Tubular product fastening connection accessory

A technology for fastening connections and pipes, which is applied in the assembly field of pipe connections. It can solve problems such as fracture failure of fasteners and complicated installation steps, and achieve the effects of preventing breakage, simple structure, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

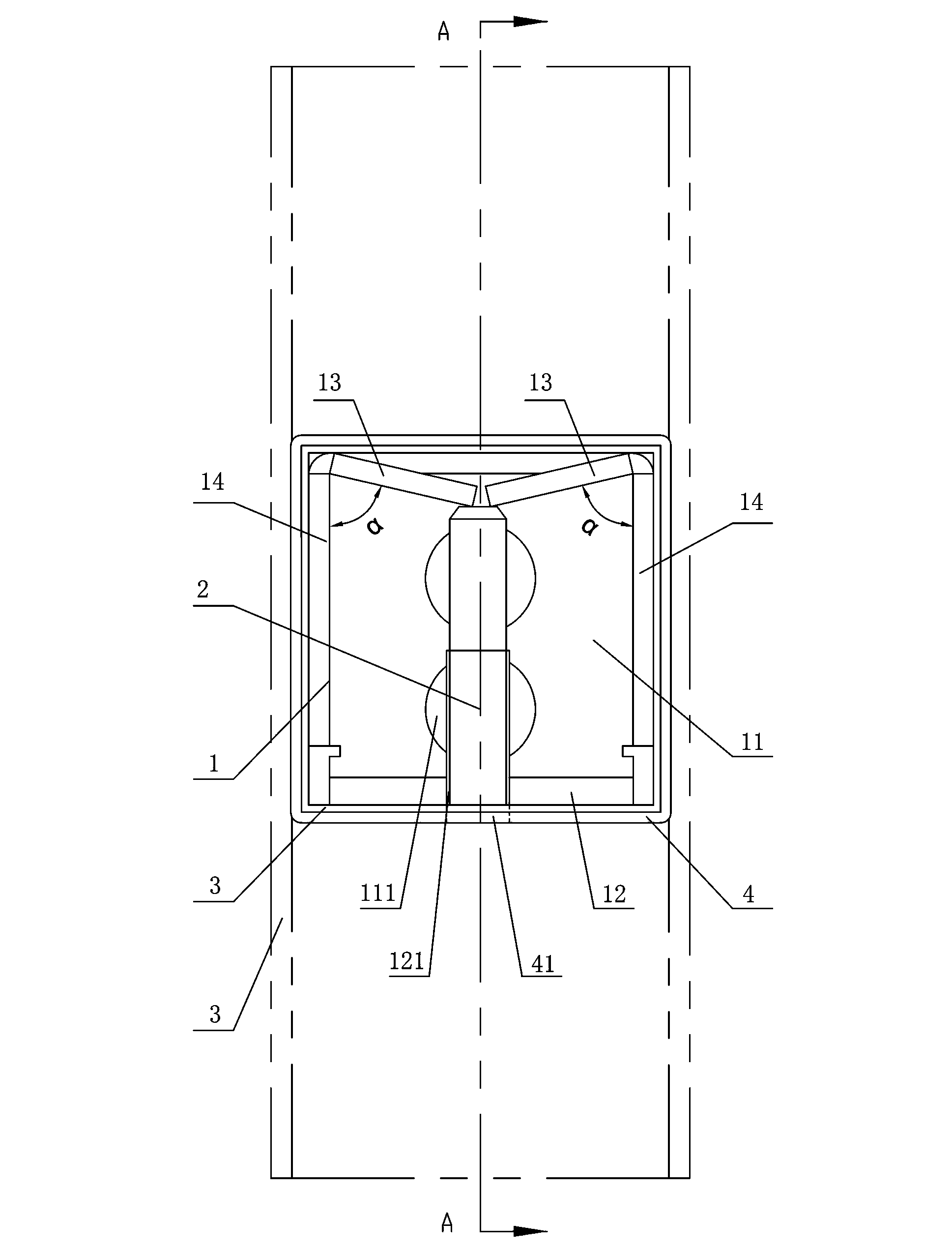

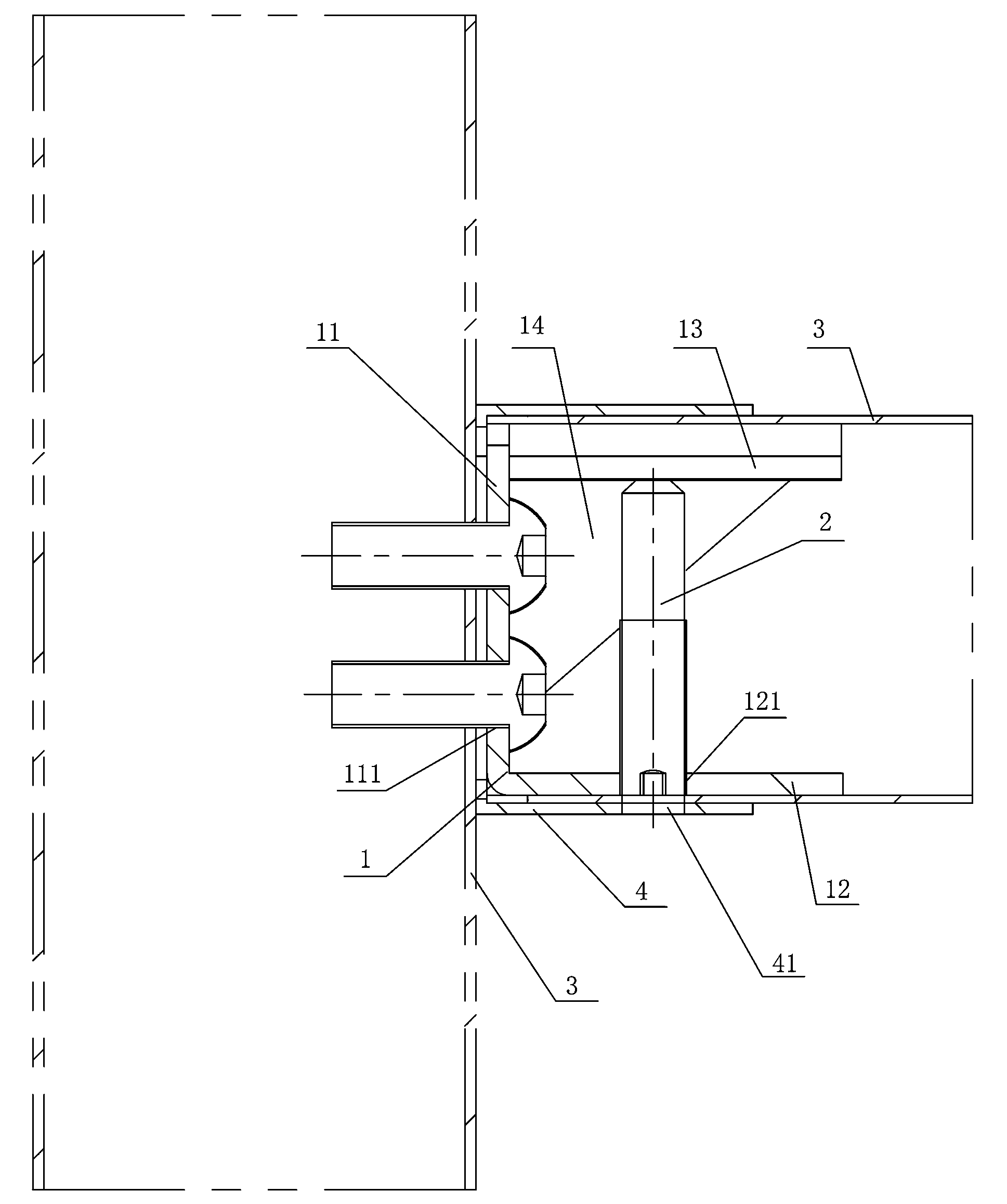

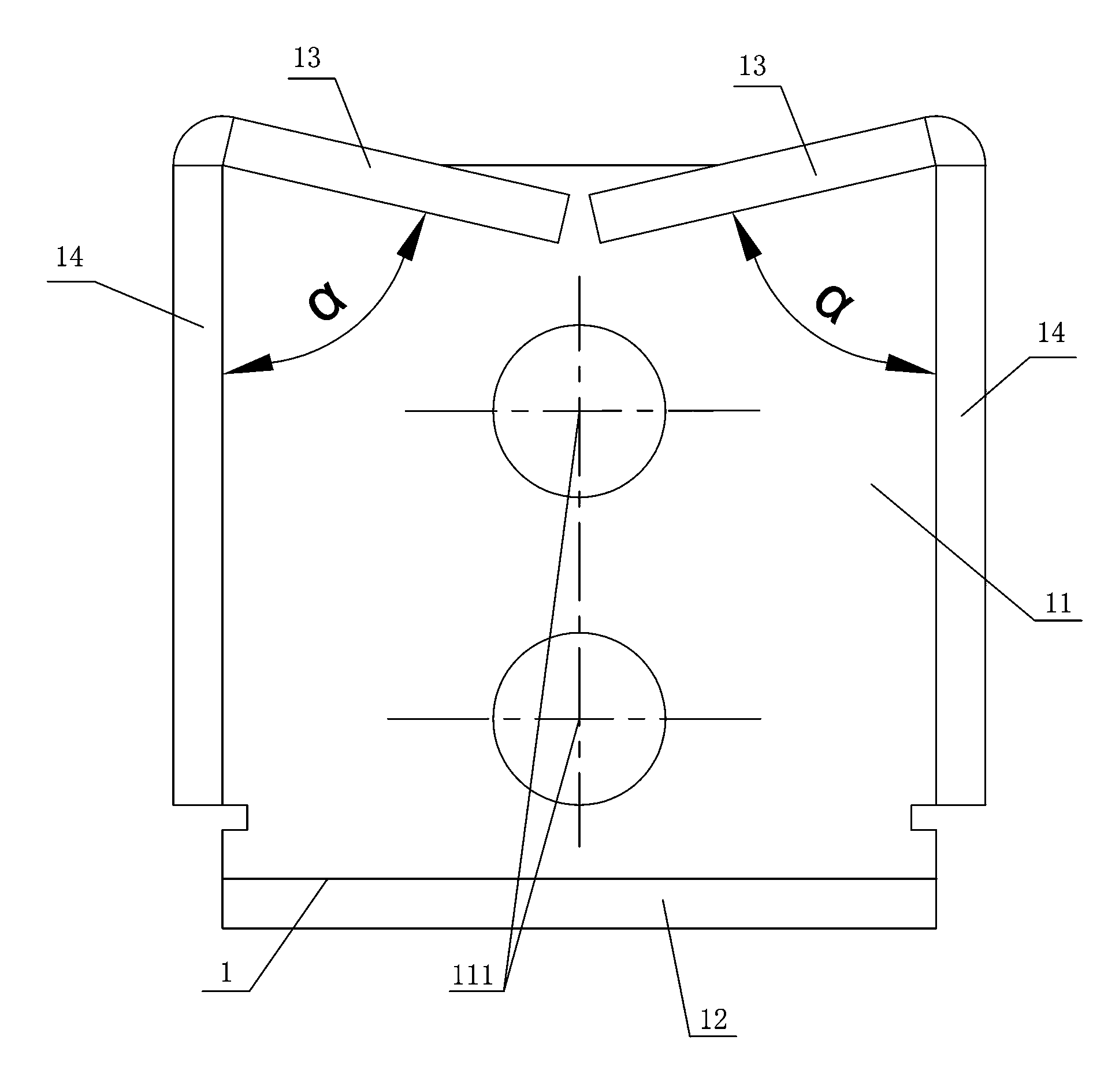

[0028] Figure 1 to Figure 5 Shows the first embodiment of the pipe fastening connection fittings of the present invention, the connection fittings include an expansion joint 1 and a top wire 2 for expanding the expansion joint 1, the expansion joint 1 includes a connection bottom plate 11, and the connection The lower end of the bottom plate 11 is bent with a jacking plate 12, two side plates 14 are bent on both sides of the connecting bottom plate 11, and the upper ends of the two side plates 14 are provided with a top plate 13 bent to connect to the top of the bottom plate 11. One end of the top wire 2 is connected to The jacking plate 12 is threaded, and the other end is connected to the two top plates 13. When the jacking screw 2 is tightened, the jacking plate 12 expands downward, the top plate 13 expands upward, and drives the two side plates 14 to expand to both sides. Open and the inner wall of the pipe 3 form a four-sided expansion tight connection, which has a simpl...

Embodiment 2

[0032] Figure 6 to Figure 10 Shows the second embodiment of the pipe fastening connection fittings of the present invention, the connection fittings are basically the same as the first embodiment, the only difference is: two top plates 13 overlap each other; When one top plate 13 expands the top plate 13 upwards, the other top plate 13 located at the upper end will also expand upwards through force transmission, and drive the two side plates 14 to expand to both sides and form a four-sided expansion on the inner wall of the pipe 3. connect.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap