Physical simulation method of flow field of continuous casting crystallizer considering vibration behaviors

A technology for continuous casting mold and physical simulation, which is applied in the field of physical simulation of continuous casting mold flow field considering vibration behavior, can solve problems such as poor effect, and achieve the effect of improving the quality of casting billet and researching accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

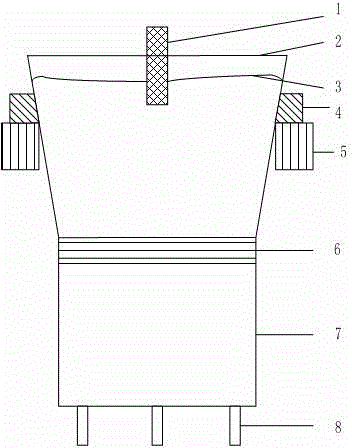

[0014] The physical simulation of the crystallizer flow field is based on the similarity principle. According to the focus of the research, select the Re standard number, the Fr standard number and the We standard number or their combination to determine the appropriate similarity ratio; then establish the hydraulic model according to the actual model parameters , and use monitoring means to analyze the characteristics of the flow field in the crystallizer under different parameters, and optimize the flow field of the crystallizer.

[0015] The current general physical simulation experiment device is a water circulation system, including tundish, submerged nozzle, crystallizer and water pump. Water circulates sequentially in the tundish-submerged nozzle-mold. This process is consistent with the actual continuous casting process. Then the water pump draws a certain flow of water from the outlet of the mold and circulates it into the tundish.

[0016] The commonly used crystalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com