Assembly line conveying device capable of locating accurately and control method thereof

A control method and transmission device technology, applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problem that the belt assembly line cannot be accurately positioned, and achieve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

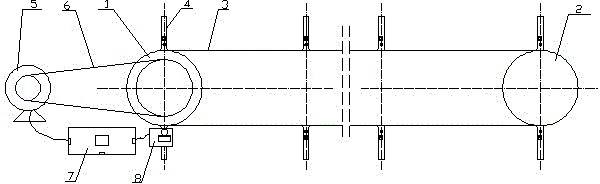

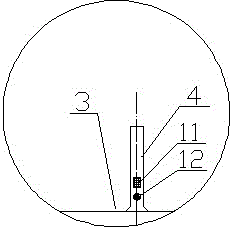

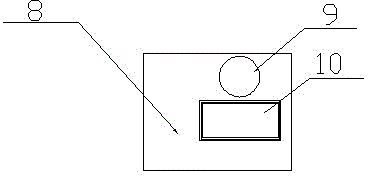

[0027] The present invention is described below in conjunction with accompanying drawing. like Figure 1-3 A kind of assembly line transfer device capable of precise positioning of the present invention shown:

[0028] An assembly line transmission device capable of precise positioning according to the present invention includes a main belt transmission wheel 1, a secondary main belt transmission wheel 2, a transmission belt 3, a motor 5, a connecting belt 6, a main control circuit board 7, and an integrated position probe 8. The conveyor belt 3 has intermediate baffles 4 at equal intervals; one side of the intermediate baffle 4 has an RFID electronic tag 11 and a permanent electromagnet block 12 attached thereto.

[0029] The entire assembly line is divided into n+1 transmission boxes (wherein n is the number of intermediate baffles) by equally spaced intermediate baffles 4 on the conveyor belt 3; each intermediate baffle 4 is uniquely identified on the RFID electronic tag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com