Piezoelectric ultrasonic atomizer

A piezoelectric ultrasonic and nebulizer technology, applied in the field of nebulizers, can solve problems such as low energy utilization rate, reduced atomization effect, and shortened service life of the nebulizer, so as to improve energy utilization rate and reduce use cost , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

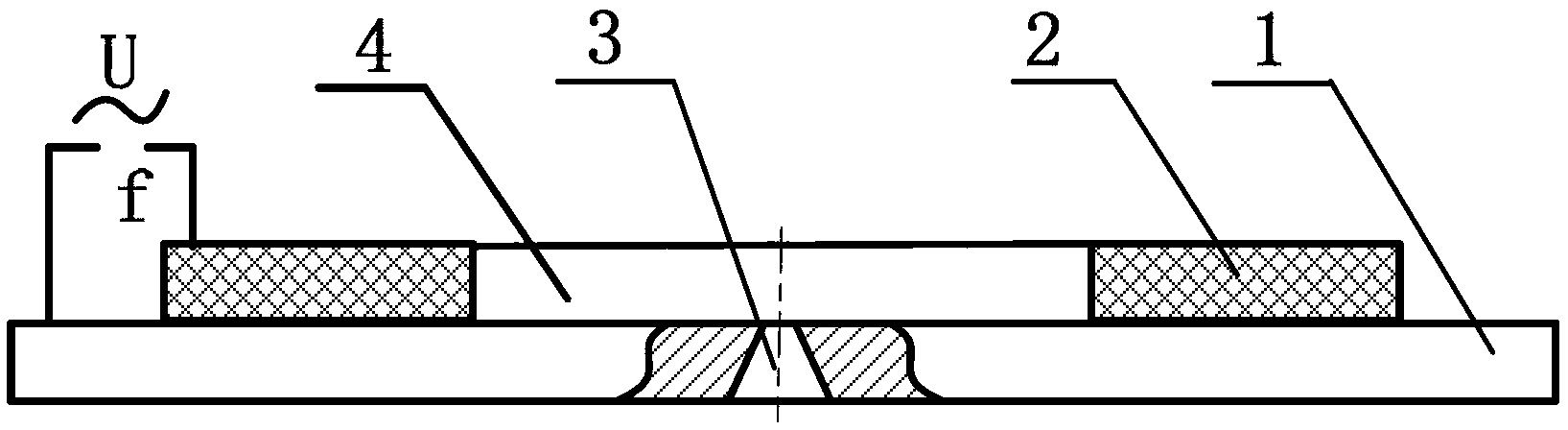

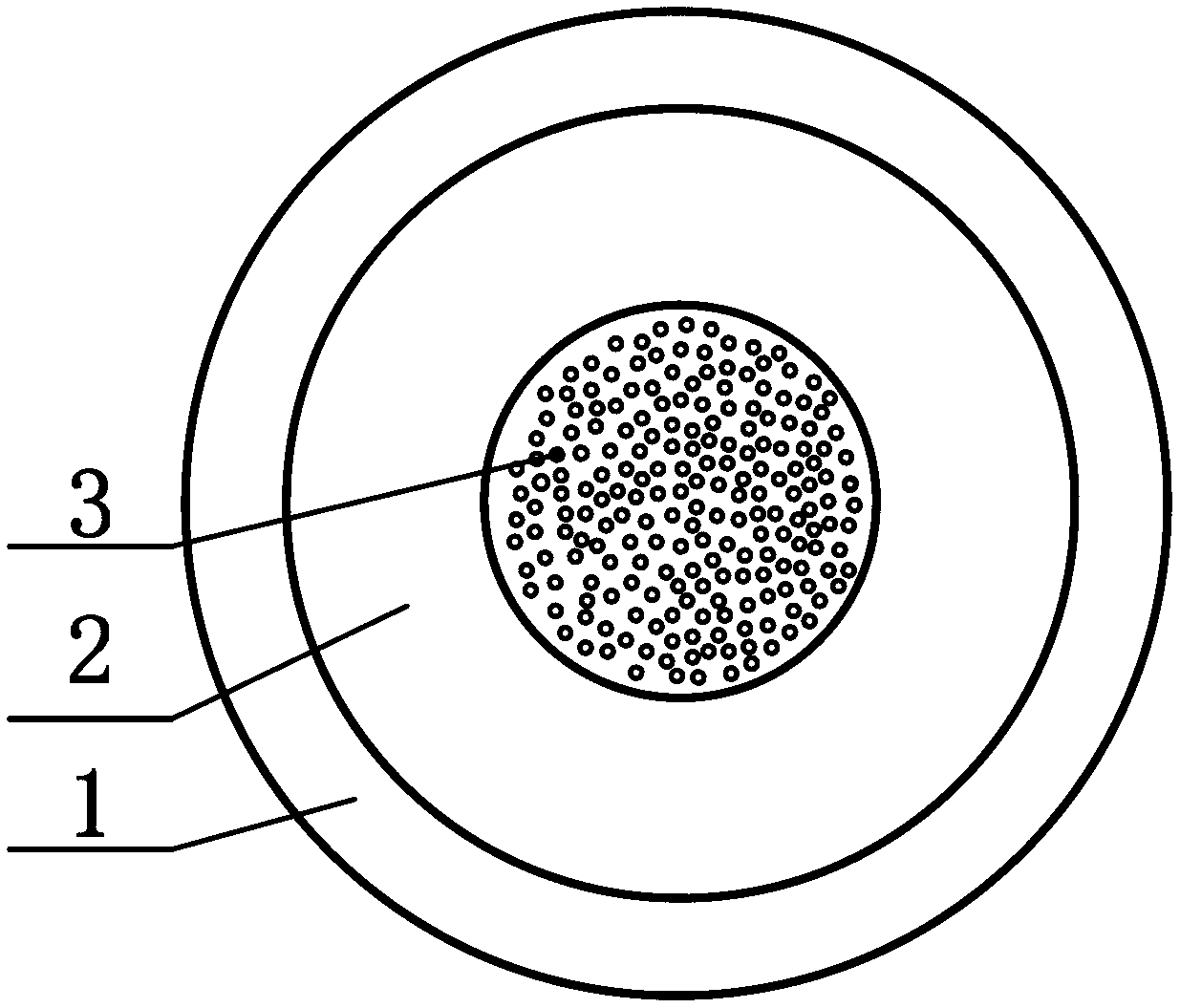

[0021] First, combine figure 1 and figure 2 Describe the working principle of piezoelectric ceramic atomizer. There is an area in the central area of the metal diaphragm 1 that is densely distributed with tiny atomization holes 3, and outside the distribution area of the atomization holes 3 is a piezoelectric ceramic ring piece 2, and the metal diaphragm 1 and the piezoelectric ceramic ring piece 2 are respectively connected to the positive and negative points of the AC power supply. The poles are connected, the input voltage value is U, and the input AC frequency is f. According to the energy calculation formula of alternating current, the energy E supplied by alternating current is proportional to the square of the voltage value U and the input frequency f, that is, E=kUf 2 (where k is a coefficient). In actual work, the input voltage value U is given, so it...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap