Sharp knife structure adopting air hydrostatic guideways

A technology of aerostatic pressure and guide rails, applied in turning equipment, large fixed members, clamping, etc., can solve the problems of inability to meet the processing requirements of complex surface parts such as micro-optics, and achieve high output force, low shape accuracy, precision The effect of efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

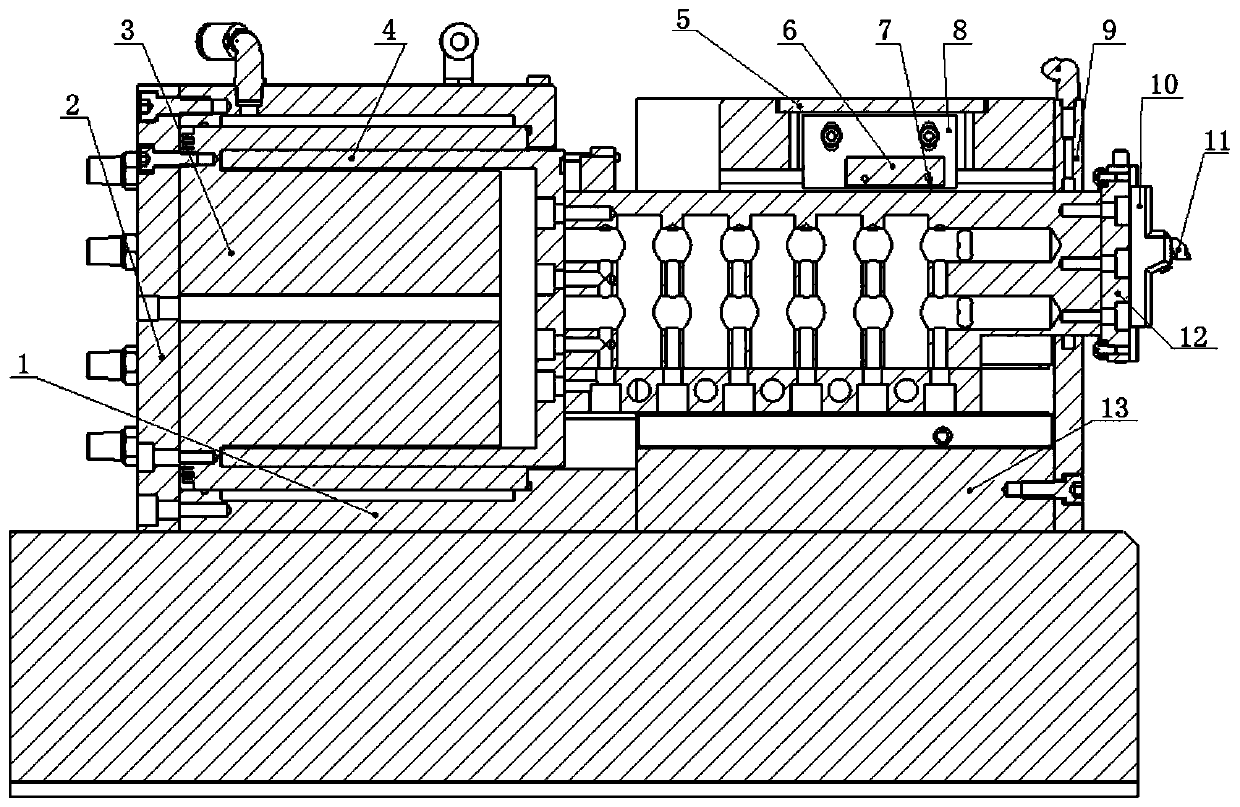

