Combined chamber wall and heat exchanger

A technology for heat exchangers and cylinder walls, applied in the field of heat exchangers, can solve the problems of different, difficult to provide, increasing the demand for heat removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

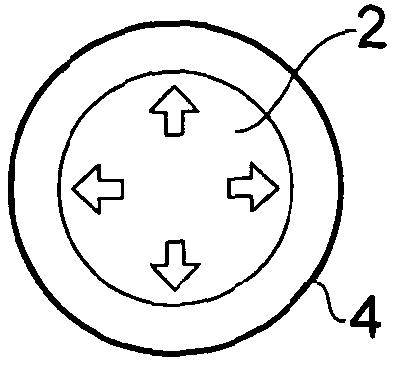

[0045] Figure 1 shows a prior art cylinder, such as that used in a reciprocating piston engine. The cylinder includes charge gas 2 which must be contained by cylinder walls 4 . The cylinder wall 4 is solid and the thickness of the cylinder wall 4 is such that it is strong enough to contain the charge gas 2 .

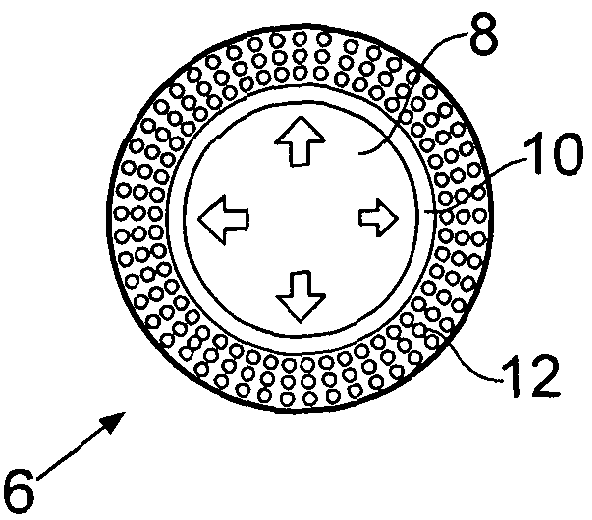

[0046] figure 2 Cylinder 6 for a reciprocating piston engine is shown. Cylinder 6 contains charge gas 8 . The walls of the cylinder 6 accommodate a solid part 10 and a heat exchanger part 12 . The heat exchanger section houses a plurality of conduits forming an array of conduits. The array of conduits is in fluid communication with the exterior of the cylinder 6 . Accordingly, heat may be removed from or sent to the cylinder 6 via fluid flowing through these conduits within the heat exchanger portion 12 .

[0047] exist figure 2 As can be seen in Fig. 1, the solid portion 10 of the wall is thinner than the cylinder wall 4 of the embodiment of Fig. 1 . Because add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com