Anti-loosening chute metal insert nut

A metal insert and chute technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of stress concentration at the pin hole, screw drilling, cumbersome process, etc., to achieve easy installation and disassembly, prevent loosening, and improve safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the examples.

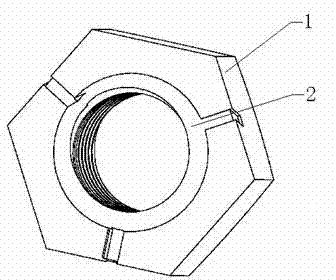

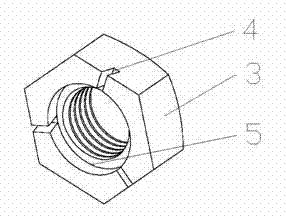

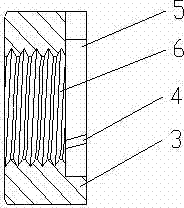

[0015] like Figures 1 to 4 As shown, this embodiment consists of a chute nut 1 and a metal insert 2. The chute nut 1 includes a nut body 3 , a rhombus chute 4 , a cylindrical slotted body 5 and a nut internal thread 6 . The metal insert 2 includes an insert body 7 , a diamond-shaped extension 8 and an insert internal thread 9 .

[0016] When assembling, first insert the metal insert 2 into the cylindrical slotted body 5 of the chute nut 1, buckle the rhombic protruding body 8 into the rhombic chute 4, and screw the assembled insert nut onto the screw rod. When tightening, the chute nut 2 pushes the nut and the insert to be tightened at the same time. Since the axial depth of the diamond-shaped chute 4 is equal to the thickness of the metal insert 2, and the depth of the metal insert 2 is the same as that of the cylindrical slotted body 5, it can effectively prevent the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com