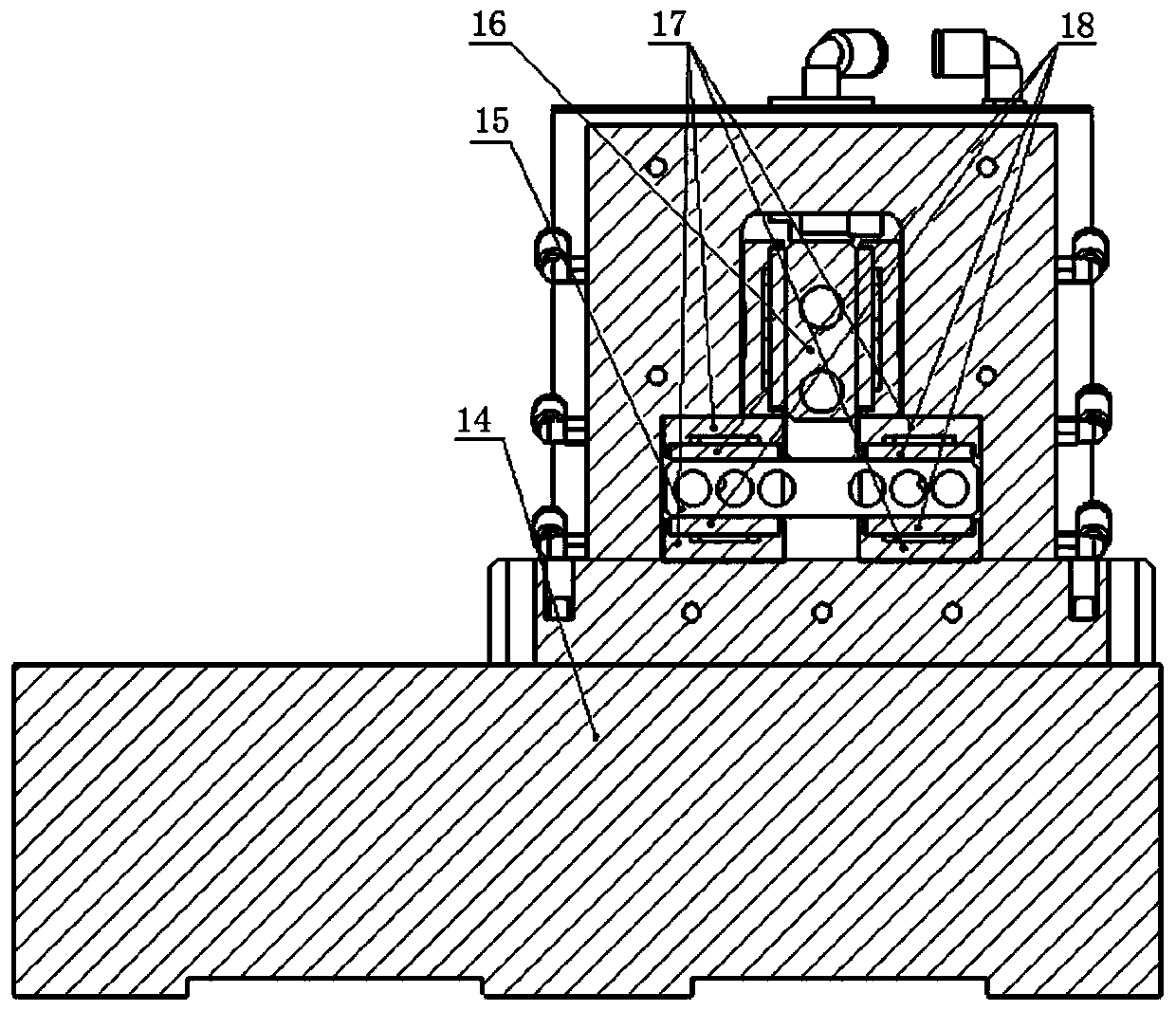

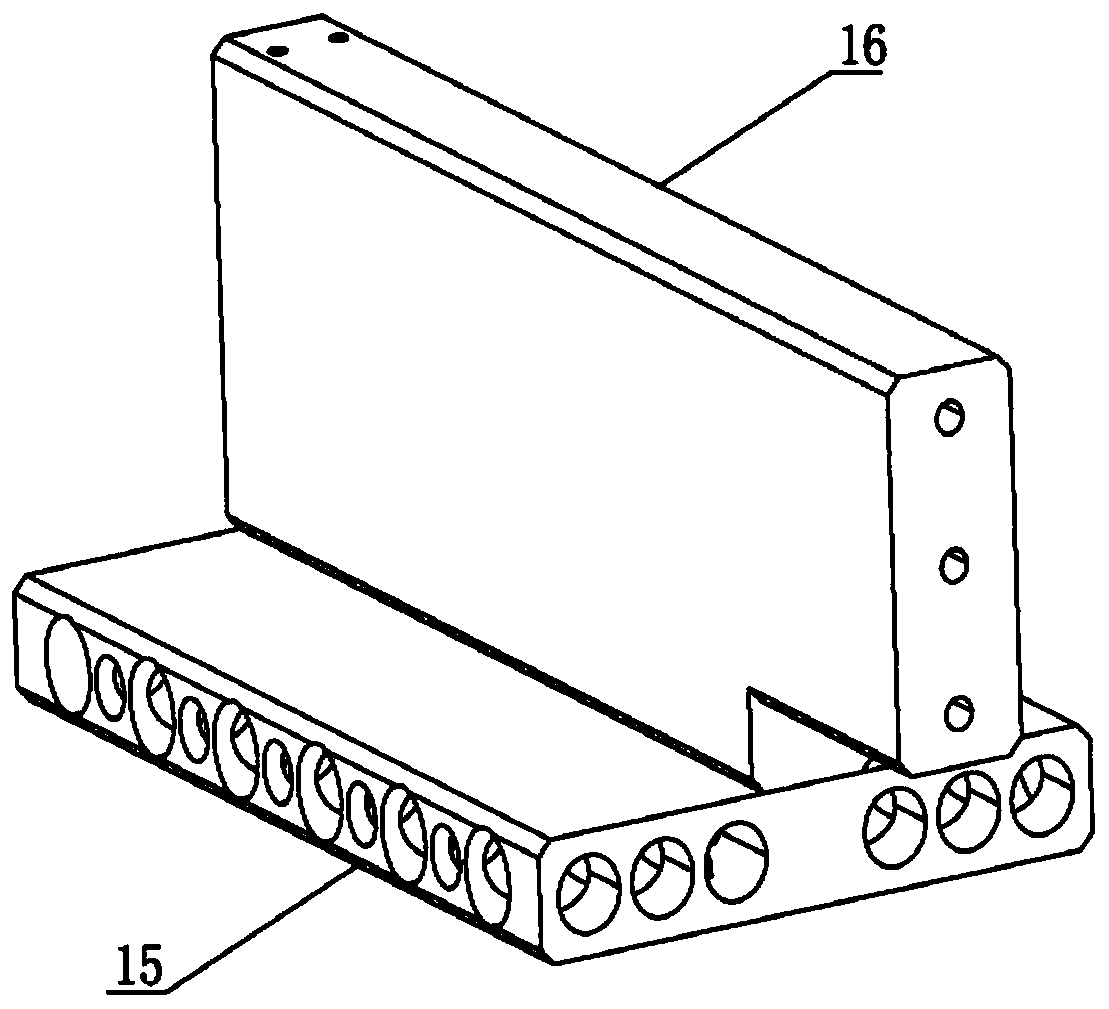

[0030] like Figure 1-Figure 3 As shown, a fast knife structure using an air static pressure guide rail in the present invention includes a motor, an air static pressure guide rail group, a tool assembly and a measuring assembly.

[0031] The motor is a voice coil motor. The voice coil motor has the advantages of large output force, high speed and acceleration, and large stroke. It can realize the high-frequency response required for the processing of complex microstructure parts, and can also meet the processing of high-steep and complex surface shapes. The required large travel requirements. The motor includes a stator 3 and a mover 4 . The stator 3 is installed on the stator base 2, and a stator water jacket 1 is arranged outside the stator 3. The stator water jacket 1 is used to cool the motor. The stator water jacket 1 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com