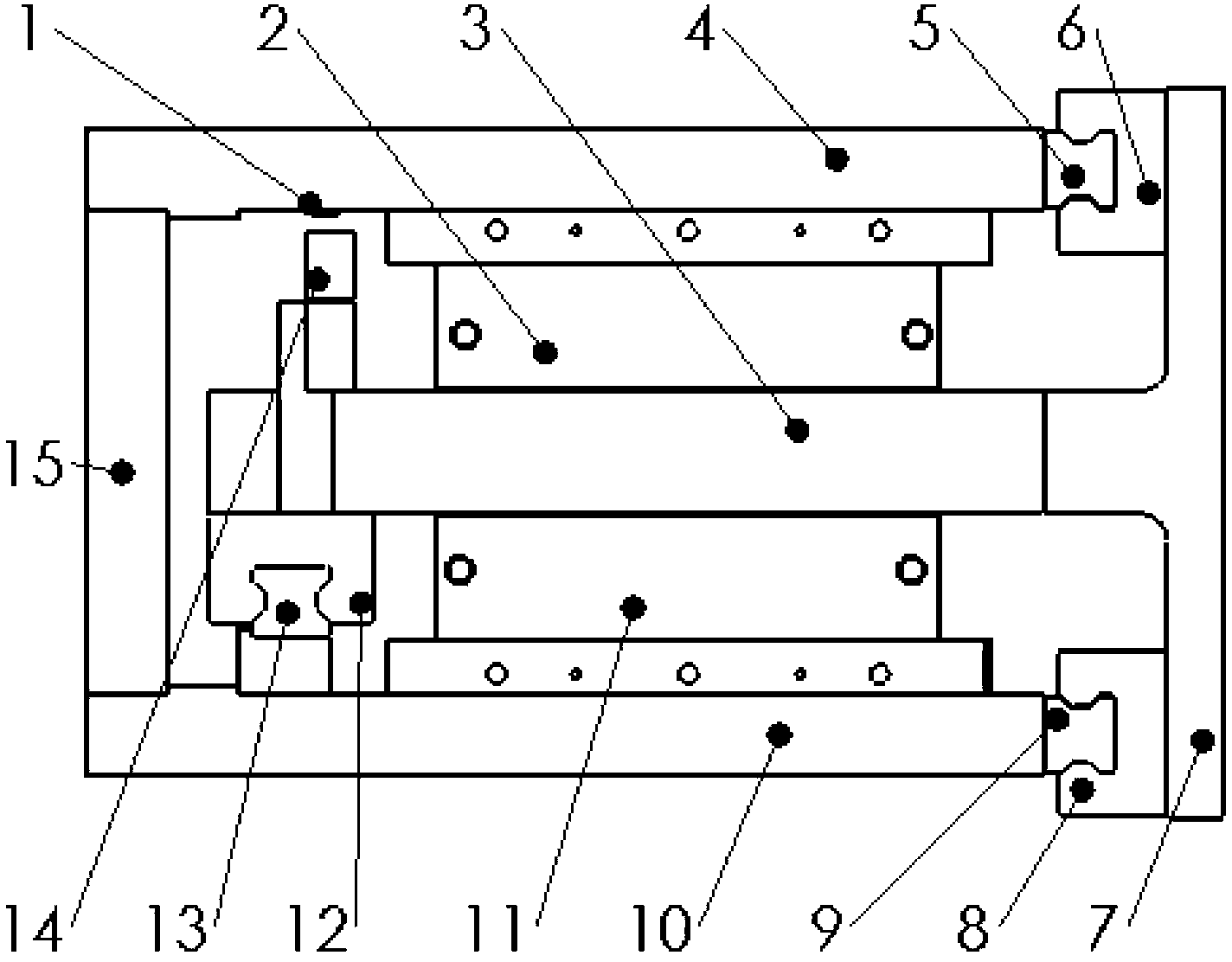

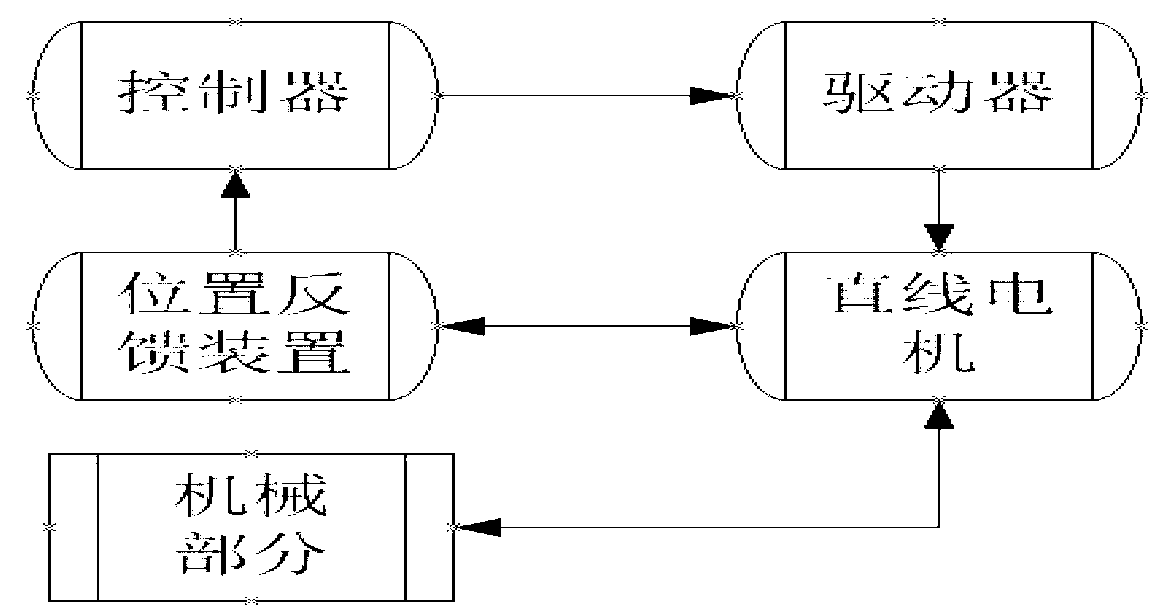

[0017] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. as attached image 3 As shown, the linear motor system is composed of a controller, a driver, and the bilateral flat linear motor of the present invention, and the grating ruler scale 1 and the grating ruler reading head are the attached image 3 The position feedback device shown.

[0018] According to the set motion plan, the controller sends corresponding command signals to the driver, and the driver amplifies the control signal, and outputs the power current to the coil I2 and coil II11 of the linear motor. The windings of coil I2 and coil II11 are arranged in a specific way. Under the action of three-phase alternating current, the stator coil generates a specific traveling wave magnetic field. In this traveling wave magnetic field, the linear motor mover 3 generates an axial thrust relative to the stator coil. Coil I2 and coil II11 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com