Motor-powered machine tool, in particular a hand-held machine tool

A hand-held machine tool and motor-driven technology, which is applied in the direction of motor tools, multi-purpose hand tools, manufacturing tools, etc., can solve the problems of restricting the shape of the top surface of the shell, and achieve the effect of simple structure, precise manufacturing, and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

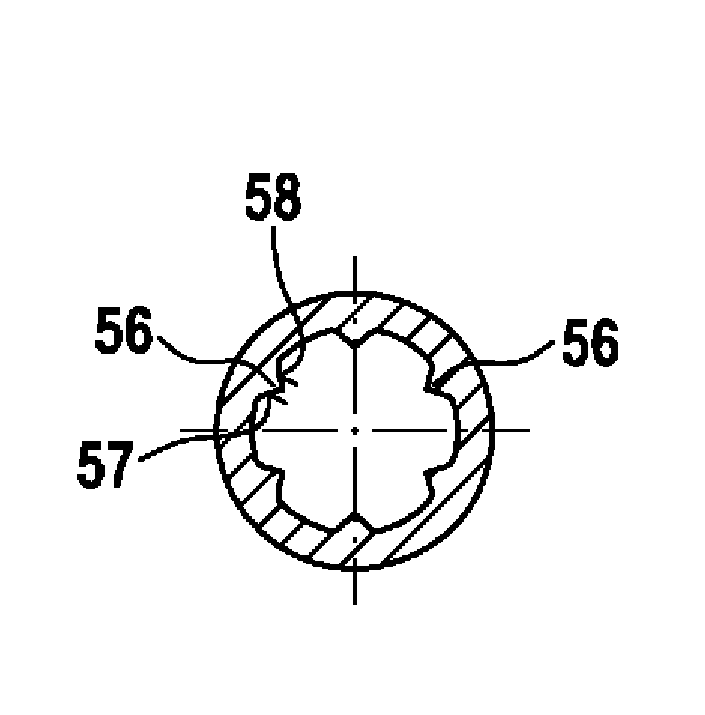

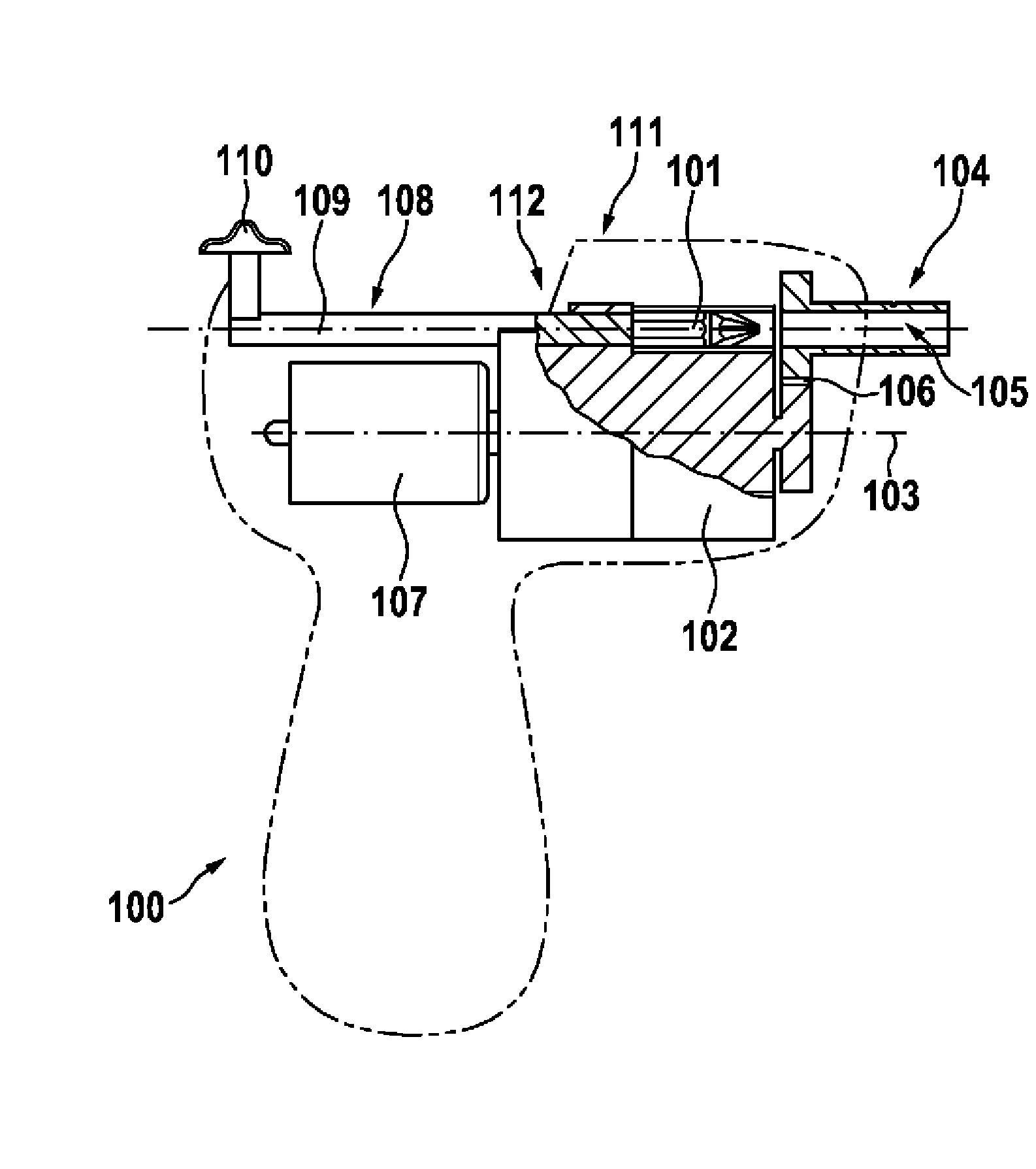

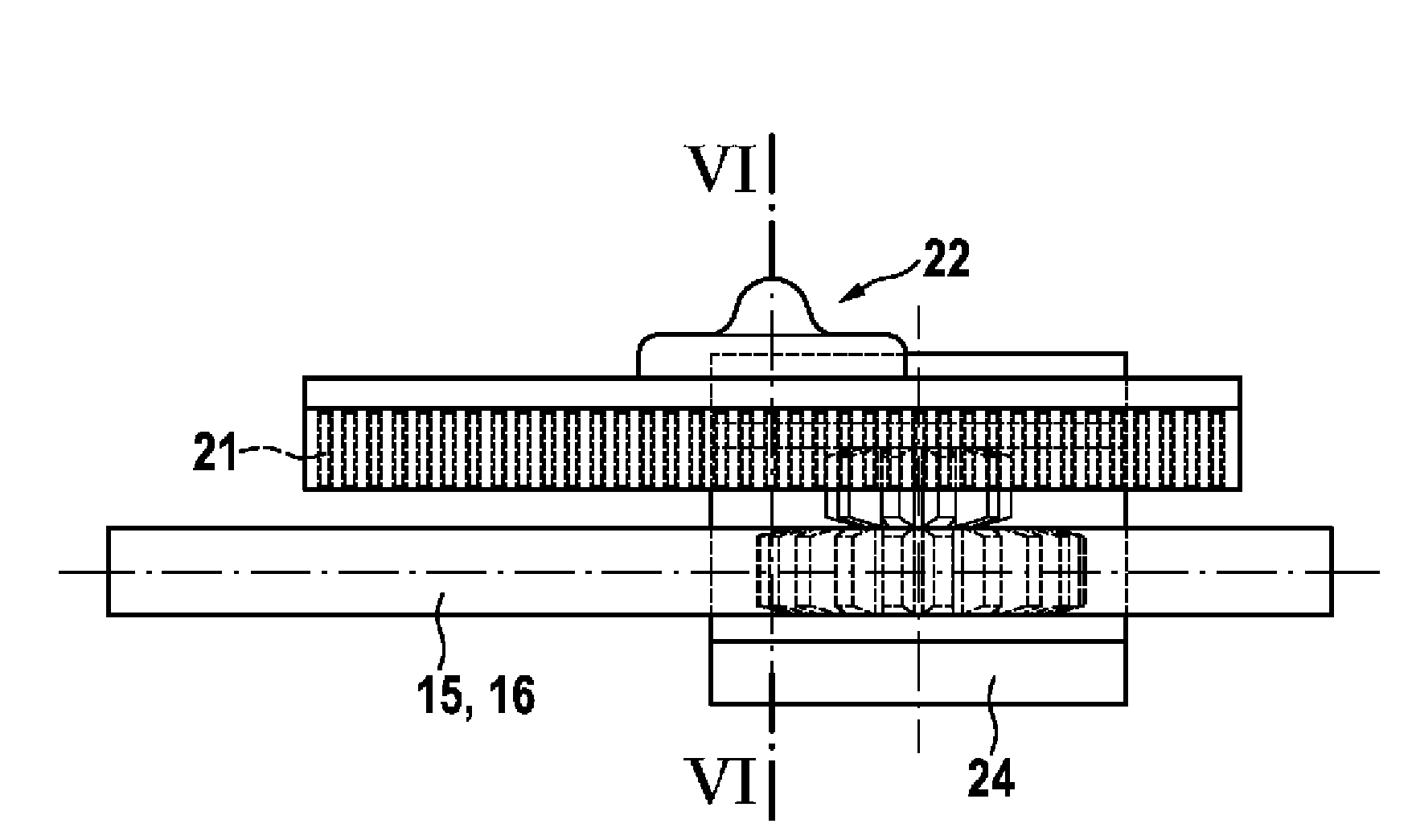

[0031] FIG. 1 shows a very simplified illustration of a motor-driven power tool 100 in the form of a hand power tool according to the prior art. The machine tool 100 is here designed in the form of a so-called "rotary screwdriver", which is suitable for handling various tools 101 in the form of rotary inserts. The tool 101 is arranged in a tool compartment of a revolver-style tool box 102 , not shown in FIG. 1 , wherein the tool box 102 is mounted rotatably in a longitudinal axis 103 . The machine tool 100 also has a tool chuck 104 which has a tubular region 105 into which a tool 101 to be used from a tool box 102 is inserted. To exchange for a new tool 101 , the tool chuck 104 is rotated centered on the empty tool chamber of the tool box 102 . The tool chuck 104 is connected to drive the tool 101 via a gear tooth 106 to a drive motor 107 , which generates a corresponding rotational movement of the tool chuck 104 , wherein the tool 101 is arranged in the tool chuck 104 in a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com