Rotary shaft device of integrated thin-wall pipe pneumatic clamping mechanism

A clamping mechanism, a technology for thin-walled pipes, applied in welding equipment, laser welding equipment, metal processing equipment, etc., to achieve good waterproof sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Various preferred embodiments of the invention are discussed below. However, those skilled in the art should understand that the detailed description herein is not intended to limit the protection scope of the present invention, and the present invention can also be realized through the modification of the following embodiments or other equivalent methods.

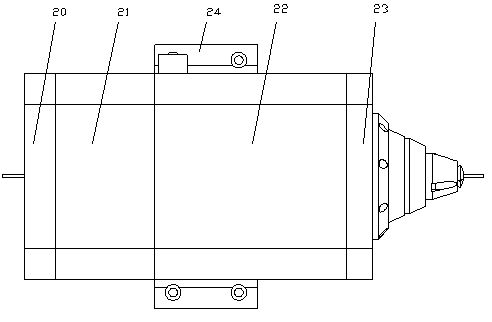

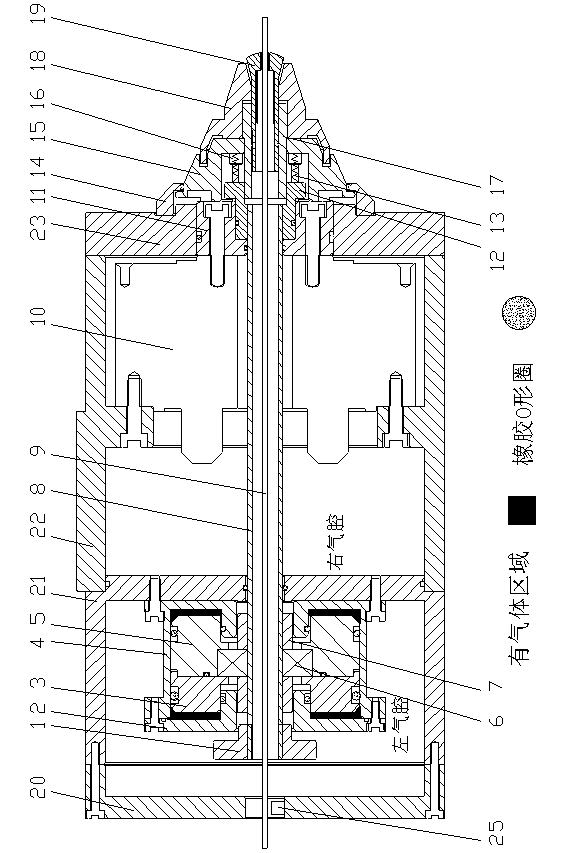

[0012] In one embodiment of the present invention, the rotary shaft device used for the integrated thin-walled pipe pneumatic clamping mechanism includes a pull rod module, a rotary shaft shell module and a collet module.

[0013] As an example, such as figure 1 As shown, the rod module can include: 1. Rod knob, 2. Rod cover, 3. Piston sleeve, 4. Rod seat, 5. Piston inner sleeve, 6. Rolling bearing, 7. Shaft sleeve, 8. Rod, 9. Pipe , 10. Direct drive motor. The role of the tie rod module is to realize the clamping and loosening of the pipe. The clamping and loosening process of the tie rod module is realized by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com