A liquid crystal display and its liquid crystal module fixing structure

A liquid crystal module and a fixed structure technology, which is applied in the field of liquid crystal display and its liquid crystal module fixed structure, can solve the problems of complex assembly and many parts, and achieve the effects of reducing fixed parts, simple and convenient assembly, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with examples in conjunction with the accompanying drawings.

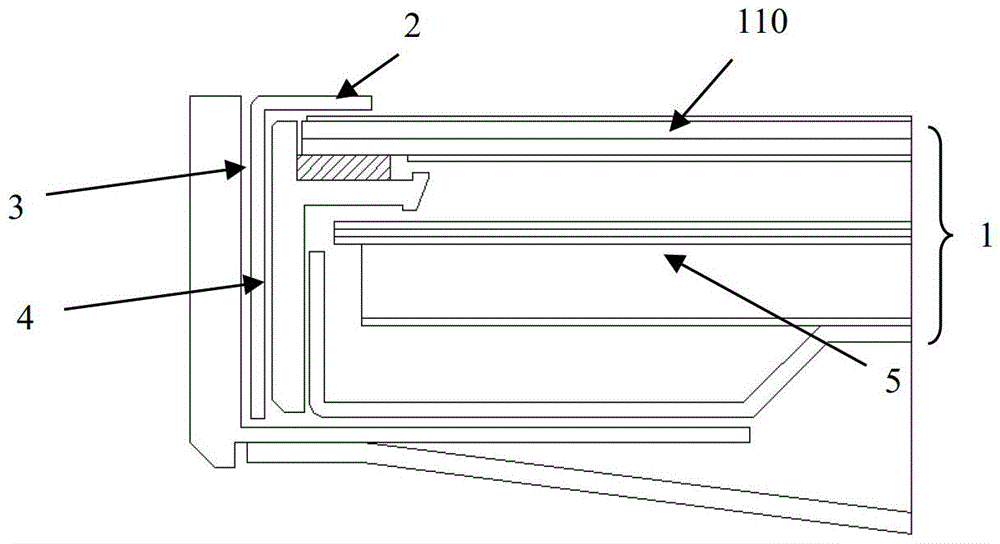

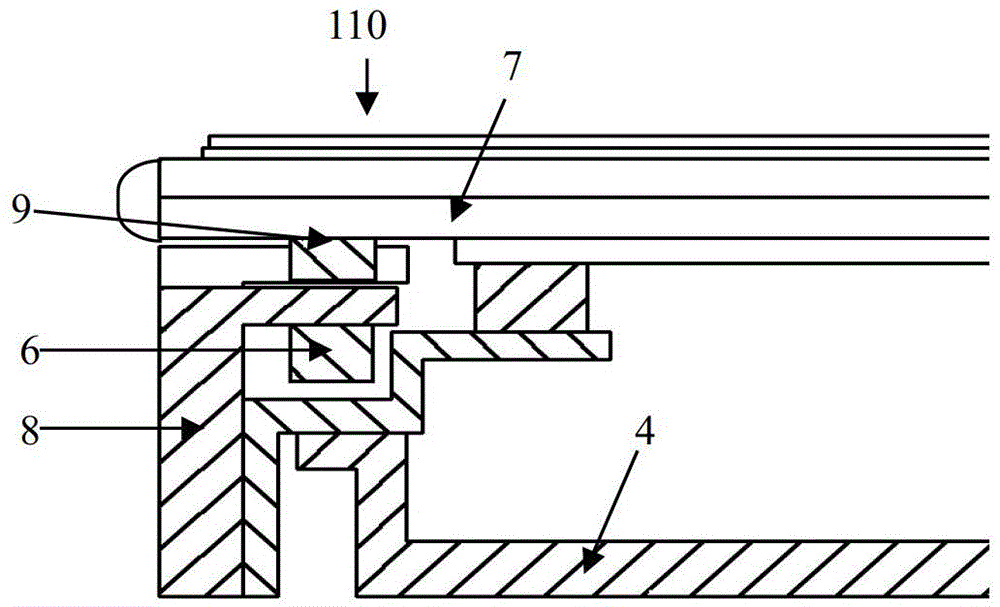

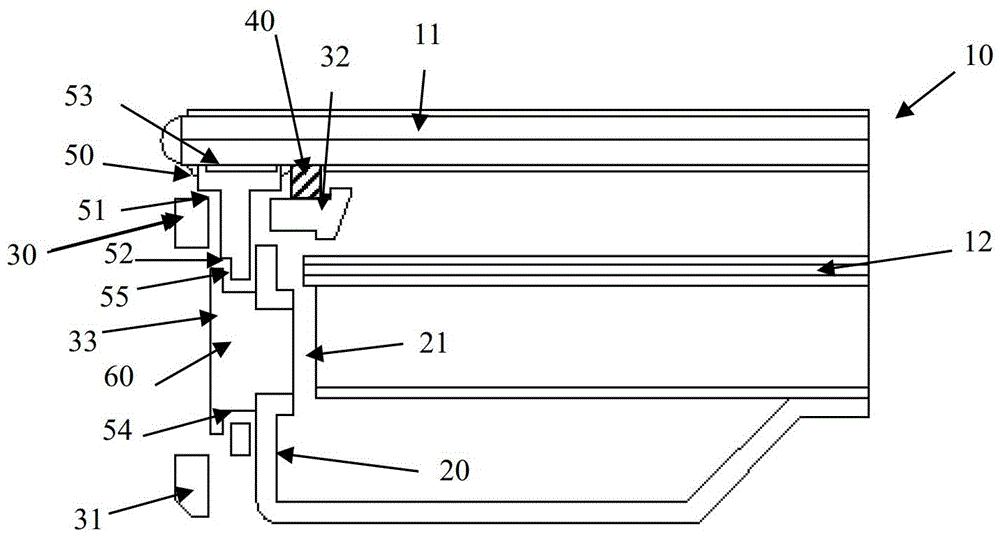

[0019] Such as image 3 , Figure 4 , Figure 5 As shown, the liquid crystal display in this embodiment includes a liquid crystal display module 10 and a back frame 20, wherein the liquid crystal display module 10 is composed of a liquid crystal module 11 and a backlight module 12, and also includes a middle frame 30, wherein the middle frame 30 is composed of side walls 31 and vertical The horizontal wall 32 fixedly connected to the side wall 31 is composed of a buffer material 40 between the liquid crystal module 11 and the bearing surface of the horizontal wall 32 of the middle frame; The bottom surface of the module 11 is fixedly connected, and the other part is connected to the back frame 20 through the fixing piece 60 , and several components 50 are distributed around to connect the liquid crystal module 11 and the back frame 20 together.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com